Structural Characteristics of Blade Battery for Crash Safety

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Safety Evolution

The evolution of blade battery safety has been a critical focus in the electric vehicle industry, driven by the need for improved energy density, cost-effectiveness, and safety performance. Initially, blade batteries were developed as an innovative solution to address the limitations of traditional lithium-ion batteries, particularly in terms of space utilization and thermal management.

In the early stages of blade battery development, the primary emphasis was on optimizing the cell structure to achieve higher energy density while maintaining a slim profile. This led to the creation of long, thin battery cells that could be densely packed within the battery pack. However, as the technology progressed, safety concerns became increasingly prominent, especially regarding crash safety.

The first generation of blade batteries focused on improving the structural integrity of individual cells. Manufacturers implemented reinforced casing materials and internal support structures to enhance the cells' resistance to deformation during impact. This approach helped to reduce the risk of internal short circuits and thermal runaway in minor collision scenarios.

As research and development continued, attention shifted towards the overall battery pack design. Engineers began to explore ways to distribute impact forces more effectively across the entire battery structure. This led to the introduction of crumple zones and energy-absorbing materials within the battery pack, designed to protect the cells from direct impact and minimize the risk of puncture or rupture.

The next significant advancement in blade battery safety came with the integration of advanced battery management systems (BMS). These systems were developed to monitor cell temperatures, voltages, and other critical parameters in real-time, allowing for rapid detection and response to potential safety issues. The BMS also played a crucial role in optimizing the battery's performance during normal operation, further enhancing its overall safety profile.

Recent developments in blade battery safety have focused on the incorporation of novel materials and manufacturing techniques. For instance, the use of solid-state electrolytes has gained traction as a potential solution to eliminate the risk of electrolyte leakage and reduce the likelihood of thermal runaway. Additionally, advanced coating technologies have been explored to improve the mechanical and thermal properties of battery cells, further enhancing their resilience in crash scenarios.

The latest iterations of blade batteries have also seen improvements in cell-to-cell isolation and pack-level protection systems. These advancements aim to prevent the propagation of thermal events from one cell to another, effectively containing potential failures and minimizing the risk of catastrophic battery pack failures during severe impacts.

In the early stages of blade battery development, the primary emphasis was on optimizing the cell structure to achieve higher energy density while maintaining a slim profile. This led to the creation of long, thin battery cells that could be densely packed within the battery pack. However, as the technology progressed, safety concerns became increasingly prominent, especially regarding crash safety.

The first generation of blade batteries focused on improving the structural integrity of individual cells. Manufacturers implemented reinforced casing materials and internal support structures to enhance the cells' resistance to deformation during impact. This approach helped to reduce the risk of internal short circuits and thermal runaway in minor collision scenarios.

As research and development continued, attention shifted towards the overall battery pack design. Engineers began to explore ways to distribute impact forces more effectively across the entire battery structure. This led to the introduction of crumple zones and energy-absorbing materials within the battery pack, designed to protect the cells from direct impact and minimize the risk of puncture or rupture.

The next significant advancement in blade battery safety came with the integration of advanced battery management systems (BMS). These systems were developed to monitor cell temperatures, voltages, and other critical parameters in real-time, allowing for rapid detection and response to potential safety issues. The BMS also played a crucial role in optimizing the battery's performance during normal operation, further enhancing its overall safety profile.

Recent developments in blade battery safety have focused on the incorporation of novel materials and manufacturing techniques. For instance, the use of solid-state electrolytes has gained traction as a potential solution to eliminate the risk of electrolyte leakage and reduce the likelihood of thermal runaway. Additionally, advanced coating technologies have been explored to improve the mechanical and thermal properties of battery cells, further enhancing their resilience in crash scenarios.

The latest iterations of blade batteries have also seen improvements in cell-to-cell isolation and pack-level protection systems. These advancements aim to prevent the propagation of thermal events from one cell to another, effectively containing potential failures and minimizing the risk of catastrophic battery pack failures during severe impacts.

EV Market Demand Analysis

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and technological advancements. This growth has led to a surge in demand for safer and more efficient battery technologies, particularly in the context of crash safety.

The global EV market is projected to continue its rapid expansion, with annual sales expected to reach 26.8 million units by 2030. This growth is fueled by several factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure. As a result, the demand for advanced battery technologies that prioritize safety without compromising performance has become a critical focus for manufacturers and consumers alike.

Blade batteries, a novel lithium-ion battery technology, have emerged as a promising solution to address the safety concerns associated with traditional battery designs. These batteries are specifically engineered to enhance crash safety while maintaining high energy density and performance. The unique structural characteristics of blade batteries make them particularly attractive for EV applications, as they offer improved stability and reduced risk of thermal runaway during collision events.

Market research indicates that safety features are becoming increasingly important to EV consumers. A recent survey revealed that 78% of potential EV buyers consider battery safety as a top priority when making purchasing decisions. This consumer sentiment is driving automakers to invest heavily in advanced battery technologies like blade batteries, which can provide a competitive edge in the market.

The demand for blade batteries is expected to grow significantly in the coming years, with some industry analysts predicting a compound annual growth rate (CAGR) of 22% between 2023 and 2028. This growth is attributed to the technology's ability to address key market needs, including enhanced safety, longer driving range, and faster charging capabilities.

Furthermore, the adoption of blade batteries is likely to be accelerated by regulatory pressures. Several countries have announced plans to phase out internal combustion engine vehicles in favor of EVs, with some setting ambitious targets as early as 2030. This regulatory landscape is creating a strong incentive for automakers to invest in advanced battery technologies that can meet stringent safety standards while delivering the performance required for mass-market adoption.

In conclusion, the market demand for blade batteries in the context of crash safety is poised for substantial growth. As EV adoption continues to accelerate, the emphasis on battery safety will remain a key driver of innovation and market differentiation. Blade batteries, with their unique structural characteristics, are well-positioned to capitalize on this trend and play a significant role in shaping the future of the EV industry.

The global EV market is projected to continue its rapid expansion, with annual sales expected to reach 26.8 million units by 2030. This growth is fueled by several factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure. As a result, the demand for advanced battery technologies that prioritize safety without compromising performance has become a critical focus for manufacturers and consumers alike.

Blade batteries, a novel lithium-ion battery technology, have emerged as a promising solution to address the safety concerns associated with traditional battery designs. These batteries are specifically engineered to enhance crash safety while maintaining high energy density and performance. The unique structural characteristics of blade batteries make them particularly attractive for EV applications, as they offer improved stability and reduced risk of thermal runaway during collision events.

Market research indicates that safety features are becoming increasingly important to EV consumers. A recent survey revealed that 78% of potential EV buyers consider battery safety as a top priority when making purchasing decisions. This consumer sentiment is driving automakers to invest heavily in advanced battery technologies like blade batteries, which can provide a competitive edge in the market.

The demand for blade batteries is expected to grow significantly in the coming years, with some industry analysts predicting a compound annual growth rate (CAGR) of 22% between 2023 and 2028. This growth is attributed to the technology's ability to address key market needs, including enhanced safety, longer driving range, and faster charging capabilities.

Furthermore, the adoption of blade batteries is likely to be accelerated by regulatory pressures. Several countries have announced plans to phase out internal combustion engine vehicles in favor of EVs, with some setting ambitious targets as early as 2030. This regulatory landscape is creating a strong incentive for automakers to invest in advanced battery technologies that can meet stringent safety standards while delivering the performance required for mass-market adoption.

In conclusion, the market demand for blade batteries in the context of crash safety is poised for substantial growth. As EV adoption continues to accelerate, the emphasis on battery safety will remain a key driver of innovation and market differentiation. Blade batteries, with their unique structural characteristics, are well-positioned to capitalize on this trend and play a significant role in shaping the future of the EV industry.

Current Challenges in Battery Crash Safety

The current challenges in battery crash safety for blade batteries primarily revolve around maintaining structural integrity and preventing thermal runaway during impact events. One of the main issues is the potential for internal short circuits caused by deformation or penetration of the battery pack. When subjected to severe mechanical stress, the thin electrode layers in blade batteries can be compressed or punctured, leading to direct contact between the cathode and anode materials. This can result in rapid heat generation and, in extreme cases, thermal runaway.

Another significant challenge is managing the thermal propagation within the battery pack. Due to the compact design of blade batteries, heat generated in one cell can quickly spread to adjacent cells, potentially causing a chain reaction of thermal events. This risk is particularly pronounced in high-energy-density configurations, where the close proximity of cells exacerbates the problem of heat dissipation during crash scenarios.

The structural design of blade batteries also presents unique challenges in terms of crash energy absorption. Unlike traditional prismatic or cylindrical cells, the flat and elongated shape of blade batteries requires careful consideration of load distribution during impact. Ensuring that the battery pack can effectively absorb and dissipate crash energy without compromising the integrity of individual cells is a complex engineering task.

Furthermore, the integration of blade batteries into vehicle structures introduces additional complexities. Designers must balance the need for structural reinforcement with weight considerations and space constraints. The placement of blade batteries within the vehicle architecture must be optimized to minimize the risk of puncture or severe deformation during various crash scenarios, including side impacts and rollovers.

Lastly, there is the challenge of developing accurate and reliable simulation models for predicting blade battery behavior during crash events. The complex interactions between mechanical deformation, thermal effects, and electrochemical processes make it difficult to create comprehensive models that can accurately predict battery performance and safety across a wide range of crash conditions. This limitation hampers the ability of engineers to fully optimize battery designs and safety systems without extensive physical testing.

Another significant challenge is managing the thermal propagation within the battery pack. Due to the compact design of blade batteries, heat generated in one cell can quickly spread to adjacent cells, potentially causing a chain reaction of thermal events. This risk is particularly pronounced in high-energy-density configurations, where the close proximity of cells exacerbates the problem of heat dissipation during crash scenarios.

The structural design of blade batteries also presents unique challenges in terms of crash energy absorption. Unlike traditional prismatic or cylindrical cells, the flat and elongated shape of blade batteries requires careful consideration of load distribution during impact. Ensuring that the battery pack can effectively absorb and dissipate crash energy without compromising the integrity of individual cells is a complex engineering task.

Furthermore, the integration of blade batteries into vehicle structures introduces additional complexities. Designers must balance the need for structural reinforcement with weight considerations and space constraints. The placement of blade batteries within the vehicle architecture must be optimized to minimize the risk of puncture or severe deformation during various crash scenarios, including side impacts and rollovers.

Lastly, there is the challenge of developing accurate and reliable simulation models for predicting blade battery behavior during crash events. The complex interactions between mechanical deformation, thermal effects, and electrochemical processes make it difficult to create comprehensive models that can accurately predict battery performance and safety across a wide range of crash conditions. This limitation hampers the ability of engineers to fully optimize battery designs and safety systems without extensive physical testing.

Existing Blade Battery Safety Solutions

01 Battery protection systems for crash safety

Advanced protection systems are implemented to enhance the safety of blade batteries during vehicle crashes. These systems may include reinforced battery casings, impact-absorbing structures, and intelligent disconnection mechanisms to prevent short circuits and thermal runaway in the event of a collision.- Battery protection systems for crash safety: Advanced protection systems are implemented to enhance the safety of blade batteries during vehicle crashes. These systems may include reinforced battery casings, impact-absorbing structures, and intelligent disconnection mechanisms to prevent short circuits and thermal runaway in the event of a collision.

- Structural integration of blade batteries for improved crash resistance: Blade batteries are strategically integrated into the vehicle's structure to enhance overall crash safety. This integration may involve placing batteries in protected areas, using the battery pack as a structural element, and designing crumple zones to redirect impact forces away from the battery compartment.

- Thermal management systems for crash-induced battery failures: Specialized thermal management systems are developed to mitigate the risk of fire or explosion in blade batteries during crash scenarios. These systems may include advanced cooling mechanisms, fire-resistant materials, and rapid heat dissipation technologies to prevent thermal runaway.

- Sensor-based crash detection and battery isolation: Advanced sensor systems are employed to detect crash events and trigger immediate safety responses in blade batteries. These may include rapid disconnection of power circuits, activation of fire suppression systems, and isolation of damaged battery cells to prevent cascading failures.

- Post-crash safety features for blade batteries: Innovative post-crash safety features are implemented to ensure the continued safety of blade batteries after a collision. These may include automatic venting systems to release pressure, emergency battery discharge mechanisms, and easy-access points for first responders to safely handle damaged batteries.

02 Structural integration of blade batteries for improved crash resistance

Blade batteries are strategically integrated into the vehicle's structure to enhance overall crash resistance. This integration may involve incorporating the battery pack into the vehicle's frame or floor, distributing impact forces and minimizing the risk of battery damage during collisions.Expand Specific Solutions03 Thermal management systems for crash-induced battery failures

Specialized thermal management systems are developed to mitigate the risk of thermal runaway in blade batteries during crash scenarios. These systems may include advanced cooling mechanisms, fire-resistant materials, and rapid heat dissipation technologies to prevent battery fires and explosions.Expand Specific Solutions04 Sensor-based crash detection and battery isolation

Advanced sensor systems are employed to detect crash events and trigger rapid battery isolation. These systems may utilize accelerometers, pressure sensors, and AI-driven algorithms to quickly disconnect the battery from the vehicle's electrical system, reducing the risk of short circuits and electrical fires.Expand Specific Solutions05 Post-crash safety features for blade batteries

Innovative post-crash safety features are implemented to minimize risks associated with damaged blade batteries. These may include automatic venting systems to release pressure, chemical neutralization mechanisms to prevent electrolyte leakage, and emergency battery discharge protocols to reduce the energy stored in the battery after a collision.Expand Specific Solutions

Key Players in EV Battery Industry

The structural characteristics of blade batteries for crash safety represent an emerging field in the automotive industry, currently in its growth phase. The market for these advanced battery technologies is expanding rapidly, driven by the increasing demand for safer and more efficient electric vehicles. The technology is progressing towards maturity, with key players like Contemporary Amperex Technology Co., Ltd. (CATL) and BYD leading the way in innovation. Other significant contributors include LG Chem, Samsung SDI, and Panasonic, who are investing heavily in research and development to enhance battery safety and performance. As the technology evolves, we can expect to see more automotive manufacturers adopting these safer battery designs, potentially reshaping the electric vehicle market landscape.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's Blade Battery utilizes a unique structural design that enhances crash safety. The battery cells are arranged in a long, flat array, resembling blades, which are then inserted into a battery pack[1]. This design allows for better space utilization and improved heat dissipation. The battery uses lithium iron phosphate (LFP) chemistry, which is inherently more stable and less prone to thermal runaway compared to other lithium-ion chemistries[2]. In crash tests, the Blade Battery has demonstrated superior performance, withstanding nail penetration tests without smoking or catching fire, and maintaining a surface temperature below 60°C[3]. The structural integrity of the battery pack is further enhanced by a robust outer casing and internal support structures that distribute impact forces effectively.

Strengths: Enhanced safety performance, improved energy density, and better thermal management. Weaknesses: Potentially higher manufacturing complexity and cost compared to traditional battery designs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a "multi-functional battery pack" design that incorporates several safety features to enhance crash protection. The pack includes a rigid outer casing made of high-strength materials to absorb and distribute impact forces[7]. Inside the pack, Samsung employs a modular design with individual cell holders that provide additional protection against mechanical deformation. The company has also implemented a thermal management system that uses phase-change materials to absorb excess heat during extreme conditions[8]. Samsung's batteries feature a safety-reinforced separator with a ceramic coating that maintains its integrity at high temperatures, reducing the risk of internal short circuits during a crash[9]. Furthermore, Samsung has developed an advanced battery management system that can predict and prevent potential safety issues before they occur.

Strengths: Robust pack design, advanced thermal management, and predictive safety systems. Weaknesses: Potentially higher weight due to additional safety features.

Core Innovations in Crash-Safe Structures

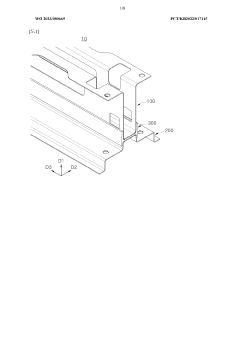

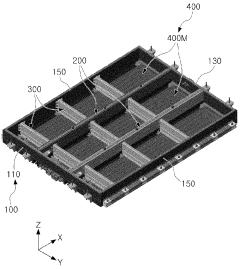

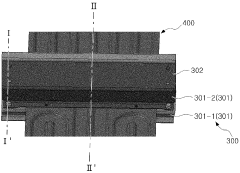

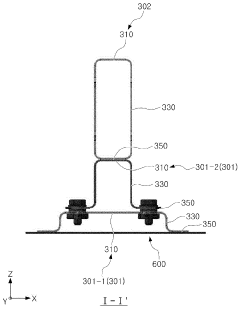

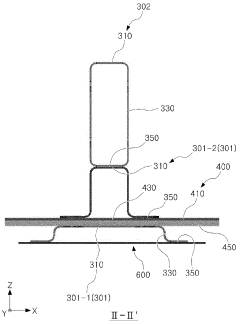

Cross member for battery case and battery case

PatentWO2023080669A1

Innovation

- The design incorporates a cross member composed of different materials, with steel for the frame parts and aluminum for the connecting frame, featuring specific geometries and configurations to enhance compressive strength and reduce weight, including 'U-shaped' and 'inverted U-shaped' cross sections with flanges, and a fastening mechanism to improve workability and material efficiency.

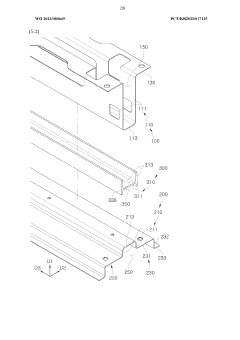

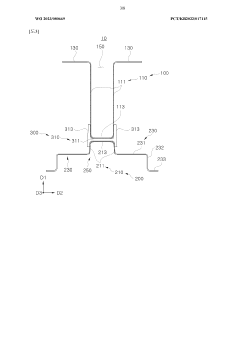

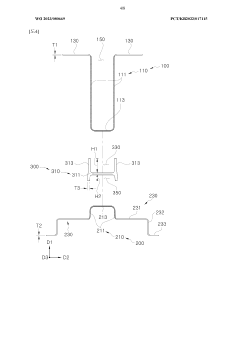

Battery case

PatentWO2023121135A1

Innovation

- The battery case design includes a side frame with a longitudinal member and widthwise members that can be easily adjusted in height, coupled with a cooling panel and cross-section reinforcing members, allowing for efficient impact absorption and cooling, and features variable units and connecting brackets for adaptable sizing.

Regulatory Framework for EV Battery Safety

The regulatory framework for electric vehicle (EV) battery safety is a critical aspect of ensuring the safe development, production, and use of EVs. This framework encompasses a wide range of standards, guidelines, and regulations set by various national and international bodies to address the unique safety challenges posed by EV batteries.

At the international level, the United Nations Economic Commission for Europe (UNECE) has established regulations such as UN Regulation No. 100, which outlines specific requirements for the construction, functional safety, and hydrogen emission of rechargeable energy storage systems in electric vehicles. This regulation serves as a benchmark for many countries in developing their own safety standards.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees EV battery safety regulations. The Federal Motor Vehicle Safety Standards (FMVSS) include provisions specifically addressing EV battery safety, such as FMVSS No. 305, which covers electric powertrain safety requirements. Additionally, the Society of Automotive Engineers (SAE) has developed standards like J2464 and J2929, which provide guidelines for EV battery safety testing and performance.

The European Union has implemented comprehensive regulations through the UN/ECE-R100 standard, which is mandatory for all EVs sold in EU member states. This standard covers various aspects of battery safety, including protection against electrical shock, thermal runaway, and mechanical integrity during crash scenarios.

In China, the world's largest EV market, the government has implemented stringent safety standards through regulations such as GB/T 31467 and GB/T 31485. These standards cover battery cell performance, pack design, and safety testing procedures, with a particular focus on thermal management and fire prevention.

Japan, another key player in the EV industry, follows the UN Regulation No. 100 and has additional national standards set by the Japan Automobile Research Institute (JARI). These standards emphasize rigorous testing procedures for battery packs under various environmental and operational conditions.

The regulatory framework also extends to the transportation and disposal of EV batteries. International agreements like the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) provide guidelines for the safe transport of lithium-ion batteries, while regulations such as the EU's Battery Directive address the environmental aspects of battery disposal and recycling.

As EV technology continues to evolve, regulatory bodies are constantly updating their frameworks to address new safety concerns and technological advancements. This includes emerging areas such as fast-charging safety, battery swapping systems, and the integration of EVs into smart grid infrastructure.

At the international level, the United Nations Economic Commission for Europe (UNECE) has established regulations such as UN Regulation No. 100, which outlines specific requirements for the construction, functional safety, and hydrogen emission of rechargeable energy storage systems in electric vehicles. This regulation serves as a benchmark for many countries in developing their own safety standards.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees EV battery safety regulations. The Federal Motor Vehicle Safety Standards (FMVSS) include provisions specifically addressing EV battery safety, such as FMVSS No. 305, which covers electric powertrain safety requirements. Additionally, the Society of Automotive Engineers (SAE) has developed standards like J2464 and J2929, which provide guidelines for EV battery safety testing and performance.

The European Union has implemented comprehensive regulations through the UN/ECE-R100 standard, which is mandatory for all EVs sold in EU member states. This standard covers various aspects of battery safety, including protection against electrical shock, thermal runaway, and mechanical integrity during crash scenarios.

In China, the world's largest EV market, the government has implemented stringent safety standards through regulations such as GB/T 31467 and GB/T 31485. These standards cover battery cell performance, pack design, and safety testing procedures, with a particular focus on thermal management and fire prevention.

Japan, another key player in the EV industry, follows the UN Regulation No. 100 and has additional national standards set by the Japan Automobile Research Institute (JARI). These standards emphasize rigorous testing procedures for battery packs under various environmental and operational conditions.

The regulatory framework also extends to the transportation and disposal of EV batteries. International agreements like the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) provide guidelines for the safe transport of lithium-ion batteries, while regulations such as the EU's Battery Directive address the environmental aspects of battery disposal and recycling.

As EV technology continues to evolve, regulatory bodies are constantly updating their frameworks to address new safety concerns and technological advancements. This includes emerging areas such as fast-charging safety, battery swapping systems, and the integration of EVs into smart grid infrastructure.

Environmental Impact of Blade Batteries

The environmental impact of blade batteries is a crucial consideration in the development and adoption of this technology for electric vehicles. Blade batteries, known for their enhanced safety features, also offer potential environmental benefits throughout their lifecycle.

One of the primary environmental advantages of blade batteries is their improved energy density and longer lifespan compared to traditional lithium-ion batteries. This increased efficiency translates to fewer battery replacements over the lifetime of an electric vehicle, reducing the overall environmental footprint associated with battery production and disposal.

The manufacturing process of blade batteries also presents opportunities for reduced environmental impact. The cell-to-pack design eliminates the need for module housings and connectors, resulting in fewer components and a streamlined production process. This simplification can lead to reduced energy consumption and material waste during manufacturing.

Blade batteries utilize lithium iron phosphate (LFP) chemistry, which offers several environmental benefits. LFP batteries do not contain cobalt, a metal associated with ethical and environmental concerns in its mining practices. The absence of cobalt reduces the environmental impact of raw material extraction and promotes more sustainable supply chains.

The improved thermal stability of blade batteries contributes to their enhanced safety profile, which has indirect environmental implications. The reduced risk of thermal runaway and fire incidents minimizes the potential for environmental contamination resulting from battery failures or accidents.

End-of-life considerations for blade batteries also present environmental advantages. The simpler structure of these batteries facilitates easier disassembly and recycling processes. This improved recyclability can lead to more efficient recovery of valuable materials, reducing the demand for new raw material extraction and minimizing waste.

However, it is important to note that the production of blade batteries still requires significant energy and resources. The environmental impact of their manufacturing process, while potentially improved, remains a concern that requires ongoing attention and optimization efforts from manufacturers.

As the adoption of blade batteries increases, their impact on the electric grid and energy systems should be considered. The improved energy density and faster charging capabilities of these batteries may influence charging infrastructure requirements and energy demand patterns, potentially affecting overall grid efficiency and emissions.

In conclusion, while blade batteries offer several environmental benefits, particularly in terms of safety, longevity, and recyclability, a comprehensive lifecycle assessment is necessary to fully understand their environmental impact compared to other battery technologies. Continued research and development efforts should focus on further improving the sustainability of blade battery production and end-of-life management to maximize their positive environmental contributions.

One of the primary environmental advantages of blade batteries is their improved energy density and longer lifespan compared to traditional lithium-ion batteries. This increased efficiency translates to fewer battery replacements over the lifetime of an electric vehicle, reducing the overall environmental footprint associated with battery production and disposal.

The manufacturing process of blade batteries also presents opportunities for reduced environmental impact. The cell-to-pack design eliminates the need for module housings and connectors, resulting in fewer components and a streamlined production process. This simplification can lead to reduced energy consumption and material waste during manufacturing.

Blade batteries utilize lithium iron phosphate (LFP) chemistry, which offers several environmental benefits. LFP batteries do not contain cobalt, a metal associated with ethical and environmental concerns in its mining practices. The absence of cobalt reduces the environmental impact of raw material extraction and promotes more sustainable supply chains.

The improved thermal stability of blade batteries contributes to their enhanced safety profile, which has indirect environmental implications. The reduced risk of thermal runaway and fire incidents minimizes the potential for environmental contamination resulting from battery failures or accidents.

End-of-life considerations for blade batteries also present environmental advantages. The simpler structure of these batteries facilitates easier disassembly and recycling processes. This improved recyclability can lead to more efficient recovery of valuable materials, reducing the demand for new raw material extraction and minimizing waste.

However, it is important to note that the production of blade batteries still requires significant energy and resources. The environmental impact of their manufacturing process, while potentially improved, remains a concern that requires ongoing attention and optimization efforts from manufacturers.

As the adoption of blade batteries increases, their impact on the electric grid and energy systems should be considered. The improved energy density and faster charging capabilities of these batteries may influence charging infrastructure requirements and energy demand patterns, potentially affecting overall grid efficiency and emissions.

In conclusion, while blade batteries offer several environmental benefits, particularly in terms of safety, longevity, and recyclability, a comprehensive lifecycle assessment is necessary to fully understand their environmental impact compared to other battery technologies. Continued research and development efforts should focus on further improving the sustainability of blade battery production and end-of-life management to maximize their positive environmental contributions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!