The Future of Bio-Polymers: Pioneered by Cellulose Acetate

Cellulose Acetate Evolution

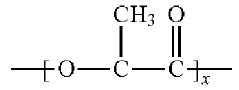

Cellulose acetate has undergone a remarkable evolution since its inception in the late 19th century. Initially developed as a photographic film base, this versatile bio-polymer has continuously adapted to meet changing industrial and consumer needs. The journey of cellulose acetate began with its discovery by Paul Schützenberger in 1865, but it wasn't until the early 1900s that it found commercial applications.

The first significant milestone in cellulose acetate's evolution came with the development of cellulose triacetate for photographic film by George Miles in 1904. This breakthrough led to the widespread use of cellulose acetate in the film industry, replacing the highly flammable cellulose nitrate. The 1920s saw further advancements with the introduction of cellulose acetate fibers, marketed as the first man-made fiber.

As the 20th century progressed, cellulose acetate found its way into various industries. In the 1950s and 1960s, it became a popular material for eyeglass frames, replacing the more brittle cellulose nitrate. This period also saw the rise of cellulose acetate in textile applications, particularly in the form of acetate rayon.

The late 20th century brought new challenges and opportunities for cellulose acetate. Environmental concerns led to increased interest in biodegradable materials, positioning cellulose acetate as a more sustainable alternative to petroleum-based plastics. This shift prompted research into improving its biodegradability and expanding its applications in eco-friendly products.

Recent decades have witnessed a renaissance in cellulose acetate research and development. Advances in nanotechnology have opened up new possibilities, such as cellulose acetate nanofibers for filtration and biomedical applications. The material's biocompatibility has also led to its exploration in drug delivery systems and tissue engineering scaffolds.

Today, cellulose acetate continues to evolve, with ongoing research focusing on enhancing its properties and expanding its applications. From its humble beginnings as a photographic film base to its current status as a versatile bio-polymer, cellulose acetate's journey exemplifies the dynamic nature of materials science and the potential for bio-based materials in a sustainable future.

Bio-Polymer Market Analysis

The bio-polymer market has been experiencing significant growth in recent years, driven by increasing environmental concerns and the shift towards sustainable materials. Cellulose acetate, as a pioneering bio-polymer, has played a crucial role in shaping this market landscape. The global bio-polymer market size was valued at approximately $10 billion in 2020 and is projected to reach $27 billion by 2025, growing at a CAGR of 22% during the forecast period.

Cellulose acetate, derived from natural cellulose, has found widespread applications across various industries, including textiles, packaging, and consumer goods. Its biodegradability and renewable sourcing have positioned it as a viable alternative to traditional petroleum-based plastics. The market for cellulose acetate is expected to grow steadily, with a projected CAGR of 5.2% from 2021 to 2026.

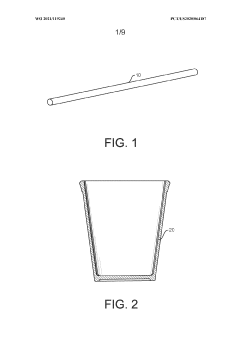

The packaging industry represents the largest end-use segment for bio-polymers, accounting for over 40% of the market share. This is primarily due to the increasing demand for sustainable packaging solutions in response to stringent environmental regulations and changing consumer preferences. Cellulose acetate's properties, such as transparency, durability, and biodegradability, make it particularly suitable for food packaging applications.

Geographically, Europe leads the bio-polymer market, followed by North America and Asia-Pacific. Europe's dominance can be attributed to its stringent environmental policies and high consumer awareness regarding sustainable products. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness.

Key market players in the bio-polymer industry include NatureWorks LLC, Novamont S.p.A., BASF SE, and Eastman Chemical Company. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of bio-polymers, including cellulose acetate derivatives.

Despite the positive growth outlook, the bio-polymer market faces challenges such as higher production costs compared to conventional plastics and limited awareness among consumers in developing regions. However, ongoing technological advancements and increasing government support for sustainable materials are expected to mitigate these challenges and drive market growth in the long term.

Bio-Polymer Tech Challenges

The development of bio-polymers, particularly cellulose acetate, faces several significant technical challenges that need to be addressed for widespread adoption and commercialization. One of the primary hurdles is the optimization of the production process to achieve cost-effectiveness and scalability. Current methods for extracting and processing cellulose from plant sources are often energy-intensive and require substantial refinement to be economically viable on an industrial scale.

Another major challenge lies in enhancing the material properties of bio-polymers to match or exceed those of traditional petroleum-based plastics. While cellulose acetate offers promising biodegradability and renewability, it still lags behind in terms of durability, heat resistance, and moisture sensitivity. Researchers are grappling with ways to improve these characteristics without compromising the environmental benefits that make bio-polymers attractive.

The variability in raw material quality presents an additional obstacle. Unlike synthetic polymers, which can be produced with consistent properties, bio-polymers derived from natural sources may exhibit fluctuations in their characteristics due to variations in plant growth conditions, harvesting methods, and processing techniques. Standardizing the quality of cellulose acetate and other bio-polymers across different batches and sources remains a significant technical challenge.

Furthermore, the development of efficient and eco-friendly plasticizers for cellulose acetate is crucial. Traditional plasticizers often leach out over time, affecting both the material's performance and its environmental impact. Finding bio-based alternatives that can maintain the flexibility and processability of cellulose acetate products while ensuring long-term stability is an ongoing area of research.

The end-of-life management of bio-polymers also presents technical hurdles. While biodegradability is a key advantage, controlling and predicting the degradation process in various environments is complex. Engineers are working on developing bio-polymers that can maintain their integrity during use but degrade efficiently under specific conditions, balancing functionality with environmental responsibility.

Compatibility with existing manufacturing infrastructure is another challenge. Many current production lines are optimized for petroleum-based plastics, and adapting these systems to work efficiently with bio-polymers like cellulose acetate requires significant engineering efforts and potential redesigns of processing equipment.

Lastly, the development of advanced functionalization techniques for cellulose acetate and other bio-polymers is essential for expanding their application range. This includes improving their barrier properties for packaging applications, enhancing their electrical properties for electronic uses, and developing biocompatible formulations for medical applications. Overcoming these technical challenges is crucial for realizing the full potential of bio-polymers in replacing traditional plastics across various industries.

Current Cellulose Acetate Apps

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications such as textiles, filters, and composite materials. The properties of these fibers can be tailored through modifications in the production process or post-treatment methods to suit specific end-use requirements.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology are discussed, including improvements in film formation, porosity control, and surface modifications. These developments enhance the performance of cellulose acetate in applications such as separation processes and packaging materials.

- Cellulose acetate blends and composites: Research on cellulose acetate blends and composites with other polymers or materials is presented. These combinations aim to enhance properties such as mechanical strength, thermal stability, or biodegradability for various industrial and consumer applications.

- Cellulose acetate modification and functionalization: Methods for modifying and functionalizing cellulose acetate are explored, including chemical treatments, grafting, and incorporation of additives. These modifications aim to impart new properties or enhance existing characteristics of cellulose acetate for specialized applications.

02 Cellulose acetate fiber and film applications

Cellulose acetate is widely used in the production of fibers and films for various industries. Innovations in this area focus on improving the properties of these materials, such as strength, flexibility, and durability, for use in textiles, packaging, and other applications.Expand Specific Solutions03 Cellulose acetate modifications and blends

Research into modifying cellulose acetate or blending it with other materials to enhance its properties is ongoing. This includes creating composites, adding plasticizers, or chemically modifying the cellulose acetate structure to improve its performance in specific applications.Expand Specific Solutions04 Cellulose acetate in filtration and separation technologies

Cellulose acetate membranes and filters are developed for various separation processes, including water purification, gas separation, and biomedical applications. Innovations focus on improving selectivity, permeability, and fouling resistance of these materials.Expand Specific Solutions05 Biodegradable and sustainable cellulose acetate products

Efforts are being made to develop more environmentally friendly cellulose acetate products, focusing on improving biodegradability and sustainability. This includes research into bio-based plasticizers, composting methods, and recycling techniques for cellulose acetate materials.Expand Specific Solutions

Bio-Polymer Industry Leaders

The bio-polymers market, particularly cellulose acetate, is in a growth phase with increasing market size due to rising environmental concerns and demand for sustainable materials. The technology maturity varies across applications, with established players like Eastman Chemical Co. and Shin-Etsu Chemical Co., Ltd. leading in traditional uses. Emerging companies such as CollPlant Ltd. and Zymergen, Inc. are pushing boundaries in novel applications. Research institutions like the Chinese Academy of Sciences and University of Alabama are driving innovation, while companies like BASF Corp. and Toray Industries, Inc. are leveraging their expertise to expand market presence. The competitive landscape is dynamic, with a mix of established chemical companies and innovative startups vying for market share in this evolving sector.

Shin-Etsu Chemical Co., Ltd.

Toray Industries, Inc.

Key Cellulose Acetate Patents

- A polymer composition combining cellulose acetate with bio-based polymers like polylactic acid, polyhydroxyalkanoate, and plasticizers to enhance melt processing and physical properties, such as elongation at break, flexural modulus, and tensile modulus, while maintaining biodegradability.

- A polymer composition combining cellulose acetate with bio-based polymers and plasticizers, such as polylactic acid and polyhydroxyalkanoate, to enhance melt processing and physical properties, achieving flexibility and stiffness similar to conventional plastics.

Environmental Impact Assessment

The environmental impact assessment of cellulose acetate as a pioneering bio-polymer reveals both promising benefits and potential challenges. As a biodegradable material derived from renewable resources, cellulose acetate offers significant advantages over traditional petroleum-based plastics in terms of sustainability and reduced carbon footprint.

One of the primary environmental benefits of cellulose acetate is its biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, cellulose acetate can decompose naturally within months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term accumulation of plastic waste in landfills and oceans, mitigating the detrimental effects on ecosystems and wildlife.

Furthermore, the production of cellulose acetate from plant-based sources contributes to a circular economy model. By utilizing renewable resources such as wood pulp or cotton linters, the manufacturing process reduces dependence on finite fossil fuel resources. This shift towards bio-based materials aligns with global efforts to decrease greenhouse gas emissions and combat climate change.

However, the environmental impact of cellulose acetate production must also be carefully considered. The acetylation process, which converts cellulose into cellulose acetate, involves the use of acetic anhydride and other chemicals. Proper management and treatment of these chemicals are crucial to prevent environmental contamination and ensure worker safety. Additionally, the energy consumption and water usage during production should be optimized to minimize the overall environmental footprint.

Another aspect to consider is the end-of-life management of cellulose acetate products. While biodegradable, improper disposal or insufficient composting infrastructure may hinder the material's ability to break down efficiently. Education and appropriate waste management systems are essential to maximize the environmental benefits of cellulose acetate.

The potential for cellulose acetate to replace conventional plastics in various applications presents an opportunity for significant environmental improvement. Its use in packaging, textiles, and consumer goods could lead to a substantial reduction in plastic pollution and associated ecological damage. However, a comprehensive life cycle assessment is necessary to fully understand the environmental trade-offs and ensure that the production and use of cellulose acetate result in a net positive impact on the environment.

As research and development in bio-polymers continue, further improvements in the production processes and material properties of cellulose acetate are expected. These advancements may lead to even greater environmental benefits, solidifying cellulose acetate's role as a sustainable alternative to traditional plastics and contributing to a more environmentally friendly future.

Regulatory Framework for Bio-Polymers

The regulatory framework for bio-polymers, including cellulose acetate, is evolving rapidly to keep pace with technological advancements and environmental concerns. Governments worldwide are implementing policies to promote the use of sustainable materials and reduce reliance on petroleum-based plastics. In the European Union, the Single-Use Plastics Directive has set ambitious targets for reducing plastic waste, creating opportunities for bio-polymer alternatives.

The United States Environmental Protection Agency (EPA) has established guidelines for the production and disposal of bio-based materials, including cellulose acetate. These regulations aim to ensure that bio-polymers meet safety standards and provide environmental benefits throughout their lifecycle. The FDA has also issued guidance on the use of bio-polymers in food packaging and medical applications, recognizing their potential as safer alternatives to traditional plastics.

In Asia, countries like Japan and South Korea have implemented comprehensive recycling programs that include provisions for bio-polymers. China's recent ban on certain types of plastic imports has accelerated the development of domestic bio-polymer industries, supported by government incentives and research funding.

International standards organizations, such as ISO and ASTM, have developed specific standards for bio-based plastics, including methods for determining bio-based content and biodegradability. These standards provide a framework for manufacturers to demonstrate compliance and build consumer trust in bio-polymer products.

The regulatory landscape also addresses end-of-life considerations for bio-polymers. Composting regulations are being updated to include provisions for bio-based materials, ensuring that these products can be properly processed in industrial composting facilities. Some jurisdictions have implemented extended producer responsibility (EPR) schemes, requiring manufacturers to take responsibility for the entire lifecycle of their bio-polymer products.

As the bio-polymer industry continues to grow, regulatory bodies are working to balance innovation with environmental protection. This includes addressing concerns about land use for bio-based feedstocks and ensuring that bio-polymers do not contribute to microplastic pollution. Future regulations are likely to focus on lifecycle assessments, carbon footprint reduction, and the promotion of circular economy principles in the bio-polymer value chain.