The Contribution of Multi-Turbo Systems to B58 Boost Management

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Multi-Turbo Evolution

The B58 engine's multi-turbo system has undergone significant evolution since its introduction, marking a pivotal advancement in BMW's boost management technology. Initially designed as a single twin-scroll turbocharger setup, the B58 engine has progressively incorporated more sophisticated multi-turbo configurations to enhance performance, efficiency, and responsiveness.

The first generation of the B58 engine, introduced in 2015, featured a single twin-scroll turbocharger. This configuration provided a balance between low-end torque and high-end power, addressing the turbo lag issues common in earlier single-turbo designs. The twin-scroll design allowed for better exhaust gas separation, improving throttle response and low-end torque.

As demand for higher performance and stricter emissions standards emerged, BMW engineers began exploring more advanced multi-turbo solutions. This led to the development of a twin-turbo system for the B58 engine, first implemented in high-performance variants. The twin-turbo setup utilized two smaller turbochargers, each responsible for a bank of cylinders, allowing for quicker spooling and improved low-end response.

The evolution continued with the introduction of electric assist technology in the turbocharging system. This hybrid turbo configuration incorporated an electric motor to provide instant boost at low engine speeds, effectively eliminating turbo lag. The electric assist also improved overall efficiency by reducing the engine's reliance on exhaust gases for initial boost pressure.

Further advancements saw the integration of variable geometry turbochargers (VGTs) into the B58 multi-turbo system. VGTs allowed for dynamic adjustment of the turbine's aspect ratio, optimizing boost pressure across a wider range of engine speeds and loads. This technology significantly improved the engine's flexibility and responsiveness, particularly in mid-range acceleration scenarios.

The latest iteration of the B58 multi-turbo system incorporates a combination of these technologies, resulting in a highly sophisticated boost management solution. This includes a primary twin-scroll turbocharger for base performance, supplemented by an electric compressor for instant low-end response, and a secondary turbocharger with variable geometry for high-end power delivery.

Throughout this evolution, BMW has consistently refined the control systems and software algorithms governing the multi-turbo setup. Advanced sensors and predictive modeling have been implemented to optimize boost pressure in real-time, considering factors such as ambient conditions, driving style, and vehicle load. This holistic approach to boost management has resulted in a highly adaptive and efficient multi-turbo system, cementing the B58 engine's position as a benchmark in modern forced induction technology.

The first generation of the B58 engine, introduced in 2015, featured a single twin-scroll turbocharger. This configuration provided a balance between low-end torque and high-end power, addressing the turbo lag issues common in earlier single-turbo designs. The twin-scroll design allowed for better exhaust gas separation, improving throttle response and low-end torque.

As demand for higher performance and stricter emissions standards emerged, BMW engineers began exploring more advanced multi-turbo solutions. This led to the development of a twin-turbo system for the B58 engine, first implemented in high-performance variants. The twin-turbo setup utilized two smaller turbochargers, each responsible for a bank of cylinders, allowing for quicker spooling and improved low-end response.

The evolution continued with the introduction of electric assist technology in the turbocharging system. This hybrid turbo configuration incorporated an electric motor to provide instant boost at low engine speeds, effectively eliminating turbo lag. The electric assist also improved overall efficiency by reducing the engine's reliance on exhaust gases for initial boost pressure.

Further advancements saw the integration of variable geometry turbochargers (VGTs) into the B58 multi-turbo system. VGTs allowed for dynamic adjustment of the turbine's aspect ratio, optimizing boost pressure across a wider range of engine speeds and loads. This technology significantly improved the engine's flexibility and responsiveness, particularly in mid-range acceleration scenarios.

The latest iteration of the B58 multi-turbo system incorporates a combination of these technologies, resulting in a highly sophisticated boost management solution. This includes a primary twin-scroll turbocharger for base performance, supplemented by an electric compressor for instant low-end response, and a secondary turbocharger with variable geometry for high-end power delivery.

Throughout this evolution, BMW has consistently refined the control systems and software algorithms governing the multi-turbo setup. Advanced sensors and predictive modeling have been implemented to optimize boost pressure in real-time, considering factors such as ambient conditions, driving style, and vehicle load. This holistic approach to boost management has resulted in a highly adaptive and efficient multi-turbo system, cementing the B58 engine's position as a benchmark in modern forced induction technology.

Market Demand Analysis

The market demand for multi-turbo systems in B58 boost management has been steadily increasing, driven by the automotive industry's push for improved engine performance, fuel efficiency, and emissions reduction. This technology has gained significant traction in the premium and high-performance vehicle segments, where consumers are willing to pay a premium for enhanced driving experiences.

The global automotive turbocharger market, which includes multi-turbo systems, has been experiencing robust growth. This growth is primarily attributed to the increasing adoption of turbocharged engines in passenger cars and commercial vehicles. The market is expected to continue its upward trajectory, with a particular focus on advanced turbocharging technologies like multi-turbo systems.

In the context of B58 boost management, multi-turbo systems have become increasingly popular due to their ability to address the inherent limitations of single turbocharger setups. These systems offer improved low-end torque, reduced turbo lag, and better overall engine responsiveness, which are highly valued attributes in modern performance vehicles.

The demand for multi-turbo systems is also being fueled by stringent emission regulations worldwide. As automakers strive to meet these standards while maintaining or improving performance, multi-turbo configurations provide an effective solution by enabling downsized engines to deliver power outputs comparable to larger naturally aspirated engines.

Furthermore, the growing trend of engine downsizing in the automotive industry has created a favorable market environment for multi-turbo systems. Manufacturers are increasingly replacing larger displacement engines with smaller, turbocharged units to achieve better fuel economy without compromising performance. This shift has opened up new opportunities for multi-turbo applications, particularly in the B58 engine platform.

The aftermarket segment also plays a significant role in driving demand for multi-turbo systems. Performance enthusiasts and tuning companies are constantly seeking ways to extract more power from their vehicles, and multi-turbo upgrades for B58 engines have become a popular option in this space.

However, it's important to note that the market demand for multi-turbo systems is not without challenges. The complexity and cost associated with these systems can be a limiting factor, especially in mass-market vehicle segments. Additionally, the ongoing transition towards electrification in the automotive industry may impact the long-term growth prospects of turbocharging technologies.

Despite these challenges, the current market trends indicate a continued strong demand for multi-turbo systems in B58 boost management, particularly in performance-oriented vehicles and premium segments. As technology advances and costs potentially decrease, there may be opportunities for wider adoption across various vehicle categories in the future.

The global automotive turbocharger market, which includes multi-turbo systems, has been experiencing robust growth. This growth is primarily attributed to the increasing adoption of turbocharged engines in passenger cars and commercial vehicles. The market is expected to continue its upward trajectory, with a particular focus on advanced turbocharging technologies like multi-turbo systems.

In the context of B58 boost management, multi-turbo systems have become increasingly popular due to their ability to address the inherent limitations of single turbocharger setups. These systems offer improved low-end torque, reduced turbo lag, and better overall engine responsiveness, which are highly valued attributes in modern performance vehicles.

The demand for multi-turbo systems is also being fueled by stringent emission regulations worldwide. As automakers strive to meet these standards while maintaining or improving performance, multi-turbo configurations provide an effective solution by enabling downsized engines to deliver power outputs comparable to larger naturally aspirated engines.

Furthermore, the growing trend of engine downsizing in the automotive industry has created a favorable market environment for multi-turbo systems. Manufacturers are increasingly replacing larger displacement engines with smaller, turbocharged units to achieve better fuel economy without compromising performance. This shift has opened up new opportunities for multi-turbo applications, particularly in the B58 engine platform.

The aftermarket segment also plays a significant role in driving demand for multi-turbo systems. Performance enthusiasts and tuning companies are constantly seeking ways to extract more power from their vehicles, and multi-turbo upgrades for B58 engines have become a popular option in this space.

However, it's important to note that the market demand for multi-turbo systems is not without challenges. The complexity and cost associated with these systems can be a limiting factor, especially in mass-market vehicle segments. Additionally, the ongoing transition towards electrification in the automotive industry may impact the long-term growth prospects of turbocharging technologies.

Despite these challenges, the current market trends indicate a continued strong demand for multi-turbo systems in B58 boost management, particularly in performance-oriented vehicles and premium segments. As technology advances and costs potentially decrease, there may be opportunities for wider adoption across various vehicle categories in the future.

Current Boost Tech Status

The current boost technology status for the B58 engine's multi-turbo system represents a significant advancement in automotive engineering. BMW's B58 engine, known for its robust performance and efficiency, utilizes a sophisticated boost management system that integrates multiple turbochargers to optimize power delivery and fuel economy.

At the heart of this system is a twin-scroll turbocharger, which effectively separates exhaust pulses from different cylinders to reduce turbo lag and improve low-end torque. This design allows for quicker spooling of the turbine and more responsive power delivery across the engine's rev range. The twin-scroll technology is complemented by BMW's Valvetronic variable valve lift system and Double-VANOS variable camshaft timing, which work in concert to fine-tune the engine's breathing and combustion efficiency.

The boost management system employs advanced electronic controls to regulate boost pressure precisely. It utilizes a combination of wastegate control and bypass valves to manage exhaust flow and boost pressure. This dynamic control allows the engine to adapt to various driving conditions, from casual cruising to high-performance demands, while maintaining optimal efficiency and power output.

One of the key innovations in the B58's boost management is the integration of an electric motor-generator unit, which can provide additional boost at low engine speeds. This system, often referred to as an e-booster or electric compressor, helps to eliminate turbo lag by providing instantaneous boost before the conventional turbocharger reaches its optimal operating range.

The multi-turbo system also incorporates intercooling technology to manage charge air temperatures effectively. By cooling the compressed air before it enters the combustion chamber, the system can maintain higher boost pressures without risking engine damage or pre-ignition. This allows for a more aggressive boost strategy, resulting in higher power output and improved thermal efficiency.

Furthermore, the B58's boost management system is integrated with the engine's overall thermal management strategy. This includes the use of a water-to-air intercooler, which provides more consistent charge air temperatures across various operating conditions compared to traditional air-to-air intercoolers. The system also features advanced coolant flow management to optimize engine temperatures and efficiency.

In terms of materials and construction, the B58 employs high-strength alloys and advanced manufacturing techniques to ensure durability under high boost pressures. The turbocharger housing and internals are designed to withstand the extreme temperatures and pressures associated with forced induction, while also minimizing weight to improve overall engine responsiveness.

At the heart of this system is a twin-scroll turbocharger, which effectively separates exhaust pulses from different cylinders to reduce turbo lag and improve low-end torque. This design allows for quicker spooling of the turbine and more responsive power delivery across the engine's rev range. The twin-scroll technology is complemented by BMW's Valvetronic variable valve lift system and Double-VANOS variable camshaft timing, which work in concert to fine-tune the engine's breathing and combustion efficiency.

The boost management system employs advanced electronic controls to regulate boost pressure precisely. It utilizes a combination of wastegate control and bypass valves to manage exhaust flow and boost pressure. This dynamic control allows the engine to adapt to various driving conditions, from casual cruising to high-performance demands, while maintaining optimal efficiency and power output.

One of the key innovations in the B58's boost management is the integration of an electric motor-generator unit, which can provide additional boost at low engine speeds. This system, often referred to as an e-booster or electric compressor, helps to eliminate turbo lag by providing instantaneous boost before the conventional turbocharger reaches its optimal operating range.

The multi-turbo system also incorporates intercooling technology to manage charge air temperatures effectively. By cooling the compressed air before it enters the combustion chamber, the system can maintain higher boost pressures without risking engine damage or pre-ignition. This allows for a more aggressive boost strategy, resulting in higher power output and improved thermal efficiency.

Furthermore, the B58's boost management system is integrated with the engine's overall thermal management strategy. This includes the use of a water-to-air intercooler, which provides more consistent charge air temperatures across various operating conditions compared to traditional air-to-air intercoolers. The system also features advanced coolant flow management to optimize engine temperatures and efficiency.

In terms of materials and construction, the B58 employs high-strength alloys and advanced manufacturing techniques to ensure durability under high boost pressures. The turbocharger housing and internals are designed to withstand the extreme temperatures and pressures associated with forced induction, while also minimizing weight to improve overall engine responsiveness.

B58 Boost Solutions

01 Turbocharger system optimization

Multi-turbo systems can be optimized for improved performance and efficiency. This involves careful design of turbocharger configurations, control strategies, and integration with engine systems. Advanced control algorithms and sensors are used to manage boost pressure, reduce lag, and enhance overall engine output across various operating conditions.- Turbocharger system optimization: Multi-turbo systems can be optimized for improved performance and efficiency. This involves careful design of turbocharger configurations, control strategies, and integration with engine systems. Advanced control algorithms and sensors are used to manage boost pressure, airflow, and fuel delivery across different operating conditions.

- Electric turbocharger integration: Incorporating electric turbochargers or electrically-assisted turbochargers in multi-turbo systems can enhance boost response and overall system efficiency. These systems can utilize electric motors to quickly spool up the turbine, reducing lag and improving low-end torque. Integration with hybrid powertrains can further optimize energy recovery and utilization.

- Variable geometry turbocharger applications: Variable geometry turbochargers (VGTs) can be employed in multi-turbo systems to provide adaptable boost characteristics across a wide range of engine speeds and loads. VGTs allow for adjustment of turbine geometry to optimize exhaust gas flow, improving overall system efficiency and responsiveness.

- Multi-stage turbocharging: Multi-stage turbocharging involves using two or more turbochargers in series or parallel configurations to enhance boost pressure and engine performance. This approach can involve combinations of differently sized turbochargers or variable geometry units to optimize airflow and pressure across various operating ranges.

- Turbo system control and diagnostics: Advanced control systems and diagnostic tools are crucial for managing complex multi-turbo setups. These systems monitor various parameters such as boost pressure, exhaust gas temperature, and engine load to optimize turbocharger performance and detect potential issues. Machine learning algorithms can be employed to continuously improve system efficiency and reliability.

02 Electric turbocharger integration

Incorporating electric turbochargers or electric assist devices in multi-turbo systems can significantly enhance boost response and overall system efficiency. These systems can provide instant boost at low engine speeds, reducing turbo lag and improving low-end torque. The integration of electric components also allows for more precise boost control and energy recovery.Expand Specific Solutions03 Variable geometry turbocharger applications

Variable geometry turbochargers (VGTs) can be effectively utilized in multi-turbo systems to provide adaptable boost characteristics across a wide range of engine operating conditions. By adjusting the turbine geometry, these systems can optimize exhaust flow and boost pressure, resulting in improved engine performance and fuel efficiency.Expand Specific Solutions04 Sequential turbocharging strategies

Sequential turbocharging involves the use of multiple turbochargers that are activated in a specific sequence based on engine speed and load. This approach can provide optimal boost pressure throughout the engine's operating range, combining the benefits of small and large turbochargers to minimize lag and maximize high-end power.Expand Specific Solutions05 Turbo system diagnostics and control

Advanced diagnostic and control systems are crucial for optimizing multi-turbo system performance. These systems employ sensors, actuators, and sophisticated algorithms to monitor and adjust turbocharger operation in real-time. They can detect faults, optimize boost pressure, and ensure efficient operation across various driving conditions.Expand Specific Solutions

Key Engine Manufacturers

The multi-turbo systems for B58 boost management represent a competitive landscape in the advanced automotive technology sector. This market is in a growth phase, driven by increasing demand for high-performance, fuel-efficient engines. The global automotive turbocharger market is projected to reach significant size in the coming years, indicating substantial opportunities. Technologically, companies like BorgWarner, Robert Bosch, and Garrett Motion are at the forefront, developing sophisticated multi-turbo solutions. Established automakers such as BMW, Mercedes-Benz, and Volkswagen are integrating these systems into their high-end models, while emerging players are focusing on innovative approaches to boost management, signaling a dynamic and evolving competitive environment.

BorgWarner, Inc.

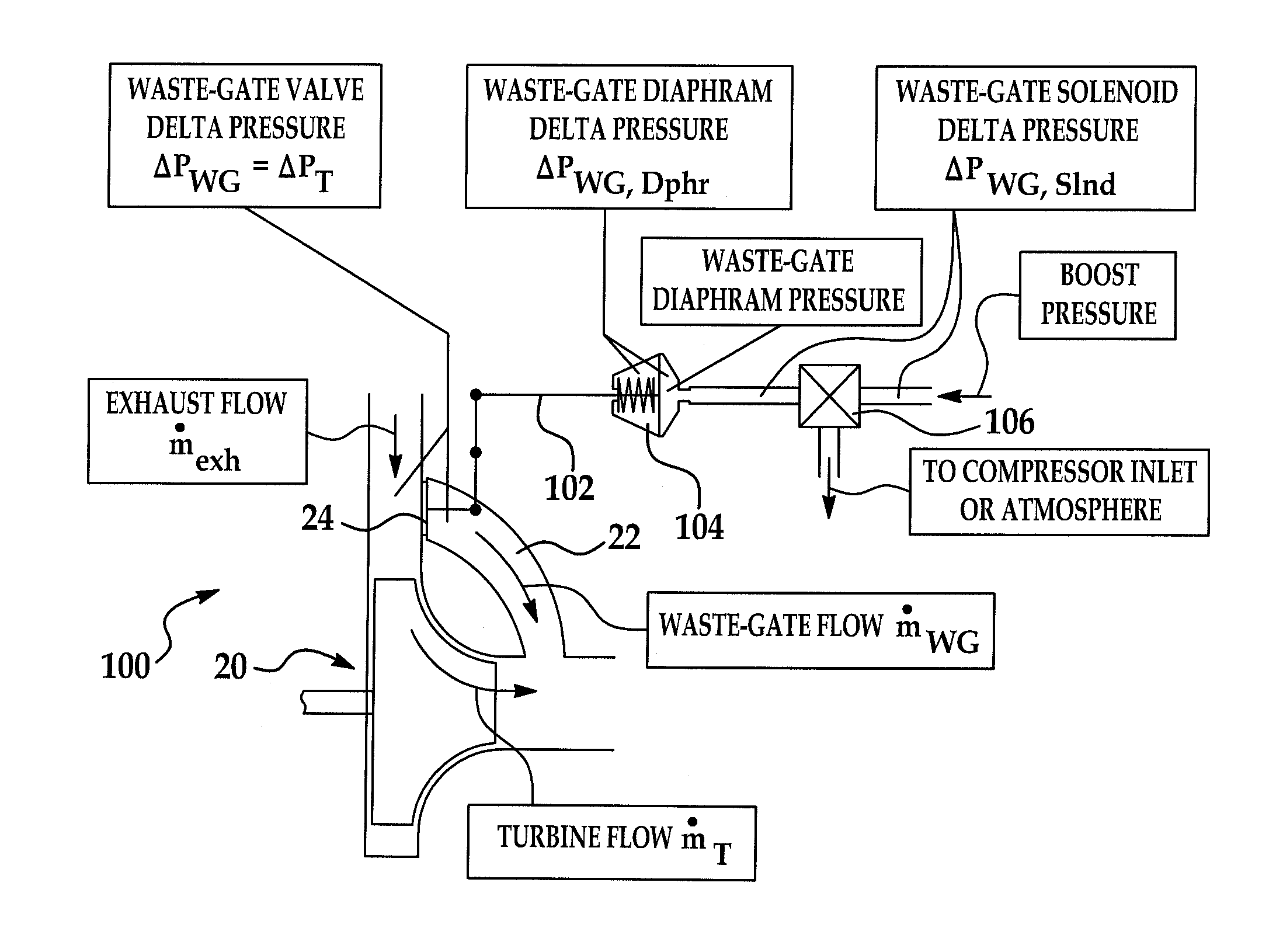

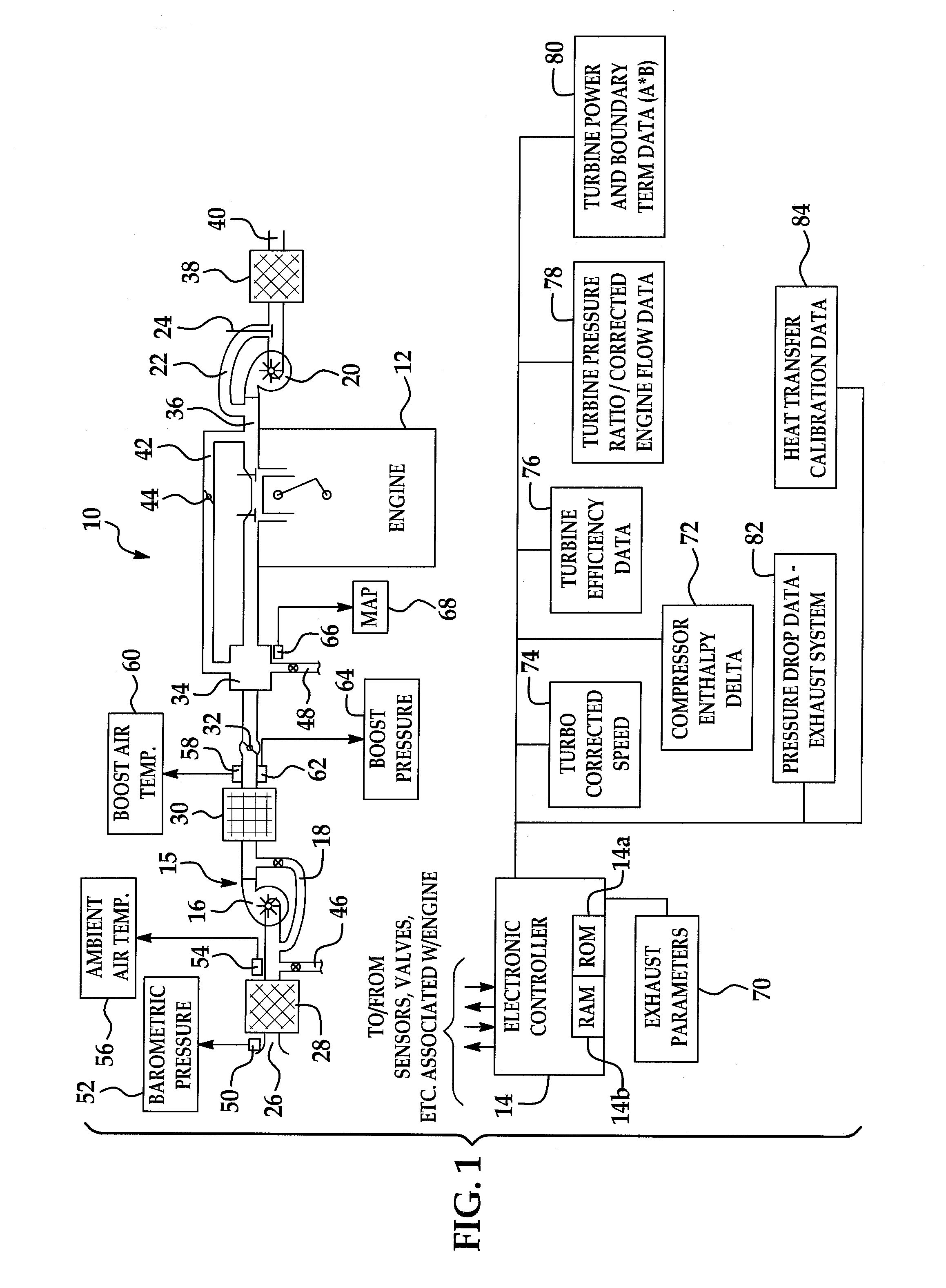

Technical Solution: BorgWarner has developed advanced multi-turbo systems that contribute significantly to boost management in engines like the B58. Their dual-volute turbocharger technology allows for optimized exhaust gas separation, improving turbine efficiency and reducing turbo lag[4]. The company's eBooster® electrically driven compressor works in conjunction with traditional turbochargers to provide instant boost at low engine speeds, enhancing overall engine responsiveness[5]. BorgWarner's multi-turbo systems also incorporate advanced wastegate and bypass valve designs, allowing for precise control of boost pressure across a wide range of operating conditions. Their integrated boost control actuators enable finer adjustments to boost pressure, contributing to improved fuel efficiency and emissions control[6].

Strengths: Cutting-edge turbocharger technology, expertise in electric boosting systems. Weaknesses: Reliance on OEM partnerships, potential cost implications for high-end solutions.

Robert Bosch GmbH

Technical Solution: Bosch's contribution to multi-turbo systems and boost management is evident in their advanced engine management systems and turbocharger technologies. Their Boost RecoverySystems (BRS) technology recovers energy from the exhaust gas, improving overall engine efficiency[7]. Bosch's engine control units (ECUs) are designed to manage complex multi-turbo setups, optimizing boost pressure in real-time based on various sensor inputs and driving conditions. The company has also developed innovative variable turbine geometry (VTG) turbochargers, which allow for precise boost control across a wide range of engine speeds[8]. Additionally, Bosch's expertise in fuel injection systems complements their boost management solutions, ensuring optimal air-fuel ratios under varying boost pressures.

Strengths: Comprehensive engine management solutions, integration of turbocharger and fuel injection technologies. Weaknesses: Potential over-reliance on traditional combustion engine technologies in a shifting market.

Core Multi-Turbo Patents

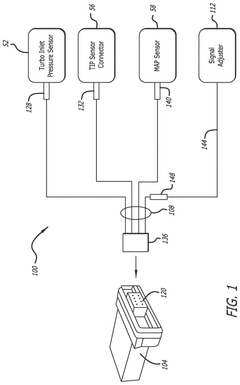

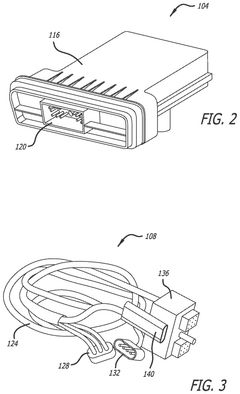

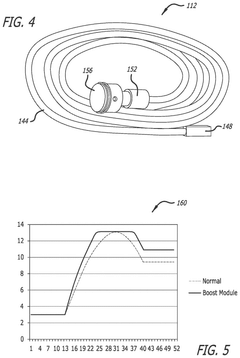

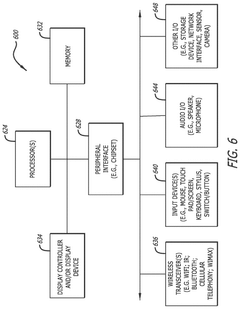

Turbo-boost control system

PatentActiveUS12129806B2

Innovation

- A turbo-boost control system that includes a control module, wiring harness, and signal adjuster to increase manifold pressure before releasing it through the waste gate, allowing for greater control over engine power output, utilizing a microprocessor-based control module and rheostat for manual adjustment.

System and method for model based boost control of turbo-charged engines

PatentActiveUS7788922B2

Innovation

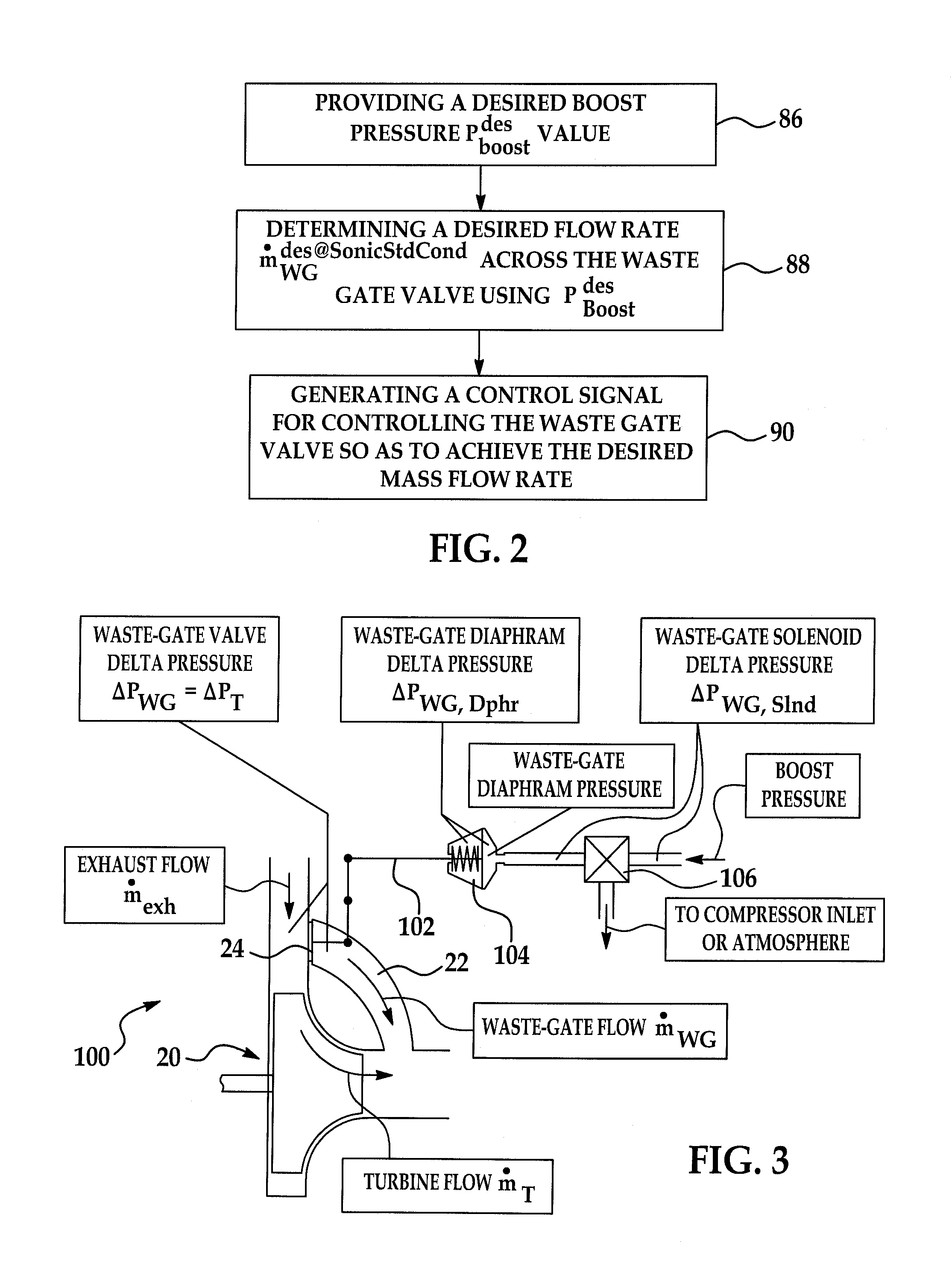

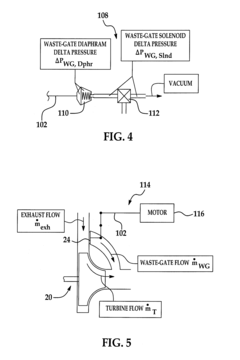

- A method for model-based boost control that determines a desired waste-gate mass flow rate and generates a control signal to achieve optimal boost pressure, allowing for flexible operation across various waste-gate mechanizations and improving engine efficiency by eliminating intake throttling.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and implementation of multi-turbo systems in automotive applications, particularly in the context of B58 boost management. These regulations aim to reduce harmful emissions and improve air quality, forcing manufacturers to innovate and adapt their engine technologies.

The European Union's Euro 6d standards and the United States' Tier 3 regulations have set ambitious targets for reducing nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These standards have directly influenced the design and operation of multi-turbo systems, as they must now not only deliver enhanced performance but also meet strict emissions criteria.

Multi-turbo systems, such as those employed in the B58 engine, have emerged as a viable solution to meet these regulatory challenges. By utilizing multiple smaller turbochargers instead of a single large unit, these systems can provide more precise boost control across a wider range of engine speeds. This improved control allows for better optimization of the air-fuel mixture, resulting in more efficient combustion and reduced emissions.

The contribution of multi-turbo systems to B58 boost management in the context of emissions regulations is multifaceted. Firstly, these systems enable faster spooling of the turbochargers, reducing lag and improving low-end torque. This characteristic allows for better engine responsiveness at lower RPMs, potentially reducing fuel consumption and emissions during urban driving cycles.

Furthermore, the ability to selectively engage or disengage individual turbochargers based on engine load and speed allows for more precise boost control. This flexibility enables engineers to fine-tune the engine's performance to meet specific emissions targets without sacrificing overall power output. For instance, during low-load conditions, a single turbocharger can be utilized to maintain efficiency, while under high-load scenarios, multiple turbochargers can be engaged to meet performance demands.

The integration of advanced electronic control systems in multi-turbo setups also plays a crucial role in emissions compliance. These systems continuously monitor and adjust boost pressure, fuel injection timing, and other parameters to ensure optimal combustion efficiency across various operating conditions. This real-time adaptation helps maintain emissions within regulatory limits while maximizing engine performance.

Moreover, multi-turbo systems contribute to the effectiveness of exhaust gas recirculation (EGR) systems, which are essential for NOx reduction. The improved boost control allows for more precise EGR rates, ensuring that the right amount of exhaust gas is recirculated to reduce combustion temperatures and NOx formation without compromising engine performance or increasing other emissions.

The European Union's Euro 6d standards and the United States' Tier 3 regulations have set ambitious targets for reducing nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These standards have directly influenced the design and operation of multi-turbo systems, as they must now not only deliver enhanced performance but also meet strict emissions criteria.

Multi-turbo systems, such as those employed in the B58 engine, have emerged as a viable solution to meet these regulatory challenges. By utilizing multiple smaller turbochargers instead of a single large unit, these systems can provide more precise boost control across a wider range of engine speeds. This improved control allows for better optimization of the air-fuel mixture, resulting in more efficient combustion and reduced emissions.

The contribution of multi-turbo systems to B58 boost management in the context of emissions regulations is multifaceted. Firstly, these systems enable faster spooling of the turbochargers, reducing lag and improving low-end torque. This characteristic allows for better engine responsiveness at lower RPMs, potentially reducing fuel consumption and emissions during urban driving cycles.

Furthermore, the ability to selectively engage or disengage individual turbochargers based on engine load and speed allows for more precise boost control. This flexibility enables engineers to fine-tune the engine's performance to meet specific emissions targets without sacrificing overall power output. For instance, during low-load conditions, a single turbocharger can be utilized to maintain efficiency, while under high-load scenarios, multiple turbochargers can be engaged to meet performance demands.

The integration of advanced electronic control systems in multi-turbo setups also plays a crucial role in emissions compliance. These systems continuously monitor and adjust boost pressure, fuel injection timing, and other parameters to ensure optimal combustion efficiency across various operating conditions. This real-time adaptation helps maintain emissions within regulatory limits while maximizing engine performance.

Moreover, multi-turbo systems contribute to the effectiveness of exhaust gas recirculation (EGR) systems, which are essential for NOx reduction. The improved boost control allows for more precise EGR rates, ensuring that the right amount of exhaust gas is recirculated to reduce combustion temperatures and NOx formation without compromising engine performance or increasing other emissions.

Turbo System Reliability

The reliability of turbo systems is a critical factor in the performance and longevity of modern engines, particularly in the context of multi-turbo systems like those employed in the BMW B58 engine. These systems are designed to enhance boost management, but their complexity also introduces potential reliability concerns that must be carefully addressed.

One of the primary challenges in maintaining turbo system reliability is managing the high temperatures and pressures inherent in forced induction. Multi-turbo setups, while offering improved boost response and overall performance, can exacerbate these issues due to the increased number of components and more complex airflow dynamics. Engineers must implement robust cooling solutions and utilize high-quality materials to withstand the extreme conditions.

Bearing wear is another significant concern in turbo system reliability. The high-speed rotation of turbocharger shafts puts considerable stress on bearings, which can lead to premature failure if not properly designed and maintained. In multi-turbo systems, this issue is multiplied, necessitating advanced bearing technologies and lubrication systems to ensure longevity.

Oil coking, a process where engine oil breaks down and forms carbon deposits, poses a particular threat to turbocharger reliability. The intense heat generated by turbochargers can accelerate this process, potentially leading to oil passages becoming clogged and turbo failure. Multi-turbo systems may be more susceptible to this issue due to the increased number of components exposed to high temperatures.

Intercooler efficiency plays a crucial role in turbo system reliability. Effective charge air cooling is essential to prevent detonation and maintain consistent performance. In multi-turbo setups, the design and placement of intercoolers become more complex, requiring careful engineering to ensure optimal cooling across all turbos.

The control systems governing multi-turbo setups must be highly sophisticated to maintain reliability. Precise management of boost pressure, wastegate actuation, and variable geometry turbo (VGT) mechanisms is essential to prevent over-boosting and ensure smooth power delivery. Any failures in these control systems can lead to catastrophic engine damage.

Vibration and harmonics present another challenge in multi-turbo systems. The interaction between multiple turbos can create complex vibration patterns that, if not properly dampened, can lead to premature component wear or failure. Engineers must conduct extensive vibration analysis and implement appropriate isolation measures to mitigate these risks.

In conclusion, while multi-turbo systems offer significant performance benefits, their reliability hinges on addressing a multitude of interconnected factors. Continuous advancements in materials science, control systems, and engineering practices are essential to ensure that these complex boost management systems can deliver sustained performance and longevity in demanding automotive applications.

One of the primary challenges in maintaining turbo system reliability is managing the high temperatures and pressures inherent in forced induction. Multi-turbo setups, while offering improved boost response and overall performance, can exacerbate these issues due to the increased number of components and more complex airflow dynamics. Engineers must implement robust cooling solutions and utilize high-quality materials to withstand the extreme conditions.

Bearing wear is another significant concern in turbo system reliability. The high-speed rotation of turbocharger shafts puts considerable stress on bearings, which can lead to premature failure if not properly designed and maintained. In multi-turbo systems, this issue is multiplied, necessitating advanced bearing technologies and lubrication systems to ensure longevity.

Oil coking, a process where engine oil breaks down and forms carbon deposits, poses a particular threat to turbocharger reliability. The intense heat generated by turbochargers can accelerate this process, potentially leading to oil passages becoming clogged and turbo failure. Multi-turbo systems may be more susceptible to this issue due to the increased number of components exposed to high temperatures.

Intercooler efficiency plays a crucial role in turbo system reliability. Effective charge air cooling is essential to prevent detonation and maintain consistent performance. In multi-turbo setups, the design and placement of intercoolers become more complex, requiring careful engineering to ensure optimal cooling across all turbos.

The control systems governing multi-turbo setups must be highly sophisticated to maintain reliability. Precise management of boost pressure, wastegate actuation, and variable geometry turbo (VGT) mechanisms is essential to prevent over-boosting and ensure smooth power delivery. Any failures in these control systems can lead to catastrophic engine damage.

Vibration and harmonics present another challenge in multi-turbo systems. The interaction between multiple turbos can create complex vibration patterns that, if not properly dampened, can lead to premature component wear or failure. Engineers must conduct extensive vibration analysis and implement appropriate isolation measures to mitigate these risks.

In conclusion, while multi-turbo systems offer significant performance benefits, their reliability hinges on addressing a multitude of interconnected factors. Continuous advancements in materials science, control systems, and engineering practices are essential to ensure that these complex boost management systems can deliver sustained performance and longevity in demanding automotive applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!