Study on the Environmental Impact of Self-cleaning Surfaces

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science that has evolved significantly over the past few decades. Initially inspired by the natural phenomenon observed in lotus leaves, known as the "lotus effect," this technology has progressed from basic hydrophobic coatings to sophisticated multi-functional surfaces with diverse applications. The development trajectory shows a clear evolution from simple water-repellent surfaces to complex systems that can actively decompose contaminants through photocatalytic processes or respond to environmental stimuli.

The technological progression of self-cleaning surfaces has been marked by several key milestones, including the discovery of superhydrophobic properties in the 1990s, the development of titanium dioxide-based photocatalytic coatings in the early 2000s, and more recently, the integration of nanotechnology to create hierarchical surface structures with enhanced durability and efficiency. Current research is increasingly focused on environmentally sustainable solutions that minimize resource consumption while maximizing cleaning effectiveness.

The primary objective of studying the environmental impact of self-cleaning surfaces is to comprehensively evaluate their life cycle effects, from production to disposal. This includes assessing the reduction in water and chemical cleaning agents, energy savings from decreased maintenance requirements, and potential environmental risks associated with nanomaterials used in these surfaces. Additionally, the research aims to quantify the carbon footprint reduction achieved through the implementation of self-cleaning technologies in various applications.

Another critical goal is to develop standardized methodologies for measuring and comparing the environmental performance of different self-cleaning technologies. This standardization would facilitate more accurate assessments of their ecological benefits and potential drawbacks, enabling informed decision-making by industries, policymakers, and consumers.

The technological objectives extend to enhancing the durability and efficiency of self-cleaning surfaces while reducing their environmental footprint. This includes developing bio-inspired and bio-based materials that maintain high performance while being inherently more sustainable than synthetic alternatives. Research is also directed toward creating multifunctional surfaces that combine self-cleaning properties with other beneficial characteristics such as antimicrobial activity, anti-fogging, or energy harvesting capabilities.

Looking forward, the field is trending toward smart self-cleaning surfaces that can adapt to changing environmental conditions and integrate with Internet of Things (IoT) systems for optimized performance. These advanced materials promise to further reduce resource consumption and environmental impact while expanding the range of practical applications across industries including construction, automotive, electronics, and healthcare.

The technological progression of self-cleaning surfaces has been marked by several key milestones, including the discovery of superhydrophobic properties in the 1990s, the development of titanium dioxide-based photocatalytic coatings in the early 2000s, and more recently, the integration of nanotechnology to create hierarchical surface structures with enhanced durability and efficiency. Current research is increasingly focused on environmentally sustainable solutions that minimize resource consumption while maximizing cleaning effectiveness.

The primary objective of studying the environmental impact of self-cleaning surfaces is to comprehensively evaluate their life cycle effects, from production to disposal. This includes assessing the reduction in water and chemical cleaning agents, energy savings from decreased maintenance requirements, and potential environmental risks associated with nanomaterials used in these surfaces. Additionally, the research aims to quantify the carbon footprint reduction achieved through the implementation of self-cleaning technologies in various applications.

Another critical goal is to develop standardized methodologies for measuring and comparing the environmental performance of different self-cleaning technologies. This standardization would facilitate more accurate assessments of their ecological benefits and potential drawbacks, enabling informed decision-making by industries, policymakers, and consumers.

The technological objectives extend to enhancing the durability and efficiency of self-cleaning surfaces while reducing their environmental footprint. This includes developing bio-inspired and bio-based materials that maintain high performance while being inherently more sustainable than synthetic alternatives. Research is also directed toward creating multifunctional surfaces that combine self-cleaning properties with other beneficial characteristics such as antimicrobial activity, anti-fogging, or energy harvesting capabilities.

Looking forward, the field is trending toward smart self-cleaning surfaces that can adapt to changing environmental conditions and integrate with Internet of Things (IoT) systems for optimized performance. These advanced materials promise to further reduce resource consumption and environmental impact while expanding the range of practical applications across industries including construction, automotive, electronics, and healthcare.

Market Analysis of Self-cleaning Surface Applications

The self-cleaning surfaces market has experienced significant growth in recent years, driven by increasing environmental awareness and the need for sustainable solutions across various industries. The global market for self-cleaning surfaces was valued at approximately $3.5 billion in 2022 and is projected to reach $6.7 billion by 2028, representing a compound annual growth rate (CAGR) of 11.4% during the forecast period.

The construction sector currently dominates the self-cleaning surfaces market, accounting for nearly 40% of the total market share. This is primarily due to the widespread application of self-cleaning coatings on building exteriors, windows, and solar panels. The reduced need for chemical cleaning agents and water consumption in buildings equipped with self-cleaning surfaces translates to substantial environmental benefits and operational cost savings.

Automotive applications represent the second-largest market segment, with approximately 25% market share. Major automotive manufacturers are increasingly incorporating self-cleaning coatings on vehicle exteriors and windshields to enhance durability and reduce the frequency of washing, thereby conserving water resources and minimizing chemical runoff.

The healthcare sector is emerging as a rapidly growing application area, with a projected CAGR of 14.2% through 2028. Self-cleaning surfaces in hospitals and medical facilities help reduce the spread of healthcare-associated infections while decreasing the use of harsh disinfectants that can be harmful to the environment.

Regionally, Europe leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing construction activities, and growing environmental concerns in countries like China and India.

Consumer awareness regarding the environmental benefits of self-cleaning surfaces has significantly influenced purchasing decisions. A recent survey indicated that 67% of consumers are willing to pay a premium for products with self-cleaning properties if they contribute to environmental sustainability.

The market is also witnessing a shift toward bio-based and environmentally friendly self-cleaning solutions. Manufacturers are increasingly focusing on developing products that minimize environmental impact throughout their lifecycle, from production to disposal. This trend is expected to accelerate as regulatory frameworks around chemical usage and environmental protection become more stringent globally.

Despite the promising growth trajectory, market penetration faces challenges related to high initial costs and limited consumer awareness about the long-term environmental and economic benefits. Educational marketing campaigns highlighting the reduced need for water, cleaning chemicals, and energy could potentially accelerate market adoption across various application segments.

The construction sector currently dominates the self-cleaning surfaces market, accounting for nearly 40% of the total market share. This is primarily due to the widespread application of self-cleaning coatings on building exteriors, windows, and solar panels. The reduced need for chemical cleaning agents and water consumption in buildings equipped with self-cleaning surfaces translates to substantial environmental benefits and operational cost savings.

Automotive applications represent the second-largest market segment, with approximately 25% market share. Major automotive manufacturers are increasingly incorporating self-cleaning coatings on vehicle exteriors and windshields to enhance durability and reduce the frequency of washing, thereby conserving water resources and minimizing chemical runoff.

The healthcare sector is emerging as a rapidly growing application area, with a projected CAGR of 14.2% through 2028. Self-cleaning surfaces in hospitals and medical facilities help reduce the spread of healthcare-associated infections while decreasing the use of harsh disinfectants that can be harmful to the environment.

Regionally, Europe leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing construction activities, and growing environmental concerns in countries like China and India.

Consumer awareness regarding the environmental benefits of self-cleaning surfaces has significantly influenced purchasing decisions. A recent survey indicated that 67% of consumers are willing to pay a premium for products with self-cleaning properties if they contribute to environmental sustainability.

The market is also witnessing a shift toward bio-based and environmentally friendly self-cleaning solutions. Manufacturers are increasingly focusing on developing products that minimize environmental impact throughout their lifecycle, from production to disposal. This trend is expected to accelerate as regulatory frameworks around chemical usage and environmental protection become more stringent globally.

Despite the promising growth trajectory, market penetration faces challenges related to high initial costs and limited consumer awareness about the long-term environmental and economic benefits. Educational marketing campaigns highlighting the reduced need for water, cleaning chemicals, and energy could potentially accelerate market adoption across various application segments.

Current Status and Technical Challenges in Self-cleaning Surfaces

Self-cleaning surfaces have gained significant attention globally, with research and development efforts intensifying over the past decade. Currently, these technologies are categorized into three main types: hydrophobic (water-repelling), hydrophilic (water-attracting), and photocatalytic surfaces. Each approach has achieved varying degrees of commercial implementation, with hydrophobic coatings being the most widely adopted in architectural glass, automotive finishes, and consumer electronics.

The global market for self-cleaning technologies reached approximately $3.5 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2028. This growth is primarily driven by increasing environmental concerns, water conservation efforts, and the rising costs associated with traditional cleaning methods. However, market penetration remains relatively limited, with adoption concentrated in high-end applications and developed economies.

Despite promising advancements, several significant technical challenges persist. Durability remains a primary concern, as most self-cleaning coatings demonstrate performance degradation after 1-3 years of environmental exposure. This limitation is particularly pronounced in harsh environments with high UV exposure, chemical pollutants, or mechanical abrasion. Research indicates that current hydrophobic coatings lose approximately 30-40% of their effectiveness after two years of outdoor exposure.

Another critical challenge involves the environmental impact of manufacturing processes and materials used in self-cleaning surfaces. Many hydrophobic coatings contain fluorinated compounds that pose potential environmental risks, including persistence in ecosystems and bioaccumulation. Similarly, some photocatalytic coatings utilize rare earth elements or toxic precursors during production, raising sustainability concerns throughout their lifecycle.

Scalability presents another significant hurdle, particularly for more advanced technologies like biomimetic surfaces that replicate natural self-cleaning mechanisms. Current manufacturing processes for these sophisticated surfaces often involve complex multi-step procedures that are difficult to scale economically for mass production. This limitation has restricted their application primarily to specialized, high-value products.

Geographically, research leadership in self-cleaning technologies is distributed across several regions. North America and Europe lead in patent filings and commercial applications, while Asia—particularly China, Japan, and South Korea—demonstrates accelerating research output and increasing market share. Academic institutions in these regions have established collaborative networks with industry partners, creating innovation ecosystems that are advancing the field through multidisciplinary approaches.

Regulatory frameworks regarding the environmental impact of self-cleaning surfaces vary significantly across regions, creating additional challenges for global commercialization and standardization. This regulatory fragmentation has slowed adoption in certain markets and complicated international expansion strategies for technology developers.

The global market for self-cleaning technologies reached approximately $3.5 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2028. This growth is primarily driven by increasing environmental concerns, water conservation efforts, and the rising costs associated with traditional cleaning methods. However, market penetration remains relatively limited, with adoption concentrated in high-end applications and developed economies.

Despite promising advancements, several significant technical challenges persist. Durability remains a primary concern, as most self-cleaning coatings demonstrate performance degradation after 1-3 years of environmental exposure. This limitation is particularly pronounced in harsh environments with high UV exposure, chemical pollutants, or mechanical abrasion. Research indicates that current hydrophobic coatings lose approximately 30-40% of their effectiveness after two years of outdoor exposure.

Another critical challenge involves the environmental impact of manufacturing processes and materials used in self-cleaning surfaces. Many hydrophobic coatings contain fluorinated compounds that pose potential environmental risks, including persistence in ecosystems and bioaccumulation. Similarly, some photocatalytic coatings utilize rare earth elements or toxic precursors during production, raising sustainability concerns throughout their lifecycle.

Scalability presents another significant hurdle, particularly for more advanced technologies like biomimetic surfaces that replicate natural self-cleaning mechanisms. Current manufacturing processes for these sophisticated surfaces often involve complex multi-step procedures that are difficult to scale economically for mass production. This limitation has restricted their application primarily to specialized, high-value products.

Geographically, research leadership in self-cleaning technologies is distributed across several regions. North America and Europe lead in patent filings and commercial applications, while Asia—particularly China, Japan, and South Korea—demonstrates accelerating research output and increasing market share. Academic institutions in these regions have established collaborative networks with industry partners, creating innovation ecosystems that are advancing the field through multidisciplinary approaches.

Regulatory frameworks regarding the environmental impact of self-cleaning surfaces vary significantly across regions, creating additional challenges for global commercialization and standardization. This regulatory fragmentation has slowed adoption in certain markets and complicated international expansion strategies for technology developers.

Current Technical Solutions for Self-cleaning Surfaces

01 Environmental benefits of self-cleaning surfaces

Self-cleaning surfaces offer significant environmental benefits by reducing the need for chemical cleaning agents and water consumption. These surfaces can help minimize pollution from cleaning chemicals that would otherwise enter waterways and soil. Additionally, they can contribute to energy savings by maintaining optimal performance of solar panels and building exteriors without frequent cleaning interventions, thereby reducing the overall environmental footprint of maintenance activities.- Environmental benefits of self-cleaning surfaces: Self-cleaning surfaces offer significant environmental benefits by reducing the need for chemical cleaning agents and water consumption. These surfaces minimize the use of detergents and other potentially harmful chemicals that can contaminate water systems. Additionally, they decrease water usage for cleaning purposes, contributing to water conservation efforts. The reduced cleaning frequency also leads to lower energy consumption and decreased carbon footprint associated with maintenance activities.

- Biodegradable and eco-friendly self-cleaning materials: Development of biodegradable and eco-friendly materials for self-cleaning surfaces addresses environmental concerns associated with traditional cleaning methods. These materials are designed to break down naturally at the end of their lifecycle, reducing waste accumulation. Innovations include bio-based coatings, naturally derived photocatalysts, and renewable resource-based materials that maintain self-cleaning properties while minimizing environmental impact throughout their production, use, and disposal phases.

- Life cycle assessment of self-cleaning technologies: Life cycle assessments evaluate the environmental impact of self-cleaning surfaces from production through disposal. These assessments consider factors such as raw material extraction, manufacturing processes, energy consumption during use, and end-of-life management. The analysis helps identify environmental hotspots and opportunities for improvement in self-cleaning technology development. Comprehensive life cycle thinking enables more sustainable design choices and better environmental performance of self-cleaning products.

- Photocatalytic self-cleaning surfaces and air purification: Photocatalytic self-cleaning surfaces not only clean themselves but also contribute to air purification by breaking down airborne pollutants. These surfaces, typically incorporating materials like titanium dioxide, use light energy to trigger reactions that decompose organic contaminants and air pollutants into harmless substances. This dual functionality helps improve indoor and outdoor air quality while maintaining clean surfaces, offering environmental benefits beyond just reducing cleaning chemical usage.

- Smart monitoring systems for environmental optimization: Smart monitoring systems integrated with self-cleaning surfaces optimize environmental performance through real-time data collection and analysis. These systems track cleaning efficiency, resource usage, and environmental conditions to adjust self-cleaning processes for maximum sustainability. By preventing unnecessary cleaning cycles and ensuring optimal resource utilization, these intelligent systems further reduce the environmental footprint of self-cleaning technologies while maintaining effectiveness.

02 Biodegradable and eco-friendly self-cleaning materials

Development of biodegradable and eco-friendly materials for self-cleaning surfaces addresses concerns about environmental impact. These innovative materials are designed to break down naturally at the end of their lifecycle without releasing harmful substances into the environment. By incorporating natural compounds and sustainable resources in their formulation, these self-cleaning surfaces minimize ecological disruption while maintaining effective cleaning properties.Expand Specific Solutions03 Life cycle assessment of self-cleaning technologies

Life cycle assessment methodologies evaluate the environmental impact of self-cleaning surfaces from production through disposal. These assessments consider factors such as resource consumption, energy use, emissions, and waste generation throughout the entire product lifecycle. By quantifying environmental impacts across different stages, manufacturers can identify opportunities for improvement and develop more sustainable self-cleaning technologies with reduced ecological footprints.Expand Specific Solutions04 Nanotechnology applications and environmental considerations

Nanotechnology plays a crucial role in developing advanced self-cleaning surfaces, but raises environmental considerations regarding nanoparticle release and persistence. Research focuses on understanding the potential ecological impacts of nanomaterials used in self-cleaning applications, including their fate in aquatic environments and effects on living organisms. Innovations aim to create effective self-cleaning properties while minimizing risks associated with nanoparticle dispersion in the environment.Expand Specific Solutions05 Sustainable manufacturing processes for self-cleaning surfaces

Sustainable manufacturing processes for self-cleaning surfaces focus on reducing environmental impact during production. These approaches include energy-efficient manufacturing methods, waste reduction strategies, and the use of renewable resources. By implementing green chemistry principles and optimizing production techniques, manufacturers can create self-cleaning surfaces with minimal environmental footprint while maintaining performance characteristics and durability.Expand Specific Solutions

Major Industry Players in Self-cleaning Surface Development

The self-cleaning surfaces market is in a growth phase, with increasing environmental awareness driving adoption across industries. The market is projected to expand significantly due to rising demand for sustainable solutions that reduce cleaning chemical usage and water consumption. Technologically, the field shows varying maturity levels, with companies like Evonik Operations and Wacker Chemie leading commercial applications through advanced chemical coatings. Research institutions including Naval Research Laboratory and University of Antwerp are pioneering next-generation solutions with reduced environmental footprints. Merck Patent GmbH and Airbus Operations are developing specialized applications for transportation sectors, while academic-industrial partnerships between universities like Clemson and companies such as Clorox are accelerating innovation in consumer applications. The competitive landscape features both established chemical conglomerates and emerging specialized manufacturers focusing on eco-friendly formulations.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced self-cleaning surface technologies based on their proprietary AEROSIL® and AEROXIDE® nanoparticle systems. Their approach combines hydrophobic and photocatalytic properties to create surfaces that actively repel water and decompose organic contaminants. The company's technology utilizes modified silica and titanium dioxide nanoparticles that form a microscopic rough texture on surfaces, creating a lotus effect where water droplets roll off, carrying away dirt particles. Their environmental impact studies show these surfaces can reduce cleaning chemical usage by up to 70% and extend maintenance intervals by 3-5 times compared to conventional surfaces. Evonik has also developed biodegradable coating formulations that minimize environmental leaching concerns while maintaining self-cleaning functionality. Their life cycle assessments indicate a net positive environmental impact through reduced water consumption, decreased chemical usage, and extended product lifespans.

Strengths: Proprietary nanoparticle technology provides superior durability and performance compared to conventional coatings. Their formulations work effectively in various environmental conditions and can be applied to multiple substrate materials. Weaknesses: Production of nanoparticles requires significant energy input, and there are ongoing concerns about potential nanoparticle release into the environment during the product lifecycle.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has developed advanced omniphobic self-cleaning surfaces specifically designed for marine environments through their SLIPS (Slippery Liquid-Infused Porous Surfaces) technology. This innovative approach uses micro/nanostructured substrates infused with lubricating liquids that create ultra-smooth surfaces resistant to both water and oil-based contaminants. Environmental impact research by NRL demonstrates these surfaces can reduce biofouling on ship hulls by up to 85% compared to conventional surfaces, significantly decreasing the need for toxic antifouling paints containing copper and other heavy metals. Their studies show potential fuel savings of 8-12% for vessels with these coatings due to reduced drag, translating to substantial reductions in carbon emissions from maritime transportation. NRL has optimized their lubricant formulations to use biodegradable perfluoropolyethers that demonstrate minimal aquatic toxicity while maintaining performance. Life cycle assessments indicate these surfaces can reduce maintenance docking frequency by 30-40%, significantly decreasing environmental impacts associated with ship maintenance operations. The technology also shows promise for reducing microplastic pollution by preventing polymer degradation on marine structures.

Strengths: Exceptional performance in challenging marine environments where traditional self-cleaning approaches often fail. The technology addresses multiple environmental concerns simultaneously (reduced biocide use, decreased fuel consumption, extended maintenance intervals). Weaknesses: The current formulations require periodic reapplication of the lubricating layer in high-shear environments, and manufacturing scale-up remains challenging for large marine applications despite promising laboratory and field test results.

Key Patents and Innovations in Self-cleaning Surface Technology

Self-cleaning surfaces due to hydrophobic structure and process for the preparation thereof

PatentInactiveEP1249467A1

Innovation

- The development of self-cleaning surfaces with artificial, partially hydrophobic structures in the nanometer range, formed by structure-forming particles fixed with a fissured structure using hot-melt adhesives or powder coatings, which reduce interfacial energy and enhance water repellency without significant chemical or physical stress.

Coating material with self-cleaning capability and preparation method thereof

PatentPendingCN117304806A

Innovation

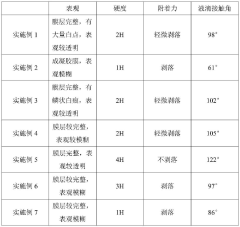

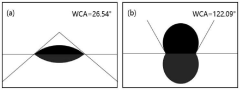

- The combination of perfluorooctyltriethoxysilane (FAS), nano-silica and hydroxyl-terminated polydimethylsiloxane (PDMS-OH) is used to form a highly hydrophobic coating through the synergistic effect of hydrolysis and diluent. The material utilizes the synergistic effect of fluorine-based and siloxane chains to enhance the hardness of the coating and substrate adhesion, and obtain a coating with self-cleaning ability through a simple preparation process.

Environmental Impact Assessment Methodologies

The assessment of environmental impacts related to self-cleaning surfaces requires robust methodological frameworks to ensure comprehensive evaluation. Life Cycle Assessment (LCA) stands as the primary methodology, offering a cradle-to-grave analysis of environmental impacts across production, use, and disposal phases. When applied to self-cleaning surfaces, LCA quantifies energy consumption, resource utilization, emissions, and waste generation throughout the product lifecycle, providing valuable comparative data against conventional surfaces.

Environmental Risk Assessment (ERA) complements LCA by focusing on potential ecological and human health risks associated with self-cleaning technologies. This approach is particularly relevant for surfaces utilizing photocatalytic materials like titanium dioxide, which may release nanoparticles or reactive oxygen species into surrounding environments. ERA protocols typically include hazard identification, exposure assessment, and risk characterization stages.

Material Flow Analysis (MFA) tracks the movement of substances through production systems and environments, offering insights into resource efficiency and potential accumulation of chemicals in ecosystems. For self-cleaning surfaces, MFA helps identify critical control points where environmental interventions might be most effective.

Ecological Footprint Analysis measures the biological capacity required to support self-cleaning surface technologies, comparing resource demands against planetary boundaries. This methodology provides a macro-level perspective on sustainability that complements more detailed technical assessments.

Real-time monitoring methodologies have emerged as essential components of environmental impact assessment, utilizing sensor networks to track emissions, leaching, and degradation products from self-cleaning surfaces in actual deployment conditions. These approaches overcome limitations of laboratory-based predictions by capturing temporal variations and environmental interactions.

Standardized testing protocols developed by organizations such as ISO, ASTM, and CEN provide consistent frameworks for evaluating specific environmental aspects of self-cleaning surfaces. These include tests for photocatalytic activity, durability under environmental stressors, and potential for harmful substance release.

Multi-criteria decision analysis (MCDA) frameworks help integrate diverse environmental indicators into coherent assessment models, balancing trade-offs between different environmental impacts. This approach is particularly valuable when comparing alternative self-cleaning technologies with varying environmental profiles across multiple impact categories.

Emerging methodologies incorporating artificial intelligence and machine learning show promise for predicting long-term environmental consequences of self-cleaning surfaces, potentially addressing current limitations in forecasting cumulative impacts across extended timeframes and diverse deployment scenarios.

Environmental Risk Assessment (ERA) complements LCA by focusing on potential ecological and human health risks associated with self-cleaning technologies. This approach is particularly relevant for surfaces utilizing photocatalytic materials like titanium dioxide, which may release nanoparticles or reactive oxygen species into surrounding environments. ERA protocols typically include hazard identification, exposure assessment, and risk characterization stages.

Material Flow Analysis (MFA) tracks the movement of substances through production systems and environments, offering insights into resource efficiency and potential accumulation of chemicals in ecosystems. For self-cleaning surfaces, MFA helps identify critical control points where environmental interventions might be most effective.

Ecological Footprint Analysis measures the biological capacity required to support self-cleaning surface technologies, comparing resource demands against planetary boundaries. This methodology provides a macro-level perspective on sustainability that complements more detailed technical assessments.

Real-time monitoring methodologies have emerged as essential components of environmental impact assessment, utilizing sensor networks to track emissions, leaching, and degradation products from self-cleaning surfaces in actual deployment conditions. These approaches overcome limitations of laboratory-based predictions by capturing temporal variations and environmental interactions.

Standardized testing protocols developed by organizations such as ISO, ASTM, and CEN provide consistent frameworks for evaluating specific environmental aspects of self-cleaning surfaces. These include tests for photocatalytic activity, durability under environmental stressors, and potential for harmful substance release.

Multi-criteria decision analysis (MCDA) frameworks help integrate diverse environmental indicators into coherent assessment models, balancing trade-offs between different environmental impacts. This approach is particularly valuable when comparing alternative self-cleaning technologies with varying environmental profiles across multiple impact categories.

Emerging methodologies incorporating artificial intelligence and machine learning show promise for predicting long-term environmental consequences of self-cleaning surfaces, potentially addressing current limitations in forecasting cumulative impacts across extended timeframes and diverse deployment scenarios.

Regulatory Compliance and Sustainability Standards

The regulatory landscape for self-cleaning surfaces is increasingly complex, with frameworks evolving to address both environmental protection and sustainability concerns. Currently, major regulatory bodies including the Environmental Protection Agency (EPA) in the United States, the European Chemicals Agency (ECHA), and similar organizations in Asia have established guidelines specifically targeting nanomaterials and surface treatments used in self-cleaning technologies. These regulations primarily focus on chemical safety, lifecycle assessment, and potential environmental leaching of active compounds.

Key regulatory standards include ISO 14040 for Life Cycle Assessment, which has become essential for manufacturers to demonstrate the environmental footprint of self-cleaning products throughout their entire lifecycle. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements for testing and documentation of chemicals used in these surfaces, particularly those containing photocatalytic titanium dioxide and other potentially reactive compounds.

Sustainability certification systems have also incorporated specific criteria for self-cleaning surfaces. The LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) building certification programs award points for materials that reduce maintenance requirements and chemical cleaning agents, creating market incentives for environmentally responsible self-cleaning technologies.

Industry-specific standards have emerged as well, with the automotive sector developing ISO 18451 for photocatalytic materials and the construction industry implementing EN 16845 for evaluating self-cleaning performance. These standards not only ensure product efficacy but also establish parameters for environmental impact assessment, including degradation byproducts and energy consumption during manufacturing.

Compliance challenges remain significant, particularly regarding the lack of harmonization between different regional regulations. Manufacturers often face conflicting requirements across markets, increasing compliance costs and potentially limiting innovation. The rapid pace of technological development in self-cleaning surfaces frequently outpaces regulatory frameworks, creating uncertainty for both producers and consumers.

Looking forward, regulatory trends indicate movement toward more comprehensive lifecycle-based approaches rather than focusing solely on individual chemical components. Emerging standards are beginning to incorporate circular economy principles, requiring manufacturers to consider end-of-life scenarios and recyclability of self-cleaning surfaces. This shift represents a more holistic approach to environmental sustainability that considers resource efficiency alongside traditional pollution prevention measures.

Key regulatory standards include ISO 14040 for Life Cycle Assessment, which has become essential for manufacturers to demonstrate the environmental footprint of self-cleaning products throughout their entire lifecycle. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements for testing and documentation of chemicals used in these surfaces, particularly those containing photocatalytic titanium dioxide and other potentially reactive compounds.

Sustainability certification systems have also incorporated specific criteria for self-cleaning surfaces. The LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) building certification programs award points for materials that reduce maintenance requirements and chemical cleaning agents, creating market incentives for environmentally responsible self-cleaning technologies.

Industry-specific standards have emerged as well, with the automotive sector developing ISO 18451 for photocatalytic materials and the construction industry implementing EN 16845 for evaluating self-cleaning performance. These standards not only ensure product efficacy but also establish parameters for environmental impact assessment, including degradation byproducts and energy consumption during manufacturing.

Compliance challenges remain significant, particularly regarding the lack of harmonization between different regional regulations. Manufacturers often face conflicting requirements across markets, increasing compliance costs and potentially limiting innovation. The rapid pace of technological development in self-cleaning surfaces frequently outpaces regulatory frameworks, creating uncertainty for both producers and consumers.

Looking forward, regulatory trends indicate movement toward more comprehensive lifecycle-based approaches rather than focusing solely on individual chemical components. Emerging standards are beginning to incorporate circular economy principles, requiring manufacturers to consider end-of-life scenarios and recyclability of self-cleaning surfaces. This shift represents a more holistic approach to environmental sustainability that considers resource efficiency alongside traditional pollution prevention measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!