The Effect of B58 Engine Calibration on Cold Start Emissions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Calibration Background and Objectives

The B58 engine, developed by BMW, represents a significant advancement in automotive engineering, particularly in the realm of emissions control during cold starts. This inline-six turbocharged engine has been a cornerstone of BMW's powertrain strategy since its introduction in 2015, finding its way into various models across the BMW and Toyota lineups. The primary objective of calibrating the B58 engine for cold start emissions is to minimize the environmental impact of vehicle operation during the critical warm-up phase.

Cold start emissions have long been a challenge for automotive engineers. When an engine is first started, especially in cold conditions, it operates less efficiently and produces higher levels of pollutants. This is due to several factors, including incomplete fuel combustion, reduced catalytic converter efficiency, and increased friction in cold engine components. The B58 engine calibration aims to address these issues through a combination of advanced technologies and precise control strategies.

The evolution of engine management systems has played a crucial role in enabling more sophisticated cold start calibration techniques. Modern electronic control units (ECUs) can process vast amounts of data in real-time, allowing for dynamic adjustments to fuel injection, ignition timing, and valve control. This level of precision is essential for optimizing the engine's performance during the cold start phase while simultaneously reducing emissions.

One of the key objectives of B58 engine calibration is to achieve rapid catalyst light-off. The catalytic converter, a critical component in the emissions control system, operates most effectively at high temperatures. During a cold start, the catalyst is below its optimal operating temperature, leading to increased emissions. Advanced calibration strategies focus on quickly heating the catalyst through methods such as retarded ignition timing and increased idle speed.

Another important goal is to optimize the air-fuel mixture during cold starts. The B58 engine employs direct fuel injection technology, which allows for precise control over fuel delivery. Calibration efforts aim to find the ideal balance between providing enough fuel for smooth engine operation and minimizing excess fuel that could lead to increased emissions.

The B58 engine calibration also targets the reduction of particulate matter emissions, which are particularly problematic during cold starts. This involves fine-tuning the fuel injection strategy to promote better atomization and more complete combustion, even at low temperatures. Additionally, calibration efforts focus on managing the engine's variable valve timing system to optimize exhaust gas recirculation and combustion chamber temperatures during the warm-up phase.

As emissions regulations continue to become more stringent worldwide, the importance of effective cold start calibration has never been greater. The B58 engine calibration work aims not only to meet current standards but also to anticipate future regulatory requirements. This forward-looking approach ensures that vehicles equipped with the B58 engine remain compliant and environmentally responsible throughout their lifecycle.

Cold start emissions have long been a challenge for automotive engineers. When an engine is first started, especially in cold conditions, it operates less efficiently and produces higher levels of pollutants. This is due to several factors, including incomplete fuel combustion, reduced catalytic converter efficiency, and increased friction in cold engine components. The B58 engine calibration aims to address these issues through a combination of advanced technologies and precise control strategies.

The evolution of engine management systems has played a crucial role in enabling more sophisticated cold start calibration techniques. Modern electronic control units (ECUs) can process vast amounts of data in real-time, allowing for dynamic adjustments to fuel injection, ignition timing, and valve control. This level of precision is essential for optimizing the engine's performance during the cold start phase while simultaneously reducing emissions.

One of the key objectives of B58 engine calibration is to achieve rapid catalyst light-off. The catalytic converter, a critical component in the emissions control system, operates most effectively at high temperatures. During a cold start, the catalyst is below its optimal operating temperature, leading to increased emissions. Advanced calibration strategies focus on quickly heating the catalyst through methods such as retarded ignition timing and increased idle speed.

Another important goal is to optimize the air-fuel mixture during cold starts. The B58 engine employs direct fuel injection technology, which allows for precise control over fuel delivery. Calibration efforts aim to find the ideal balance between providing enough fuel for smooth engine operation and minimizing excess fuel that could lead to increased emissions.

The B58 engine calibration also targets the reduction of particulate matter emissions, which are particularly problematic during cold starts. This involves fine-tuning the fuel injection strategy to promote better atomization and more complete combustion, even at low temperatures. Additionally, calibration efforts focus on managing the engine's variable valve timing system to optimize exhaust gas recirculation and combustion chamber temperatures during the warm-up phase.

As emissions regulations continue to become more stringent worldwide, the importance of effective cold start calibration has never been greater. The B58 engine calibration work aims not only to meet current standards but also to anticipate future regulatory requirements. This forward-looking approach ensures that vehicles equipped with the B58 engine remain compliant and environmentally responsible throughout their lifecycle.

Cold Start Emissions Market Analysis

The market for cold start emissions control technologies has been experiencing significant growth in recent years, driven by increasingly stringent environmental regulations and a growing awareness of the impact of vehicle emissions on air quality and public health. Cold start emissions, which occur during the initial phase of engine operation when the catalytic converter is not yet fully operational, contribute disproportionately to overall vehicle emissions.

The global market for cold start emissions control technologies is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily fueled by the implementation of more rigorous emissions standards in major automotive markets worldwide, including Europe, North America, and China. The European Union's Euro 7 standards, set to take effect in 2025, are expected to further tighten regulations on cold start emissions, creating additional demand for advanced control technologies.

In the context of B58 engine calibration, the market analysis reveals a growing interest in optimizing engine performance during cold starts to reduce emissions. Automotive manufacturers are increasingly focusing on developing and implementing sophisticated engine management systems that can rapidly bring catalytic converters to their optimal operating temperature, thereby minimizing cold start emissions.

The market for cold start emissions control technologies is segmented based on vehicle type, with passenger vehicles representing the largest share due to their higher production volumes and stricter regulatory focus. However, the commercial vehicle segment is expected to witness faster growth as regulations for heavy-duty vehicles become more stringent.

Geographically, Europe leads the market for cold start emissions control technologies, followed closely by North America and Asia-Pacific. The dominance of these regions is attributed to their advanced automotive industries, stringent emissions regulations, and high consumer awareness of environmental issues. Emerging markets in Asia and Latin America are also showing increased adoption of these technologies as they align their emissions standards with global norms.

Key market players in the cold start emissions control sector include major automotive suppliers such as Bosch, Delphi Technologies, and Denso Corporation. These companies are investing heavily in research and development to create innovative solutions for reducing cold start emissions, with a particular focus on advanced engine calibration techniques, rapid catalyst light-off technologies, and integrated exhaust aftertreatment systems.

The market analysis also highlights the growing importance of software-based solutions in addressing cold start emissions. Engine calibration software that can optimize fuel injection, ignition timing, and air-fuel mixture during cold starts is becoming increasingly sophisticated, offering automakers greater flexibility in meeting emissions targets while maintaining performance and fuel efficiency.

The global market for cold start emissions control technologies is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily fueled by the implementation of more rigorous emissions standards in major automotive markets worldwide, including Europe, North America, and China. The European Union's Euro 7 standards, set to take effect in 2025, are expected to further tighten regulations on cold start emissions, creating additional demand for advanced control technologies.

In the context of B58 engine calibration, the market analysis reveals a growing interest in optimizing engine performance during cold starts to reduce emissions. Automotive manufacturers are increasingly focusing on developing and implementing sophisticated engine management systems that can rapidly bring catalytic converters to their optimal operating temperature, thereby minimizing cold start emissions.

The market for cold start emissions control technologies is segmented based on vehicle type, with passenger vehicles representing the largest share due to their higher production volumes and stricter regulatory focus. However, the commercial vehicle segment is expected to witness faster growth as regulations for heavy-duty vehicles become more stringent.

Geographically, Europe leads the market for cold start emissions control technologies, followed closely by North America and Asia-Pacific. The dominance of these regions is attributed to their advanced automotive industries, stringent emissions regulations, and high consumer awareness of environmental issues. Emerging markets in Asia and Latin America are also showing increased adoption of these technologies as they align their emissions standards with global norms.

Key market players in the cold start emissions control sector include major automotive suppliers such as Bosch, Delphi Technologies, and Denso Corporation. These companies are investing heavily in research and development to create innovative solutions for reducing cold start emissions, with a particular focus on advanced engine calibration techniques, rapid catalyst light-off technologies, and integrated exhaust aftertreatment systems.

The market analysis also highlights the growing importance of software-based solutions in addressing cold start emissions. Engine calibration software that can optimize fuel injection, ignition timing, and air-fuel mixture during cold starts is becoming increasingly sophisticated, offering automakers greater flexibility in meeting emissions targets while maintaining performance and fuel efficiency.

B58 Engine Calibration Challenges

The B58 engine, a 3.0-liter inline-six turbocharged powerplant developed by BMW, presents several calibration challenges, particularly in relation to cold start emissions. These challenges stem from the complex interplay between engine design, fuel injection strategies, and emission control systems under cold operating conditions.

One of the primary calibration challenges is optimizing the air-fuel mixture during cold starts. The B58 engine must achieve a delicate balance between providing enough fuel for reliable ignition and minimizing excess fuel that can lead to increased emissions. This is particularly challenging in cold temperatures when fuel vaporization is less efficient, and engine oil viscosity is higher, leading to increased friction.

Another significant challenge lies in managing the catalytic converter's light-off time. During cold starts, the catalytic converter is not yet at its optimal operating temperature, resulting in reduced efficiency in converting harmful emissions. Calibration engineers must develop strategies to rapidly heat the catalyst while simultaneously minimizing emissions during this warm-up period.

The B58's direct injection system adds another layer of complexity to cold start calibration. While direct injection offers benefits in terms of fuel efficiency and power output, it can lead to increased particulate emissions during cold starts. Calibrating the injection timing, pressure, and spray pattern to minimize these emissions without compromising engine performance is a delicate task.

Turbocharger management during cold starts presents additional challenges. The B58's twin-scroll turbocharger must be carefully controlled to provide optimal boost without overwhelming the cold engine or exacerbating emissions. This requires precise calibration of wastegate control and boost pressure regulation.

Exhaust gas recirculation (EGR) systems, which are crucial for reducing NOx emissions, also require careful calibration during cold starts. The EGR system must be gradually introduced as the engine warms up to avoid negatively impacting combustion stability and increasing other emissions.

The B58's variable valve timing system adds another dimension to the calibration challenge. Optimizing valve timing during cold starts to improve fuel mixing and exhaust scavenging while maintaining stable combustion requires sophisticated control strategies.

Furthermore, the integration of start-stop technology in many B58-equipped vehicles introduces additional calibration complexities. Ensuring smooth and emissions-compliant restarts after engine shutdown, particularly in cold conditions, requires careful tuning of fuel injection, ignition timing, and air management systems.

Lastly, meeting increasingly stringent emissions regulations across various global markets adds an overarching challenge to B58 engine calibration. Engineers must develop calibration strategies that not only address cold start emissions but also ensure compliance with diverse regulatory requirements while maintaining consistent performance and drivability across different regions.

One of the primary calibration challenges is optimizing the air-fuel mixture during cold starts. The B58 engine must achieve a delicate balance between providing enough fuel for reliable ignition and minimizing excess fuel that can lead to increased emissions. This is particularly challenging in cold temperatures when fuel vaporization is less efficient, and engine oil viscosity is higher, leading to increased friction.

Another significant challenge lies in managing the catalytic converter's light-off time. During cold starts, the catalytic converter is not yet at its optimal operating temperature, resulting in reduced efficiency in converting harmful emissions. Calibration engineers must develop strategies to rapidly heat the catalyst while simultaneously minimizing emissions during this warm-up period.

The B58's direct injection system adds another layer of complexity to cold start calibration. While direct injection offers benefits in terms of fuel efficiency and power output, it can lead to increased particulate emissions during cold starts. Calibrating the injection timing, pressure, and spray pattern to minimize these emissions without compromising engine performance is a delicate task.

Turbocharger management during cold starts presents additional challenges. The B58's twin-scroll turbocharger must be carefully controlled to provide optimal boost without overwhelming the cold engine or exacerbating emissions. This requires precise calibration of wastegate control and boost pressure regulation.

Exhaust gas recirculation (EGR) systems, which are crucial for reducing NOx emissions, also require careful calibration during cold starts. The EGR system must be gradually introduced as the engine warms up to avoid negatively impacting combustion stability and increasing other emissions.

The B58's variable valve timing system adds another dimension to the calibration challenge. Optimizing valve timing during cold starts to improve fuel mixing and exhaust scavenging while maintaining stable combustion requires sophisticated control strategies.

Furthermore, the integration of start-stop technology in many B58-equipped vehicles introduces additional calibration complexities. Ensuring smooth and emissions-compliant restarts after engine shutdown, particularly in cold conditions, requires careful tuning of fuel injection, ignition timing, and air management systems.

Lastly, meeting increasingly stringent emissions regulations across various global markets adds an overarching challenge to B58 engine calibration. Engineers must develop calibration strategies that not only address cold start emissions but also ensure compliance with diverse regulatory requirements while maintaining consistent performance and drivability across different regions.

Current B58 Cold Start Calibration Strategies

01 Engine heating systems for cold start emissions reduction

Various heating systems are employed to quickly warm up the engine during cold starts, reducing emissions. These systems may include electric heaters, coolant preheating, or exhaust gas recirculation to rapidly increase engine temperature and improve combustion efficiency.- Engine heating systems for cold start emissions reduction: Various heating systems are employed to quickly warm up the engine during cold starts, reducing emissions. These systems may include electric heaters, heat exchangers, or thermal storage devices that pre-heat the engine or its components before startup.

- Exhaust gas recirculation (EGR) strategies for cold starts: Specialized EGR strategies are implemented during cold starts to manage exhaust gas temperature and composition. These may involve adjusting EGR rates, using dedicated cold-start EGR paths, or employing EGR coolers to optimize emissions reduction.

- Fuel injection control for cold start conditions: Advanced fuel injection control strategies are used during cold starts to optimize fuel atomization, mixture formation, and combustion. These may include multiple injection events, adjusted injection timing, or variable fuel pressure to reduce emissions.

- Catalytic converter pre-heating techniques: Methods for rapidly heating the catalytic converter during cold starts are employed to improve its efficiency in reducing emissions. These may include electric heating elements, secondary air injection, or retarded ignition timing to increase exhaust gas temperature.

- Engine control strategies for cold start emission reduction: Comprehensive engine control strategies are implemented to manage various parameters during cold starts. These may include adjusting valve timing, controlling idle speed, managing air-fuel ratios, and coordinating multiple systems to minimize emissions.

02 Fuel injection strategies for cold start conditions

Specialized fuel injection strategies are implemented during cold starts to optimize combustion and reduce emissions. These may include adjusting injection timing, duration, and pressure, as well as using multiple injection events to improve fuel atomization and mixture formation.Expand Specific Solutions03 Catalytic converter technologies for cold start emissions

Advanced catalytic converter designs and materials are used to improve cold start emissions performance. These may include close-coupled catalysts, electrically heated catalysts, or phase-change materials to quickly reach optimal operating temperatures and efficiently convert pollutants.Expand Specific Solutions04 Engine control strategies for cold start emissions management

Sophisticated engine control strategies are employed to manage various parameters during cold starts. These may include adjusting idle speed, valve timing, ignition timing, and air-fuel ratio to optimize combustion and minimize emissions until the engine reaches normal operating temperature.Expand Specific Solutions05 Exhaust aftertreatment systems for cold start emissions reduction

Specialized exhaust aftertreatment systems are designed to address cold start emissions. These may include adsorber technologies to trap pollutants during the cold start phase, which are then released and treated once the main catalytic system reaches its operating temperature.Expand Specific Solutions

Key Players in Engine Calibration Industry

The competition landscape for B58 engine calibration's effect on cold start emissions is in a mature phase, with established players like Ford, GM, and Volkswagen leading the market. The global automotive engine calibration market size is estimated to be over $5 billion, driven by stringent emission regulations. Technologically, companies like Bosch, Delphi, and Continental are at the forefront, offering advanced calibration solutions. OEMs such as BMW, Mercedes-Benz, and Volvo are actively investing in optimizing cold start emissions through sophisticated engine management systems and calibration techniques. Research institutions like Southwest Research Institute are also contributing to advancements in this field.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced engine calibration strategy for their B58 engine to reduce cold start emissions. Their approach involves a combination of precise fuel injection control, variable valve timing, and exhaust gas recirculation (EGR) optimization. The system uses predictive algorithms to adjust engine parameters based on ambient temperature and engine coolant temperature[1]. GM's calibration includes a rapid catalyst light-off strategy, which involves slightly retarding ignition timing and increasing idle speed during the first few seconds of operation to quickly heat the catalytic converter[3]. Additionally, they have implemented a cylinder deactivation feature that selectively shuts off cylinders during the warm-up phase to maintain optimal exhaust gas temperature[5].

Strengths: Comprehensive approach addressing multiple aspects of cold start emissions. Predictive algorithms allow for adaptive control. Weaknesses: May result in slightly increased fuel consumption during warm-up phase. Complexity of the system could lead to higher maintenance costs.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a sophisticated B58 engine calibration system focusing on minimizing cold start emissions. Their solution incorporates advanced lambda sensor technology for precise air-fuel ratio control during cold starts[2]. Bosch's system utilizes a dual-injection strategy, combining port and direct fuel injection to optimize fuel atomization and reduce particulate emissions[4]. The calibration also features an intelligent thermal management system that rapidly heats the engine and exhaust components to their optimal operating temperatures. Bosch has integrated their proprietary engine control unit (ECU) with machine learning capabilities to continuously refine the cold start strategy based on historical data and driving patterns[6].

Strengths: High precision air-fuel ratio control. Adaptive learning capabilities for ongoing optimization. Weaknesses: Reliance on proprietary ECU may limit compatibility with other systems. Higher initial cost due to advanced sensor technology.

Innovative Cold Start Emission Reduction Technologies

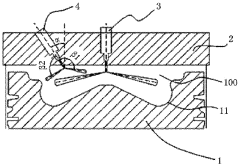

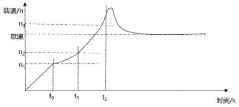

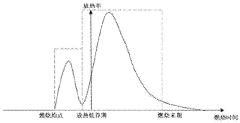

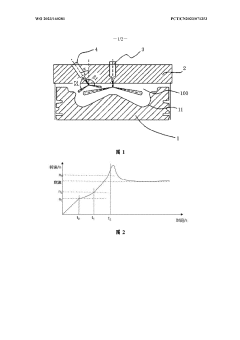

Double-main-injecting device of engine and calibration method for cold starting process of engine

PatentWO2023160281A1

Innovation

- Design an engine dual main injection device, including main injector and auxiliary injector. By adjusting the injection strategy of injection interval and injection volume, the dual injectors are used to perform the injection process respectively, combined with ECU control, to calibrate the injection process. parameters to improve combustion efficiency.

Method for reducing cold-start hydrocarbon emissions in a gasoline, natural gas, or propane fueled engine

PatentInactiveUS6244044B1

Innovation

- A partial oxidation catalyst is positioned between the engine's exhaust manifold and the catalytic converter, converting hydrocarbons into CO and H2 under rich engine conditions, facilitating faster light-off of the downstream catalyst and reducing tailpipe emissions by promoting a stoichiometric exhaust gas mixture.

Environmental Regulations Impact

Environmental regulations play a crucial role in shaping the automotive industry's approach to engine calibration, particularly concerning cold start emissions. The B58 engine, a popular inline-six powerplant used in various BMW models, is subject to stringent emission standards that have become increasingly rigorous over the years.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have set progressively stricter limits on vehicle emissions, with a particular focus on cold start conditions. These regulations have forced manufacturers to develop advanced calibration strategies to minimize pollutants during the critical warm-up phase of engine operation.

The European Union has also implemented stringent emission standards through the Euro 6 regulations, which place significant emphasis on reducing nitrogen oxides (NOx) and particulate matter emissions. These standards have directly influenced the calibration requirements for engines like the B58, necessitating sophisticated control strategies to meet compliance targets.

China, another major automotive market, has adopted emission standards similar to Euro 6, known as China 6. These regulations have further intensified the global push for cleaner cold start performance, affecting how manufacturers approach engine calibration for vehicles sold in the Chinese market.

The impact of these regulations on B58 engine calibration is multifaceted. Engineers must balance the need for rapid catalyst light-off with the requirement to minimize raw emissions during the cold start phase. This has led to the development of advanced thermal management systems, precise fuel injection strategies, and optimized ignition timing maps specifically tailored for cold start conditions.

Moreover, the introduction of Real Driving Emissions (RDE) tests in various jurisdictions has added another layer of complexity to engine calibration. These tests evaluate emissions performance under real-world driving conditions, including cold starts, forcing manufacturers to ensure that their calibration strategies are effective across a wide range of operating scenarios.

As environmental regulations continue to evolve, the automotive industry faces ongoing challenges in meeting emission targets while maintaining performance and fuel efficiency. This regulatory landscape has spurred innovation in engine management systems, sensor technologies, and aftertreatment solutions, all of which play a critical role in optimizing cold start emissions for engines like the B58.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have set progressively stricter limits on vehicle emissions, with a particular focus on cold start conditions. These regulations have forced manufacturers to develop advanced calibration strategies to minimize pollutants during the critical warm-up phase of engine operation.

The European Union has also implemented stringent emission standards through the Euro 6 regulations, which place significant emphasis on reducing nitrogen oxides (NOx) and particulate matter emissions. These standards have directly influenced the calibration requirements for engines like the B58, necessitating sophisticated control strategies to meet compliance targets.

China, another major automotive market, has adopted emission standards similar to Euro 6, known as China 6. These regulations have further intensified the global push for cleaner cold start performance, affecting how manufacturers approach engine calibration for vehicles sold in the Chinese market.

The impact of these regulations on B58 engine calibration is multifaceted. Engineers must balance the need for rapid catalyst light-off with the requirement to minimize raw emissions during the cold start phase. This has led to the development of advanced thermal management systems, precise fuel injection strategies, and optimized ignition timing maps specifically tailored for cold start conditions.

Moreover, the introduction of Real Driving Emissions (RDE) tests in various jurisdictions has added another layer of complexity to engine calibration. These tests evaluate emissions performance under real-world driving conditions, including cold starts, forcing manufacturers to ensure that their calibration strategies are effective across a wide range of operating scenarios.

As environmental regulations continue to evolve, the automotive industry faces ongoing challenges in meeting emission targets while maintaining performance and fuel efficiency. This regulatory landscape has spurred innovation in engine management systems, sensor technologies, and aftertreatment solutions, all of which play a critical role in optimizing cold start emissions for engines like the B58.

B58 Engine Calibration Tools and Software

The B58 engine calibration process relies heavily on sophisticated tools and software to optimize performance and emissions control. These calibration tools are essential for fine-tuning engine parameters, especially during cold start conditions when emissions are typically higher. The primary software used for B58 engine calibration is INCA (Integrated Calibration and Acquisition System), developed by ETAS. INCA provides a comprehensive platform for measurement, calibration, and diagnostics of electronic control units (ECUs).

INCA allows calibration engineers to access and modify ECU parameters in real-time, enabling precise adjustments to fuel injection timing, ignition timing, and valve timing. This level of control is crucial for managing cold start emissions, as it allows for rapid warm-up strategies to be implemented and refined. The software also integrates with various measurement devices, facilitating the collection and analysis of exhaust gas composition data during cold start events.

Complementing INCA, many calibration teams utilize MATLAB and Simulink for model-based development and calibration. These tools enable the creation of complex engine models that can simulate cold start conditions, allowing engineers to test and optimize calibration strategies before implementation on physical engines. The integration between MATLAB/Simulink and INCA streamlines the process of transferring optimized calibrations from simulation to real-world testing.

Another critical tool in the B58 calibration toolkit is ATI VISION, which provides advanced data acquisition and visualization capabilities. This software is particularly useful for analyzing the transient behavior of engine parameters during cold starts, offering high-resolution data capture and customizable display options. ATI VISION's ability to synchronize multiple data streams helps calibration engineers correlate emissions data with specific engine operating conditions.

For emissions-specific analysis, HORIBA's MEXA systems are widely used in conjunction with the aforementioned software tools. These systems provide real-time measurement of exhaust gas components, including hydrocarbons, carbon monoxide, and nitrogen oxides, which are particularly critical during cold start events. The integration of MEXA data with calibration software allows for immediate feedback on the effects of calibration changes on emissions output.

Additionally, OEM-specific diagnostic tools play a crucial role in B58 engine calibration. For BMW, the ISTA (Integrated Service Technical Application) system is used for comprehensive vehicle diagnostics and software updates. This tool ensures that calibration changes are compatible with the overall vehicle system and can be seamlessly integrated into production vehicles.

INCA allows calibration engineers to access and modify ECU parameters in real-time, enabling precise adjustments to fuel injection timing, ignition timing, and valve timing. This level of control is crucial for managing cold start emissions, as it allows for rapid warm-up strategies to be implemented and refined. The software also integrates with various measurement devices, facilitating the collection and analysis of exhaust gas composition data during cold start events.

Complementing INCA, many calibration teams utilize MATLAB and Simulink for model-based development and calibration. These tools enable the creation of complex engine models that can simulate cold start conditions, allowing engineers to test and optimize calibration strategies before implementation on physical engines. The integration between MATLAB/Simulink and INCA streamlines the process of transferring optimized calibrations from simulation to real-world testing.

Another critical tool in the B58 calibration toolkit is ATI VISION, which provides advanced data acquisition and visualization capabilities. This software is particularly useful for analyzing the transient behavior of engine parameters during cold starts, offering high-resolution data capture and customizable display options. ATI VISION's ability to synchronize multiple data streams helps calibration engineers correlate emissions data with specific engine operating conditions.

For emissions-specific analysis, HORIBA's MEXA systems are widely used in conjunction with the aforementioned software tools. These systems provide real-time measurement of exhaust gas components, including hydrocarbons, carbon monoxide, and nitrogen oxides, which are particularly critical during cold start events. The integration of MEXA data with calibration software allows for immediate feedback on the effects of calibration changes on emissions output.

Additionally, OEM-specific diagnostic tools play a crucial role in B58 engine calibration. For BMW, the ISTA (Integrated Service Technical Application) system is used for comprehensive vehicle diagnostics and software updates. This tool ensures that calibration changes are compatible with the overall vehicle system and can be seamlessly integrated into production vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!