The Science Behind Thermite Reaction Control

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Reaction Fundamentals and Objectives

Thermite reactions have been a subject of scientific fascination and practical application for over a century. These highly exothermic redox reactions involve the reduction of a metal oxide by a more reactive metal, typically aluminum. The fundamental principle behind thermite reactions lies in the transfer of oxygen from the metal oxide to the more reactive metal, resulting in the production of a different metal oxide and the reduction of the original metal oxide.

The history of thermite reactions dates back to 1893 when German chemist Hans Goldschmidt discovered the process while attempting to produce pure metals. Since then, the understanding of thermite reactions has evolved significantly, leading to diverse applications in various industries. The primary objective of studying thermite reactions is to harness their intense heat-generating capabilities while maintaining control over the reaction process.

Thermite reactions are characterized by their ability to generate temperatures exceeding 2500°C, making them valuable in applications such as welding, metal purification, and incendiary devices. The reaction is typically initiated by an ignition source and proceeds rapidly due to the high enthalpy change associated with the transfer of oxygen between the reactants. This self-sustaining nature of thermite reactions presents both opportunities and challenges in terms of control and application.

The science behind thermite reaction control focuses on several key aspects. First, the composition of the thermite mixture plays a crucial role in determining the reaction rate and temperature. By adjusting the ratio of metal oxide to reducing agent, researchers can fine-tune the reaction characteristics to suit specific applications. Additionally, the particle size of the reactants significantly influences the reaction kinetics, with smaller particles generally leading to faster and more complete reactions.

Another important factor in thermite reaction control is the method of initiation. Traditional ignition techniques include the use of magnesium ribbon or chemical igniters. However, advanced methods such as laser ignition and electrical resistance heating have been developed to provide more precise control over the reaction initiation point and timing.

The ongoing research in thermite reaction control aims to address several challenges and objectives. These include improving reaction efficiency, enhancing safety measures, and developing novel applications. Scientists are exploring ways to modulate the reaction rate and temperature profile, which is crucial for applications requiring controlled heat release. Furthermore, efforts are being made to develop environmentally friendly thermite compositions that minimize harmful byproducts and maximize energy utilization.

As we delve deeper into the science of thermite reaction control, it becomes evident that this field holds significant potential for technological advancements across various sectors. The continuous evolution of our understanding and control over these powerful reactions promises to unlock new possibilities in materials processing, energy storage, and advanced manufacturing techniques.

The history of thermite reactions dates back to 1893 when German chemist Hans Goldschmidt discovered the process while attempting to produce pure metals. Since then, the understanding of thermite reactions has evolved significantly, leading to diverse applications in various industries. The primary objective of studying thermite reactions is to harness their intense heat-generating capabilities while maintaining control over the reaction process.

Thermite reactions are characterized by their ability to generate temperatures exceeding 2500°C, making them valuable in applications such as welding, metal purification, and incendiary devices. The reaction is typically initiated by an ignition source and proceeds rapidly due to the high enthalpy change associated with the transfer of oxygen between the reactants. This self-sustaining nature of thermite reactions presents both opportunities and challenges in terms of control and application.

The science behind thermite reaction control focuses on several key aspects. First, the composition of the thermite mixture plays a crucial role in determining the reaction rate and temperature. By adjusting the ratio of metal oxide to reducing agent, researchers can fine-tune the reaction characteristics to suit specific applications. Additionally, the particle size of the reactants significantly influences the reaction kinetics, with smaller particles generally leading to faster and more complete reactions.

Another important factor in thermite reaction control is the method of initiation. Traditional ignition techniques include the use of magnesium ribbon or chemical igniters. However, advanced methods such as laser ignition and electrical resistance heating have been developed to provide more precise control over the reaction initiation point and timing.

The ongoing research in thermite reaction control aims to address several challenges and objectives. These include improving reaction efficiency, enhancing safety measures, and developing novel applications. Scientists are exploring ways to modulate the reaction rate and temperature profile, which is crucial for applications requiring controlled heat release. Furthermore, efforts are being made to develop environmentally friendly thermite compositions that minimize harmful byproducts and maximize energy utilization.

As we delve deeper into the science of thermite reaction control, it becomes evident that this field holds significant potential for technological advancements across various sectors. The continuous evolution of our understanding and control over these powerful reactions promises to unlock new possibilities in materials processing, energy storage, and advanced manufacturing techniques.

Industrial Applications and Market Demand

The thermite reaction, known for its high-temperature exothermic properties, has found significant applications across various industrial sectors. The market demand for controlled thermite reactions has been steadily growing, driven by the need for efficient and cost-effective solutions in metallurgy, welding, and material synthesis.

In the metallurgical industry, thermite reactions play a crucial role in the production of high-purity metals and alloys. The ability to control these reactions has led to improved product quality and reduced production costs. As a result, there is a growing demand for advanced thermite reaction control systems in steel manufacturing, aluminum production, and other metal processing industries.

The welding sector has also witnessed an increased adoption of thermite-based techniques, particularly in rail track welding and pipeline joining. The market for thermite welding equipment and materials has expanded, driven by infrastructure development projects worldwide. The need for reliable, long-lasting welds in challenging environments has further boosted the demand for controlled thermite reactions in this sector.

In the field of material synthesis, thermite reactions have gained traction for producing advanced ceramics, composites, and nanomaterials. The ability to precisely control the reaction parameters has opened up new possibilities for creating materials with tailored properties. This has led to a growing market for thermite-based material synthesis systems in research institutions and high-tech manufacturing industries.

The defense and aerospace sectors have shown increasing interest in controlled thermite reactions for applications such as propellants, incendiary devices, and thermal batteries. The demand for reliable, high-energy density solutions in these industries has driven research and development efforts in thermite reaction control technologies.

Environmental remediation and waste management industries have also begun exploring the potential of controlled thermite reactions for treating hazardous materials and contaminated soils. This emerging application area represents a promising market opportunity, as regulations on environmental protection become more stringent globally.

The global market for thermite reaction control technologies is expected to grow significantly in the coming years. Factors such as increasing industrialization in developing countries, ongoing infrastructure development projects, and the push for advanced materials in various sectors are driving this growth. Additionally, the focus on energy efficiency and sustainable manufacturing processes has created new opportunities for innovative thermite reaction control solutions.

In the metallurgical industry, thermite reactions play a crucial role in the production of high-purity metals and alloys. The ability to control these reactions has led to improved product quality and reduced production costs. As a result, there is a growing demand for advanced thermite reaction control systems in steel manufacturing, aluminum production, and other metal processing industries.

The welding sector has also witnessed an increased adoption of thermite-based techniques, particularly in rail track welding and pipeline joining. The market for thermite welding equipment and materials has expanded, driven by infrastructure development projects worldwide. The need for reliable, long-lasting welds in challenging environments has further boosted the demand for controlled thermite reactions in this sector.

In the field of material synthesis, thermite reactions have gained traction for producing advanced ceramics, composites, and nanomaterials. The ability to precisely control the reaction parameters has opened up new possibilities for creating materials with tailored properties. This has led to a growing market for thermite-based material synthesis systems in research institutions and high-tech manufacturing industries.

The defense and aerospace sectors have shown increasing interest in controlled thermite reactions for applications such as propellants, incendiary devices, and thermal batteries. The demand for reliable, high-energy density solutions in these industries has driven research and development efforts in thermite reaction control technologies.

Environmental remediation and waste management industries have also begun exploring the potential of controlled thermite reactions for treating hazardous materials and contaminated soils. This emerging application area represents a promising market opportunity, as regulations on environmental protection become more stringent globally.

The global market for thermite reaction control technologies is expected to grow significantly in the coming years. Factors such as increasing industrialization in developing countries, ongoing infrastructure development projects, and the push for advanced materials in various sectors are driving this growth. Additionally, the focus on energy efficiency and sustainable manufacturing processes has created new opportunities for innovative thermite reaction control solutions.

Current Challenges in Thermite Reaction Control

Despite significant advancements in thermite reaction control, several challenges persist in this field. One of the primary issues is the difficulty in precisely controlling the reaction rate and temperature. Thermite reactions are known for their rapid and exothermic nature, making it challenging to modulate the reaction speed and heat output for specific applications.

Another major challenge lies in the containment and directionality of the reaction. The intense heat and molten products generated during thermite reactions can be difficult to confine and direct, potentially leading to safety concerns and limitations in practical applications. This issue is particularly critical in scenarios where controlled, localized heating is required.

The initiation and termination of thermite reactions also present significant hurdles. While ignition can be achieved through various methods, ensuring consistent and reliable initiation across different scales and environmental conditions remains a challenge. Similarly, developing effective methods to rapidly quench or terminate the reaction when desired is an area that requires further research and innovation.

Scalability is another key challenge in thermite reaction control. Techniques that work effectively at laboratory scales may not translate well to larger industrial applications. This scaling issue affects not only the reaction control itself but also the associated safety measures and equipment design.

The environmental impact and safety concerns associated with thermite reactions pose additional challenges. The production of high-temperature metal oxides and potential for uncontrolled reactions raise questions about the long-term sustainability and safety of these processes in various applications.

Furthermore, the development of novel thermite compositions that offer enhanced controllability while maintaining desired performance characteristics remains an ongoing challenge. This includes research into new fuel-oxidizer combinations, particle size optimization, and the incorporation of additives to modify reaction properties.

Lastly, the integration of advanced sensing and control technologies with thermite reactions presents both opportunities and challenges. While these technologies offer the potential for more precise reaction control, their implementation in the high-temperature, high-energy environment of thermite reactions requires innovative approaches and materials.

Another major challenge lies in the containment and directionality of the reaction. The intense heat and molten products generated during thermite reactions can be difficult to confine and direct, potentially leading to safety concerns and limitations in practical applications. This issue is particularly critical in scenarios where controlled, localized heating is required.

The initiation and termination of thermite reactions also present significant hurdles. While ignition can be achieved through various methods, ensuring consistent and reliable initiation across different scales and environmental conditions remains a challenge. Similarly, developing effective methods to rapidly quench or terminate the reaction when desired is an area that requires further research and innovation.

Scalability is another key challenge in thermite reaction control. Techniques that work effectively at laboratory scales may not translate well to larger industrial applications. This scaling issue affects not only the reaction control itself but also the associated safety measures and equipment design.

The environmental impact and safety concerns associated with thermite reactions pose additional challenges. The production of high-temperature metal oxides and potential for uncontrolled reactions raise questions about the long-term sustainability and safety of these processes in various applications.

Furthermore, the development of novel thermite compositions that offer enhanced controllability while maintaining desired performance characteristics remains an ongoing challenge. This includes research into new fuel-oxidizer combinations, particle size optimization, and the incorporation of additives to modify reaction properties.

Lastly, the integration of advanced sensing and control technologies with thermite reactions presents both opportunities and challenges. While these technologies offer the potential for more precise reaction control, their implementation in the high-temperature, high-energy environment of thermite reactions requires innovative approaches and materials.

Existing Thermite Reaction Control Methods

01 Composition control for thermite reactions

Controlling the composition of thermite mixtures is crucial for managing the reaction. This involves carefully selecting and proportioning the metal fuel and metal oxide components to achieve desired reaction rates and temperatures. Additives can be incorporated to modify reaction characteristics, such as slowing the reaction or altering the heat output.- Composition control for thermite reactions: Controlling the composition of thermite mixtures is crucial for managing the reaction. This involves adjusting the ratios of fuel and oxidizer, as well as incorporating additives to modify reaction characteristics. Precise composition control allows for tailoring the reaction speed, temperature, and energy output to suit specific applications.

- Ignition and initiation control methods: Various techniques are employed to control the initiation of thermite reactions. These include using specialized ignition systems, controlling the ignition timing, and implementing safety mechanisms to prevent accidental ignition. Advanced ignition control methods allow for more precise and reliable thermite reactions in various applications.

- Reaction rate and temperature modulation: Modulating the reaction rate and temperature of thermite reactions is essential for many applications. This can be achieved through the use of catalysts, inhibitors, or by controlling the particle size of reactants. Such control allows for sustained reactions, controlled energy release, and improved safety in handling thermite materials.

- Containment and directional control: Controlling the direction and containment of thermite reactions is crucial for many applications, especially in welding and metal cutting. This involves designing specialized containers, nozzles, or reaction chambers that can withstand high temperatures and pressures while directing the reaction products as desired.

- Safety and environmental considerations: Implementing safety measures and addressing environmental concerns are vital aspects of thermite reaction control. This includes developing methods for safe storage and transport of thermite materials, designing fail-safe mechanisms, and creating environmentally friendly formulations that minimize harmful byproducts or emissions from the reaction.

02 Ignition and initiation control methods

Various techniques are employed to control the initiation of thermite reactions. These include using specialized ignition systems, precise timing mechanisms, and controlled energy inputs. Some methods involve gradual or staged ignition to manage reaction progression and prevent uncontrolled propagation.Expand Specific Solutions03 Containment and reaction vessel design

Specialized containment vessels and reaction chambers are designed to safely control thermite reactions. These designs incorporate features for heat management, pressure regulation, and reaction product containment. Some vessels include mechanisms for controlled release of reaction products or energy.Expand Specific Solutions04 Reaction rate modulation techniques

Methods for modulating the rate of thermite reactions include the use of diluents, particle size control, and the incorporation of reaction inhibitors. These techniques allow for finer control over reaction kinetics, enabling more predictable and manageable thermite processes.Expand Specific Solutions05 Application-specific control strategies

Tailored control strategies are developed for specific applications of thermite reactions, such as in welding, metal purification, or pyrotechnics. These strategies may involve unique combinations of composition control, ignition methods, and containment designs optimized for the particular use case.Expand Specific Solutions

Key Players in Thermite Research and Industry

The thermite reaction control technology is in a mature development stage, with a substantial market size driven by industrial applications. The technology's maturity is evident from the involvement of established players like Aluminum Corp. of China Ltd. and Alcoa, Inc., which are major aluminum producers. Research institutions such as California Institute of Technology and Naval Research Laboratory contribute to advancing the science behind thermite reactions. Companies like Elektro-Thermit GmbH & Co. KG specialize in thermite welding applications, indicating a well-developed commercial ecosystem. The competitive landscape is diverse, with players from various sectors including materials science, energy, and defense, suggesting widespread applicability and ongoing innovation in thermite reaction control.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced thermite compositions and reaction control methods for military applications. Their research focuses on tailoring the reaction rate and energy output of thermite mixtures by adjusting particle sizes, adding diluents, and using novel initiation techniques. They have also explored the use of nanoscale reactants to enhance reactivity and control. Their approach involves precise control of stoichiometry, particle morphology, and the addition of gas-generating additives to modulate the reaction kinetics.

Strengths: Extensive experience in energetic materials, access to advanced characterization techniques, and ability to develop specialized formulations. Weaknesses: Limited commercial applications due to focus on military use.

California Institute of Technology

Technical Solution: Caltech researchers have made significant advancements in understanding and controlling thermite reactions at the nanoscale. They have developed methods to synthesize highly reactive nanocomposite thermites with precisely controlled structures. Their approach involves using sol-gel chemistry to create intimately mixed metal oxide and fuel components, allowing for unprecedented control over reaction rates. They have also pioneered the use of in-situ high-speed imaging and spectroscopy techniques to study the reaction mechanisms in real-time, providing insights into how to tailor the reaction for specific applications.

Strengths: Cutting-edge research in nanotechnology, world-class facilities for material characterization, and interdisciplinary approach. Weaknesses: Focus on fundamental research may limit immediate practical applications.

Innovative Approaches in Thermite Reaction Management

Metal/metal oxide fueled engine

PatentUndeterminedNZ546023A

Innovation

- A method involving the ignition of a thermite mixture in a chamber, where water or steam is introduced to control the reaction temperature, produce hydrogen, and sustain the thermite reaction, allowing the conversion of heat and pressure into mechanical energy through the use of a heat engine.

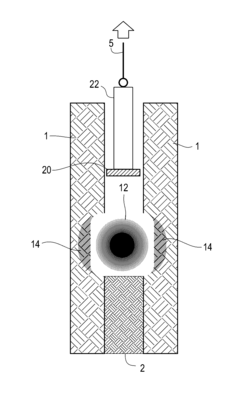

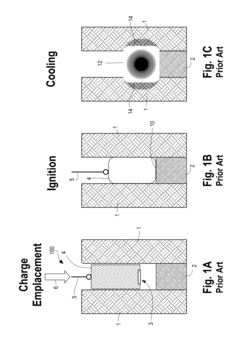

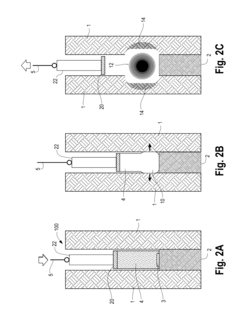

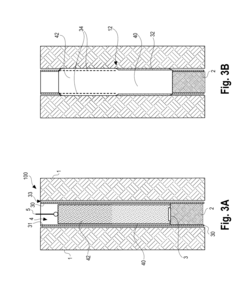

Well sealing via thermite reactions

PatentActiveUS20160312572A1

Innovation

- The method involves applying a compressive vertical load during the thermite reaction using a heavy mass to reduce porosity, diluting the thermite mixture with additives to control reaction temperatures and velocities, and designing the thermite charge with layered structures and specific ignition geometries to achieve radial expansion and containment of the reaction products.

Safety Protocols and Regulations

The handling of thermite reactions requires strict adherence to safety protocols and regulations due to the high temperatures and potential hazards involved. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established comprehensive guidelines for the safe use and control of thermite reactions in industrial and research settings.

Personal protective equipment (PPE) is paramount when working with thermite. This includes fire-resistant clothing, heat-resistant gloves, face shields, and respiratory protection. The specific PPE requirements may vary depending on the scale and nature of the thermite reaction being conducted.

Proper storage and handling of thermite components are critical. Aluminum powder and metal oxides must be stored separately in cool, dry locations away from potential ignition sources. Strict inventory control and access restrictions should be implemented to prevent unauthorized use or accidental mixing of components.

Reaction containment is another crucial aspect of thermite safety. Reactions should be conducted in designated areas with appropriate fire suppression systems and containment measures. The use of sand or other inert materials as a barrier around the reaction site can help contain potential spills or unexpected ignitions.

Emergency response procedures must be well-established and regularly practiced. This includes evacuation plans, fire suppression techniques specific to metal fires, and first aid protocols for thermal burns and other potential injuries associated with thermite reactions.

Training and certification requirements for personnel working with thermite are typically stringent. Operators must demonstrate a thorough understanding of the chemical processes involved, safety procedures, and emergency protocols before being authorized to handle thermite materials or conduct reactions.

Environmental considerations are also an important part of thermite reaction control regulations. Proper disposal of reaction byproducts and unused materials must comply with local and national environmental protection standards to prevent contamination of soil or water sources.

Regular safety audits and inspections are mandated to ensure ongoing compliance with established protocols. These audits often include reviews of documentation, equipment maintenance records, and on-site observations of safety practices.

Incident reporting and investigation procedures are critical components of the regulatory framework. Any accidents or near-misses must be thoroughly documented and analyzed to prevent future occurrences and improve safety measures continually.

Personal protective equipment (PPE) is paramount when working with thermite. This includes fire-resistant clothing, heat-resistant gloves, face shields, and respiratory protection. The specific PPE requirements may vary depending on the scale and nature of the thermite reaction being conducted.

Proper storage and handling of thermite components are critical. Aluminum powder and metal oxides must be stored separately in cool, dry locations away from potential ignition sources. Strict inventory control and access restrictions should be implemented to prevent unauthorized use or accidental mixing of components.

Reaction containment is another crucial aspect of thermite safety. Reactions should be conducted in designated areas with appropriate fire suppression systems and containment measures. The use of sand or other inert materials as a barrier around the reaction site can help contain potential spills or unexpected ignitions.

Emergency response procedures must be well-established and regularly practiced. This includes evacuation plans, fire suppression techniques specific to metal fires, and first aid protocols for thermal burns and other potential injuries associated with thermite reactions.

Training and certification requirements for personnel working with thermite are typically stringent. Operators must demonstrate a thorough understanding of the chemical processes involved, safety procedures, and emergency protocols before being authorized to handle thermite materials or conduct reactions.

Environmental considerations are also an important part of thermite reaction control regulations. Proper disposal of reaction byproducts and unused materials must comply with local and national environmental protection standards to prevent contamination of soil or water sources.

Regular safety audits and inspections are mandated to ensure ongoing compliance with established protocols. These audits often include reviews of documentation, equipment maintenance records, and on-site observations of safety practices.

Incident reporting and investigation procedures are critical components of the regulatory framework. Any accidents or near-misses must be thoroughly documented and analyzed to prevent future occurrences and improve safety measures continually.

Environmental Impact Assessment

The environmental impact of thermite reactions is a critical consideration in their application and control. These reactions, known for their high temperatures and intense energy release, can have significant effects on the surrounding ecosystem if not properly managed.

Atmospheric emissions are a primary concern. The combustion of thermite mixtures typically produces metal oxide fumes and particulate matter. These emissions can contribute to air pollution, potentially affecting local air quality and posing respiratory risks to nearby populations. The specific composition of these emissions varies depending on the thermite mixture used, but often includes aluminum oxide and iron oxide particles.

Soil contamination is another potential environmental issue. Residues from thermite reactions, including metal oxides and unreacted materials, can leach into the soil. This may alter soil chemistry and potentially impact plant growth and soil microorganisms. The extent of soil contamination depends on the scale of the reaction and the effectiveness of containment measures.

Water resources can also be affected by thermite reactions. Runoff from reaction sites may carry contaminants into nearby water bodies, potentially impacting aquatic ecosystems. The high temperatures associated with these reactions can cause localized thermal pollution if the heat is not properly dissipated.

The intense heat generated by thermite reactions can have direct impacts on local flora and fauna. In uncontrolled scenarios, it may lead to vegetation damage or destruction and disrupt wildlife habitats. However, when properly controlled, these effects can be minimized.

Noise pollution is an often-overlooked aspect of thermite reactions. The rapid, exothermic nature of these reactions can produce significant noise levels, which may cause disturbance to local communities and wildlife, particularly if conducted in populated or ecologically sensitive areas.

Long-term ecological effects must also be considered. Repeated use of thermite reactions in a specific area could lead to cumulative environmental impacts, potentially altering local ecosystems over time. This is particularly relevant in industrial or military applications where thermite reactions are used regularly.

To mitigate these environmental impacts, strict control measures are essential. These include proper containment of reaction materials, efficient fume and particulate capture systems, and appropriate disposal of reaction byproducts. Additionally, site selection for thermite reactions should consider potential environmental sensitivities, avoiding areas with vulnerable ecosystems or water resources.

Ongoing research into more environmentally friendly thermite compositions and reaction control methods is crucial. This includes developing mixtures that produce less harmful emissions and exploring ways to better contain and manage the reaction's energy output. Such advancements could significantly reduce the environmental footprint of thermite reactions while maintaining their utility in various applications.

Atmospheric emissions are a primary concern. The combustion of thermite mixtures typically produces metal oxide fumes and particulate matter. These emissions can contribute to air pollution, potentially affecting local air quality and posing respiratory risks to nearby populations. The specific composition of these emissions varies depending on the thermite mixture used, but often includes aluminum oxide and iron oxide particles.

Soil contamination is another potential environmental issue. Residues from thermite reactions, including metal oxides and unreacted materials, can leach into the soil. This may alter soil chemistry and potentially impact plant growth and soil microorganisms. The extent of soil contamination depends on the scale of the reaction and the effectiveness of containment measures.

Water resources can also be affected by thermite reactions. Runoff from reaction sites may carry contaminants into nearby water bodies, potentially impacting aquatic ecosystems. The high temperatures associated with these reactions can cause localized thermal pollution if the heat is not properly dissipated.

The intense heat generated by thermite reactions can have direct impacts on local flora and fauna. In uncontrolled scenarios, it may lead to vegetation damage or destruction and disrupt wildlife habitats. However, when properly controlled, these effects can be minimized.

Noise pollution is an often-overlooked aspect of thermite reactions. The rapid, exothermic nature of these reactions can produce significant noise levels, which may cause disturbance to local communities and wildlife, particularly if conducted in populated or ecologically sensitive areas.

Long-term ecological effects must also be considered. Repeated use of thermite reactions in a specific area could lead to cumulative environmental impacts, potentially altering local ecosystems over time. This is particularly relevant in industrial or military applications where thermite reactions are used regularly.

To mitigate these environmental impacts, strict control measures are essential. These include proper containment of reaction materials, efficient fume and particulate capture systems, and appropriate disposal of reaction byproducts. Additionally, site selection for thermite reactions should consider potential environmental sensitivities, avoiding areas with vulnerable ecosystems or water resources.

Ongoing research into more environmentally friendly thermite compositions and reaction control methods is crucial. This includes developing mixtures that produce less harmful emissions and exploring ways to better contain and manage the reaction's energy output. Such advancements could significantly reduce the environmental footprint of thermite reactions while maintaining their utility in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!