Thermal Runaway Mitigation Strategies in Blade Battery Packs

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Thermal Runaway Background and Objectives

Blade batteries, a revolutionary technology in the electric vehicle (EV) industry, have gained significant attention due to their enhanced safety features and energy density. However, thermal runaway remains a critical concern in battery pack design and operation. This report aims to explore the background of thermal runaway in blade battery packs and outline the objectives for developing effective mitigation strategies.

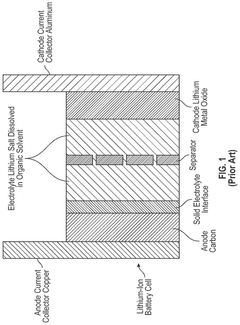

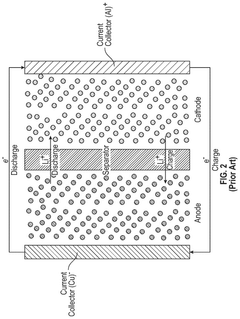

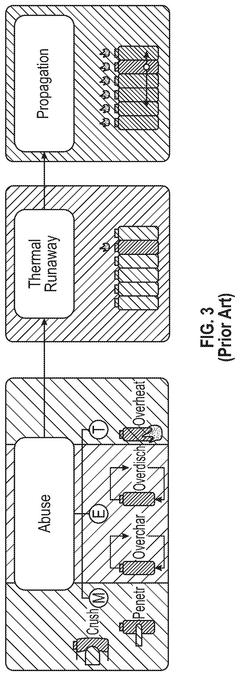

Thermal runaway in lithium-ion batteries occurs when the heat generation rate exceeds the heat dissipation rate, leading to a rapid increase in temperature and potential catastrophic failure. In blade batteries, which utilize a unique cell-to-pack design, the risk of thermal runaway propagation is particularly challenging due to the compact arrangement of cells.

The evolution of blade battery technology has been driven by the need for safer, more energy-dense power sources in EVs. Traditional lithium-ion batteries faced issues with thermal management and safety, prompting researchers to explore alternative designs. Blade batteries emerged as a promising solution, offering improved thermal stability and higher energy density.

Despite these advancements, thermal runaway remains a significant concern in blade battery packs. The close proximity of cells in the pack design can facilitate rapid heat transfer between adjacent cells, potentially leading to cascading failures. This risk is further exacerbated by the high energy density of blade batteries, which can release substantial thermal energy during a runaway event.

The primary objective of thermal runaway mitigation strategies in blade battery packs is to prevent the initiation and propagation of thermal events. This involves developing advanced thermal management systems, implementing robust battery management algorithms, and designing innovative pack architectures that minimize heat transfer between cells.

Another crucial objective is to enhance the early detection of thermal anomalies within the battery pack. This requires the integration of sophisticated sensing technologies and real-time monitoring systems capable of identifying potential thermal runaway precursors before they escalate into critical events.

Furthermore, the development of novel materials and cell chemistries that exhibit improved thermal stability is a key focus area. Researchers aim to create battery components that can withstand higher temperatures and resist thermal runaway initiation, even under extreme conditions.

Ultimately, the goal is to create blade battery packs that maintain their high energy density and performance advantages while significantly reducing the risk of thermal runaway. This balance between performance and safety is essential for the widespread adoption of blade batteries in the EV market and other energy storage applications.

Thermal runaway in lithium-ion batteries occurs when the heat generation rate exceeds the heat dissipation rate, leading to a rapid increase in temperature and potential catastrophic failure. In blade batteries, which utilize a unique cell-to-pack design, the risk of thermal runaway propagation is particularly challenging due to the compact arrangement of cells.

The evolution of blade battery technology has been driven by the need for safer, more energy-dense power sources in EVs. Traditional lithium-ion batteries faced issues with thermal management and safety, prompting researchers to explore alternative designs. Blade batteries emerged as a promising solution, offering improved thermal stability and higher energy density.

Despite these advancements, thermal runaway remains a significant concern in blade battery packs. The close proximity of cells in the pack design can facilitate rapid heat transfer between adjacent cells, potentially leading to cascading failures. This risk is further exacerbated by the high energy density of blade batteries, which can release substantial thermal energy during a runaway event.

The primary objective of thermal runaway mitigation strategies in blade battery packs is to prevent the initiation and propagation of thermal events. This involves developing advanced thermal management systems, implementing robust battery management algorithms, and designing innovative pack architectures that minimize heat transfer between cells.

Another crucial objective is to enhance the early detection of thermal anomalies within the battery pack. This requires the integration of sophisticated sensing technologies and real-time monitoring systems capable of identifying potential thermal runaway precursors before they escalate into critical events.

Furthermore, the development of novel materials and cell chemistries that exhibit improved thermal stability is a key focus area. Researchers aim to create battery components that can withstand higher temperatures and resist thermal runaway initiation, even under extreme conditions.

Ultimately, the goal is to create blade battery packs that maintain their high energy density and performance advantages while significantly reducing the risk of thermal runaway. This balance between performance and safety is essential for the widespread adoption of blade batteries in the EV market and other energy storage applications.

Market Analysis for Safer EV Battery Technologies

The market for safer EV battery technologies has experienced significant growth in recent years, driven by increasing concerns over battery safety and the rapid expansion of the electric vehicle industry. The global EV battery market is projected to reach $133.46 billion by 2027, with a compound annual growth rate (CAGR) of 18.0% from 2020 to 2027. This growth is largely attributed to the rising demand for electric vehicles and the need for more reliable and safer battery technologies.

Blade battery packs, particularly those incorporating thermal runaway mitigation strategies, have emerged as a promising solution to address safety concerns in the EV industry. These advanced battery systems offer improved energy density, reduced risk of thermal runaway, and enhanced overall safety performance. The market for blade batteries is expected to grow at a CAGR of 12.5% from 2021 to 2026, reflecting the increasing adoption of this technology by major automakers.

Consumer demand for safer EV batteries has been a key driver in the market. A survey conducted by J.D. Power in 2022 revealed that 76% of potential EV buyers consider battery safety as a crucial factor in their purchasing decision. This consumer sentiment has pushed manufacturers to invest heavily in research and development of advanced safety features, including thermal runaway mitigation strategies.

The regulatory landscape has also played a significant role in shaping the market for safer EV battery technologies. Governments worldwide have implemented stricter safety standards for electric vehicles, with a particular focus on battery performance and thermal management. For instance, the United Nations Economic Commission for Europe (UNECE) has introduced regulations specifically addressing thermal propagation in EV batteries, which has further accelerated the adoption of advanced safety technologies.

Major players in the EV battery market, including CATL, LG Energy Solution, and Samsung SDI, have all invested in developing safer battery technologies. CATL's blade battery, in particular, has gained significant attention for its improved safety features and resistance to thermal runaway. The company has reported a 35% increase in orders for blade batteries in 2022 compared to the previous year, indicating strong market acceptance of this technology.

The market for safer EV battery technologies is not limited to passenger vehicles. Commercial electric vehicles, including buses and trucks, are also driving demand for advanced battery safety systems. The commercial EV battery market is expected to grow at a CAGR of 16.8% from 2021 to 2028, with safety features being a key consideration for fleet operators and logistics companies.

As the EV market continues to expand, the demand for safer battery technologies is expected to grow proportionally. Industry analysts predict that by 2025, over 60% of new EVs will incorporate advanced thermal management systems and other safety features designed to mitigate the risk of thermal runaway. This trend underscores the critical importance of continued innovation in battery safety technologies to support the sustainable growth of the electric vehicle industry.

Blade battery packs, particularly those incorporating thermal runaway mitigation strategies, have emerged as a promising solution to address safety concerns in the EV industry. These advanced battery systems offer improved energy density, reduced risk of thermal runaway, and enhanced overall safety performance. The market for blade batteries is expected to grow at a CAGR of 12.5% from 2021 to 2026, reflecting the increasing adoption of this technology by major automakers.

Consumer demand for safer EV batteries has been a key driver in the market. A survey conducted by J.D. Power in 2022 revealed that 76% of potential EV buyers consider battery safety as a crucial factor in their purchasing decision. This consumer sentiment has pushed manufacturers to invest heavily in research and development of advanced safety features, including thermal runaway mitigation strategies.

The regulatory landscape has also played a significant role in shaping the market for safer EV battery technologies. Governments worldwide have implemented stricter safety standards for electric vehicles, with a particular focus on battery performance and thermal management. For instance, the United Nations Economic Commission for Europe (UNECE) has introduced regulations specifically addressing thermal propagation in EV batteries, which has further accelerated the adoption of advanced safety technologies.

Major players in the EV battery market, including CATL, LG Energy Solution, and Samsung SDI, have all invested in developing safer battery technologies. CATL's blade battery, in particular, has gained significant attention for its improved safety features and resistance to thermal runaway. The company has reported a 35% increase in orders for blade batteries in 2022 compared to the previous year, indicating strong market acceptance of this technology.

The market for safer EV battery technologies is not limited to passenger vehicles. Commercial electric vehicles, including buses and trucks, are also driving demand for advanced battery safety systems. The commercial EV battery market is expected to grow at a CAGR of 16.8% from 2021 to 2028, with safety features being a key consideration for fleet operators and logistics companies.

As the EV market continues to expand, the demand for safer battery technologies is expected to grow proportionally. Industry analysts predict that by 2025, over 60% of new EVs will incorporate advanced thermal management systems and other safety features designed to mitigate the risk of thermal runaway. This trend underscores the critical importance of continued innovation in battery safety technologies to support the sustainable growth of the electric vehicle industry.

Current Challenges in Blade Battery Thermal Management

Blade battery packs, while offering significant advantages in energy density and safety, still face several critical challenges in thermal management. One of the primary concerns is the uneven heat distribution within the pack. Due to the compact design of blade batteries, heat tends to accumulate in certain areas, particularly in the center of the pack, leading to potential hotspots. These temperature gradients can accelerate battery degradation and, in extreme cases, trigger thermal runaway events.

Another significant challenge is the limited space for thermal management systems. The slim profile of blade batteries, which contributes to their high energy density, also restricts the implementation of traditional cooling methods. This constraint makes it difficult to incorporate adequate cooling channels or heat dissipation materials without compromising the pack's energy density or increasing its overall size and weight.

The high energy density of blade batteries also presents a unique thermal management challenge. As these batteries can store more energy in a smaller volume, they generate more heat during charging and discharging cycles. This increased heat generation requires more efficient cooling strategies to maintain optimal operating temperatures and prevent thermal runaway.

Furthermore, the thermal behavior of blade batteries under extreme conditions, such as rapid charging or high-power discharge scenarios, remains a concern. These situations can lead to sudden temperature spikes that are difficult to manage with current thermal control systems, potentially compromising the safety and longevity of the battery pack.

The integration of thermal management systems with battery management systems (BMS) also poses a challenge. Effective thermal control requires real-time temperature monitoring and adaptive cooling strategies, which necessitate sophisticated BMS algorithms and sensor networks. Developing and implementing such integrated systems while maintaining cost-effectiveness and reliability is a complex task.

Lastly, the environmental impact and sustainability of thermal management solutions for blade batteries are becoming increasingly important. Traditional cooling methods often rely on materials or fluids that may have negative environmental effects. Developing eco-friendly thermal management strategies that are both effective and sustainable is a growing challenge in the industry.

Another significant challenge is the limited space for thermal management systems. The slim profile of blade batteries, which contributes to their high energy density, also restricts the implementation of traditional cooling methods. This constraint makes it difficult to incorporate adequate cooling channels or heat dissipation materials without compromising the pack's energy density or increasing its overall size and weight.

The high energy density of blade batteries also presents a unique thermal management challenge. As these batteries can store more energy in a smaller volume, they generate more heat during charging and discharging cycles. This increased heat generation requires more efficient cooling strategies to maintain optimal operating temperatures and prevent thermal runaway.

Furthermore, the thermal behavior of blade batteries under extreme conditions, such as rapid charging or high-power discharge scenarios, remains a concern. These situations can lead to sudden temperature spikes that are difficult to manage with current thermal control systems, potentially compromising the safety and longevity of the battery pack.

The integration of thermal management systems with battery management systems (BMS) also poses a challenge. Effective thermal control requires real-time temperature monitoring and adaptive cooling strategies, which necessitate sophisticated BMS algorithms and sensor networks. Developing and implementing such integrated systems while maintaining cost-effectiveness and reliability is a complex task.

Lastly, the environmental impact and sustainability of thermal management solutions for blade batteries are becoming increasingly important. Traditional cooling methods often rely on materials or fluids that may have negative environmental effects. Developing eco-friendly thermal management strategies that are both effective and sustainable is a growing challenge in the industry.

Existing Thermal Runaway Prevention Solutions

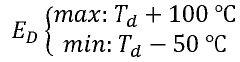

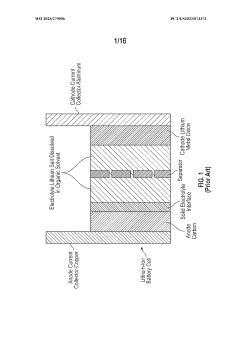

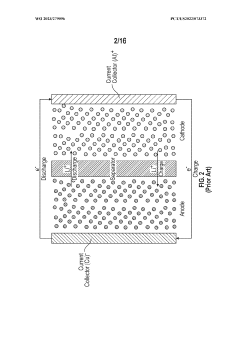

01 Thermal management systems for blade battery packs

Advanced thermal management systems are implemented in blade battery packs to prevent thermal runaway. These systems may include cooling channels, heat dissipation materials, and temperature sensors to monitor and regulate battery temperature. Efficient heat distribution and dissipation mechanisms help maintain optimal operating conditions and reduce the risk of thermal events.- Thermal management systems for blade battery packs: Advanced thermal management systems are implemented in blade battery packs to prevent thermal runaway. These systems may include cooling channels, heat dissipation materials, and temperature sensors to monitor and regulate battery temperature. Efficient heat distribution and dissipation mechanisms are crucial for maintaining safe operating conditions and preventing localized hot spots that could lead to thermal runaway.

- Safety mechanisms and protective structures: Blade battery packs incorporate various safety mechanisms and protective structures to mitigate the risk of thermal runaway. These may include pressure relief valves, fire-resistant materials, and isolation systems that can contain and suppress potential thermal events. Structural designs that minimize the propagation of thermal runaway between cells or modules are also implemented.

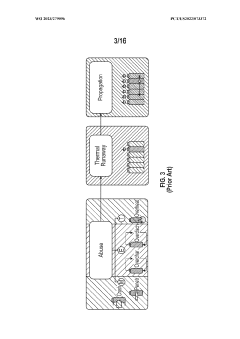

- Advanced battery management systems (BMS): Sophisticated battery management systems are employed in blade battery packs to monitor and control various parameters such as voltage, current, and temperature. These systems use algorithms to detect early signs of potential thermal runaway and can initiate preventive measures such as load balancing, cell disconnection, or emergency shutdown to prevent escalation of thermal events.

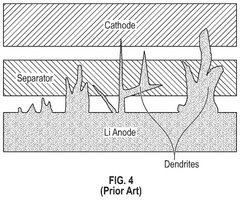

- Novel electrode and electrolyte materials: Research and development efforts focus on creating new electrode and electrolyte materials that are more resistant to thermal runaway. These materials may have higher thermal stability, improved ionic conductivity, or self-healing properties that can prevent or mitigate the onset of thermal runaway conditions in blade battery packs.

- Modular design and rapid disassembly mechanisms: Blade battery packs are designed with modular architectures that allow for quick isolation and removal of problematic cells or modules. This approach includes rapid disassembly mechanisms and strategically placed disconnection points that can be activated in case of a thermal event, minimizing the risk of propagation to the entire battery pack.

02 Safety mechanisms and protective structures

Blade battery packs incorporate various safety mechanisms and protective structures to mitigate the risk of thermal runaway. These may include pressure relief valves, fire-resistant materials, and isolation systems that can contain and suppress thermal events. Structural designs aim to prevent the propagation of thermal runaway between cells and modules.Expand Specific Solutions03 Advanced battery management systems (BMS)

Sophisticated battery management systems are employed to monitor and control blade battery packs. These systems use algorithms to detect early signs of thermal abnormalities, manage charge/discharge rates, and implement protective measures. Real-time monitoring and predictive analytics help prevent conditions that could lead to thermal runaway.Expand Specific Solutions04 Novel electrode and electrolyte materials

Research focuses on developing new electrode and electrolyte materials for blade batteries that are more resistant to thermal runaway. These materials may have higher thermal stability, improved conductivity, or self-healing properties. The goal is to enhance the inherent safety of the battery chemistry and reduce the likelihood of thermal events.Expand Specific Solutions05 Modular design and rapid disconnection systems

Blade battery packs utilize modular designs and rapid disconnection systems to isolate faulty components quickly. This approach allows for the swift removal of problematic cells or modules, preventing the spread of thermal events. Intelligent circuit designs and fast-acting switches enable immediate power cut-off in case of detected anomalies.Expand Specific Solutions

Key Players in Blade Battery Manufacturing

The thermal runaway mitigation strategies in blade battery packs market is in a growth phase, driven by increasing demand for safer and more efficient electric vehicle batteries. The market size is expanding rapidly, with major players like LG Energy Solution, Tesla, and BYD investing heavily in research and development. Technologically, the field is advancing quickly, with companies like Contemporary Amperex Technology and Samsung SDI leading innovations in battery design and safety features. However, the technology is still evolving, with ongoing efforts to improve thermal management systems and develop more stable battery chemistries. The competitive landscape is intense, with both established automotive giants and specialized battery manufacturers vying for market share and technological breakthroughs.

Tesla, Inc.

Technical Solution: Tesla's approach to thermal runaway mitigation in battery packs involves a multi-faceted strategy: 1) Advanced cell design using high-quality materials and precise manufacturing processes to minimize internal defects. 2) Sophisticated battery management system (BMS) that continuously monitors individual cell voltages, temperatures, and overall pack health[4]. 3) Implementation of a patented intumescent material between cells that expands when heated, creating a barrier to prevent thermal propagation[5]. 4) Use of a dedicated cooling system, typically a glycol-based liquid coolant circulating through channels between cells. 5) Integration of safety fuses and contactors to isolate faulty cells or modules. 6) Structural pack design that incorporates venting mechanisms to safely release pressure in case of a thermal event[6].

Strengths: Comprehensive approach combining active and passive safety features, high energy density. Weaknesses: Complex system integration, potentially higher costs due to advanced materials and cooling systems.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic's thermal runaway mitigation strategies for battery packs include: 1) Development of heat-resistant separators that maintain integrity at high temperatures, preventing short circuits[10]. 2) Implementation of a proprietary "heat dissipation layer" within cells to quickly spread and dissipate heat. 3) Use of advanced non-flammable electrolytes to reduce fire risk. 4) Integration of multi-layer safety mechanisms at the cell, module, and pack levels. 5) Sophisticated battery management systems with thermal modeling capabilities for predictive heat management. 6) Design of robust mechanical structures to prevent physical damage and contain thermal events. 7) Incorporation of phase-change materials for passive thermal regulation[11].

Strengths: Multi-layered safety approach, focus on cell-level innovations. Weaknesses: Potential trade-offs between safety features and energy density, complexity in manufacturing processes.

Innovative Thermal Management Technologies

Systems and methods for mitigating thermal propagation in battery-based energy storage systems

PatentWO2023279096A2

Innovation

- A compressible thermal barrier material is introduced between battery cells, tailored to the areal energy density of individual cells, which prevents thermal propagation by absorbing mechanical energy and maintaining structural integrity during thermal events, using a multilayer material configuration with insulation and thermal conductive layers to manage heat dissipation.

Systems and methods for mitigating thermal propagation in battery-based energy storage systems

PatentActiveUS20240313291A1

Innovation

- A compressible thermal barrier material is introduced between battery cells, tailored to the areal energy density of individual cells, which prevents thermal propagation by maintaining adjacent cells below critical temperatures during thermal events, using a multilayer material with insulation and thermal conductive layers to manage heat dissipation and mechanical stress.

Regulatory Framework for EV Battery Safety

The regulatory framework for electric vehicle (EV) battery safety is a critical aspect of the automotive industry's transition towards electrification. As the adoption of EVs continues to grow, governments and regulatory bodies worldwide have been developing and implementing stringent safety standards to address the unique challenges posed by high-capacity lithium-ion batteries.

At the international level, the United Nations Economic Commission for Europe (UNECE) has established the Global Technical Regulation No. 20 (GTR 20) on Electric Vehicle Safety. This regulation provides a harmonized approach to EV safety requirements, including battery safety, and serves as a foundation for many national and regional standards.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees EV battery safety regulations. The Federal Motor Vehicle Safety Standards (FMVSS) No. 305 specifically addresses electric powertrain safety, including battery pack integrity during crash events. Additionally, the Society of Automotive Engineers (SAE) has developed standards such as J2929, which outlines safety requirements for EV batteries.

The European Union has implemented the UN Regulation No. 100, which covers battery electric vehicle safety. This regulation includes requirements for protection against electrical shock, functional safety, and hydrogen emissions from batteries. Furthermore, the EU Battery Directive (2006/66/EC) addresses the environmental aspects of battery production and disposal.

China, as a major player in the EV market, has established its own set of regulations. The GB/T 31485 standard focuses on safety requirements for traction battery packs and systems in electric vehicles. This standard includes rigorous testing procedures for thermal runaway, overcharge, and mechanical integrity.

Regulatory bodies are continuously updating these frameworks to address emerging challenges in EV battery safety. Recent updates have focused on thermal runaway mitigation, battery management systems, and fire suppression technologies. For instance, the UN GTR 20 is undergoing revisions to incorporate more comprehensive thermal propagation requirements.

As the technology evolves, regulators are also considering new testing methodologies. These include more realistic abuse scenarios, such as partial thermal runaway initiation, to better simulate real-world conditions. Additionally, there is a growing emphasis on the entire lifecycle of EV batteries, from production to end-of-life management, to ensure comprehensive safety measures.

At the international level, the United Nations Economic Commission for Europe (UNECE) has established the Global Technical Regulation No. 20 (GTR 20) on Electric Vehicle Safety. This regulation provides a harmonized approach to EV safety requirements, including battery safety, and serves as a foundation for many national and regional standards.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees EV battery safety regulations. The Federal Motor Vehicle Safety Standards (FMVSS) No. 305 specifically addresses electric powertrain safety, including battery pack integrity during crash events. Additionally, the Society of Automotive Engineers (SAE) has developed standards such as J2929, which outlines safety requirements for EV batteries.

The European Union has implemented the UN Regulation No. 100, which covers battery electric vehicle safety. This regulation includes requirements for protection against electrical shock, functional safety, and hydrogen emissions from batteries. Furthermore, the EU Battery Directive (2006/66/EC) addresses the environmental aspects of battery production and disposal.

China, as a major player in the EV market, has established its own set of regulations. The GB/T 31485 standard focuses on safety requirements for traction battery packs and systems in electric vehicles. This standard includes rigorous testing procedures for thermal runaway, overcharge, and mechanical integrity.

Regulatory bodies are continuously updating these frameworks to address emerging challenges in EV battery safety. Recent updates have focused on thermal runaway mitigation, battery management systems, and fire suppression technologies. For instance, the UN GTR 20 is undergoing revisions to incorporate more comprehensive thermal propagation requirements.

As the technology evolves, regulators are also considering new testing methodologies. These include more realistic abuse scenarios, such as partial thermal runaway initiation, to better simulate real-world conditions. Additionally, there is a growing emphasis on the entire lifecycle of EV batteries, from production to end-of-life management, to ensure comprehensive safety measures.

Environmental Impact of Battery Safety Measures

The environmental impact of battery safety measures in blade battery packs is a critical consideration in the development and implementation of thermal runaway mitigation strategies. As the automotive industry shifts towards electrification, the environmental footprint of battery production and safety systems becomes increasingly significant.

One of the primary environmental concerns associated with battery safety measures is the use of fire-retardant materials. These substances, while essential for preventing thermal runaway propagation, often contain halogenated compounds that can be harmful to ecosystems if released into the environment. The production and disposal of these materials require careful management to minimize their ecological impact.

The design of thermal management systems also plays a crucial role in the environmental impact of battery safety measures. Advanced cooling systems, such as liquid cooling or phase-change materials, can significantly improve battery performance and safety. However, the production of these systems may involve energy-intensive processes and the use of rare earth elements, potentially increasing the overall carbon footprint of the battery pack.

Recycling and end-of-life considerations are paramount when assessing the environmental impact of battery safety measures. The complex nature of blade battery packs, with their integrated safety features, can make recycling more challenging. Developing efficient recycling processes that can recover valuable materials while safely disposing of hazardous components is essential for minimizing the long-term environmental impact.

The choice of battery chemistry also influences the environmental impact of safety measures. For instance, lithium iron phosphate (LFP) batteries, commonly used in blade battery configurations, are generally considered more environmentally friendly due to their lower cobalt content and improved thermal stability. This inherent safety characteristic may reduce the need for extensive additional safety measures, potentially decreasing the overall environmental impact.

Furthermore, the implementation of smart battery management systems (BMS) can contribute to both safety and environmental sustainability. Advanced BMS can optimize battery performance, extend lifespan, and prevent overcharging or deep discharging, all of which contribute to reduced waste and improved resource efficiency. However, the electronic components in these systems may contain materials that require careful handling and disposal.

Lastly, the manufacturing processes for blade battery packs and their associated safety measures must be considered. Implementing cleaner production techniques, such as using renewable energy in manufacturing facilities and adopting water-saving technologies, can significantly reduce the environmental footprint of battery safety systems.

One of the primary environmental concerns associated with battery safety measures is the use of fire-retardant materials. These substances, while essential for preventing thermal runaway propagation, often contain halogenated compounds that can be harmful to ecosystems if released into the environment. The production and disposal of these materials require careful management to minimize their ecological impact.

The design of thermal management systems also plays a crucial role in the environmental impact of battery safety measures. Advanced cooling systems, such as liquid cooling or phase-change materials, can significantly improve battery performance and safety. However, the production of these systems may involve energy-intensive processes and the use of rare earth elements, potentially increasing the overall carbon footprint of the battery pack.

Recycling and end-of-life considerations are paramount when assessing the environmental impact of battery safety measures. The complex nature of blade battery packs, with their integrated safety features, can make recycling more challenging. Developing efficient recycling processes that can recover valuable materials while safely disposing of hazardous components is essential for minimizing the long-term environmental impact.

The choice of battery chemistry also influences the environmental impact of safety measures. For instance, lithium iron phosphate (LFP) batteries, commonly used in blade battery configurations, are generally considered more environmentally friendly due to their lower cobalt content and improved thermal stability. This inherent safety characteristic may reduce the need for extensive additional safety measures, potentially decreasing the overall environmental impact.

Furthermore, the implementation of smart battery management systems (BMS) can contribute to both safety and environmental sustainability. Advanced BMS can optimize battery performance, extend lifespan, and prevent overcharging or deep discharging, all of which contribute to reduced waste and improved resource efficiency. However, the electronic components in these systems may contain materials that require careful handling and disposal.

Lastly, the manufacturing processes for blade battery packs and their associated safety measures must be considered. Implementing cleaner production techniques, such as using renewable energy in manufacturing facilities and adopting water-saving technologies, can significantly reduce the environmental footprint of battery safety systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!