Thermite: Advancements in Armament and Defense Technology

JUN 24, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Evolution

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has undergone significant evolution since its discovery in 1893. Initially developed as a welding compound, thermite's potential in military applications quickly became apparent due to its intense exothermic reaction.

The early 20th century saw thermite's first military use in incendiary grenades and bombs during World War I. This period marked the beginning of thermite's role in armament technology, with researchers focusing on optimizing its composition for maximum heat output and penetration capabilities.

Post-World War II, thermite research shifted towards enhancing its stability and controllability. The 1950s and 1960s witnessed the development of more sophisticated thermite mixtures, incorporating additives to modify burn rates and increase energy density. These advancements led to the creation of thermate, a more potent variant used in incendiary weapons.

The late 20th century brought a new focus on thermite's potential in defensive technologies. Researchers began exploring its use in reactive armor systems, where thermite's rapid heat generation could be harnessed to counter incoming projectiles. This period also saw the development of thermite-based breaching charges, utilized in urban warfare scenarios.

Entering the 21st century, thermite evolution took a more nuanced approach. Nanotechnology advancements allowed for the creation of nano-thermites, offering significantly increased reaction rates and energy output. These nano-scale materials opened new possibilities in both offensive and defensive applications, from more efficient incendiary devices to advanced self-destruct mechanisms for sensitive equipment.

Recent years have seen a growing interest in environmentally friendly thermite formulations. Researchers are exploring green alternatives that maintain thermite's effectiveness while reducing its environmental impact. This includes the development of non-toxic variants and formulations designed for easier post-use cleanup.

The evolution of thermite in armament and defense technology continues to be driven by the dual needs of increased effectiveness and enhanced safety. Current research focuses on precision-controlled reactions, allowing for more targeted and efficient use of thermite in various military scenarios. Additionally, there is ongoing work to integrate thermite-based systems with modern electronic warfare capabilities, creating hybrid solutions that combine thermal and electromagnetic effects.

The early 20th century saw thermite's first military use in incendiary grenades and bombs during World War I. This period marked the beginning of thermite's role in armament technology, with researchers focusing on optimizing its composition for maximum heat output and penetration capabilities.

Post-World War II, thermite research shifted towards enhancing its stability and controllability. The 1950s and 1960s witnessed the development of more sophisticated thermite mixtures, incorporating additives to modify burn rates and increase energy density. These advancements led to the creation of thermate, a more potent variant used in incendiary weapons.

The late 20th century brought a new focus on thermite's potential in defensive technologies. Researchers began exploring its use in reactive armor systems, where thermite's rapid heat generation could be harnessed to counter incoming projectiles. This period also saw the development of thermite-based breaching charges, utilized in urban warfare scenarios.

Entering the 21st century, thermite evolution took a more nuanced approach. Nanotechnology advancements allowed for the creation of nano-thermites, offering significantly increased reaction rates and energy output. These nano-scale materials opened new possibilities in both offensive and defensive applications, from more efficient incendiary devices to advanced self-destruct mechanisms for sensitive equipment.

Recent years have seen a growing interest in environmentally friendly thermite formulations. Researchers are exploring green alternatives that maintain thermite's effectiveness while reducing its environmental impact. This includes the development of non-toxic variants and formulations designed for easier post-use cleanup.

The evolution of thermite in armament and defense technology continues to be driven by the dual needs of increased effectiveness and enhanced safety. Current research focuses on precision-controlled reactions, allowing for more targeted and efficient use of thermite in various military scenarios. Additionally, there is ongoing work to integrate thermite-based systems with modern electronic warfare capabilities, creating hybrid solutions that combine thermal and electromagnetic effects.

Military Applications

Thermite has played a significant role in military applications, revolutionizing various aspects of armament and defense technology. Its unique properties, including high temperature combustion and rapid reaction rates, have made it a versatile material in military operations. One of the primary uses of thermite in military applications is in incendiary devices. These devices are designed to generate intense heat and flames, capable of penetrating armor and destroying equipment. Thermite-based incendiary weapons have been employed in both offensive and defensive scenarios, proving particularly effective against fortified positions and vehicles.

In addition to incendiary applications, thermite has found use in breaching operations. Military forces utilize thermite charges to quickly cut through metal barriers, locks, and other obstacles, facilitating rapid entry into secured areas. This capability has proven invaluable in urban warfare scenarios and hostage rescue operations, where speed and precision are critical.

Thermite's heat-generating properties have also been harnessed for emergency destruction of sensitive equipment and documents. Military units can deploy thermite charges to rapidly and thoroughly destroy classified materials, preventing them from falling into enemy hands. This application has become increasingly important in the age of digital warfare, where protecting sensitive information is paramount.

The development of thermite-based reactive armor has significantly enhanced vehicle protection in combat situations. When integrated into armor systems, thermite reactions can help dissipate the energy of incoming projectiles, reducing their penetrative power and improving crew survivability. This technology has been particularly beneficial for armored personnel carriers and main battle tanks operating in high-threat environments.

Thermite has also found applications in underwater demolitions and sabotage operations. Special forces units have employed thermite charges for disabling ship propellers, rudders, and other critical maritime infrastructure. The material's ability to burn underwater and generate extreme heat makes it an effective tool for these specialized missions.

In the realm of pyrotechnics, thermite-based compositions have been used to create high-intensity flares and signaling devices. These applications leverage thermite's bright, long-lasting burn characteristics to enhance visibility and communication in battlefield conditions. Additionally, thermite has been incorporated into some types of tracer ammunition, improving target acquisition and fire correction capabilities for military personnel.

In addition to incendiary applications, thermite has found use in breaching operations. Military forces utilize thermite charges to quickly cut through metal barriers, locks, and other obstacles, facilitating rapid entry into secured areas. This capability has proven invaluable in urban warfare scenarios and hostage rescue operations, where speed and precision are critical.

Thermite's heat-generating properties have also been harnessed for emergency destruction of sensitive equipment and documents. Military units can deploy thermite charges to rapidly and thoroughly destroy classified materials, preventing them from falling into enemy hands. This application has become increasingly important in the age of digital warfare, where protecting sensitive information is paramount.

The development of thermite-based reactive armor has significantly enhanced vehicle protection in combat situations. When integrated into armor systems, thermite reactions can help dissipate the energy of incoming projectiles, reducing their penetrative power and improving crew survivability. This technology has been particularly beneficial for armored personnel carriers and main battle tanks operating in high-threat environments.

Thermite has also found applications in underwater demolitions and sabotage operations. Special forces units have employed thermite charges for disabling ship propellers, rudders, and other critical maritime infrastructure. The material's ability to burn underwater and generate extreme heat makes it an effective tool for these specialized missions.

In the realm of pyrotechnics, thermite-based compositions have been used to create high-intensity flares and signaling devices. These applications leverage thermite's bright, long-lasting burn characteristics to enhance visibility and communication in battlefield conditions. Additionally, thermite has been incorporated into some types of tracer ammunition, improving target acquisition and fire correction capabilities for military personnel.

Technical Challenges

The development of thermite technology in armament and defense faces several significant technical challenges. One of the primary issues is controlling the reaction rate and temperature of thermite mixtures. While the high heat output of thermite reactions is desirable for certain applications, it can also lead to unpredictable and potentially dangerous situations if not properly managed.

Another challenge lies in the stability and storage of thermite compounds. Many thermite mixtures are highly reactive and can be sensitive to environmental factors such as humidity, temperature, and mechanical shock. Ensuring long-term stability without compromising performance is a critical area of ongoing research and development.

The precision of thermite reactions presents another technical hurdle. In military applications, such as in armor-piercing munitions, the ability to focus and direct the thermite reaction with high accuracy is crucial. Achieving this level of precision while maintaining the desired destructive power requires advanced engineering and materials science.

Miniaturization of thermite-based systems is an additional challenge. As modern warfare increasingly relies on compact and lightweight equipment, there is a growing demand for smaller thermite devices that maintain their effectiveness. This necessitates innovations in both the chemical composition of thermites and the design of delivery systems.

Environmental concerns also pose significant challenges. The use of thermite in military operations can leave behind toxic residues and cause long-lasting environmental damage. Developing more environmentally friendly thermite formulations that maintain their effectiveness while reducing ecological impact is a key area of research.

Safety considerations in handling and deployment of thermite-based weapons and defensive systems remain a constant challenge. The extreme heat and potential for uncontrolled reactions make thermite inherently dangerous to work with, requiring robust safety protocols and protective equipment.

Lastly, the development of countermeasures against thermite-based weapons is an ongoing technical challenge. As thermite technology advances, so too must the methods for detecting, neutralizing, and protecting against these powerful incendiary agents. This includes research into heat-resistant materials, advanced fire suppression systems, and early detection technologies.

Another challenge lies in the stability and storage of thermite compounds. Many thermite mixtures are highly reactive and can be sensitive to environmental factors such as humidity, temperature, and mechanical shock. Ensuring long-term stability without compromising performance is a critical area of ongoing research and development.

The precision of thermite reactions presents another technical hurdle. In military applications, such as in armor-piercing munitions, the ability to focus and direct the thermite reaction with high accuracy is crucial. Achieving this level of precision while maintaining the desired destructive power requires advanced engineering and materials science.

Miniaturization of thermite-based systems is an additional challenge. As modern warfare increasingly relies on compact and lightweight equipment, there is a growing demand for smaller thermite devices that maintain their effectiveness. This necessitates innovations in both the chemical composition of thermites and the design of delivery systems.

Environmental concerns also pose significant challenges. The use of thermite in military operations can leave behind toxic residues and cause long-lasting environmental damage. Developing more environmentally friendly thermite formulations that maintain their effectiveness while reducing ecological impact is a key area of research.

Safety considerations in handling and deployment of thermite-based weapons and defensive systems remain a constant challenge. The extreme heat and potential for uncontrolled reactions make thermite inherently dangerous to work with, requiring robust safety protocols and protective equipment.

Lastly, the development of countermeasures against thermite-based weapons is an ongoing technical challenge. As thermite technology advances, so too must the methods for detecting, neutralizing, and protecting against these powerful incendiary agents. This includes research into heat-resistant materials, advanced fire suppression systems, and early detection technologies.

Current Formulations

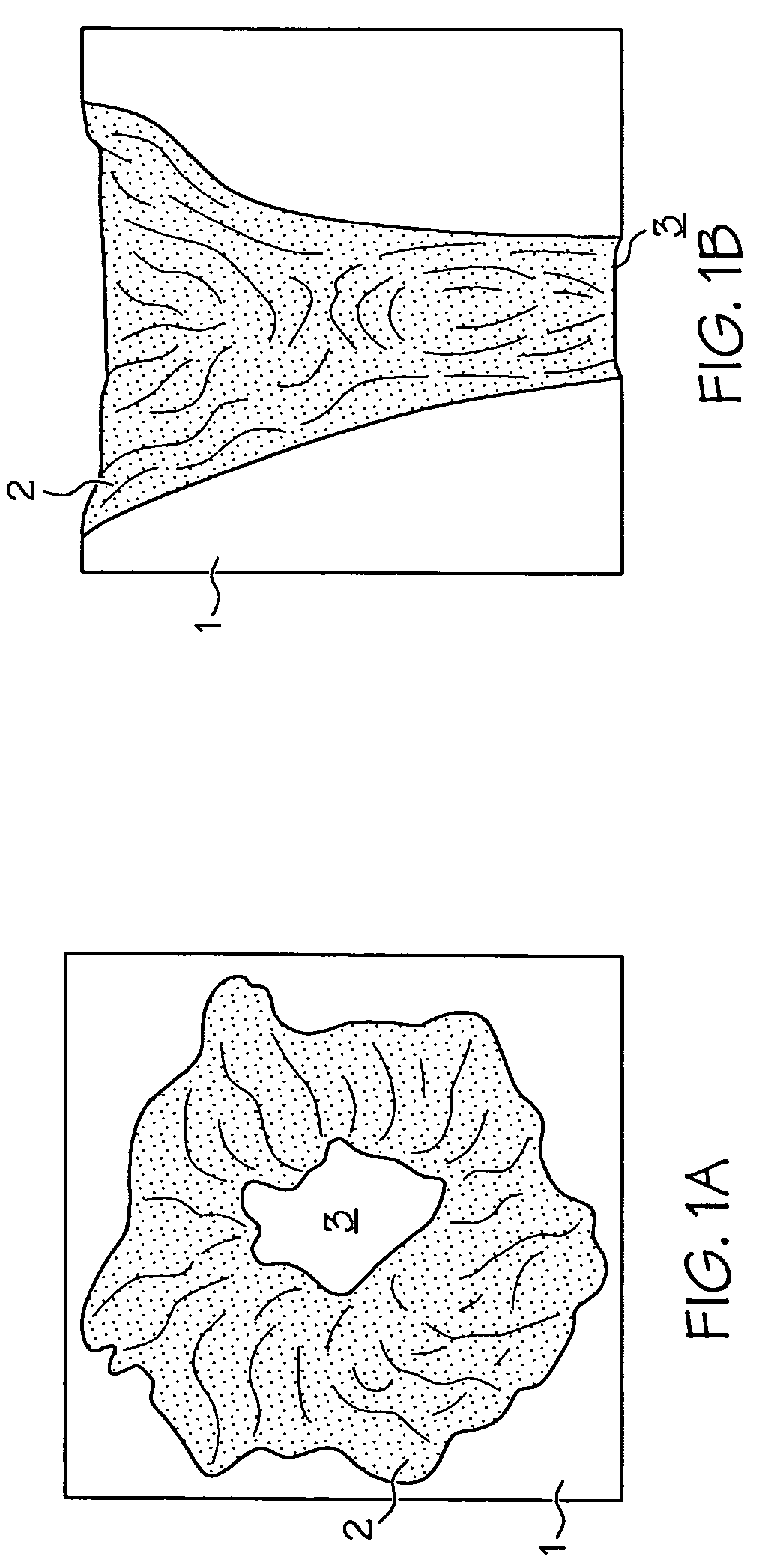

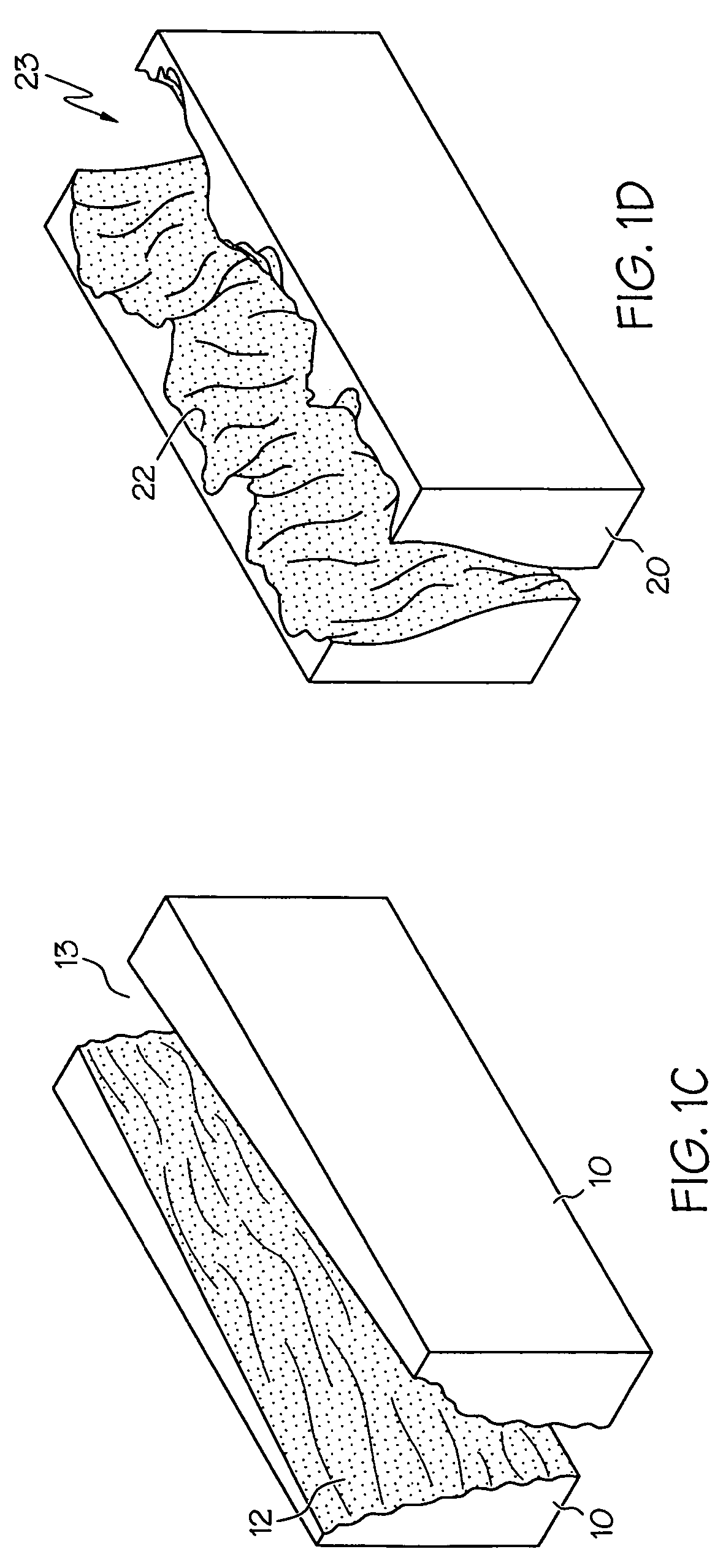

01 Thermite composition and applications

Thermite is a pyrotechnic composition of metal powder fuel and metal oxide. It's used in various applications including welding, incendiary devices, and metal purification. The reaction produces intense heat and molten metal, making it suitable for specialized industrial and military uses.- Thermite composition and manufacturing: Thermite compositions typically consist of metal oxides and aluminum powder. The manufacturing process involves careful mixing and preparation of these components to create a stable and effective thermite mixture. Various additives and processing techniques can be used to enhance the performance and safety of thermite compositions.

- Thermite welding applications: Thermite reactions are widely used in welding applications, particularly for joining railway tracks and large metal components. The process involves igniting a thermite mixture in a mold surrounding the parts to be joined, resulting in a strong, seamless weld. Specialized equipment and techniques have been developed to improve the efficiency and quality of thermite welding.

- Thermite in military and defense applications: Thermite reactions are utilized in various military and defense applications, including incendiary devices, armor-piercing projectiles, and emergency destruction of sensitive equipment. Research in this area focuses on improving the effectiveness, safety, and controllability of thermite-based systems for specific military requirements.

- Thermite for metal purification and production: Thermite reactions can be used in metallurgical processes for the production and purification of metals. This includes the reduction of metal oxides to produce pure metals and the creation of metal alloys. The high temperatures generated by thermite reactions make them suitable for certain specialized metallurgical applications.

- Safety and control mechanisms for thermite reactions: Due to the high temperatures and rapid reactions involved in thermite processes, safety and control mechanisms are crucial. This includes the development of specialized ignition systems, containment vessels, and monitoring equipment. Research in this area aims to improve the safety of thermite handling and use across various applications.

02 Thermite in downhole tools and well operations

Thermite reactions are utilized in downhole tools for oil and gas wells. These tools employ thermite to generate heat for cutting, sealing, or perforating operations in wellbores. The controlled thermite reaction provides a reliable and powerful heat source in challenging downhole environments.Expand Specific Solutions03 Enhanced thermite formulations

Research focuses on improving thermite formulations for increased performance and safety. This includes developing nanoparticle-based thermites, adjusting fuel-to-oxidizer ratios, and incorporating additives to control reaction rates and energy output. These enhancements aim to optimize thermite for specific applications.Expand Specific Solutions04 Thermite in additive manufacturing

Thermite reactions are being explored in additive manufacturing processes. This innovative approach uses the heat generated by thermite reactions to fuse metal powders, potentially enabling new methods for 3D printing of metal components or rapid prototyping in challenging environments.Expand Specific Solutions05 Safety and control mechanisms for thermite reactions

Given the intense nature of thermite reactions, significant emphasis is placed on developing safety mechanisms and controlled ignition systems. This includes designing specialized containers, remote ignition methods, and reaction moderators to ensure safe handling and deployment of thermite in various applications.Expand Specific Solutions

Industry Leaders

The thermite technology sector is in a mature stage of development, with ongoing advancements in armament and defense applications. The market size is substantial, driven by military and industrial demands. Technological maturity is high, with established players like Lockheed Martin Corp., Raytheon Co., and Northrop Grumman Systems Corp. leading innovation. Research institutions such as Naval Research Laboratory and Beijing Institute of Technology contribute to cutting-edge developments. Emerging companies like BiSN Oil Tools Ltd. and Anasphere, Inc. are exploring niche applications, while universities like Nanjing University of Science & Technology and Central South University focus on fundamental research. The competitive landscape is characterized by a mix of defense contractors, specialized firms, and academic institutions collaborating to push the boundaries of thermite technology.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed a novel underwater thermite welding system for rapid repair and construction of naval vessels and underwater structures. This technology utilizes specially formulated thermite mixtures that can react and generate high temperatures even in submerged conditions. The system includes a waterproof ignition mechanism and a containment apparatus that allows for precise application of the thermite weld. Additionally, they have incorporated additives to the thermite mixture that enhance its adhesion to wet surfaces and improve the quality of the resulting weld under water.

Strengths: Enables rapid underwater repairs, potential for significant time and cost savings in naval operations. Weaknesses: Limited to specific types of materials and joint configurations, potential environmental concerns regarding underwater use of reactive materials.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based reactive materials for use in armament and defense applications. Their technology focuses on enhancing the energy release and controllability of thermite reactions. They have engineered nanostructured thermite composites that offer improved ignition sensitivity and energy output compared to traditional thermite formulations. These advanced materials are designed for use in penetrating warheads, incendiary devices, and specialized demolition charges. Lockheed Martin's approach involves precise control of particle size distribution and the incorporation of catalysts to optimize reaction kinetics.

Strengths: High energy density, improved ignition reliability, and enhanced performance in extreme environments. Weaknesses: Potential safety concerns during manufacturing and storage, higher production costs compared to conventional explosives.

Key Innovations

Thermite torch formulation including molybdenum trioxide

PatentInactiveUS20100089507A1

Innovation

- A thermite formulation using a magnalium alloy as the metal fuel and a combination of CuO and MoO3 as oxidizers, with a binder, optimized to provide excellent material perforation and low toxicity, where the magnalium alloy comprises about 3-35 weight percent, CuO 30-70 weight percent, MoO3 15-35 weight percent, and a small amount of binder, such as polytetrafluoroethylene.

Thermite charge

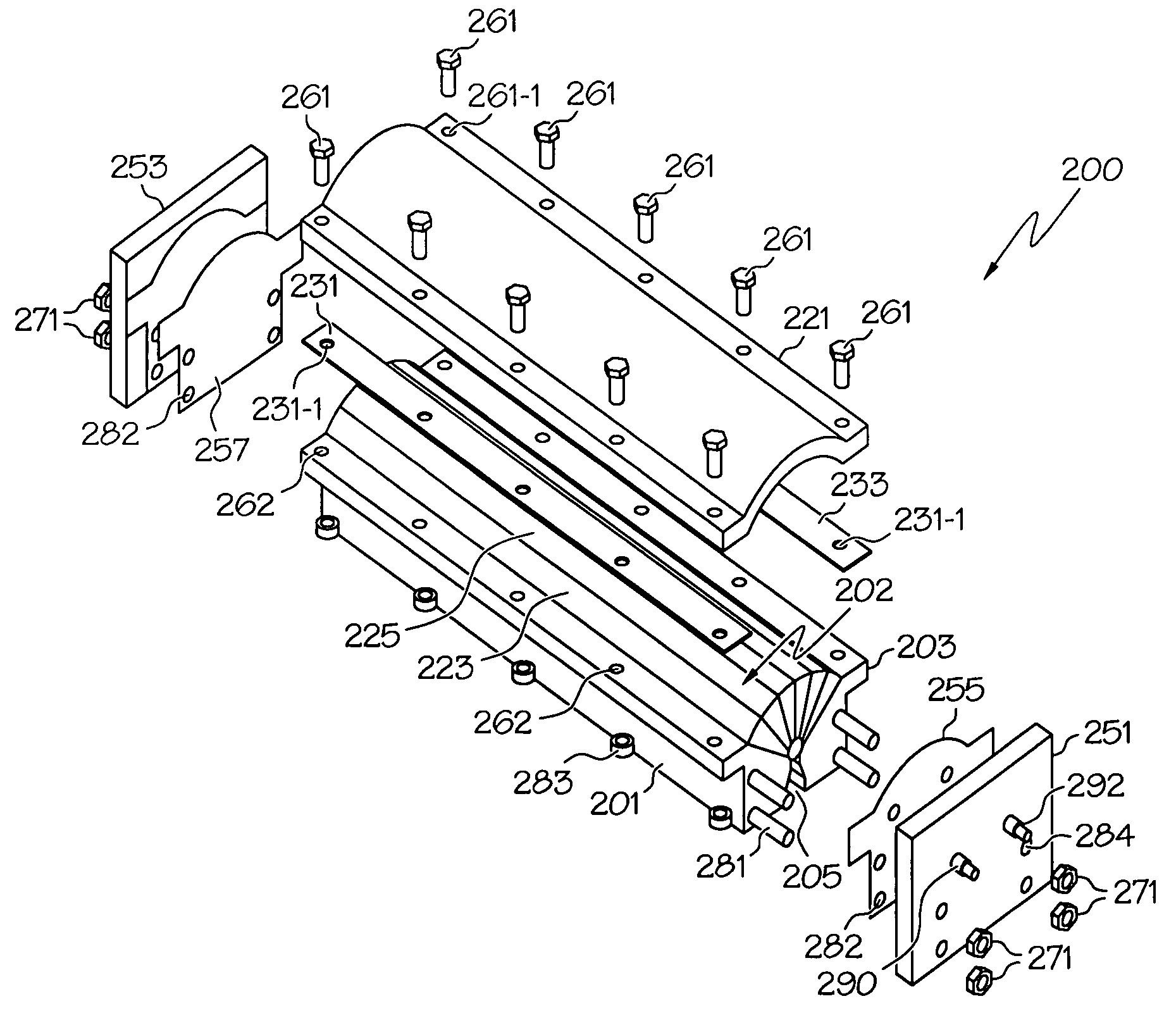

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Safety Regulations

The development and use of thermite in armament and defense technology necessitate stringent safety regulations to mitigate potential risks and ensure responsible handling. These regulations encompass various aspects of thermite production, storage, transportation, and application.

Manufacturing facilities producing thermite are subject to strict safety protocols. These include proper ventilation systems, fire suppression equipment, and protective gear for workers. Regular safety inspections and maintenance checks are mandated to prevent accidents and ensure compliance with industry standards.

Storage of thermite requires specialized facilities designed to minimize the risk of accidental ignition. Temperature-controlled environments, moisture-resistant containers, and secure access controls are essential components of safe storage practices. Inventory management systems are implemented to track quantities and monitor shelf life.

Transportation of thermite is heavily regulated to prevent accidents during transit. Specialized vehicles equipped with fire suppression systems and impact-resistant containers are used. Drivers undergo specific training in handling hazardous materials, and transportation routes are carefully planned to avoid populated areas when possible.

Safety regulations also extend to the application of thermite in military and defense contexts. Personnel handling thermite must receive comprehensive training on proper usage, potential hazards, and emergency procedures. Protective equipment, including fire-resistant clothing and respiratory protection, is mandatory during operations involving thermite.

Environmental considerations are increasingly important in thermite regulations. Guidelines for proper disposal of unused thermite and contaminated materials are in place to prevent environmental damage. Cleanup protocols for accidental spills or releases are also part of the regulatory framework.

Research and development activities involving thermite are subject to oversight to ensure ethical and safe practices. Experimental protocols must be approved by safety committees, and all testing must be conducted in controlled environments with appropriate safety measures in place.

International agreements and treaties play a role in harmonizing safety regulations across borders. These agreements aim to prevent the misuse of thermite and ensure consistent safety standards globally. Cooperation between nations includes sharing best practices and coordinating efforts to combat illegal trafficking of thermite materials.

As advancements in thermite technology continue, safety regulations evolve to address new challenges. Ongoing research into safer formulations and application methods informs updates to regulatory frameworks, ensuring that safety measures keep pace with technological progress in the field of armament and defense.

Manufacturing facilities producing thermite are subject to strict safety protocols. These include proper ventilation systems, fire suppression equipment, and protective gear for workers. Regular safety inspections and maintenance checks are mandated to prevent accidents and ensure compliance with industry standards.

Storage of thermite requires specialized facilities designed to minimize the risk of accidental ignition. Temperature-controlled environments, moisture-resistant containers, and secure access controls are essential components of safe storage practices. Inventory management systems are implemented to track quantities and monitor shelf life.

Transportation of thermite is heavily regulated to prevent accidents during transit. Specialized vehicles equipped with fire suppression systems and impact-resistant containers are used. Drivers undergo specific training in handling hazardous materials, and transportation routes are carefully planned to avoid populated areas when possible.

Safety regulations also extend to the application of thermite in military and defense contexts. Personnel handling thermite must receive comprehensive training on proper usage, potential hazards, and emergency procedures. Protective equipment, including fire-resistant clothing and respiratory protection, is mandatory during operations involving thermite.

Environmental considerations are increasingly important in thermite regulations. Guidelines for proper disposal of unused thermite and contaminated materials are in place to prevent environmental damage. Cleanup protocols for accidental spills or releases are also part of the regulatory framework.

Research and development activities involving thermite are subject to oversight to ensure ethical and safe practices. Experimental protocols must be approved by safety committees, and all testing must be conducted in controlled environments with appropriate safety measures in place.

International agreements and treaties play a role in harmonizing safety regulations across borders. These agreements aim to prevent the misuse of thermite and ensure consistent safety standards globally. Cooperation between nations includes sharing best practices and coordinating efforts to combat illegal trafficking of thermite materials.

As advancements in thermite technology continue, safety regulations evolve to address new challenges. Ongoing research into safer formulations and application methods informs updates to regulatory frameworks, ensuring that safety measures keep pace with technological progress in the field of armament and defense.

Environmental Impact

The environmental impact of thermite technology in armament and defense applications is a critical consideration that demands thorough examination. Thermite reactions, characterized by their high-temperature exothermic nature, can have significant consequences for the surrounding ecosystem when deployed in military contexts.

One of the primary environmental concerns associated with thermite use is soil contamination. The intense heat generated during thermite reactions can alter soil composition and structure, potentially rendering affected areas infertile for extended periods. This thermal alteration may lead to the destruction of beneficial microorganisms and disrupt local nutrient cycles, impacting vegetation growth and ecosystem balance.

Atmospheric pollution is another notable environmental issue stemming from thermite deployment. The combustion process releases various particulate matter and gaseous emissions, including metal oxides and carbon dioxide. These emissions can contribute to air quality degradation, potentially affecting both human health and wildlife in the vicinity of thermite use.

Water resources are also at risk from thermite applications. Runoff from thermite-affected areas can introduce harmful substances into water bodies, potentially contaminating groundwater and surface water sources. This contamination may have far-reaching effects on aquatic ecosystems and pose risks to human populations relying on these water sources.

The use of thermite in military operations can lead to long-term ecological disruptions. The intense heat and chemical reactions associated with thermite can alter habitat structures, potentially displacing or harming local flora and fauna. Recovery of affected ecosystems may require significant time and resources, depending on the extent and frequency of thermite use.

Efforts to mitigate the environmental impact of thermite technology have led to research into more eco-friendly formulations and controlled application methods. Some advancements focus on developing thermite compositions that produce fewer harmful byproducts or designing containment systems to limit the spread of contaminants.

Environmental monitoring and remediation strategies are increasingly integrated into defense planning to address the potential ecological consequences of thermite use. These approaches aim to assess and minimize long-term environmental damage, ensuring that military operations do not result in lasting harm to ecosystems.

As the defense industry continues to advance thermite technology, balancing operational effectiveness with environmental stewardship remains a crucial challenge. Future developments in this field will likely prioritize innovations that reduce ecological footprints while maintaining the strategic advantages offered by thermite-based armaments and defense systems.

One of the primary environmental concerns associated with thermite use is soil contamination. The intense heat generated during thermite reactions can alter soil composition and structure, potentially rendering affected areas infertile for extended periods. This thermal alteration may lead to the destruction of beneficial microorganisms and disrupt local nutrient cycles, impacting vegetation growth and ecosystem balance.

Atmospheric pollution is another notable environmental issue stemming from thermite deployment. The combustion process releases various particulate matter and gaseous emissions, including metal oxides and carbon dioxide. These emissions can contribute to air quality degradation, potentially affecting both human health and wildlife in the vicinity of thermite use.

Water resources are also at risk from thermite applications. Runoff from thermite-affected areas can introduce harmful substances into water bodies, potentially contaminating groundwater and surface water sources. This contamination may have far-reaching effects on aquatic ecosystems and pose risks to human populations relying on these water sources.

The use of thermite in military operations can lead to long-term ecological disruptions. The intense heat and chemical reactions associated with thermite can alter habitat structures, potentially displacing or harming local flora and fauna. Recovery of affected ecosystems may require significant time and resources, depending on the extent and frequency of thermite use.

Efforts to mitigate the environmental impact of thermite technology have led to research into more eco-friendly formulations and controlled application methods. Some advancements focus on developing thermite compositions that produce fewer harmful byproducts or designing containment systems to limit the spread of contaminants.

Environmental monitoring and remediation strategies are increasingly integrated into defense planning to address the potential ecological consequences of thermite use. These approaches aim to assess and minimize long-term environmental damage, ensuring that military operations do not result in lasting harm to ecosystems.

As the defense industry continues to advance thermite technology, balancing operational effectiveness with environmental stewardship remains a crucial challenge. Future developments in this field will likely prioritize innovations that reduce ecological footprints while maintaining the strategic advantages offered by thermite-based armaments and defense systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!