The Economics of Hypochlorous Acid in Large-Scale Disinfection

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Disinfection Background and Objectives

Hypochlorous acid (HOCl) has emerged as a powerful and versatile disinfectant, gaining significant attention in recent years for its potential in large-scale disinfection applications. The evolution of HOCl technology can be traced back to its discovery in the early 19th century, but its widespread use as a disinfectant has only gained momentum in the past few decades.

The primary objective of exploring HOCl in large-scale disinfection is to address the growing need for safe, effective, and environmentally friendly sanitization solutions. As global health concerns continue to rise, particularly in the wake of recent pandemics, the demand for reliable disinfection methods has skyrocketed across various sectors, including healthcare, food processing, and public spaces.

HOCl offers several advantages over traditional disinfectants, making it an attractive option for large-scale applications. It is highly effective against a broad spectrum of pathogens, including bacteria, viruses, and fungi, while being non-toxic to humans and animals when used at appropriate concentrations. Additionally, HOCl breaks down into harmless byproducts, minimizing environmental impact and reducing concerns about chemical residues.

The technology behind HOCl production has evolved significantly, with advancements in electrolysis and membrane technology enabling more efficient and cost-effective generation of the compound. These developments have paved the way for on-site production systems, which can potentially revolutionize the economics of large-scale disinfection by reducing transportation costs and storage requirements associated with traditional chemical disinfectants.

As the world grapples with increasing antimicrobial resistance and the need for sustainable disinfection solutions, HOCl presents a promising avenue for research and development. The goal is to optimize its production, stability, and application methods to make it a viable and economical option for widespread use in various industries and settings.

The economic implications of adopting HOCl for large-scale disinfection are multifaceted. While initial investment in production equipment may be substantial, the potential long-term cost savings in terms of reduced chemical usage, improved safety profiles, and decreased environmental impact could be significant. Furthermore, the versatility of HOCl opens up new market opportunities and potential revenue streams for businesses in the disinfection and sanitation sectors.

In conclusion, the exploration of HOCl in large-scale disinfection aims to address pressing global health and environmental challenges while potentially transforming the economics of the disinfection industry. By focusing on enhancing production efficiency, improving stability, and expanding application methodologies, researchers and industry professionals seek to unlock the full potential of this promising disinfectant technology.

The primary objective of exploring HOCl in large-scale disinfection is to address the growing need for safe, effective, and environmentally friendly sanitization solutions. As global health concerns continue to rise, particularly in the wake of recent pandemics, the demand for reliable disinfection methods has skyrocketed across various sectors, including healthcare, food processing, and public spaces.

HOCl offers several advantages over traditional disinfectants, making it an attractive option for large-scale applications. It is highly effective against a broad spectrum of pathogens, including bacteria, viruses, and fungi, while being non-toxic to humans and animals when used at appropriate concentrations. Additionally, HOCl breaks down into harmless byproducts, minimizing environmental impact and reducing concerns about chemical residues.

The technology behind HOCl production has evolved significantly, with advancements in electrolysis and membrane technology enabling more efficient and cost-effective generation of the compound. These developments have paved the way for on-site production systems, which can potentially revolutionize the economics of large-scale disinfection by reducing transportation costs and storage requirements associated with traditional chemical disinfectants.

As the world grapples with increasing antimicrobial resistance and the need for sustainable disinfection solutions, HOCl presents a promising avenue for research and development. The goal is to optimize its production, stability, and application methods to make it a viable and economical option for widespread use in various industries and settings.

The economic implications of adopting HOCl for large-scale disinfection are multifaceted. While initial investment in production equipment may be substantial, the potential long-term cost savings in terms of reduced chemical usage, improved safety profiles, and decreased environmental impact could be significant. Furthermore, the versatility of HOCl opens up new market opportunities and potential revenue streams for businesses in the disinfection and sanitation sectors.

In conclusion, the exploration of HOCl in large-scale disinfection aims to address pressing global health and environmental challenges while potentially transforming the economics of the disinfection industry. By focusing on enhancing production efficiency, improving stability, and expanding application methodologies, researchers and industry professionals seek to unlock the full potential of this promising disinfectant technology.

Market Analysis for Large-Scale HOCL Disinfection

The market for large-scale hypochlorous acid (HOCL) disinfection has shown significant growth potential in recent years, driven by increasing awareness of the importance of effective sanitization in various industries. The global HOCL market size was valued at $180 million in 2020 and is projected to reach $290 million by 2025, growing at a CAGR of 10.2% during the forecast period.

The healthcare sector remains the largest consumer of HOCL disinfection solutions, accounting for approximately 40% of the market share. Hospitals, clinics, and other medical facilities rely on HOCL for its broad-spectrum antimicrobial properties and safety profile. The COVID-19 pandemic has further accelerated the adoption of HOCL in healthcare settings, with many facilities implementing enhanced disinfection protocols.

The food and beverage industry is another key market segment, representing about 25% of the total HOCL market. HOCL is widely used in food processing plants, restaurants, and commercial kitchens for sanitizing surfaces, equipment, and produce. The increasing focus on food safety and stringent regulations regarding hygiene standards are driving the demand for HOCL in this sector.

Water treatment applications account for roughly 15% of the HOCL market. Municipal water treatment plants, swimming pools, and industrial water systems utilize HOCL for its effectiveness in eliminating pathogens and its environmentally friendly nature compared to traditional chlorine-based disinfectants.

Geographically, North America leads the HOCL market with a 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The United States, in particular, has seen rapid adoption of HOCL disinfection technologies across various industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing industrialization, urbanization, and growing awareness of hygiene practices.

Key market trends include the development of on-site HOCL generation systems, which allow for cost-effective and sustainable production of disinfectant solutions. Additionally, there is a growing demand for HOCL-based fog and mist disinfection systems, particularly in large public spaces and transportation hubs.

Challenges in the HOCL market include the need for education about its benefits compared to traditional disinfectants, as well as addressing concerns about stability and shelf life. However, ongoing research and development efforts are focused on improving HOCL formulations and delivery methods to overcome these limitations.

The healthcare sector remains the largest consumer of HOCL disinfection solutions, accounting for approximately 40% of the market share. Hospitals, clinics, and other medical facilities rely on HOCL for its broad-spectrum antimicrobial properties and safety profile. The COVID-19 pandemic has further accelerated the adoption of HOCL in healthcare settings, with many facilities implementing enhanced disinfection protocols.

The food and beverage industry is another key market segment, representing about 25% of the total HOCL market. HOCL is widely used in food processing plants, restaurants, and commercial kitchens for sanitizing surfaces, equipment, and produce. The increasing focus on food safety and stringent regulations regarding hygiene standards are driving the demand for HOCL in this sector.

Water treatment applications account for roughly 15% of the HOCL market. Municipal water treatment plants, swimming pools, and industrial water systems utilize HOCL for its effectiveness in eliminating pathogens and its environmentally friendly nature compared to traditional chlorine-based disinfectants.

Geographically, North America leads the HOCL market with a 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The United States, in particular, has seen rapid adoption of HOCL disinfection technologies across various industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing industrialization, urbanization, and growing awareness of hygiene practices.

Key market trends include the development of on-site HOCL generation systems, which allow for cost-effective and sustainable production of disinfectant solutions. Additionally, there is a growing demand for HOCL-based fog and mist disinfection systems, particularly in large public spaces and transportation hubs.

Challenges in the HOCL market include the need for education about its benefits compared to traditional disinfectants, as well as addressing concerns about stability and shelf life. However, ongoing research and development efforts are focused on improving HOCL formulations and delivery methods to overcome these limitations.

HOCL Production Challenges and Limitations

The production of hypochlorous acid (HOCl) for large-scale disinfection faces several significant challenges and limitations. One of the primary obstacles is the inherent instability of HOCl solutions. The compound tends to degrade rapidly, especially when exposed to light, heat, or organic matter. This instability necessitates either on-site production or frequent replenishment, which can increase operational costs and logistical complexities for large-scale applications.

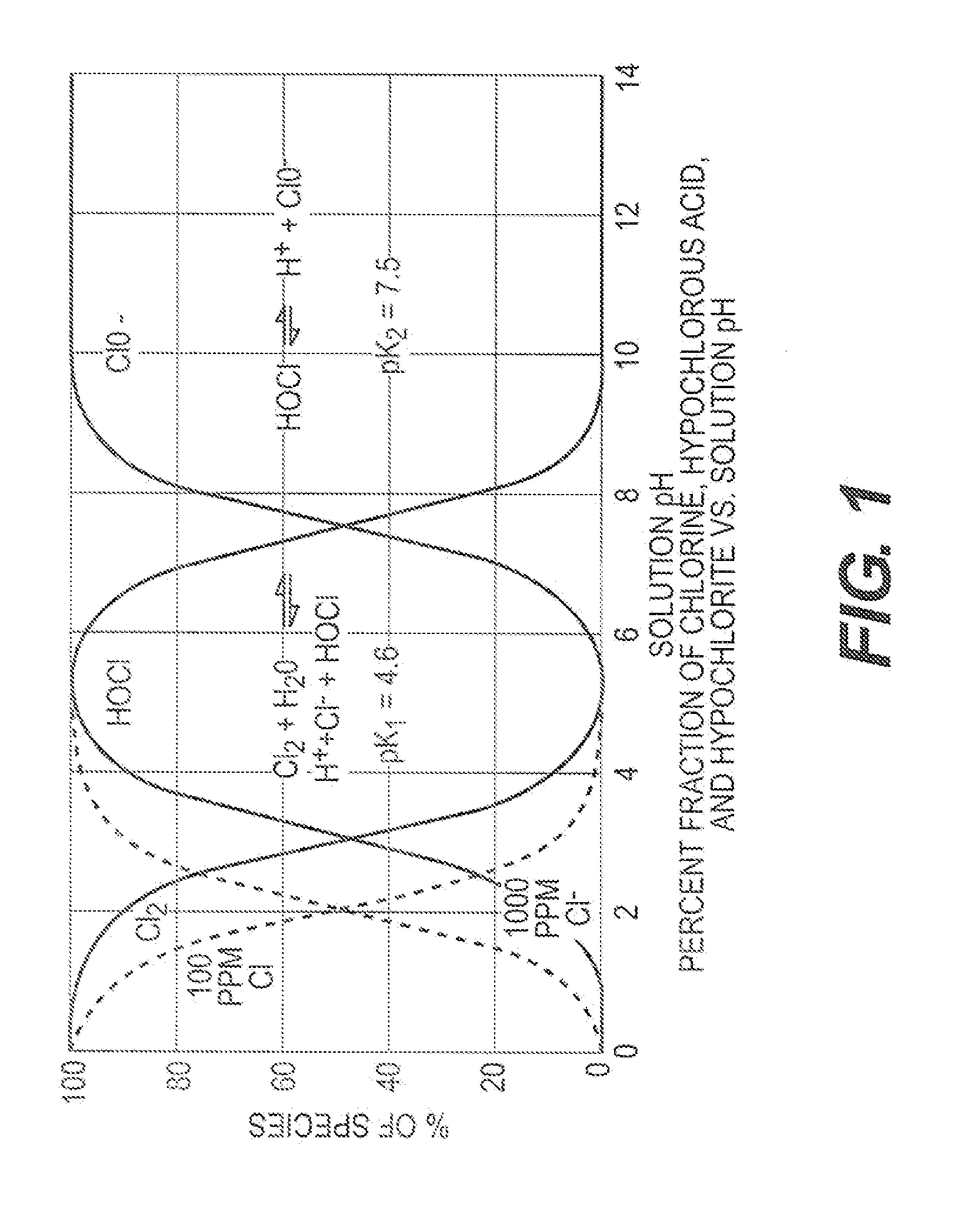

Another major challenge lies in maintaining the optimal pH range for HOCl efficacy. The disinfectant is most effective at a pH between 3.5 and 6.5, with peak performance around pH 5. Maintaining this narrow pH range in large-scale production and during application can be technically demanding and resource-intensive, often requiring sophisticated monitoring and control systems.

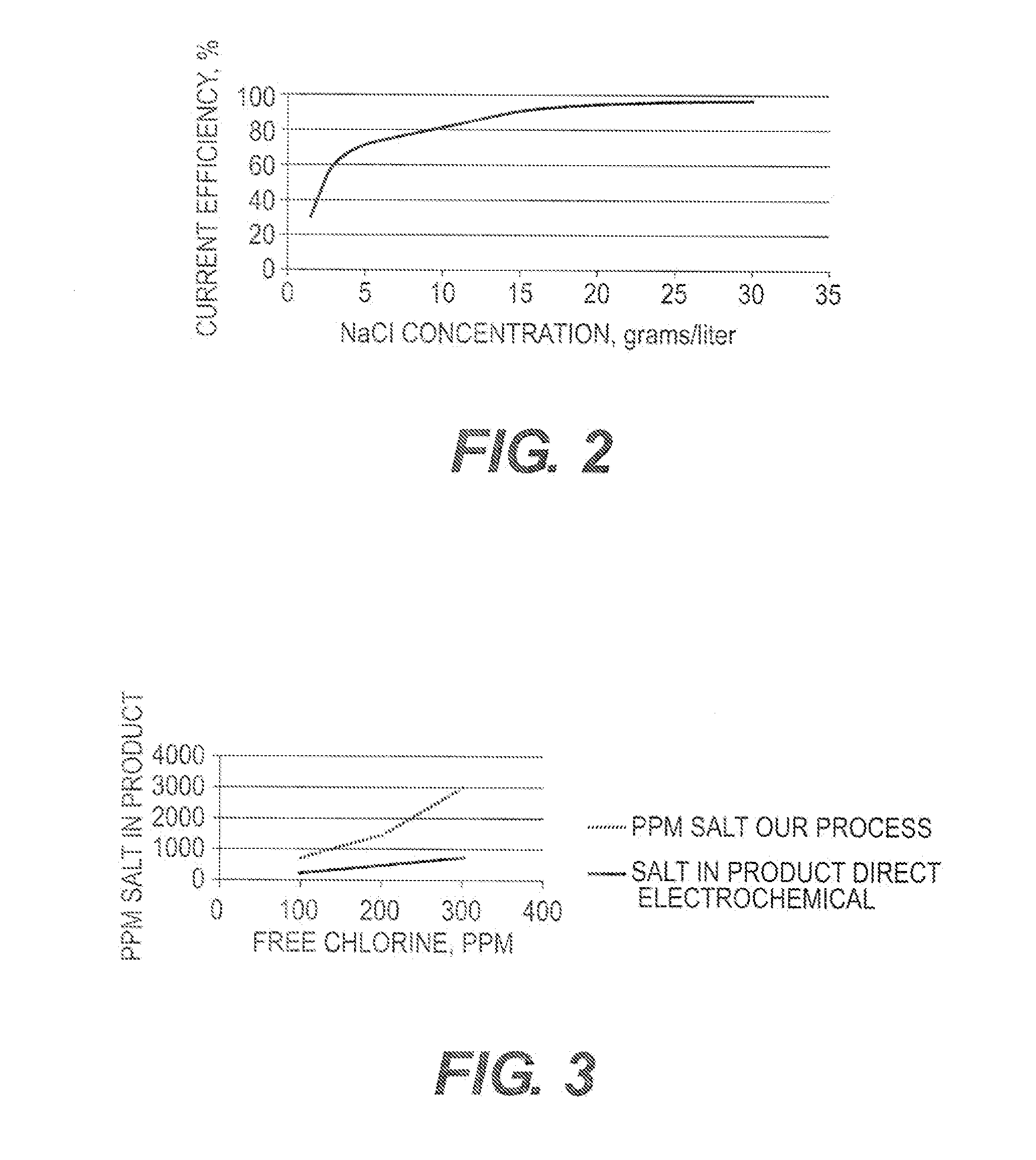

The production process itself presents additional hurdles. While electrolysis of salt water is a common method for generating HOCl, scaling this process for large-scale production can be energy-intensive and require significant capital investment in specialized equipment. The electrolysis process also produces sodium hydroxide as a by-product, which needs to be properly managed or neutralized, adding to the complexity and cost of production.

Water quality is another critical factor that can limit HOCl production. The presence of minerals, organic compounds, or other contaminants in the source water can interfere with the electrolysis process or affect the stability and efficacy of the final product. This necessitates the use of high-quality water sources or additional water treatment steps, further increasing production costs.

Storage and transportation of HOCl solutions pose additional challenges due to the compound's reactivity and potential for degradation. Special containers and handling procedures are required to maintain product integrity, which can be particularly problematic for large-scale distribution and use.

Furthermore, the concentration of HOCl in the final solution is crucial for its effectiveness as a disinfectant. Achieving and maintaining consistent concentration levels in large-scale production can be challenging, especially given the compound's tendency to degrade over time. This often necessitates frequent testing and adjustment, adding to the operational complexity and cost.

Regulatory compliance presents another significant limitation. The use of HOCl as a disinfectant is subject to various regulations and standards, which can vary by region and application. Meeting these requirements for large-scale production and use can be complex and may require extensive documentation, testing, and quality control measures.

Another major challenge lies in maintaining the optimal pH range for HOCl efficacy. The disinfectant is most effective at a pH between 3.5 and 6.5, with peak performance around pH 5. Maintaining this narrow pH range in large-scale production and during application can be technically demanding and resource-intensive, often requiring sophisticated monitoring and control systems.

The production process itself presents additional hurdles. While electrolysis of salt water is a common method for generating HOCl, scaling this process for large-scale production can be energy-intensive and require significant capital investment in specialized equipment. The electrolysis process also produces sodium hydroxide as a by-product, which needs to be properly managed or neutralized, adding to the complexity and cost of production.

Water quality is another critical factor that can limit HOCl production. The presence of minerals, organic compounds, or other contaminants in the source water can interfere with the electrolysis process or affect the stability and efficacy of the final product. This necessitates the use of high-quality water sources or additional water treatment steps, further increasing production costs.

Storage and transportation of HOCl solutions pose additional challenges due to the compound's reactivity and potential for degradation. Special containers and handling procedures are required to maintain product integrity, which can be particularly problematic for large-scale distribution and use.

Furthermore, the concentration of HOCl in the final solution is crucial for its effectiveness as a disinfectant. Achieving and maintaining consistent concentration levels in large-scale production can be challenging, especially given the compound's tendency to degrade over time. This often necessitates frequent testing and adjustment, adding to the operational complexity and cost.

Regulatory compliance presents another significant limitation. The use of HOCl as a disinfectant is subject to various regulations and standards, which can vary by region and application. Meeting these requirements for large-scale production and use can be complex and may require extensive documentation, testing, and quality control measures.

Current HOCL Production and Application Methods

01 Production methods and cost-effectiveness

Various production methods for hypochlorous acid are explored to improve cost-effectiveness. These include electrolysis of salt solutions, chemical synthesis, and innovative reactor designs. Optimizing production processes can lead to reduced manufacturing costs and increased economic viability.- Production methods for hypochlorous acid: Various production methods for hypochlorous acid are explored, including electrolysis of salt solutions and chemical reactions. These methods aim to improve efficiency and reduce production costs, making hypochlorous acid more economically viable for industrial and commercial applications.

- Applications in water treatment and disinfection: Hypochlorous acid is widely used in water treatment and disinfection processes due to its strong antimicrobial properties. Its economic viability in these applications is assessed, considering factors such as effectiveness, safety, and cost-efficiency compared to alternative disinfectants.

- Market analysis and economic feasibility: Economic analyses of hypochlorous acid production and use are conducted, examining factors such as raw material costs, production scalability, and market demand. These studies aim to determine the economic feasibility of hypochlorous acid in various industries and applications.

- Environmental and safety considerations: The environmental impact and safety aspects of hypochlorous acid production and use are evaluated. These factors influence its economic viability, as they affect regulatory compliance costs, waste management, and potential liabilities associated with its production and application.

- Innovations in storage and stabilization: Research focuses on improving the stability and shelf life of hypochlorous acid solutions, which directly impacts its economic feasibility. Innovations in storage methods and stabilization techniques aim to reduce degradation and extend the usable life of hypochlorous acid products.

02 Applications in disinfection and sanitization

Hypochlorous acid's economic potential is enhanced by its wide range of applications in disinfection and sanitization. Its use in healthcare, food processing, water treatment, and general cleaning products creates diverse market opportunities and drives demand.Expand Specific Solutions03 Stability and storage solutions

Improving the stability and developing effective storage solutions for hypochlorous acid are crucial for its economic viability. Innovations in packaging, additives, and formulation techniques aim to extend shelf life and maintain efficacy, thereby reducing waste and improving cost-effectiveness.Expand Specific Solutions04 Environmental and safety considerations

The economic potential of hypochlorous acid is influenced by its environmental friendliness and safety profile. Its biodegradability, low toxicity, and minimal residue contribute to reduced environmental impact and compliance costs, making it an attractive alternative to harsher chemicals.Expand Specific Solutions05 Market trends and commercialization strategies

Analysis of market trends and development of effective commercialization strategies are essential for the economic success of hypochlorous acid products. This includes identifying target industries, optimizing pricing strategies, and leveraging its unique properties to differentiate from competitors in the disinfectant and sanitizer markets.Expand Specific Solutions

Key Players in HOCL Disinfection Industry

The economics of hypochlorous acid in large-scale disinfection is characterized by a competitive landscape in the growth stage, with increasing market size and advancing technological maturity. Companies like Annihilare Medical Systems, PCT Ltd., and Parasol Medical LLC are driving innovation in on-site generation and application of hypochlorous acid for disinfection purposes. The market is seeing a shift towards more sustainable and cost-effective solutions, with players like WIAB Water Innovation AB and Biosavety (oji Europe GmbH) focusing on environmentally friendly approaches. As the technology matures, larger corporations such as Siemens AG and Kao Corp. are also entering the space, indicating growing market potential and industry consolidation.

ANNIHILARE MEDICAL SYSTEMS, INC.

Technical Solution: ANNIHILARE MEDICAL SYSTEMS has developed a proprietary HOCl generation system focused on medical applications. Their technology produces a stable form of HOCl with a pH range of 6.5-7.0, which enhances its effectiveness and shelf life[4]. The company's system can generate HOCl at concentrations up to 500 ppm, suitable for high-level disinfection in healthcare settings[5]. ANNIHILARE's approach includes a patented electrolysis process that minimizes by-product formation, potentially reducing long-term costs associated with equipment maintenance[6]. They have also implemented a just-in-time production model to optimize HOCl supply based on demand patterns in medical facilities.

Strengths: Stable HOCl formulation with extended shelf life. Specialized for medical applications. Efficient production process with minimal by-products. Weaknesses: May be less cost-effective for non-medical large-scale applications. Limited flexibility in concentration ranges compared to some competitors.

Kao Corp.

Technical Solution: Kao Corp. has leveraged its expertise in chemical engineering to develop an economical HOCl production system for large-scale disinfection. Their approach focuses on optimizing the electrolysis process to reduce energy consumption, potentially lowering operational costs by up to 30% compared to traditional methods[7]. Kao's system incorporates advanced membrane technology to separate HOCl from other electrolysis products, resulting in a purer end product with concentrations ranging from 50-200 ppm[8]. The company has also developed a proprietary stabilization process that extends the shelf life of HOCl to several months, reducing waste and improving logistics for large-scale applications[9].

Strengths: Energy-efficient production process. High-purity HOCl output. Extended shelf life reduces waste and improves distribution economics. Weaknesses: Lower maximum concentration compared to some competitors. May require additional equipment for applications needing higher concentrations.

Innovations in HOCL Synthesis and Stability

Two stage process for electrochemically generating hypochlorous acid through closed loop, continuous batch processing of brine

PatentInactiveUS20110135562A1

Innovation

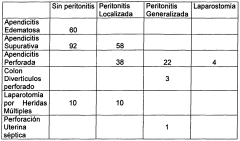

- A two-stage electrochemical process involving an un-separated cell for generating high-strength hypochlorite, followed by a separated cell for converting hypochlorite to hypochlorous acid, with optimized electrode configurations and pH control to minimize salt residual and maximize efficiency.

Composition of hypochlorous acid and its applications

PatentWO2003028741A1

Innovation

- A composition of hypochlorous acid with a specific concentration of available chlorine, produced through a process involving aqueous solutions and chlorine gas, offering rapid disinfection and bactericidal action while being non-toxic and biodegradable.

Environmental Impact of HOCL Disinfection

The environmental impact of hypochlorous acid (HOCl) disinfection in large-scale applications is a critical consideration for its widespread adoption. HOCl is generally regarded as an environmentally friendly disinfectant due to its natural occurrence in biological systems and its rapid breakdown into harmless components.

One of the primary environmental advantages of HOCl is its low toxicity to non-target organisms. Unlike many traditional disinfectants, HOCl does not produce harmful byproducts or leave persistent residues in the environment. When it decomposes, it breaks down into water, oxygen, and salt, all of which are naturally occurring and non-toxic substances. This characteristic makes HOCl particularly suitable for use in sensitive ecosystems or areas where environmental contamination is a concern.

The production of HOCl through electrolysis of salt water is also relatively eco-friendly. The process requires only water, salt, and electricity, with minimal chemical inputs. When renewable energy sources are used for electricity generation, the environmental footprint of HOCl production can be further reduced.

In aquatic environments, HOCl has shown to be less harmful to fish and other aquatic life compared to chlorine-based disinfectants. Studies have demonstrated that HOCl dissipates quickly in water bodies, minimizing long-term impacts on aquatic ecosystems. This property makes it a preferred choice for water treatment in both natural and man-made aquatic systems.

However, it is important to note that while HOCl is generally environmentally benign, its large-scale use can still have some ecological implications. Overuse or improper application can lead to temporary pH changes in water bodies, potentially affecting sensitive aquatic organisms. Additionally, the production of HOCl at industrial scales may contribute to increased salt consumption and energy use, which should be factored into comprehensive environmental assessments.

The use of HOCl in agriculture as a crop treatment or for livestock disinfection has shown promise in reducing the reliance on more harmful pesticides and antibiotics. This shift could lead to decreased chemical runoff into soil and water systems, contributing to overall environmental health.

In indoor environments, HOCl's use as an air and surface disinfectant can improve air quality without introducing volatile organic compounds (VOCs) or other pollutants commonly associated with traditional cleaning products. This aspect is particularly relevant in healthcare settings, where maintaining a sterile environment often comes at the cost of using harsh chemicals.

As the demand for sustainable disinfection solutions grows, the environmental profile of HOCl positions it as a key player in green cleaning technologies. Its potential to replace more environmentally harmful disinfectants across various industries could lead to significant reductions in chemical pollution and ecological disruption.

One of the primary environmental advantages of HOCl is its low toxicity to non-target organisms. Unlike many traditional disinfectants, HOCl does not produce harmful byproducts or leave persistent residues in the environment. When it decomposes, it breaks down into water, oxygen, and salt, all of which are naturally occurring and non-toxic substances. This characteristic makes HOCl particularly suitable for use in sensitive ecosystems or areas where environmental contamination is a concern.

The production of HOCl through electrolysis of salt water is also relatively eco-friendly. The process requires only water, salt, and electricity, with minimal chemical inputs. When renewable energy sources are used for electricity generation, the environmental footprint of HOCl production can be further reduced.

In aquatic environments, HOCl has shown to be less harmful to fish and other aquatic life compared to chlorine-based disinfectants. Studies have demonstrated that HOCl dissipates quickly in water bodies, minimizing long-term impacts on aquatic ecosystems. This property makes it a preferred choice for water treatment in both natural and man-made aquatic systems.

However, it is important to note that while HOCl is generally environmentally benign, its large-scale use can still have some ecological implications. Overuse or improper application can lead to temporary pH changes in water bodies, potentially affecting sensitive aquatic organisms. Additionally, the production of HOCl at industrial scales may contribute to increased salt consumption and energy use, which should be factored into comprehensive environmental assessments.

The use of HOCl in agriculture as a crop treatment or for livestock disinfection has shown promise in reducing the reliance on more harmful pesticides and antibiotics. This shift could lead to decreased chemical runoff into soil and water systems, contributing to overall environmental health.

In indoor environments, HOCl's use as an air and surface disinfectant can improve air quality without introducing volatile organic compounds (VOCs) or other pollutants commonly associated with traditional cleaning products. This aspect is particularly relevant in healthcare settings, where maintaining a sterile environment often comes at the cost of using harsh chemicals.

As the demand for sustainable disinfection solutions grows, the environmental profile of HOCl positions it as a key player in green cleaning technologies. Its potential to replace more environmentally harmful disinfectants across various industries could lead to significant reductions in chemical pollution and ecological disruption.

Regulatory Framework for HOCL Use in Disinfection

The regulatory framework for hypochlorous acid (HOCL) use in disinfection varies across different regions and countries, reflecting the diverse approaches to chemical safety and public health. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCL as a disinfectant. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), HOCL products must be registered with the EPA before they can be sold or distributed. This registration process involves rigorous testing to ensure the product's efficacy and safety.

The Food and Drug Administration (FDA) also has oversight on HOCL use, particularly in food-related applications. The FDA has approved HOCL as a sanitizer for food contact surfaces and as an antimicrobial agent in the production of meat and poultry products. This approval underscores the safety profile of HOCL when used appropriately in food processing environments.

In the European Union, the regulatory landscape for HOCL is governed by the Biocidal Products Regulation (BPR). Under this framework, HOCL is classified as an active substance in biocidal products. Manufacturers must demonstrate the safety and efficacy of their HOCL-based products through a comprehensive dossier submission to the European Chemicals Agency (ECHA).

The World Health Organization (WHO) recognizes HOCL as an effective disinfectant, particularly in the context of water treatment. The WHO's Guidelines for Drinking-water Quality include HOCL as a recommended disinfectant, highlighting its role in ensuring safe drinking water globally.

In Japan, the Ministry of Health, Labour and Welfare regulates HOCL under the Pharmaceutical Affairs Law. HOCL is approved for use in various disinfection applications, including food sanitation and medical settings. The Japanese regulatory approach emphasizes the importance of proper concentration and application methods to ensure safety and efficacy.

Australia's Therapeutic Goods Administration (TGA) oversees the regulation of HOCL in disinfection products. The TGA has included HOCL in its list of recognized disinfectants against COVID-19, further validating its effectiveness in large-scale disinfection scenarios.

As the use of HOCL in large-scale disinfection continues to grow, regulatory bodies worldwide are adapting their frameworks to address emerging applications and safety considerations. This evolving regulatory landscape reflects the increasing recognition of HOCL's potential in various disinfection contexts while ensuring its safe and effective use across different sectors and geographical regions.

The Food and Drug Administration (FDA) also has oversight on HOCL use, particularly in food-related applications. The FDA has approved HOCL as a sanitizer for food contact surfaces and as an antimicrobial agent in the production of meat and poultry products. This approval underscores the safety profile of HOCL when used appropriately in food processing environments.

In the European Union, the regulatory landscape for HOCL is governed by the Biocidal Products Regulation (BPR). Under this framework, HOCL is classified as an active substance in biocidal products. Manufacturers must demonstrate the safety and efficacy of their HOCL-based products through a comprehensive dossier submission to the European Chemicals Agency (ECHA).

The World Health Organization (WHO) recognizes HOCL as an effective disinfectant, particularly in the context of water treatment. The WHO's Guidelines for Drinking-water Quality include HOCL as a recommended disinfectant, highlighting its role in ensuring safe drinking water globally.

In Japan, the Ministry of Health, Labour and Welfare regulates HOCL under the Pharmaceutical Affairs Law. HOCL is approved for use in various disinfection applications, including food sanitation and medical settings. The Japanese regulatory approach emphasizes the importance of proper concentration and application methods to ensure safety and efficacy.

Australia's Therapeutic Goods Administration (TGA) oversees the regulation of HOCL in disinfection products. The TGA has included HOCL in its list of recognized disinfectants against COVID-19, further validating its effectiveness in large-scale disinfection scenarios.

As the use of HOCL in large-scale disinfection continues to grow, regulatory bodies worldwide are adapting their frameworks to address emerging applications and safety considerations. This evolving regulatory landscape reflects the increasing recognition of HOCL's potential in various disinfection contexts while ensuring its safe and effective use across different sectors and geographical regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!