Thermite Safety Measures for Industrial Workshop Settings

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Safety Overview

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, is widely used in various industrial applications due to its high heat generation capabilities. However, its use in workshop settings presents significant safety challenges that require careful consideration and management.

The primary safety concern with thermite is its extremely high reaction temperature, which can exceed 2500°C. This intense heat can cause severe burns, ignite surrounding materials, and damage equipment if not properly contained. Additionally, the reaction produces molten metal and slag, which can cause fires and pose serious risks to personnel in the vicinity.

Another critical safety aspect is the potential for unintended ignition. Thermite can be ignited by various means, including electrical sparks, open flames, or even friction under certain conditions. This sensitivity necessitates strict handling and storage protocols to prevent accidental initiation of the reaction.

The byproducts of thermite reactions also present health hazards. The reaction generates metal fumes and particulate matter that can be harmful if inhaled. Proper ventilation and respiratory protection are essential to mitigate these risks in enclosed workshop environments.

Fire suppression for thermite-related incidents requires specialized approaches. Traditional water-based extinguishing methods are ineffective and can potentially exacerbate the situation due to the reaction's independence from external oxygen sources. Dry chemical agents or specially formulated foams are typically required for effective control.

To address these safety challenges, a comprehensive approach is necessary. This includes implementing strict handling procedures, providing appropriate personal protective equipment (PPE), designing proper storage facilities, and establishing emergency response protocols. Regular training and drills are crucial to ensure all personnel are prepared to handle thermite safely and respond effectively to potential incidents.

Engineering controls play a vital role in thermite safety. These may include designated reaction areas with heat-resistant materials, automated systems for mixing and ignition to minimize human exposure, and advanced fire detection and suppression systems tailored to thermite-specific risks.

Regulatory compliance is another key aspect of thermite safety in industrial settings. Adherence to relevant standards and regulations, such as those set by OSHA and NFPA in the United States, is essential for maintaining a safe work environment and avoiding legal liabilities.

The primary safety concern with thermite is its extremely high reaction temperature, which can exceed 2500°C. This intense heat can cause severe burns, ignite surrounding materials, and damage equipment if not properly contained. Additionally, the reaction produces molten metal and slag, which can cause fires and pose serious risks to personnel in the vicinity.

Another critical safety aspect is the potential for unintended ignition. Thermite can be ignited by various means, including electrical sparks, open flames, or even friction under certain conditions. This sensitivity necessitates strict handling and storage protocols to prevent accidental initiation of the reaction.

The byproducts of thermite reactions also present health hazards. The reaction generates metal fumes and particulate matter that can be harmful if inhaled. Proper ventilation and respiratory protection are essential to mitigate these risks in enclosed workshop environments.

Fire suppression for thermite-related incidents requires specialized approaches. Traditional water-based extinguishing methods are ineffective and can potentially exacerbate the situation due to the reaction's independence from external oxygen sources. Dry chemical agents or specially formulated foams are typically required for effective control.

To address these safety challenges, a comprehensive approach is necessary. This includes implementing strict handling procedures, providing appropriate personal protective equipment (PPE), designing proper storage facilities, and establishing emergency response protocols. Regular training and drills are crucial to ensure all personnel are prepared to handle thermite safely and respond effectively to potential incidents.

Engineering controls play a vital role in thermite safety. These may include designated reaction areas with heat-resistant materials, automated systems for mixing and ignition to minimize human exposure, and advanced fire detection and suppression systems tailored to thermite-specific risks.

Regulatory compliance is another key aspect of thermite safety in industrial settings. Adherence to relevant standards and regulations, such as those set by OSHA and NFPA in the United States, is essential for maintaining a safe work environment and avoiding legal liabilities.

Industrial Demand Analysis

The demand for thermite safety measures in industrial workshop settings has been steadily increasing due to the growing awareness of potential hazards associated with thermite reactions. Thermite, a mixture of metal powder fuel and metal oxide, is widely used in various industrial processes, including welding, metal purification, and incendiary devices. However, its highly exothermic nature poses significant safety risks in workshop environments.

Market analysis indicates a substantial growth in the global thermite market, driven by expanding applications in metallurgy, railway maintenance, and construction industries. This growth directly correlates with an increased demand for robust safety measures to mitigate risks associated with thermite handling and usage. The industrial safety equipment market, specifically for thermite-related applications, is projected to experience substantial growth in the coming years.

Key factors driving the demand for thermite safety measures include stringent workplace safety regulations, rising incidents of industrial accidents, and growing emphasis on worker protection. Regulatory bodies worldwide are implementing stricter guidelines for handling and storing thermite materials, compelling industries to invest in advanced safety technologies and protocols.

The construction sector, particularly in developing economies, is emerging as a significant consumer of thermite-based products, thereby fueling the need for comprehensive safety solutions. Additionally, the railway industry's increasing use of thermite welding for track maintenance has created a niche market for specialized safety equipment and training programs.

Industrial demand analysis reveals a shift towards integrated safety systems that combine physical barriers, advanced monitoring technologies, and automated emergency response mechanisms. There is a growing preference for smart safety solutions that can detect potential hazards in real-time and initiate preventive measures autonomously.

The market also shows a rising demand for specialized personal protective equipment (PPE) designed specifically for thermite-related operations. This includes heat-resistant clothing, face shields, and respiratory protection devices tailored to withstand the extreme temperatures and potential fume hazards associated with thermite reactions.

Training and certification programs focused on thermite safety have seen increased enrollment, indicating a growing recognition of the importance of human factors in maintaining workshop safety. Industries are investing in virtual reality and augmented reality-based training modules to simulate thermite-related hazards and emergency scenarios, enhancing worker preparedness.

In conclusion, the industrial demand for thermite safety measures is driven by a combination of regulatory pressures, technological advancements, and a growing safety-conscious culture in industrial settings. As the use of thermite continues to expand across various sectors, the market for innovative, efficient, and reliable safety solutions is expected to grow proportionally, presenting significant opportunities for safety equipment manufacturers and service providers.

Market analysis indicates a substantial growth in the global thermite market, driven by expanding applications in metallurgy, railway maintenance, and construction industries. This growth directly correlates with an increased demand for robust safety measures to mitigate risks associated with thermite handling and usage. The industrial safety equipment market, specifically for thermite-related applications, is projected to experience substantial growth in the coming years.

Key factors driving the demand for thermite safety measures include stringent workplace safety regulations, rising incidents of industrial accidents, and growing emphasis on worker protection. Regulatory bodies worldwide are implementing stricter guidelines for handling and storing thermite materials, compelling industries to invest in advanced safety technologies and protocols.

The construction sector, particularly in developing economies, is emerging as a significant consumer of thermite-based products, thereby fueling the need for comprehensive safety solutions. Additionally, the railway industry's increasing use of thermite welding for track maintenance has created a niche market for specialized safety equipment and training programs.

Industrial demand analysis reveals a shift towards integrated safety systems that combine physical barriers, advanced monitoring technologies, and automated emergency response mechanisms. There is a growing preference for smart safety solutions that can detect potential hazards in real-time and initiate preventive measures autonomously.

The market also shows a rising demand for specialized personal protective equipment (PPE) designed specifically for thermite-related operations. This includes heat-resistant clothing, face shields, and respiratory protection devices tailored to withstand the extreme temperatures and potential fume hazards associated with thermite reactions.

Training and certification programs focused on thermite safety have seen increased enrollment, indicating a growing recognition of the importance of human factors in maintaining workshop safety. Industries are investing in virtual reality and augmented reality-based training modules to simulate thermite-related hazards and emergency scenarios, enhancing worker preparedness.

In conclusion, the industrial demand for thermite safety measures is driven by a combination of regulatory pressures, technological advancements, and a growing safety-conscious culture in industrial settings. As the use of thermite continues to expand across various sectors, the market for innovative, efficient, and reliable safety solutions is expected to grow proportionally, presenting significant opportunities for safety equipment manufacturers and service providers.

Current Safety Challenges

The use of thermite in industrial workshop settings presents significant safety challenges that require careful consideration and management. One of the primary concerns is the extremely high temperatures generated during thermite reactions, which can exceed 2500°C. This intense heat poses severe risks of burns, fires, and damage to surrounding equipment and structures if not properly contained.

Another critical safety challenge is the potential for unintended ignition. Thermite mixtures can be sensitive to friction, impact, or electrostatic discharge, making accidental activation a constant threat. This risk is particularly pronounced in workshop environments where various tools, machinery, and activities could potentially trigger a reaction.

The production of molten metal as a byproduct of thermite reactions introduces additional hazards. This superheated liquid metal can cause severe burns, ignite flammable materials, and damage equipment. Controlling and safely disposing of this molten material requires specialized containment systems and handling procedures, which may not be readily available in all workshop settings.

Respiratory hazards also present a significant challenge. The thermite reaction produces fine metal oxide particles and fumes that can be harmful if inhaled. These airborne contaminants may cause both acute and chronic health issues for workers exposed to them, necessitating robust ventilation systems and personal protective equipment.

The storage and handling of thermite components pose their own set of challenges. The reactive nature of the materials requires strict segregation and environmental control to prevent degradation or accidental mixing. Improper storage can lead to decreased effectiveness of the thermite mixture or, more dangerously, spontaneous ignition.

Emergency response to thermite-related incidents is particularly challenging due to the unique nature of these fires. Traditional firefighting methods may be ineffective or even counterproductive when dealing with thermite reactions. This necessitates specialized training and equipment for workshop personnel and local emergency responders.

The potential for thermite to be used maliciously or as an incendiary device adds another layer of security concerns. Workshops must implement strict access controls and inventory management to prevent unauthorized use or theft of thermite materials.

Lastly, the regulatory landscape surrounding thermite use in industrial settings can be complex and varies by jurisdiction. Ensuring compliance with all relevant safety standards, handling protocols, and reporting requirements presents an ongoing challenge for workshop managers and safety officers.

Another critical safety challenge is the potential for unintended ignition. Thermite mixtures can be sensitive to friction, impact, or electrostatic discharge, making accidental activation a constant threat. This risk is particularly pronounced in workshop environments where various tools, machinery, and activities could potentially trigger a reaction.

The production of molten metal as a byproduct of thermite reactions introduces additional hazards. This superheated liquid metal can cause severe burns, ignite flammable materials, and damage equipment. Controlling and safely disposing of this molten material requires specialized containment systems and handling procedures, which may not be readily available in all workshop settings.

Respiratory hazards also present a significant challenge. The thermite reaction produces fine metal oxide particles and fumes that can be harmful if inhaled. These airborne contaminants may cause both acute and chronic health issues for workers exposed to them, necessitating robust ventilation systems and personal protective equipment.

The storage and handling of thermite components pose their own set of challenges. The reactive nature of the materials requires strict segregation and environmental control to prevent degradation or accidental mixing. Improper storage can lead to decreased effectiveness of the thermite mixture or, more dangerously, spontaneous ignition.

Emergency response to thermite-related incidents is particularly challenging due to the unique nature of these fires. Traditional firefighting methods may be ineffective or even counterproductive when dealing with thermite reactions. This necessitates specialized training and equipment for workshop personnel and local emergency responders.

The potential for thermite to be used maliciously or as an incendiary device adds another layer of security concerns. Workshops must implement strict access controls and inventory management to prevent unauthorized use or theft of thermite materials.

Lastly, the regulatory landscape surrounding thermite use in industrial settings can be complex and varies by jurisdiction. Ensuring compliance with all relevant safety standards, handling protocols, and reporting requirements presents an ongoing challenge for workshop managers and safety officers.

Existing Safety Solutions

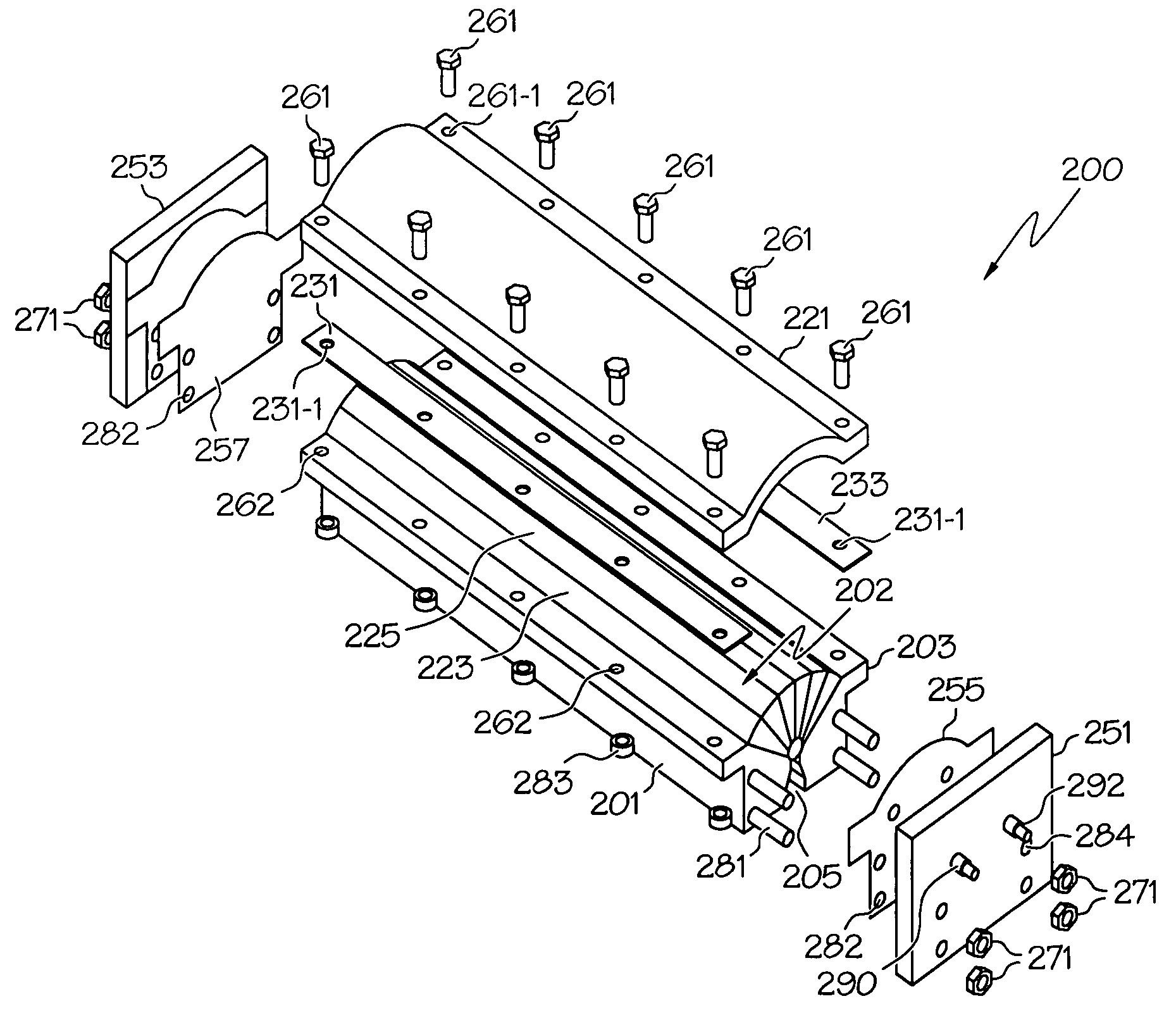

01 Containment and control of thermite reactions

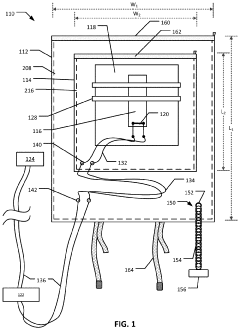

Safety measures for containing and controlling thermite reactions include specialized reaction chambers, pressure vessels, and controlled ignition systems. These designs help manage the high temperatures and pressures generated during thermite reactions, reducing the risk of accidents and ensuring safer handling of the materials.- Containment and control of thermite reactions: Specialized containers and control mechanisms are used to safely contain and manage thermite reactions. These include reinforced vessels, pressure relief systems, and precise ignition controls to prevent unintended reactions or explosions. Such measures ensure the controlled and safe use of thermite in various applications.

- Protective equipment and handling procedures: Safety protocols for handling thermite involve the use of specialized protective equipment such as heat-resistant suits, face shields, and gloves. Proper handling procedures, including storage guidelines and transportation methods, are crucial to minimize risks associated with thermite materials.

- Fire suppression and emergency response: Advanced fire suppression systems and emergency response protocols are developed specifically for thermite-related incidents. These include specialized extinguishing agents, rapid response procedures, and training programs for handling thermite fires and accidents.

- Composition modifications for enhanced safety: Research focuses on modifying thermite compositions to improve safety while maintaining effectiveness. This includes developing less reactive variants, incorporating stabilizing agents, and creating formulations with reduced sensitivity to accidental ignition.

- Monitoring and detection systems: Advanced monitoring and detection systems are employed to enhance thermite safety. These include temperature sensors, pressure monitors, and chemical detectors that can provide early warning of potential hazards or unintended reactions, allowing for timely intervention and risk mitigation.

02 Protective equipment and handling procedures

Proper protective equipment and handling procedures are crucial for thermite safety. This includes the use of heat-resistant clothing, face shields, and gloves. Established protocols for storage, transportation, and disposal of thermite materials are essential to minimize risks associated with their use.Expand Specific Solutions03 Fire suppression and emergency response

Specialized fire suppression systems and emergency response protocols are developed for thermite-related incidents. These may include the use of specific extinguishing agents, containment strategies, and rapid response procedures to mitigate potential hazards in case of accidental ignition or spills.Expand Specific Solutions04 Safe ignition and initiation methods

Development of safe ignition and initiation methods for thermite reactions is crucial. This includes remote ignition systems, controlled electronic initiators, and fail-safe mechanisms to prevent accidental activation. These methods aim to reduce the risk of premature or unintended ignition during handling and use.Expand Specific Solutions05 Composition modifications for enhanced safety

Research into modifying thermite compositions to enhance safety while maintaining desired performance characteristics. This may involve the use of stabilizers, inhibitors, or alternative formulations that reduce sensitivity to accidental ignition or improve control over the reaction process, thereby increasing overall safety in handling and application.Expand Specific Solutions

Key Industry Players

The thermite safety measures market for industrial workshop settings is in a growth phase, driven by increasing safety regulations and awareness. The market size is expanding as more industries adopt advanced safety protocols. Technologically, the field is moderately mature, with ongoing innovations focused on enhancing safety and efficiency. Companies like Battelle Memorial Institute and Southwest Research Institute are at the forefront of research and development, while industrial players such as ExxonMobil Technology & Engineering Co. and AICHELIN Ges.m.b.H. are implementing advanced safety solutions. Emerging technologies from firms like BiSN Oil Tools Ltd. and Dynamic Engineering & Solutions are pushing the boundaries of thermite safety, indicating a competitive landscape with room for further advancements and market growth.

Battelle Memorial Institute

Technical Solution: Battelle has developed advanced thermite safety measures for industrial workshop settings, focusing on containment and controlled ignition. Their system includes a specially designed reaction chamber with heat-resistant materials and a remote ignition mechanism. The chamber is equipped with pressure relief valves and temperature sensors to monitor and control the thermite reaction. Additionally, they have implemented a multi-layer fire suppression system that combines inert gas flooding and specialized foam agents to quickly extinguish any potential fires resulting from thermite reactions.

Strengths: Comprehensive safety approach, advanced monitoring systems, and multi-layer fire suppression. Weaknesses: Potentially high implementation costs and complexity of the system.

Airbus Defence & Space SAS

Technical Solution: Airbus Defence & Space has adapted its aerospace safety technologies to create a comprehensive thermite safety system for industrial workshops. Their solution includes a real-time monitoring system using infrared cameras and gas sensors to detect early signs of thermite reactions. This is coupled with an AI-driven predictive analysis tool that can anticipate potential hazards based on workshop conditions. The system also features an automated emergency response mechanism that can deploy fire suppression measures and initiate evacuation protocols. Additionally, they have developed a modular containment unit that can quickly isolate areas where thermite is being used or stored.

Strengths: Advanced early detection capabilities, AI-driven predictive analysis, and rapid emergency response system. Weaknesses: High initial setup costs and potential over-reliance on technology.

Innovative Safety Tech

Thermite charge

PatentActiveUS7555986B2

Innovation

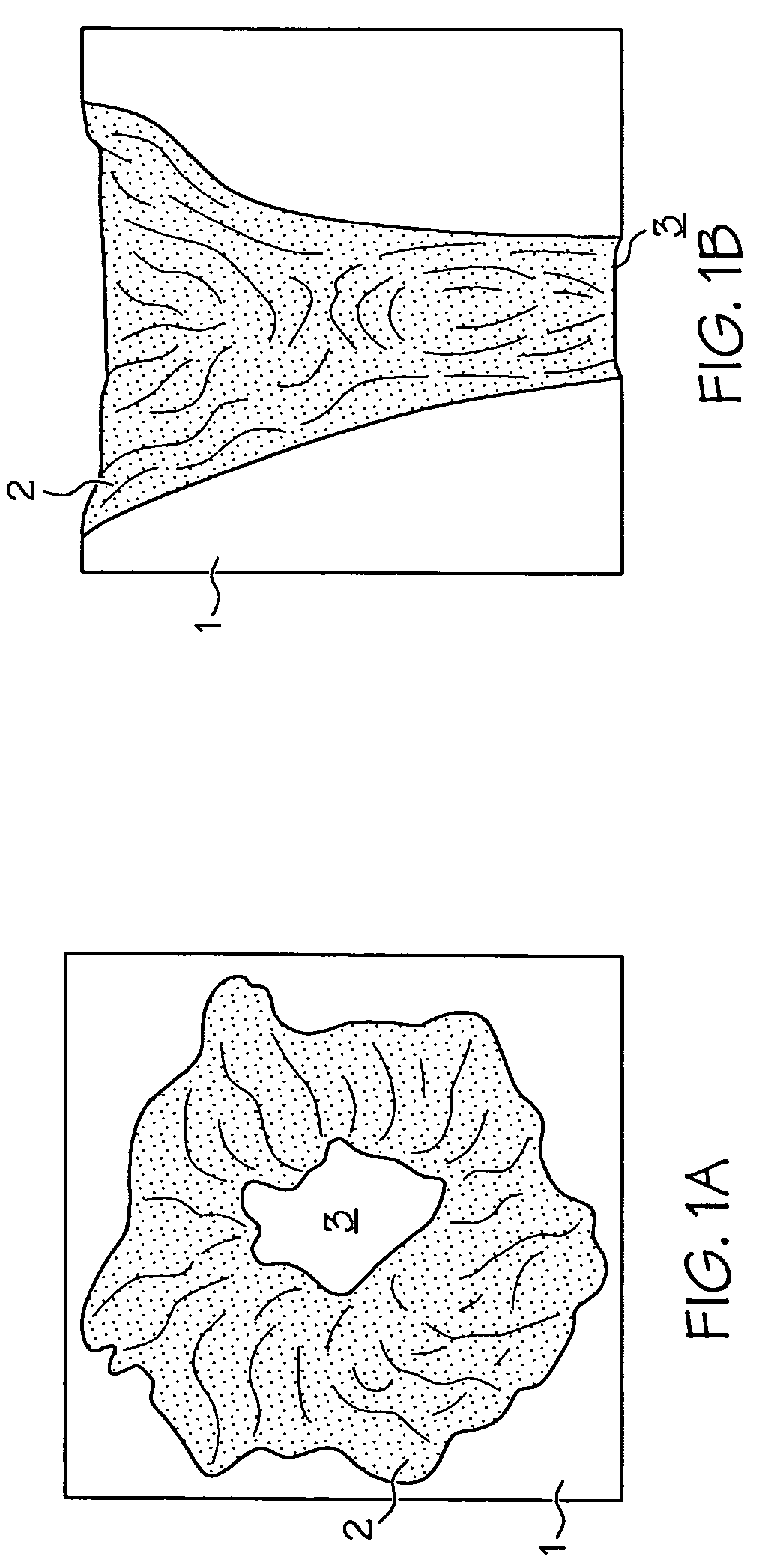

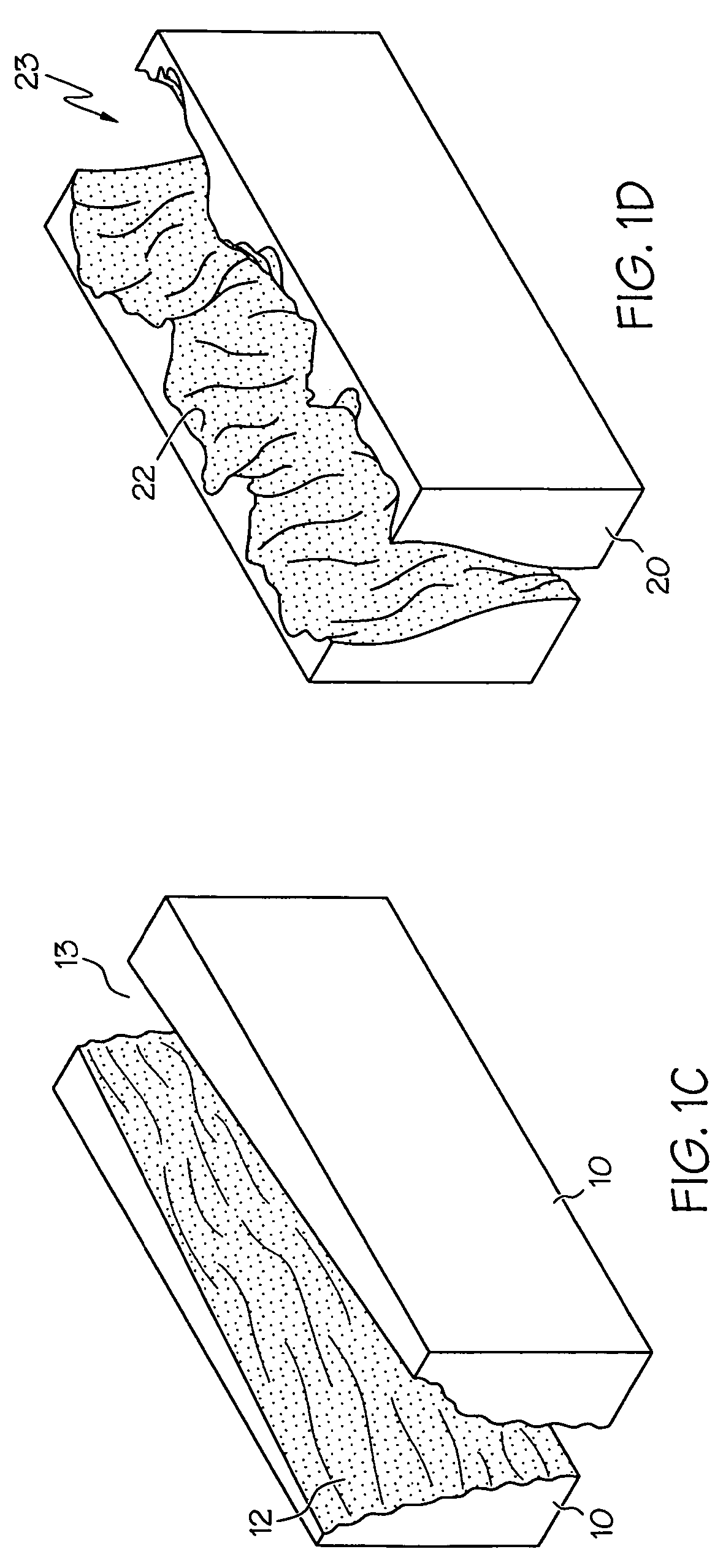

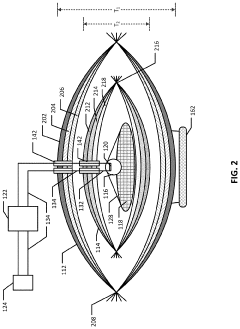

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Thermite Bag For Chemical / Biological Agent Munition And Hazardous Waste Disposal System

PatentActiveUS20200080722A1

Innovation

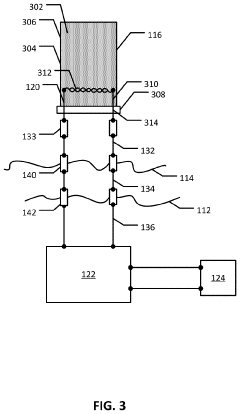

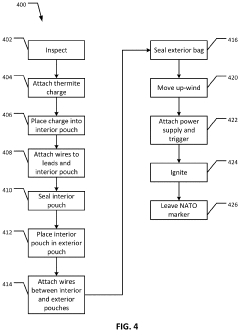

- A thermite bag system comprising a sealable pouch with a thermite charge, igniter, and electrical connections, allowing for rapid and controlled thermal decomposition of hazardous materials, including chemical and biological agents, using a portable and lightweight design.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing thermite safety measures in industrial workshop settings. The use of thermite, a highly exothermic mixture, is subject to stringent regulations due to its potential hazards. In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for the safe handling and storage of thermite materials. These regulations mandate proper labeling, storage conditions, and handling procedures to minimize risks associated with thermite reactions.

The National Fire Protection Association (NFPA) provides additional standards for fire prevention and control in industrial settings where thermite is used. NFPA 484, specifically addressing combustible metals, outlines requirements for fire protection systems, emergency response plans, and personnel training. Compliance with these standards is essential for maintaining a safe work environment and preventing catastrophic incidents.

Internationally, the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a framework for communicating chemical hazards. Industrial workshops using thermite must adhere to GHS guidelines for proper labeling and safety data sheets, ensuring clear communication of risks across borders.

Environmental regulations also play a significant role in thermite safety compliance. The Environmental Protection Agency (EPA) in the United States regulates the disposal of thermite residues and byproducts. Proper waste management practices must be implemented to prevent environmental contamination and comply with hazardous waste disposal regulations.

Workshop operators must establish comprehensive safety management systems that incorporate these regulatory requirements. This includes regular safety audits, documentation of safety procedures, and ongoing employee training programs. Failure to comply with these regulations can result in severe penalties, including fines and potential shutdown of operations.

Staying current with evolving regulations is crucial for maintaining compliance. Regulatory bodies frequently update their standards based on new research and incident data. Industrial workshops must establish mechanisms for monitoring regulatory changes and implementing necessary updates to their safety protocols.

Collaboration with regulatory agencies and industry associations can facilitate better understanding and implementation of safety measures. Many organizations offer compliance assistance programs and resources to help industrial workshops navigate complex regulatory landscapes. Proactive engagement with these resources can lead to improved safety outcomes and reduced regulatory risks.

The National Fire Protection Association (NFPA) provides additional standards for fire prevention and control in industrial settings where thermite is used. NFPA 484, specifically addressing combustible metals, outlines requirements for fire protection systems, emergency response plans, and personnel training. Compliance with these standards is essential for maintaining a safe work environment and preventing catastrophic incidents.

Internationally, the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a framework for communicating chemical hazards. Industrial workshops using thermite must adhere to GHS guidelines for proper labeling and safety data sheets, ensuring clear communication of risks across borders.

Environmental regulations also play a significant role in thermite safety compliance. The Environmental Protection Agency (EPA) in the United States regulates the disposal of thermite residues and byproducts. Proper waste management practices must be implemented to prevent environmental contamination and comply with hazardous waste disposal regulations.

Workshop operators must establish comprehensive safety management systems that incorporate these regulatory requirements. This includes regular safety audits, documentation of safety procedures, and ongoing employee training programs. Failure to comply with these regulations can result in severe penalties, including fines and potential shutdown of operations.

Staying current with evolving regulations is crucial for maintaining compliance. Regulatory bodies frequently update their standards based on new research and incident data. Industrial workshops must establish mechanisms for monitoring regulatory changes and implementing necessary updates to their safety protocols.

Collaboration with regulatory agencies and industry associations can facilitate better understanding and implementation of safety measures. Many organizations offer compliance assistance programs and resources to help industrial workshops navigate complex regulatory landscapes. Proactive engagement with these resources can lead to improved safety outcomes and reduced regulatory risks.

Environmental Impact

The environmental impact of thermite reactions in industrial workshop settings is a critical consideration for safety measures and sustainable practices. Thermite reactions, known for their high-temperature exothermic nature, can potentially lead to significant environmental consequences if not properly managed.

One of the primary environmental concerns associated with thermite reactions is the release of particulate matter and fumes. These emissions can contain metal oxides, which may pose risks to air quality in the immediate vicinity and beyond. The fine particles generated during thermite reactions can remain suspended in the air for extended periods, potentially affecting respiratory health of workers and nearby communities.

Soil contamination is another environmental issue that must be addressed when implementing thermite safety measures. Residues from thermite reactions, including metal oxides and unreacted materials, can accumulate in the soil over time. This accumulation may alter soil chemistry and potentially impact local ecosystems, including plant growth and soil microorganisms.

Water pollution is a further environmental risk associated with thermite use in industrial settings. Runoff from areas where thermite reactions occur can carry contaminants into nearby water bodies, potentially affecting aquatic ecosystems and water quality. Proper containment and treatment of wastewater from thermite-related processes are essential to mitigate this risk.

The high temperatures generated by thermite reactions also contribute to thermal pollution. This can lead to localized heating of the environment, potentially disrupting local microclimates and affecting heat-sensitive organisms in the immediate vicinity of industrial workshops.

To address these environmental concerns, comprehensive safety measures must be implemented. These may include advanced filtration systems to capture particulate emissions, proper containment and disposal protocols for thermite residues, and robust wastewater treatment processes. Additionally, regular environmental monitoring and impact assessments should be conducted to ensure that thermite use does not lead to long-term environmental degradation.

Innovative approaches to thermite use, such as closed-system reactions and recycling of byproducts, can further reduce environmental impact. Research into more environmentally friendly alternatives or modifications to traditional thermite compositions may also contribute to minimizing ecological footprints while maintaining industrial efficiency.

By carefully considering and addressing the environmental impact of thermite reactions, industrial workshops can ensure safer, more sustainable operations that align with broader environmental protection goals and regulations.

One of the primary environmental concerns associated with thermite reactions is the release of particulate matter and fumes. These emissions can contain metal oxides, which may pose risks to air quality in the immediate vicinity and beyond. The fine particles generated during thermite reactions can remain suspended in the air for extended periods, potentially affecting respiratory health of workers and nearby communities.

Soil contamination is another environmental issue that must be addressed when implementing thermite safety measures. Residues from thermite reactions, including metal oxides and unreacted materials, can accumulate in the soil over time. This accumulation may alter soil chemistry and potentially impact local ecosystems, including plant growth and soil microorganisms.

Water pollution is a further environmental risk associated with thermite use in industrial settings. Runoff from areas where thermite reactions occur can carry contaminants into nearby water bodies, potentially affecting aquatic ecosystems and water quality. Proper containment and treatment of wastewater from thermite-related processes are essential to mitigate this risk.

The high temperatures generated by thermite reactions also contribute to thermal pollution. This can lead to localized heating of the environment, potentially disrupting local microclimates and affecting heat-sensitive organisms in the immediate vicinity of industrial workshops.

To address these environmental concerns, comprehensive safety measures must be implemented. These may include advanced filtration systems to capture particulate emissions, proper containment and disposal protocols for thermite residues, and robust wastewater treatment processes. Additionally, regular environmental monitoring and impact assessments should be conducted to ensure that thermite use does not lead to long-term environmental degradation.

Innovative approaches to thermite use, such as closed-system reactions and recycling of byproducts, can further reduce environmental impact. Research into more environmentally friendly alternatives or modifications to traditional thermite compositions may also contribute to minimizing ecological footprints while maintaining industrial efficiency.

By carefully considering and addressing the environmental impact of thermite reactions, industrial workshops can ensure safer, more sustainable operations that align with broader environmental protection goals and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!