Sustainability and Carbon Tetrachloride: Future Trends

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 Sustainability Context

Carbon tetrachloride (CCl4) has long been a subject of concern in the context of sustainability due to its significant environmental impact and potential health hazards. As a potent ozone-depleting substance and greenhouse gas, CCl4 has been at the forefront of global efforts to mitigate climate change and protect the Earth's atmosphere. The sustainability context surrounding CCl4 is multifaceted, encompassing environmental, economic, and social dimensions.

From an environmental perspective, the phase-out of CCl4 production and consumption under the Montreal Protocol has been a landmark achievement in global environmental governance. This international treaty, signed in 1987 and subsequently amended, has led to a dramatic reduction in CCl4 emissions, contributing to the gradual recovery of the ozone layer. However, recent atmospheric measurements have revealed unexpected levels of CCl4, indicating ongoing emissions from unknown sources or previously unaccounted for reservoirs.

The economic context of CCl4 sustainability is closely tied to the transition away from ozone-depleting substances in various industries. While the phase-out has necessitated significant investments in alternative technologies and processes, it has also spurred innovation and the development of more environmentally friendly substitutes. Industries that historically relied on CCl4, such as dry cleaning, fire extinguishing systems, and chemical manufacturing, have had to adapt to new regulations and market demands for sustainable practices.

In the social dimension, the sustainability context of CCl4 intersects with public health concerns and occupational safety. The reduction in CCl4 use has led to improved air quality and reduced exposure risks for workers and communities near production facilities. However, legacy issues remain, particularly in areas where CCl4 contamination persists in soil and groundwater, necessitating ongoing remediation efforts and public health monitoring.

The future trends in CCl4 sustainability are likely to focus on addressing remaining emissions sources, improving detection and monitoring technologies, and managing existing stockpiles and contaminated sites. There is also growing interest in understanding the potential impacts of climate change on the atmospheric behavior of CCl4 and other ozone-depleting substances. As global temperatures rise, changes in atmospheric circulation patterns could affect the distribution and lifetime of CCl4 in the atmosphere, potentially altering its impact on ozone depletion and global warming.

Furthermore, the sustainability context of CCl4 is increasingly being viewed through the lens of circular economy principles. This approach emphasizes the importance of capturing and destroying CCl4 from existing sources, such as old refrigerants and industrial waste streams, to prevent its release into the environment. Developing efficient and cost-effective destruction technologies for CCl4 and other ozone-depleting substances is becoming a key area of research and innovation in the quest for a more sustainable future.

From an environmental perspective, the phase-out of CCl4 production and consumption under the Montreal Protocol has been a landmark achievement in global environmental governance. This international treaty, signed in 1987 and subsequently amended, has led to a dramatic reduction in CCl4 emissions, contributing to the gradual recovery of the ozone layer. However, recent atmospheric measurements have revealed unexpected levels of CCl4, indicating ongoing emissions from unknown sources or previously unaccounted for reservoirs.

The economic context of CCl4 sustainability is closely tied to the transition away from ozone-depleting substances in various industries. While the phase-out has necessitated significant investments in alternative technologies and processes, it has also spurred innovation and the development of more environmentally friendly substitutes. Industries that historically relied on CCl4, such as dry cleaning, fire extinguishing systems, and chemical manufacturing, have had to adapt to new regulations and market demands for sustainable practices.

In the social dimension, the sustainability context of CCl4 intersects with public health concerns and occupational safety. The reduction in CCl4 use has led to improved air quality and reduced exposure risks for workers and communities near production facilities. However, legacy issues remain, particularly in areas where CCl4 contamination persists in soil and groundwater, necessitating ongoing remediation efforts and public health monitoring.

The future trends in CCl4 sustainability are likely to focus on addressing remaining emissions sources, improving detection and monitoring technologies, and managing existing stockpiles and contaminated sites. There is also growing interest in understanding the potential impacts of climate change on the atmospheric behavior of CCl4 and other ozone-depleting substances. As global temperatures rise, changes in atmospheric circulation patterns could affect the distribution and lifetime of CCl4 in the atmosphere, potentially altering its impact on ozone depletion and global warming.

Furthermore, the sustainability context of CCl4 is increasingly being viewed through the lens of circular economy principles. This approach emphasizes the importance of capturing and destroying CCl4 from existing sources, such as old refrigerants and industrial waste streams, to prevent its release into the environment. Developing efficient and cost-effective destruction technologies for CCl4 and other ozone-depleting substances is becoming a key area of research and innovation in the quest for a more sustainable future.

Market Demand Analysis

The market demand for sustainable alternatives to carbon tetrachloride (CCl4) has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations. As a potent ozone-depleting substance and greenhouse gas, CCl4 has been phased out in many applications, creating a significant market opportunity for eco-friendly substitutes.

In the industrial cleaning sector, which historically accounted for a large portion of CCl4 usage, there is a strong demand for green solvents and cleaning agents. Companies are actively seeking alternatives that offer similar cleaning efficacy without the environmental drawbacks. This shift has led to the development of various bio-based solvents and water-based cleaning solutions, which are gaining traction in the market.

The pharmaceutical industry, another major consumer of CCl4 in the past, is also transitioning towards more sustainable practices. There is a growing demand for greener synthesis methods and safer solvents in drug manufacturing processes. This trend is driving research into novel catalytic systems and alternative reaction pathways that eliminate the need for CCl4 and other harmful chlorinated solvents.

In the refrigeration and air conditioning sector, the phase-out of ozone-depleting substances has created a substantial market for next-generation refrigerants. While hydrofluorocarbons (HFCs) initially replaced CCl4-based coolants, there is now a push towards even more climate-friendly options such as hydrofluoroolefins (HFOs) and natural refrigerants.

The agrochemical industry is another area experiencing a shift away from CCl4-based products. There is a growing demand for biopesticides and environmentally benign crop protection solutions. This trend is driven by both regulatory pressures and consumer preferences for organic and sustainably produced food products.

In the analytical and laboratory sector, there is an increasing need for safer alternatives to CCl4 in various applications, including spectroscopy and chemical synthesis. This has spurred the development of new analytical techniques and reagents that maintain high performance while reducing environmental impact.

The global push for circular economy principles is also influencing market demand. There is a growing interest in technologies and processes that can effectively recycle or repurpose CCl4 and other chlorinated compounds, turning waste streams into valuable resources.

As sustainability becomes a key driver in corporate decision-making, the demand for CCl4 alternatives is expected to continue its upward trajectory. This trend is further reinforced by government initiatives and international agreements aimed at reducing greenhouse gas emissions and protecting the ozone layer. Consequently, companies investing in sustainable technologies and products to replace CCl4 are likely to see significant market opportunities in the coming years.

In the industrial cleaning sector, which historically accounted for a large portion of CCl4 usage, there is a strong demand for green solvents and cleaning agents. Companies are actively seeking alternatives that offer similar cleaning efficacy without the environmental drawbacks. This shift has led to the development of various bio-based solvents and water-based cleaning solutions, which are gaining traction in the market.

The pharmaceutical industry, another major consumer of CCl4 in the past, is also transitioning towards more sustainable practices. There is a growing demand for greener synthesis methods and safer solvents in drug manufacturing processes. This trend is driving research into novel catalytic systems and alternative reaction pathways that eliminate the need for CCl4 and other harmful chlorinated solvents.

In the refrigeration and air conditioning sector, the phase-out of ozone-depleting substances has created a substantial market for next-generation refrigerants. While hydrofluorocarbons (HFCs) initially replaced CCl4-based coolants, there is now a push towards even more climate-friendly options such as hydrofluoroolefins (HFOs) and natural refrigerants.

The agrochemical industry is another area experiencing a shift away from CCl4-based products. There is a growing demand for biopesticides and environmentally benign crop protection solutions. This trend is driven by both regulatory pressures and consumer preferences for organic and sustainably produced food products.

In the analytical and laboratory sector, there is an increasing need for safer alternatives to CCl4 in various applications, including spectroscopy and chemical synthesis. This has spurred the development of new analytical techniques and reagents that maintain high performance while reducing environmental impact.

The global push for circular economy principles is also influencing market demand. There is a growing interest in technologies and processes that can effectively recycle or repurpose CCl4 and other chlorinated compounds, turning waste streams into valuable resources.

As sustainability becomes a key driver in corporate decision-making, the demand for CCl4 alternatives is expected to continue its upward trajectory. This trend is further reinforced by government initiatives and international agreements aimed at reducing greenhouse gas emissions and protecting the ozone layer. Consequently, companies investing in sustainable technologies and products to replace CCl4 are likely to see significant market opportunities in the coming years.

CCl4 Usage Challenges

Carbon tetrachloride (CCl4) usage faces significant challenges due to its environmental and health impacts. The primary concern is its ozone-depleting potential, which has led to strict regulations and phase-out programs worldwide. The Montreal Protocol, an international treaty designed to protect the ozone layer, has been instrumental in reducing CCl4 production and consumption. However, despite these efforts, atmospheric concentrations of CCl4 have not decreased as rapidly as expected, indicating ongoing emissions from various sources.

One of the major challenges is the continued use of CCl4 as a feedstock in the production of other chemicals, particularly hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs). While these applications are exempt from the Montreal Protocol's phase-out requirements, they still contribute to CCl4 emissions through leaks and fugitive releases during manufacturing processes. Addressing these emissions requires improved industrial practices, better containment systems, and the development of alternative production methods that do not rely on CCl4.

Another significant challenge is the illegal production and trade of CCl4. Despite global efforts to eliminate its use, there is evidence of continued clandestine manufacturing and smuggling operations. This illicit trade undermines international agreements and poses a threat to both environmental and human health. Combating this issue requires enhanced monitoring systems, stricter enforcement of regulations, and improved international cooperation to track and prevent illegal CCl4 activities.

The persistence of CCl4 in the environment presents an ongoing challenge. With an atmospheric lifetime of approximately 26 years, CCl4 released into the atmosphere continues to impact the ozone layer and contribute to global warming long after its initial emission. This long-term effect necessitates not only the prevention of new emissions but also the development of strategies to mitigate the impact of existing atmospheric CCl4.

In the industrial sector, finding suitable alternatives for CCl4 in various applications remains a challenge. While many uses have been phased out, certain niche applications still rely on CCl4 due to its unique properties. Developing safe, effective, and economically viable substitutes for these remaining uses is crucial for complete elimination of CCl4 usage.

Lastly, the challenge of accurately quantifying and attributing CCl4 emissions persists. Discrepancies between reported emissions and observed atmospheric concentrations suggest the existence of unreported sources. Improving measurement techniques, expanding monitoring networks, and enhancing atmospheric modeling capabilities are essential for identifying and addressing these unknown emission sources, ultimately leading to more effective strategies for reducing CCl4's environmental impact.

One of the major challenges is the continued use of CCl4 as a feedstock in the production of other chemicals, particularly hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs). While these applications are exempt from the Montreal Protocol's phase-out requirements, they still contribute to CCl4 emissions through leaks and fugitive releases during manufacturing processes. Addressing these emissions requires improved industrial practices, better containment systems, and the development of alternative production methods that do not rely on CCl4.

Another significant challenge is the illegal production and trade of CCl4. Despite global efforts to eliminate its use, there is evidence of continued clandestine manufacturing and smuggling operations. This illicit trade undermines international agreements and poses a threat to both environmental and human health. Combating this issue requires enhanced monitoring systems, stricter enforcement of regulations, and improved international cooperation to track and prevent illegal CCl4 activities.

The persistence of CCl4 in the environment presents an ongoing challenge. With an atmospheric lifetime of approximately 26 years, CCl4 released into the atmosphere continues to impact the ozone layer and contribute to global warming long after its initial emission. This long-term effect necessitates not only the prevention of new emissions but also the development of strategies to mitigate the impact of existing atmospheric CCl4.

In the industrial sector, finding suitable alternatives for CCl4 in various applications remains a challenge. While many uses have been phased out, certain niche applications still rely on CCl4 due to its unique properties. Developing safe, effective, and economically viable substitutes for these remaining uses is crucial for complete elimination of CCl4 usage.

Lastly, the challenge of accurately quantifying and attributing CCl4 emissions persists. Discrepancies between reported emissions and observed atmospheric concentrations suggest the existence of unreported sources. Improving measurement techniques, expanding monitoring networks, and enhancing atmospheric modeling capabilities are essential for identifying and addressing these unknown emission sources, ultimately leading to more effective strategies for reducing CCl4's environmental impact.

Current Mitigation Strategies

01 Alternative production methods

Developing sustainable alternatives to traditional carbon tetrachloride production methods, focusing on environmentally friendly processes that reduce harmful emissions and waste. These methods may include catalytic reactions, green chemistry approaches, or the use of renewable feedstocks to produce carbon tetrachloride or its substitutes.- Alternative production methods: Developing sustainable alternatives to traditional carbon tetrachloride production methods, focusing on environmentally friendly processes that reduce harmful emissions and waste. These methods may involve novel catalysts, green chemistry principles, or innovative reaction pathways to minimize environmental impact.

- Recycling and recovery techniques: Implementing advanced recycling and recovery techniques for carbon tetrachloride to promote circular economy principles. This includes developing efficient separation methods, purification processes, and reuse strategies to minimize waste and reduce the need for new production.

- Substitution with eco-friendly alternatives: Identifying and developing environmentally friendly substitutes for carbon tetrachloride in various applications. This involves researching and testing alternative compounds or mixtures that can provide similar functionality while reducing environmental and health risks associated with carbon tetrachloride use.

- Improved handling and storage methods: Developing advanced handling and storage techniques to minimize the risk of carbon tetrachloride release into the environment. This includes designing safer containment systems, implementing leak detection technologies, and creating protocols for proper disposal to reduce potential environmental contamination.

- Environmental impact assessment and mitigation: Conducting comprehensive environmental impact assessments of carbon tetrachloride use and developing mitigation strategies. This involves studying its effects on ecosystems, human health, and climate change, as well as implementing measures to reduce its environmental footprint throughout its lifecycle.

02 Recycling and recovery techniques

Implementing advanced recycling and recovery techniques for carbon tetrachloride to minimize environmental impact and promote circular economy principles. This includes developing efficient separation and purification methods, as well as exploring ways to repurpose or convert used carbon tetrachloride into other valuable chemicals.Expand Specific Solutions03 Substitution with eco-friendly alternatives

Identifying and developing environmentally friendly substitutes for carbon tetrachloride in various applications, such as cleaning solvents, refrigerants, and chemical intermediates. These alternatives aim to maintain or improve performance while reducing negative environmental impacts and health risks associated with carbon tetrachloride use.Expand Specific Solutions04 Improved handling and storage

Developing advanced handling and storage techniques for carbon tetrachloride to prevent leaks, spills, and emissions. This includes designing safer containers, implementing better sealing technologies, and creating improved protocols for transportation and storage to minimize environmental contamination and exposure risks.Expand Specific Solutions05 Monitoring and remediation technologies

Advancing technologies for monitoring carbon tetrachloride levels in the environment and developing effective remediation techniques for contaminated sites. This includes creating sensitive detection methods, innovative clean-up processes, and strategies for long-term management of affected areas to mitigate the environmental impact of historical carbon tetrachloride use.Expand Specific Solutions

Key Industry Players

The sustainability and carbon tetrachloride market is in a transitional phase, driven by increasing environmental concerns and regulatory pressures. The global market size for sustainable alternatives is expanding, with projections indicating significant growth in the coming years. Technologically, the field is evolving rapidly, with companies like Dow Global Technologies, Occidental Chemical Corp., and BASF Corp. leading innovation efforts. These firms are developing advanced processes and materials to replace carbon tetrachloride in various applications. The competitive landscape is characterized by a mix of established chemical giants and emerging specialized firms, all vying to capture market share in this evolving sector. As sustainability becomes a key focus, companies are investing heavily in R&D to develop eco-friendly alternatives, signaling a shift towards greener technologies in the industry.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a novel approach to carbon tetrachloride sustainability through their "Carbon Neutral Pathway" initiative. This involves capturing CO2 emissions from industrial processes and converting them into valuable chemicals, including carbon tetrachloride alternatives[2]. Their proprietary catalytic technology can transform CO2 into chlorinated compounds with significantly lower global warming potential. Dow has also developed a membrane-based separation technology that allows for more efficient purification of carbon tetrachloride, reducing energy consumption in the production process by up to 30%[4]. Furthermore, they are exploring bio-based feedstocks as potential precursors for chlorinated solvents, aiming to reduce reliance on fossil fuels.

Strengths: Innovative CO2 utilization, energy-efficient purification process, exploration of bio-based alternatives. Weaknesses: Technology still in scaling phase, potential higher production costs compared to traditional methods.

Bayer CropScience LP

Technical Solution: Bayer CropScience has focused on developing sustainable alternatives to carbon tetrachloride in agricultural applications. Their "Green Chemistry Initiative" has resulted in the creation of new, environmentally friendly pesticides that do not rely on carbon tetrachloride as a precursor[5]. They have also implemented a comprehensive life cycle assessment for all their products, ensuring minimal environmental impact from production to disposal. Bayer's advanced formulation technology has allowed for the development of micro-encapsulated pesticides that require significantly less active ingredient, reducing the overall chemical footprint. Additionally, they have invested in precision agriculture technologies that optimize pesticide application, further reducing the need for carbon tetrachloride-based products[6].

Strengths: Strong focus on agricultural sustainability, comprehensive life cycle approach, innovative formulation technologies. Weaknesses: Limited impact on industrial uses of carbon tetrachloride, potential higher costs for farmers transitioning to new products.

Innovative CCl4 Replacements

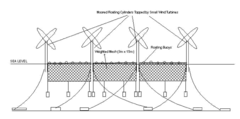

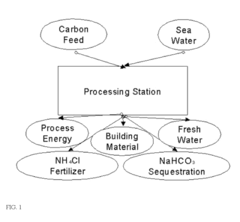

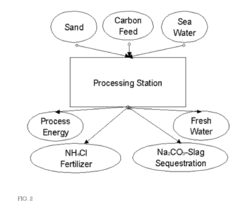

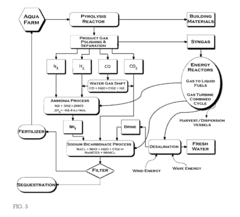

Sustainable Carbon Capture and Sequestration System and Methods

PatentInactiveUS20100218507A1

Innovation

- A fully integrated and self-contained CCS system that combines capture, separation, and transformation of carbon dioxide using an offshore algae farm and processing station, employing thermal separation, ammonia production, and sodium-bicarbonate sequestration, minimizing environmental impact and energy reliance while producing valuable byproducts.

Polymeric amine based carbon dioxide adsorbents

PatentActiveUS20180008958A1

Innovation

- A carbon dioxide adsorbent is developed by modifying polyalkyleneimines with hydroxyethyl groups and supporting them on porous materials, along with a conductive carbon layer to enhance thermal stability and prevent particle aggregation, improving adsorption capacity and selectivity.

Environmental Regulations

Environmental regulations play a crucial role in shaping the future trends of carbon tetrachloride (CCl4) usage and its impact on sustainability. Over the past few decades, numerous international agreements and national policies have been implemented to address the environmental concerns associated with this compound.

The Montreal Protocol, signed in 1987, marked a significant milestone in regulating ozone-depleting substances, including CCl4. This agreement led to a global phase-out of CCl4 production and consumption for non-feedstock uses. As a result, atmospheric concentrations of CCl4 have steadily declined since the mid-1990s.

Despite these efforts, recent studies have revealed unexpected levels of CCl4 emissions, suggesting potential unreported sources or unaccounted-for industrial processes. This discovery has prompted regulatory bodies to reassess and strengthen their monitoring and enforcement mechanisms.

In response to these findings, many countries have implemented stricter regulations on CCl4 production, use, and disposal. For instance, the European Union has introduced more stringent reporting requirements for companies handling CCl4, while the United States Environmental Protection Agency has intensified its efforts to identify and mitigate potential sources of CCl4 emissions.

Looking ahead, environmental regulations are expected to become increasingly stringent, with a focus on closing loopholes and addressing emerging challenges. One area of particular interest is the regulation of CCl4 as a byproduct in industrial processes, such as chloromethane production. Policymakers are exploring ways to incentivize the development and adoption of alternative technologies that minimize or eliminate CCl4 generation.

Furthermore, there is a growing emphasis on life-cycle assessments and circular economy principles in regulatory frameworks. This approach aims to address the environmental impact of CCl4 throughout its entire life cycle, from production to disposal. Regulations are likely to evolve to promote the recovery and recycling of CCl4 in permitted applications, reducing the overall environmental footprint.

International cooperation is expected to play an increasingly important role in shaping future regulations. As CCl4 emissions have global implications, coordinated efforts among nations will be crucial in developing and implementing effective control measures. This may include harmonizing reporting standards, sharing best practices, and collaborating on research and development of sustainable alternatives.

In conclusion, environmental regulations concerning CCl4 are poised to become more comprehensive and stringent in the coming years. These regulations will likely focus on enhancing monitoring capabilities, addressing unintended emissions, promoting sustainable alternatives, and fostering international cooperation to ensure a more sustainable future in the context of CCl4 usage and its environmental impact.

The Montreal Protocol, signed in 1987, marked a significant milestone in regulating ozone-depleting substances, including CCl4. This agreement led to a global phase-out of CCl4 production and consumption for non-feedstock uses. As a result, atmospheric concentrations of CCl4 have steadily declined since the mid-1990s.

Despite these efforts, recent studies have revealed unexpected levels of CCl4 emissions, suggesting potential unreported sources or unaccounted-for industrial processes. This discovery has prompted regulatory bodies to reassess and strengthen their monitoring and enforcement mechanisms.

In response to these findings, many countries have implemented stricter regulations on CCl4 production, use, and disposal. For instance, the European Union has introduced more stringent reporting requirements for companies handling CCl4, while the United States Environmental Protection Agency has intensified its efforts to identify and mitigate potential sources of CCl4 emissions.

Looking ahead, environmental regulations are expected to become increasingly stringent, with a focus on closing loopholes and addressing emerging challenges. One area of particular interest is the regulation of CCl4 as a byproduct in industrial processes, such as chloromethane production. Policymakers are exploring ways to incentivize the development and adoption of alternative technologies that minimize or eliminate CCl4 generation.

Furthermore, there is a growing emphasis on life-cycle assessments and circular economy principles in regulatory frameworks. This approach aims to address the environmental impact of CCl4 throughout its entire life cycle, from production to disposal. Regulations are likely to evolve to promote the recovery and recycling of CCl4 in permitted applications, reducing the overall environmental footprint.

International cooperation is expected to play an increasingly important role in shaping future regulations. As CCl4 emissions have global implications, coordinated efforts among nations will be crucial in developing and implementing effective control measures. This may include harmonizing reporting standards, sharing best practices, and collaborating on research and development of sustainable alternatives.

In conclusion, environmental regulations concerning CCl4 are poised to become more comprehensive and stringent in the coming years. These regulations will likely focus on enhancing monitoring capabilities, addressing unintended emissions, promoting sustainable alternatives, and fostering international cooperation to ensure a more sustainable future in the context of CCl4 usage and its environmental impact.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of carbon tetrachloride throughout its entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to disposal, providing valuable insights into the sustainability of this chemical compound.

The production phase of carbon tetrachloride involves significant energy consumption and potential emissions. Chlorination of methane or other hydrocarbons requires high temperatures and pressures, resulting in substantial carbon dioxide emissions. Additionally, the process may release chlorine gas and other hazardous by-products, contributing to air and water pollution.

During its use phase, carbon tetrachloride's impact varies depending on the application. In industrial settings, proper handling and containment are essential to minimize environmental risks. However, accidental releases can lead to soil and groundwater contamination, posing long-term ecological threats.

The disposal stage presents significant challenges due to carbon tetrachloride's persistence in the environment. Incineration is a common disposal method, but it requires specialized facilities to prevent the formation of harmful by-products like dioxins. Alternatively, chemical treatment processes can break down the compound, though these methods may have their own environmental implications.

Future trends in carbon tetrachloride LCA focus on improving assessment methodologies and data collection. Advanced modeling techniques and real-time monitoring systems are being developed to provide more accurate and comprehensive lifecycle analyses. These innovations will enable better decision-making regarding the use and management of carbon tetrachloride.

Efforts to reduce the environmental footprint of carbon tetrachloride are also gaining momentum. Research into green chemistry alternatives aims to develop less harmful substitutes for various applications. Additionally, improved recycling and recovery technologies are being explored to minimize waste and promote circular economy principles.

The global shift towards sustainability is driving increased scrutiny of carbon tetrachloride's lifecycle impacts. Regulatory bodies are implementing stricter guidelines for its production, use, and disposal. This trend is likely to continue, pushing industries to adopt more environmentally friendly practices and seek alternatives where possible.

As LCA methodologies evolve, a more holistic understanding of carbon tetrachloride's environmental impact is emerging. This comprehensive approach considers not only direct effects but also indirect consequences, such as impacts on biodiversity and human health. Such insights are crucial for developing effective mitigation strategies and informing policy decisions.

The production phase of carbon tetrachloride involves significant energy consumption and potential emissions. Chlorination of methane or other hydrocarbons requires high temperatures and pressures, resulting in substantial carbon dioxide emissions. Additionally, the process may release chlorine gas and other hazardous by-products, contributing to air and water pollution.

During its use phase, carbon tetrachloride's impact varies depending on the application. In industrial settings, proper handling and containment are essential to minimize environmental risks. However, accidental releases can lead to soil and groundwater contamination, posing long-term ecological threats.

The disposal stage presents significant challenges due to carbon tetrachloride's persistence in the environment. Incineration is a common disposal method, but it requires specialized facilities to prevent the formation of harmful by-products like dioxins. Alternatively, chemical treatment processes can break down the compound, though these methods may have their own environmental implications.

Future trends in carbon tetrachloride LCA focus on improving assessment methodologies and data collection. Advanced modeling techniques and real-time monitoring systems are being developed to provide more accurate and comprehensive lifecycle analyses. These innovations will enable better decision-making regarding the use and management of carbon tetrachloride.

Efforts to reduce the environmental footprint of carbon tetrachloride are also gaining momentum. Research into green chemistry alternatives aims to develop less harmful substitutes for various applications. Additionally, improved recycling and recovery technologies are being explored to minimize waste and promote circular economy principles.

The global shift towards sustainability is driving increased scrutiny of carbon tetrachloride's lifecycle impacts. Regulatory bodies are implementing stricter guidelines for its production, use, and disposal. This trend is likely to continue, pushing industries to adopt more environmentally friendly practices and seek alternatives where possible.

As LCA methodologies evolve, a more holistic understanding of carbon tetrachloride's environmental impact is emerging. This comprehensive approach considers not only direct effects but also indirect consequences, such as impacts on biodiversity and human health. Such insights are crucial for developing effective mitigation strategies and informing policy decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!