Thermite Reactions: Balancing Energy Input and Output

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Reaction Fundamentals and Objectives

Thermite reactions have been a subject of fascination and study for over a century, with their origins dating back to the late 19th century. These highly exothermic reactions involve the reduction of metal oxides by a more reactive metal, typically aluminum, resulting in the production of intense heat and light. The evolution of thermite technology has been driven by the need for efficient, controlled energy release in various applications.

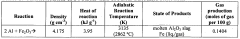

The fundamental principle behind thermite reactions lies in the transfer of oxygen from the metal oxide to the more reactive metal. This process is governed by the difference in the heat of formation of the oxides involved. The most common thermite reaction utilizes aluminum as the reducing agent and iron oxide as the oxidizer, though numerous other combinations have been explored over the years.

As research in this field progressed, scientists and engineers began to focus on optimizing the energy balance within thermite reactions. This optimization involves carefully managing the energy input required to initiate the reaction against the energy output produced. The goal is to achieve maximum efficiency while maintaining control over the reaction's intensity and duration.

One of the key objectives in thermite reaction research is to enhance the reaction's energy density. This involves developing formulations that can produce more heat and light per unit mass of reactants. Researchers have experimented with various metal-oxide combinations and particle sizes to achieve this goal, leading to the development of more potent and versatile thermite mixtures.

Another critical aspect of thermite reaction development is the control of reaction kinetics. By manipulating factors such as particle size distribution, additives, and reaction vessel design, researchers aim to fine-tune the rate at which energy is released. This control is essential for applications that require precise energy delivery or sustained heat output.

The pursuit of safer and more stable thermite formulations represents another significant objective in this field. As the applications for thermite reactions expanded, so did the need for compositions that could be handled and stored safely without compromising their performance. This has led to the development of passivated powders and stabilized mixtures that reduce the risk of accidental ignition while maintaining their reactive properties.

In recent years, the focus has shifted towards developing environmentally friendly thermite reactions. This involves exploring alternatives to traditional metal oxides that may have harmful environmental impacts. Researchers are investigating the use of sustainable materials and reaction products that minimize ecological footprints without sacrificing performance.

The fundamental principle behind thermite reactions lies in the transfer of oxygen from the metal oxide to the more reactive metal. This process is governed by the difference in the heat of formation of the oxides involved. The most common thermite reaction utilizes aluminum as the reducing agent and iron oxide as the oxidizer, though numerous other combinations have been explored over the years.

As research in this field progressed, scientists and engineers began to focus on optimizing the energy balance within thermite reactions. This optimization involves carefully managing the energy input required to initiate the reaction against the energy output produced. The goal is to achieve maximum efficiency while maintaining control over the reaction's intensity and duration.

One of the key objectives in thermite reaction research is to enhance the reaction's energy density. This involves developing formulations that can produce more heat and light per unit mass of reactants. Researchers have experimented with various metal-oxide combinations and particle sizes to achieve this goal, leading to the development of more potent and versatile thermite mixtures.

Another critical aspect of thermite reaction development is the control of reaction kinetics. By manipulating factors such as particle size distribution, additives, and reaction vessel design, researchers aim to fine-tune the rate at which energy is released. This control is essential for applications that require precise energy delivery or sustained heat output.

The pursuit of safer and more stable thermite formulations represents another significant objective in this field. As the applications for thermite reactions expanded, so did the need for compositions that could be handled and stored safely without compromising their performance. This has led to the development of passivated powders and stabilized mixtures that reduce the risk of accidental ignition while maintaining their reactive properties.

In recent years, the focus has shifted towards developing environmentally friendly thermite reactions. This involves exploring alternatives to traditional metal oxides that may have harmful environmental impacts. Researchers are investigating the use of sustainable materials and reaction products that minimize ecological footprints without sacrificing performance.

Market Applications of Thermite Reactions

Thermite reactions have found diverse applications across various industries due to their unique properties and high energy output. In the manufacturing sector, thermite welding has become a crucial technique for joining railway tracks, ensuring seamless connections and improved durability. This method is particularly valuable in remote locations where traditional welding equipment may be impractical.

The construction industry has also embraced thermite reactions for specialized applications. Thermite can be used for underwater welding and repair of large metal structures, such as offshore oil platforms and ship hulls. Its ability to generate intense heat rapidly makes it ideal for these challenging environments where conventional welding techniques may be ineffective.

In the field of metallurgy, thermite reactions play a significant role in the production of metal alloys and purification processes. The high temperatures generated by thermite reactions enable the reduction of metal oxides, facilitating the extraction of pure metals from their ores. This application is particularly important in the production of specialty metals and alloys used in advanced technologies.

The aerospace and defense industries utilize thermite reactions in various applications, including the development of incendiary devices and pyrotechnics. Thermite-based formulations are used in military ordnance for their ability to penetrate armor and ignite fuel supplies. Additionally, thermite reactions are employed in the design of emergency flares and signaling devices due to their intense light and heat output.

In the realm of materials science, thermite reactions are being explored for the synthesis of advanced materials. Researchers are investigating the use of controlled thermite reactions to produce nanoparticles and novel composite materials with enhanced properties. This application has potential implications for the development of next-generation electronics, catalysts, and energy storage devices.

The energy sector is also exploring the potential of thermite reactions for thermal energy storage systems. The high energy density and rapid heat release characteristics of thermite reactions make them attractive candidates for developing compact and efficient thermal batteries. These systems could play a crucial role in renewable energy integration and grid stabilization.

As the demand for sustainable technologies grows, researchers are investigating environmentally friendly applications of thermite reactions. One promising area is the development of thermite-based methods for recycling and waste treatment. These techniques could potentially offer more efficient and cost-effective solutions for processing electronic waste and recovering valuable metals from industrial byproducts.

The construction industry has also embraced thermite reactions for specialized applications. Thermite can be used for underwater welding and repair of large metal structures, such as offshore oil platforms and ship hulls. Its ability to generate intense heat rapidly makes it ideal for these challenging environments where conventional welding techniques may be ineffective.

In the field of metallurgy, thermite reactions play a significant role in the production of metal alloys and purification processes. The high temperatures generated by thermite reactions enable the reduction of metal oxides, facilitating the extraction of pure metals from their ores. This application is particularly important in the production of specialty metals and alloys used in advanced technologies.

The aerospace and defense industries utilize thermite reactions in various applications, including the development of incendiary devices and pyrotechnics. Thermite-based formulations are used in military ordnance for their ability to penetrate armor and ignite fuel supplies. Additionally, thermite reactions are employed in the design of emergency flares and signaling devices due to their intense light and heat output.

In the realm of materials science, thermite reactions are being explored for the synthesis of advanced materials. Researchers are investigating the use of controlled thermite reactions to produce nanoparticles and novel composite materials with enhanced properties. This application has potential implications for the development of next-generation electronics, catalysts, and energy storage devices.

The energy sector is also exploring the potential of thermite reactions for thermal energy storage systems. The high energy density and rapid heat release characteristics of thermite reactions make them attractive candidates for developing compact and efficient thermal batteries. These systems could play a crucial role in renewable energy integration and grid stabilization.

As the demand for sustainable technologies grows, researchers are investigating environmentally friendly applications of thermite reactions. One promising area is the development of thermite-based methods for recycling and waste treatment. These techniques could potentially offer more efficient and cost-effective solutions for processing electronic waste and recovering valuable metals from industrial byproducts.

Current Challenges in Thermite Energy Balance

Thermite reactions, known for their high exothermic nature, present significant challenges in achieving optimal energy balance. One of the primary issues is controlling the reaction rate to prevent rapid, uncontrolled energy release. The intense heat generated during these reactions can lead to safety concerns and difficulties in harnessing the energy effectively for practical applications.

The stoichiometry of thermite reactions poses another challenge. Achieving the right balance of reactants is crucial for maximizing energy output while minimizing waste. Variations in particle size, purity, and composition of the metal fuel and metal oxide can significantly impact the reaction efficiency and energy balance.

Heat dissipation and thermal management represent ongoing challenges in thermite systems. The extreme temperatures produced can cause material degradation and compromise the structural integrity of containment vessels. Developing heat-resistant materials and efficient cooling mechanisms is essential for maintaining energy balance and ensuring system longevity.

Another critical issue is the optimization of energy transfer from the thermite reaction to the intended application. Inefficiencies in this process can result in significant energy losses, reducing the overall effectiveness of the system. Researchers are exploring various methods to improve energy coupling and utilization, including the use of novel reaction vessel designs and advanced heat transfer materials.

The scalability of thermite reactions presents additional challenges in maintaining energy balance. As the scale of the reaction increases, issues such as heat accumulation, pressure buildup, and reaction propagation become more pronounced. Developing strategies to manage these factors across different scales is crucial for the practical implementation of thermite-based technologies.

Environmental considerations also play a role in the challenges of thermite energy balance. The byproducts of these reactions can be environmentally harmful, necessitating the development of cleaner, more sustainable thermite compositions. Balancing the energy output with environmental impact is an ongoing area of research and development.

Lastly, the precise measurement and control of energy input and output in thermite reactions remain technically challenging. Advanced sensing and monitoring technologies are needed to accurately assess reaction parameters in real-time, allowing for better control and optimization of the energy balance. This includes developing robust instrumentation capable of withstanding the extreme conditions inherent in thermite reactions.

The stoichiometry of thermite reactions poses another challenge. Achieving the right balance of reactants is crucial for maximizing energy output while minimizing waste. Variations in particle size, purity, and composition of the metal fuel and metal oxide can significantly impact the reaction efficiency and energy balance.

Heat dissipation and thermal management represent ongoing challenges in thermite systems. The extreme temperatures produced can cause material degradation and compromise the structural integrity of containment vessels. Developing heat-resistant materials and efficient cooling mechanisms is essential for maintaining energy balance and ensuring system longevity.

Another critical issue is the optimization of energy transfer from the thermite reaction to the intended application. Inefficiencies in this process can result in significant energy losses, reducing the overall effectiveness of the system. Researchers are exploring various methods to improve energy coupling and utilization, including the use of novel reaction vessel designs and advanced heat transfer materials.

The scalability of thermite reactions presents additional challenges in maintaining energy balance. As the scale of the reaction increases, issues such as heat accumulation, pressure buildup, and reaction propagation become more pronounced. Developing strategies to manage these factors across different scales is crucial for the practical implementation of thermite-based technologies.

Environmental considerations also play a role in the challenges of thermite energy balance. The byproducts of these reactions can be environmentally harmful, necessitating the development of cleaner, more sustainable thermite compositions. Balancing the energy output with environmental impact is an ongoing area of research and development.

Lastly, the precise measurement and control of energy input and output in thermite reactions remain technically challenging. Advanced sensing and monitoring technologies are needed to accurately assess reaction parameters in real-time, allowing for better control and optimization of the energy balance. This includes developing robust instrumentation capable of withstanding the extreme conditions inherent in thermite reactions.

Existing Methods for Thermite Energy Control

01 Thermite reaction composition and energy release

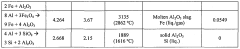

Thermite reactions involve the combination of metal oxides and aluminum, resulting in a highly exothermic reaction. The composition of the thermite mixture significantly affects the energy balance, with various metal oxides producing different levels of heat and reaction products. Optimizing the ratio of components can enhance energy output and control reaction rates.- Thermite reaction composition and energy release: Thermite reactions involve the combustion of metal powders with metal oxides, resulting in a highly exothermic reaction. The composition of the thermite mixture significantly affects the energy balance, with factors such as particle size, reactant ratios, and additives influencing the reaction rate and heat output. Optimizing these parameters can lead to improved energy efficiency and controlled heat release.

- Applications in welding and metal joining: Thermite reactions are utilized in welding and metal joining processes due to their high heat generation. The energy balance in these applications is crucial for achieving proper fusion and joint strength. Controlled energy release allows for precise heating of the materials to be joined, while minimizing thermal damage to surrounding areas. Innovations in this field focus on improving energy efficiency and reducing waste heat.

- Energy harvesting and power generation: The high energy output of thermite reactions can be harnessed for power generation and energy harvesting applications. Research in this area focuses on converting the thermal energy from thermite reactions into usable electrical or mechanical energy. Innovations include the development of thermite-based heat engines, thermoelectric generators, and energy storage systems that capitalize on the rapid heat release of these reactions.

- Safety and control mechanisms: Managing the energy balance in thermite reactions is crucial for safety and control. Innovations in this area include the development of reaction inhibitors, controlled ignition systems, and containment vessels designed to withstand the high temperatures and pressures generated. These advancements aim to improve the safety of thermite-based processes while maintaining their energy efficiency and effectiveness.

- Novel thermite compositions and additives: Research into novel thermite compositions and additives aims to optimize the energy balance of these reactions. This includes the exploration of nanoscale materials, alternative metal-oxide combinations, and the incorporation of catalysts or moderators. These innovations seek to enhance reaction efficiency, control energy release rates, and tailor the thermite reaction properties for specific applications.

02 Energy balance in thermite-based welding and cutting

Thermite reactions are utilized in welding and cutting applications, where the energy balance is crucial for achieving desired results. The heat generated from the reaction is used to melt and join metals or create precise cuts. Controlling the energy release and distribution is essential for ensuring effective and safe operations in various industrial settings.Expand Specific Solutions03 Thermite reaction initiation and propagation

The initiation and propagation of thermite reactions play a significant role in the overall energy balance. Various methods are employed to start the reaction, including electrical ignition systems and chemical initiators. The propagation rate and uniformity of the reaction affect the energy distribution and efficiency of the process.Expand Specific Solutions04 Heat management and containment in thermite reactions

Managing and containing the heat generated by thermite reactions is crucial for safety and efficiency. Specialized containers, heat-resistant materials, and cooling systems are employed to control the energy release and prevent unintended consequences. Proper heat management ensures optimal energy utilization and reduces risks associated with high-temperature reactions.Expand Specific Solutions05 Energy recovery and utilization from thermite reactions

Efforts are made to recover and utilize the energy released during thermite reactions for various applications. This includes capturing thermal energy for power generation, using the heat for material processing, or employing the reaction products in secondary processes. Innovative approaches aim to maximize the overall energy efficiency of thermite-based systems.Expand Specific Solutions

Key Players in Thermite Research and Industry

The thermite reaction market is in a growth phase, driven by increasing applications in various industries. The market size is expanding, with a projected CAGR of 4-5% over the next five years. Technologically, thermite reactions are well-established, but innovation continues in energy efficiency and control. Companies like Elkem ASA, Alcoa, Inc., and Arconic, Inc. are leading in material development, while Battelle Memorial Institute and Lockheed Martin Corp. focus on advanced applications. Universities such as Xi'an Jiaotong University and Zhejiang University contribute to fundamental research. The industry is seeing a shift towards more precise energy balance and safer, controlled reactions, with firms like Heatgen LLC and NCC Nano LLC developing novel approaches to optimize energy input and output in thermite reactions.

Battelle Memorial Institute

Technical Solution: Battelle has developed advanced thermite formulations that optimize energy input and output for various applications. Their approach involves precise control of particle size distribution and the use of additives to tailor the reaction kinetics. They have also implemented novel ignition methods, such as laser-induced initiation, to improve control over the reaction initiation and propagation. Battelle's research extends to the development of environmentally friendly thermite compositions that reduce harmful byproducts while maintaining high energy output.

Strengths: Extensive research capabilities, diverse application expertise, and advanced formulation techniques. Weaknesses: Potential high costs associated with specialized materials and equipment.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has focused on developing high-performance thermite reactions for military and aerospace applications. Their approach includes the use of nanoscale reactants to increase reaction rates and energy density. They have also explored the integration of thermite reactions with other energetic materials to create hybrid systems with enhanced performance. Lockheed Martin's research includes the development of controllable thermite reactions for use in propulsion systems and ordnance applications, with a focus on maximizing energy output while minimizing overall system weight.

Strengths: Cutting-edge research in nanomaterials and hybrid systems. Weaknesses: Limited applicability outside of defense and aerospace sectors.

Innovative Approaches to Thermite Efficiency

Solid-state thermite composition based heating device

PatentWO2010117857A2

Innovation

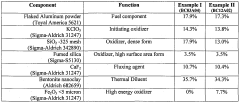

- A solid-state thermite reaction composition comprising a fuel component, primary oxidizer, initiating oxidizers, thermal diluent, and fluxing agents, integrated with a heating device featuring a reaction chamber and actuable trigger mechanism, allowing controlled thermite reactions for precise heat generation, with activation mechanisms like piezoelectric spark ignitors or exothermic couples to initiate the reaction safely.

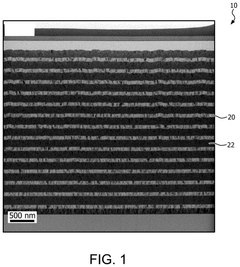

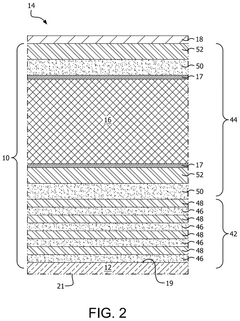

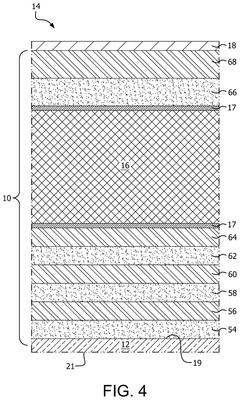

Fuzzy Interface Layer For Thermite And Primer Made From Thermite With Fuzzy Layer

PatentPendingUS20240361113A1

Innovation

- A layered thermite composite with a fuzzy interface layer is developed, comprising alternating metal oxide and reducing metal layers deposited on a substrate, where the fuzzy interface layer contains a mixture of reducing metal, reducing metal oxide, and metal oxide, enhancing ignition rates while protecting against oxidization and facilitating automated manufacturing.

Safety Regulations for Thermite Reactions

Safety regulations for thermite reactions are critical to ensure the responsible and secure handling of these highly exothermic processes. The primary focus of these regulations is to minimize risks associated with the intense heat and potential for fire or explosions during thermite reactions. Key safety measures include proper personal protective equipment (PPE), such as heat-resistant clothing, face shields, and gloves, which must be worn at all times when handling thermite materials or conducting reactions.

Workplace safety protocols are essential and typically involve designated reaction areas with fire-resistant surfaces, adequate ventilation, and readily accessible fire suppression equipment. The storage and transportation of thermite components are strictly regulated, with requirements for separate storage of fuel and oxidizer components to prevent accidental ignition. Proper labeling and documentation of all materials are mandatory to ensure traceability and appropriate handling.

Training and certification programs for personnel involved in thermite reactions are often required by regulatory bodies. These programs cover proper handling techniques, emergency response procedures, and the specific hazards associated with thermite reactions. Regular safety audits and inspections are typically mandated to ensure compliance with established protocols and to identify potential hazards before they lead to incidents.

Environmental considerations are also addressed in safety regulations, with guidelines for proper disposal of reaction byproducts and unreacted materials. Containment measures to prevent the spread of molten metal or slag are typically required, along with protocols for managing potential environmental contamination in case of accidents.

Emergency response plans are a crucial component of safety regulations, outlining procedures for dealing with fires, spills, or injuries related to thermite reactions. These plans often include coordination with local fire departments and emergency services to ensure a rapid and effective response in case of incidents.

Regulations also address the scale of thermite reactions, with different safety requirements for small-scale laboratory experiments versus large industrial applications. Scaling up reactions often requires additional safety measures and may be subject to more stringent oversight and permitting processes.

Continuous monitoring and record-keeping of reaction parameters, such as temperature and pressure, are typically required to ensure that reactions remain within safe operational limits. Advanced safety systems, including automatic shut-offs and remote monitoring capabilities, may be mandated for larger-scale operations to provide an additional layer of protection against potential accidents.

Workplace safety protocols are essential and typically involve designated reaction areas with fire-resistant surfaces, adequate ventilation, and readily accessible fire suppression equipment. The storage and transportation of thermite components are strictly regulated, with requirements for separate storage of fuel and oxidizer components to prevent accidental ignition. Proper labeling and documentation of all materials are mandatory to ensure traceability and appropriate handling.

Training and certification programs for personnel involved in thermite reactions are often required by regulatory bodies. These programs cover proper handling techniques, emergency response procedures, and the specific hazards associated with thermite reactions. Regular safety audits and inspections are typically mandated to ensure compliance with established protocols and to identify potential hazards before they lead to incidents.

Environmental considerations are also addressed in safety regulations, with guidelines for proper disposal of reaction byproducts and unreacted materials. Containment measures to prevent the spread of molten metal or slag are typically required, along with protocols for managing potential environmental contamination in case of accidents.

Emergency response plans are a crucial component of safety regulations, outlining procedures for dealing with fires, spills, or injuries related to thermite reactions. These plans often include coordination with local fire departments and emergency services to ensure a rapid and effective response in case of incidents.

Regulations also address the scale of thermite reactions, with different safety requirements for small-scale laboratory experiments versus large industrial applications. Scaling up reactions often requires additional safety measures and may be subject to more stringent oversight and permitting processes.

Continuous monitoring and record-keeping of reaction parameters, such as temperature and pressure, are typically required to ensure that reactions remain within safe operational limits. Advanced safety systems, including automatic shut-offs and remote monitoring capabilities, may be mandated for larger-scale operations to provide an additional layer of protection against potential accidents.

Environmental Impact of Thermite Processes

Thermite reactions, while powerful and efficient in their energy output, can have significant environmental impacts that must be carefully considered and managed. The primary environmental concerns associated with thermite processes revolve around air pollution, soil contamination, and potential water pollution.

Air pollution is a major issue due to the release of particulate matter and various gases during thermite reactions. The high temperatures generated in these reactions can lead to the formation of metal oxide fumes, which may contain toxic compounds depending on the specific metals involved. These airborne particles can contribute to respiratory problems and other health issues in nearby populations. Additionally, the release of carbon dioxide and other greenhouse gases during the reaction process contributes to global warming and climate change.

Soil contamination is another significant environmental concern. The residues from thermite reactions, including metal oxides and other byproducts, can accumulate in the soil surrounding the reaction site. This contamination may alter soil chemistry, potentially affecting plant growth and soil ecosystems. In some cases, these contaminants can persist in the environment for extended periods, leading to long-term ecological impacts.

Water pollution is a potential risk, particularly if thermite reactions occur near water sources or if proper containment measures are not in place. Runoff from contaminated soil or direct contact with reaction byproducts can introduce harmful substances into water systems. This can lead to the degradation of aquatic ecosystems and pose risks to human health if the affected water is used for drinking or irrigation.

The management of waste products from thermite processes is crucial in mitigating environmental impacts. Proper disposal and treatment of reaction residues are necessary to prevent the spread of contaminants. This may involve specialized handling procedures and dedicated disposal facilities to ensure that hazardous materials are contained and do not leach into the environment.

To address these environmental concerns, various mitigation strategies can be employed. These include the use of containment systems to capture and filter emissions, the implementation of dust suppression techniques, and the development of more environmentally friendly thermite compositions. Additionally, site selection for thermite processes should consider potential environmental impacts, avoiding sensitive ecosystems and water resources where possible.

Research into greener alternatives and process optimizations is ongoing, aiming to reduce the environmental footprint of thermite reactions while maintaining their effectiveness. This includes exploring the use of recyclable materials in thermite compositions and developing closed-loop systems that minimize waste and emissions. As environmental regulations become increasingly stringent, the thermite industry must continue to innovate and adapt to ensure sustainable practices that balance energy output with environmental stewardship.

Air pollution is a major issue due to the release of particulate matter and various gases during thermite reactions. The high temperatures generated in these reactions can lead to the formation of metal oxide fumes, which may contain toxic compounds depending on the specific metals involved. These airborne particles can contribute to respiratory problems and other health issues in nearby populations. Additionally, the release of carbon dioxide and other greenhouse gases during the reaction process contributes to global warming and climate change.

Soil contamination is another significant environmental concern. The residues from thermite reactions, including metal oxides and other byproducts, can accumulate in the soil surrounding the reaction site. This contamination may alter soil chemistry, potentially affecting plant growth and soil ecosystems. In some cases, these contaminants can persist in the environment for extended periods, leading to long-term ecological impacts.

Water pollution is a potential risk, particularly if thermite reactions occur near water sources or if proper containment measures are not in place. Runoff from contaminated soil or direct contact with reaction byproducts can introduce harmful substances into water systems. This can lead to the degradation of aquatic ecosystems and pose risks to human health if the affected water is used for drinking or irrigation.

The management of waste products from thermite processes is crucial in mitigating environmental impacts. Proper disposal and treatment of reaction residues are necessary to prevent the spread of contaminants. This may involve specialized handling procedures and dedicated disposal facilities to ensure that hazardous materials are contained and do not leach into the environment.

To address these environmental concerns, various mitigation strategies can be employed. These include the use of containment systems to capture and filter emissions, the implementation of dust suppression techniques, and the development of more environmentally friendly thermite compositions. Additionally, site selection for thermite processes should consider potential environmental impacts, avoiding sensitive ecosystems and water resources where possible.

Research into greener alternatives and process optimizations is ongoing, aiming to reduce the environmental footprint of thermite reactions while maintaining their effectiveness. This includes exploring the use of recyclable materials in thermite compositions and developing closed-loop systems that minimize waste and emissions. As environmental regulations become increasingly stringent, the thermite industry must continue to innovate and adapt to ensure sustainable practices that balance energy output with environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!