Hypochlorous Acid: Trends in Shelf-Life Extension Techniques

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Preservation Goals

Hypochlorous acid (HOCl) has gained significant attention in recent years due to its potent antimicrobial properties and wide-ranging applications. As a naturally occurring compound produced by the human immune system, HOCl has proven to be an effective and safe disinfectant. However, its inherent instability poses a major challenge for long-term storage and commercial use. The primary goal of HOCl preservation techniques is to extend its shelf life while maintaining its efficacy as a disinfectant.

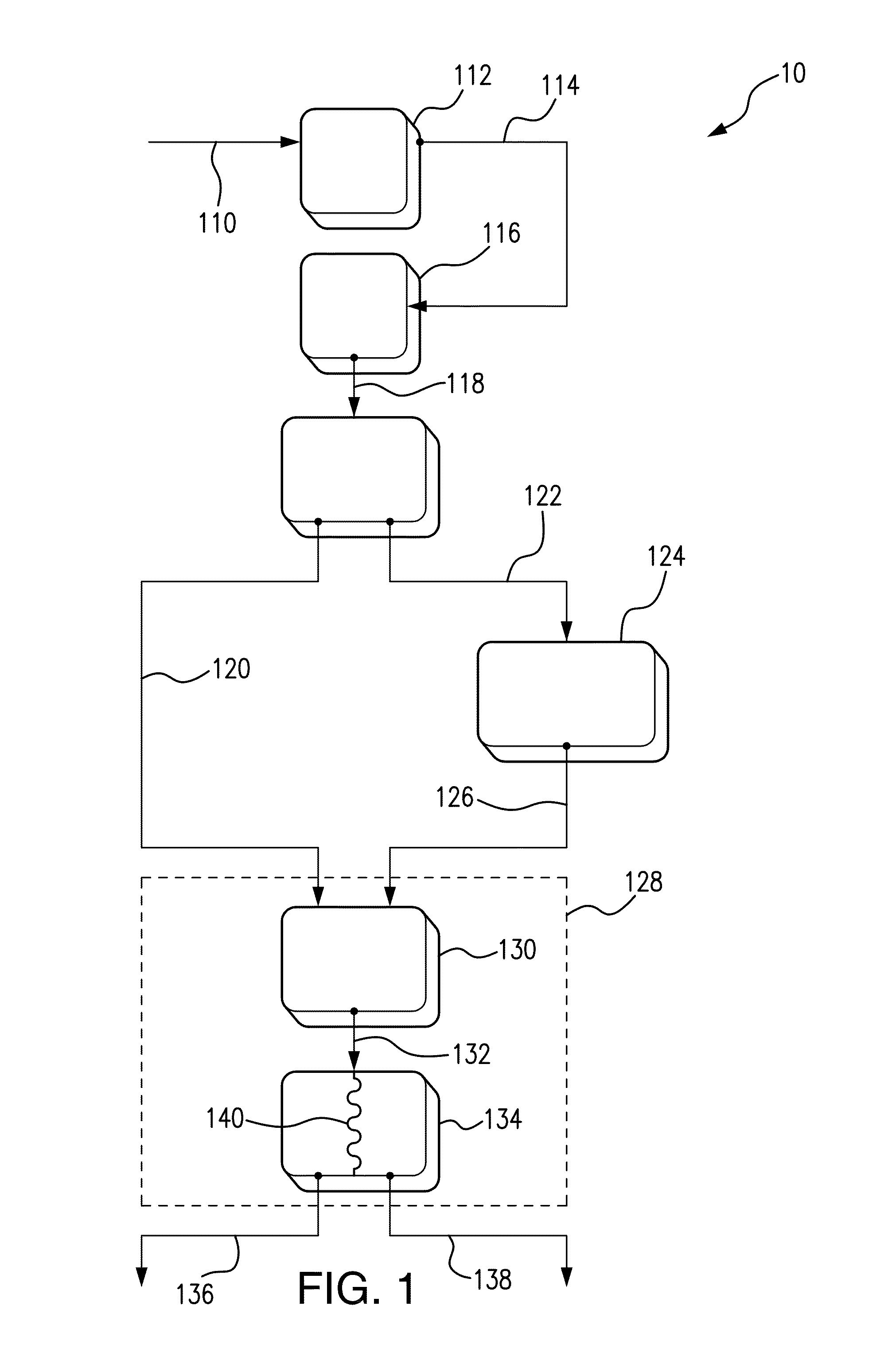

One of the key objectives in HOCl preservation is to stabilize the compound's pH level. HOCl is most effective at a slightly acidic pH range of 4.5 to 6.5. Outside this range, it can quickly degrade into less effective forms such as hypochlorite ions or chlorine gas. Developing methods to maintain this optimal pH range over extended periods is crucial for enhancing HOCl's shelf life.

Another important preservation goal is to minimize HOCl's exposure to light and heat. These factors can accelerate the decomposition of HOCl, reducing its antimicrobial effectiveness. Researchers aim to develop packaging solutions and storage conditions that protect HOCl from these environmental factors, thereby prolonging its stability and potency.

Preventing contamination is also a critical objective in HOCl preservation. As a powerful disinfectant, HOCl can react with organic matter and other contaminants, leading to its rapid degradation. Developing clean production processes and maintaining sterile storage conditions are essential for extending HOCl's shelf life.

Researchers are also focusing on enhancing HOCl's chemical stability through the use of stabilizing agents. These additives aim to slow down the natural decomposition process of HOCl without compromising its antimicrobial efficacy. Finding the right balance between stability and effectiveness is a key challenge in this area of research.

Additionally, there is a growing interest in developing concentrated HOCl formulations that can be diluted before use. This approach not only extends shelf life but also reduces packaging and transportation costs. However, ensuring the stability and efficacy of these concentrated solutions presents its own set of challenges that researchers are working to overcome.

Lastly, the development of novel production methods for HOCl is an important goal in preservation efforts. By improving the purity and consistency of HOCl production, researchers aim to create more stable formulations that inherently have a longer shelf life. This includes exploring electrochemical generation techniques and optimizing the precursor materials used in HOCl synthesis.

One of the key objectives in HOCl preservation is to stabilize the compound's pH level. HOCl is most effective at a slightly acidic pH range of 4.5 to 6.5. Outside this range, it can quickly degrade into less effective forms such as hypochlorite ions or chlorine gas. Developing methods to maintain this optimal pH range over extended periods is crucial for enhancing HOCl's shelf life.

Another important preservation goal is to minimize HOCl's exposure to light and heat. These factors can accelerate the decomposition of HOCl, reducing its antimicrobial effectiveness. Researchers aim to develop packaging solutions and storage conditions that protect HOCl from these environmental factors, thereby prolonging its stability and potency.

Preventing contamination is also a critical objective in HOCl preservation. As a powerful disinfectant, HOCl can react with organic matter and other contaminants, leading to its rapid degradation. Developing clean production processes and maintaining sterile storage conditions are essential for extending HOCl's shelf life.

Researchers are also focusing on enhancing HOCl's chemical stability through the use of stabilizing agents. These additives aim to slow down the natural decomposition process of HOCl without compromising its antimicrobial efficacy. Finding the right balance between stability and effectiveness is a key challenge in this area of research.

Additionally, there is a growing interest in developing concentrated HOCl formulations that can be diluted before use. This approach not only extends shelf life but also reduces packaging and transportation costs. However, ensuring the stability and efficacy of these concentrated solutions presents its own set of challenges that researchers are working to overcome.

Lastly, the development of novel production methods for HOCl is an important goal in preservation efforts. By improving the purity and consistency of HOCl production, researchers aim to create more stable formulations that inherently have a longer shelf life. This includes exploring electrochemical generation techniques and optimizing the precursor materials used in HOCl synthesis.

Market Demand Analysis

The market demand for shelf-life extension techniques for Hypochlorous Acid (HOCl) has been steadily increasing due to its wide-ranging applications in various industries. HOCl is known for its potent antimicrobial properties, making it a valuable solution for disinfection and sanitization purposes. However, its inherent instability poses challenges for long-term storage and distribution, driving the need for innovative shelf-life extension methods.

In the healthcare sector, there is a growing demand for stable HOCl solutions for wound care, dental hygiene, and general disinfection. Hospitals, clinics, and long-term care facilities are seeking reliable HOCl products with extended shelf lives to ensure consistent efficacy and reduce waste. The COVID-19 pandemic has further accelerated this demand, as HOCl has proven effective against various pathogens, including coronaviruses.

The food and beverage industry represents another significant market for HOCl shelf-life extension techniques. With increasing consumer awareness of food safety and the push for clean label products, HOCl is gaining traction as a natural antimicrobial agent for food preservation and surface disinfection. Producers are looking for ways to incorporate HOCl into their processes while maintaining its stability throughout the product lifecycle.

Water treatment and sanitation sectors also contribute to the market demand for HOCl shelf-life extension. Municipal water treatment plants, swimming pools, and industrial water systems require stable HOCl solutions for effective disinfection. The ability to store and transport HOCl over longer periods without degradation is crucial for these applications, especially in remote or challenging environments.

The agriculture industry is emerging as a promising market for HOCl, with applications in crop protection, livestock health, and post-harvest treatment. Farmers and agribusinesses are seeking sustainable alternatives to traditional chemical pesticides and disinfectants, driving interest in stable HOCl formulations that can be stored and applied efficiently throughout the growing season.

Market analysis indicates that the global HOCl market is expected to grow significantly in the coming years, with shelf-life extension techniques playing a crucial role in this expansion. Factors such as increasing hygiene awareness, stringent regulations on chemical usage, and the shift towards environmentally friendly solutions are driving this growth. Additionally, the versatility of HOCl across multiple industries suggests a diverse and robust market demand for improved stability and longevity of HOCl products.

As research and development in HOCl shelf-life extension techniques continue to advance, the market is likely to see new product innovations and formulations that address the stability challenges. This progress is expected to open up new application areas and market opportunities, further fueling the demand for extended shelf-life HOCl solutions across various sectors.

In the healthcare sector, there is a growing demand for stable HOCl solutions for wound care, dental hygiene, and general disinfection. Hospitals, clinics, and long-term care facilities are seeking reliable HOCl products with extended shelf lives to ensure consistent efficacy and reduce waste. The COVID-19 pandemic has further accelerated this demand, as HOCl has proven effective against various pathogens, including coronaviruses.

The food and beverage industry represents another significant market for HOCl shelf-life extension techniques. With increasing consumer awareness of food safety and the push for clean label products, HOCl is gaining traction as a natural antimicrobial agent for food preservation and surface disinfection. Producers are looking for ways to incorporate HOCl into their processes while maintaining its stability throughout the product lifecycle.

Water treatment and sanitation sectors also contribute to the market demand for HOCl shelf-life extension. Municipal water treatment plants, swimming pools, and industrial water systems require stable HOCl solutions for effective disinfection. The ability to store and transport HOCl over longer periods without degradation is crucial for these applications, especially in remote or challenging environments.

The agriculture industry is emerging as a promising market for HOCl, with applications in crop protection, livestock health, and post-harvest treatment. Farmers and agribusinesses are seeking sustainable alternatives to traditional chemical pesticides and disinfectants, driving interest in stable HOCl formulations that can be stored and applied efficiently throughout the growing season.

Market analysis indicates that the global HOCl market is expected to grow significantly in the coming years, with shelf-life extension techniques playing a crucial role in this expansion. Factors such as increasing hygiene awareness, stringent regulations on chemical usage, and the shift towards environmentally friendly solutions are driving this growth. Additionally, the versatility of HOCl across multiple industries suggests a diverse and robust market demand for improved stability and longevity of HOCl products.

As research and development in HOCl shelf-life extension techniques continue to advance, the market is likely to see new product innovations and formulations that address the stability challenges. This progress is expected to open up new application areas and market opportunities, further fueling the demand for extended shelf-life HOCl solutions across various sectors.

HOCl Stability Challenges

Hypochlorous acid (HOCl) faces significant stability challenges that hinder its widespread application and long-term storage. The primary issue stems from its inherent chemical instability, as HOCl readily decomposes into chlorine gas and water. This decomposition process is accelerated by various environmental factors, including temperature, pH, light exposure, and the presence of organic matter.

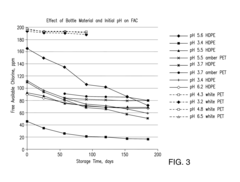

Temperature plays a crucial role in HOCl stability. Higher temperatures increase the rate of decomposition, with studies showing that HOCl solutions can lose up to 50% of their active chlorine content within 24 hours at room temperature. Conversely, refrigeration can significantly extend the shelf life, but this approach is not always practical for large-scale industrial applications or consumer use.

pH is another critical factor affecting HOCl stability. The acid is most stable at a pH range of 4-6, with stability decreasing rapidly outside this range. In alkaline conditions, HOCl dissociates into hypochlorite ions, while in highly acidic environments, it can form chlorine gas. Maintaining the optimal pH range is challenging, especially in solutions with low buffering capacity.

Light exposure, particularly UV radiation, catalyzes the decomposition of HOCl. This photosensitivity necessitates the use of opaque or UV-resistant packaging, which can increase production costs and limit certain applications where transparent containers are preferred.

The presence of organic matter in HOCl solutions accelerates decomposition through oxidation reactions. This poses challenges in applications where the acid comes into contact with biological materials or in environments with high organic content, such as wastewater treatment or food processing.

Metal ions, especially transition metals like iron and copper, can catalyze HOCl decomposition. This limits the use of certain materials in storage and application equipment, necessitating careful selection of compatible materials for containers, pipes, and dispensing systems.

The concentration of HOCl in solution also affects its stability. Higher concentrations tend to be less stable, which creates a trade-off between potency and shelf life. This challenge is particularly relevant in developing concentrated formulations for transport and storage efficiency.

These stability issues collectively impact the efficacy, safety, and economic viability of HOCl-based products. They necessitate careful formulation, packaging, and storage strategies to maintain the acid's potency over time. The development of stabilized HOCl solutions and novel preservation techniques remains an active area of research and development in the field.

Temperature plays a crucial role in HOCl stability. Higher temperatures increase the rate of decomposition, with studies showing that HOCl solutions can lose up to 50% of their active chlorine content within 24 hours at room temperature. Conversely, refrigeration can significantly extend the shelf life, but this approach is not always practical for large-scale industrial applications or consumer use.

pH is another critical factor affecting HOCl stability. The acid is most stable at a pH range of 4-6, with stability decreasing rapidly outside this range. In alkaline conditions, HOCl dissociates into hypochlorite ions, while in highly acidic environments, it can form chlorine gas. Maintaining the optimal pH range is challenging, especially in solutions with low buffering capacity.

Light exposure, particularly UV radiation, catalyzes the decomposition of HOCl. This photosensitivity necessitates the use of opaque or UV-resistant packaging, which can increase production costs and limit certain applications where transparent containers are preferred.

The presence of organic matter in HOCl solutions accelerates decomposition through oxidation reactions. This poses challenges in applications where the acid comes into contact with biological materials or in environments with high organic content, such as wastewater treatment or food processing.

Metal ions, especially transition metals like iron and copper, can catalyze HOCl decomposition. This limits the use of certain materials in storage and application equipment, necessitating careful selection of compatible materials for containers, pipes, and dispensing systems.

The concentration of HOCl in solution also affects its stability. Higher concentrations tend to be less stable, which creates a trade-off between potency and shelf life. This challenge is particularly relevant in developing concentrated formulations for transport and storage efficiency.

These stability issues collectively impact the efficacy, safety, and economic viability of HOCl-based products. They necessitate careful formulation, packaging, and storage strategies to maintain the acid's potency over time. The development of stabilized HOCl solutions and novel preservation techniques remains an active area of research and development in the field.

Current Preservation Methods

01 Stabilization methods for hypochlorous acid

Various stabilization methods are employed to extend the shelf-life of hypochlorous acid solutions. These include pH adjustment, addition of stabilizing agents, and control of environmental factors such as temperature and light exposure. Proper stabilization can significantly increase the longevity of hypochlorous acid products.- Stabilization methods for hypochlorous acid: Various stabilization methods are employed to extend the shelf-life of hypochlorous acid solutions. These may include pH adjustment, addition of stabilizing agents, or use of specific packaging materials. Such methods aim to prevent degradation and maintain the efficacy of the hypochlorous acid over time.

- Formulation techniques for improved stability: Specific formulation techniques are developed to enhance the stability of hypochlorous acid solutions. These may involve careful selection of ingredients, optimizing concentrations, or incorporating protective compounds. The goal is to create formulations that resist breakdown and maintain potency during storage.

- Storage conditions affecting shelf-life: The storage conditions of hypochlorous acid solutions significantly impact their shelf-life. Factors such as temperature, light exposure, and container material play crucial roles. Proper storage guidelines are developed to maximize the product's longevity and maintain its effectiveness.

- Analytical methods for shelf-life determination: Various analytical techniques are employed to assess and predict the shelf-life of hypochlorous acid solutions. These may include spectroscopic methods, chemical assays, or accelerated stability testing. Such methods help in determining the product's stability profile and setting appropriate expiration dates.

- Packaging innovations for extended shelf-life: Innovative packaging solutions are developed to extend the shelf-life of hypochlorous acid products. These may include specialized containers, barrier materials, or dispensing systems designed to minimize degradation and contamination. Such packaging innovations aim to preserve the product's integrity throughout its intended use period.

02 Packaging and storage solutions

Specialized packaging and storage solutions play a crucial role in maintaining the stability of hypochlorous acid. This includes using opaque or light-resistant containers, airtight sealing mechanisms, and innovative dispensing systems that minimize exposure to air and contaminants during use.Expand Specific Solutions03 Formulation techniques for enhanced stability

Advanced formulation techniques are developed to enhance the stability of hypochlorous acid. These may involve the use of specific buffer systems, incorporation of compatible ingredients that do not react with hypochlorous acid, and optimizing the concentration of active ingredients to maintain efficacy over time.Expand Specific Solutions04 Monitoring and quality control measures

Implementing robust monitoring and quality control measures throughout the production and storage process is essential for ensuring the shelf-life of hypochlorous acid products. This includes regular testing of stability, potency, and purity, as well as the use of indicators or smart packaging to track product integrity over time.Expand Specific Solutions05 Novel production methods for improved stability

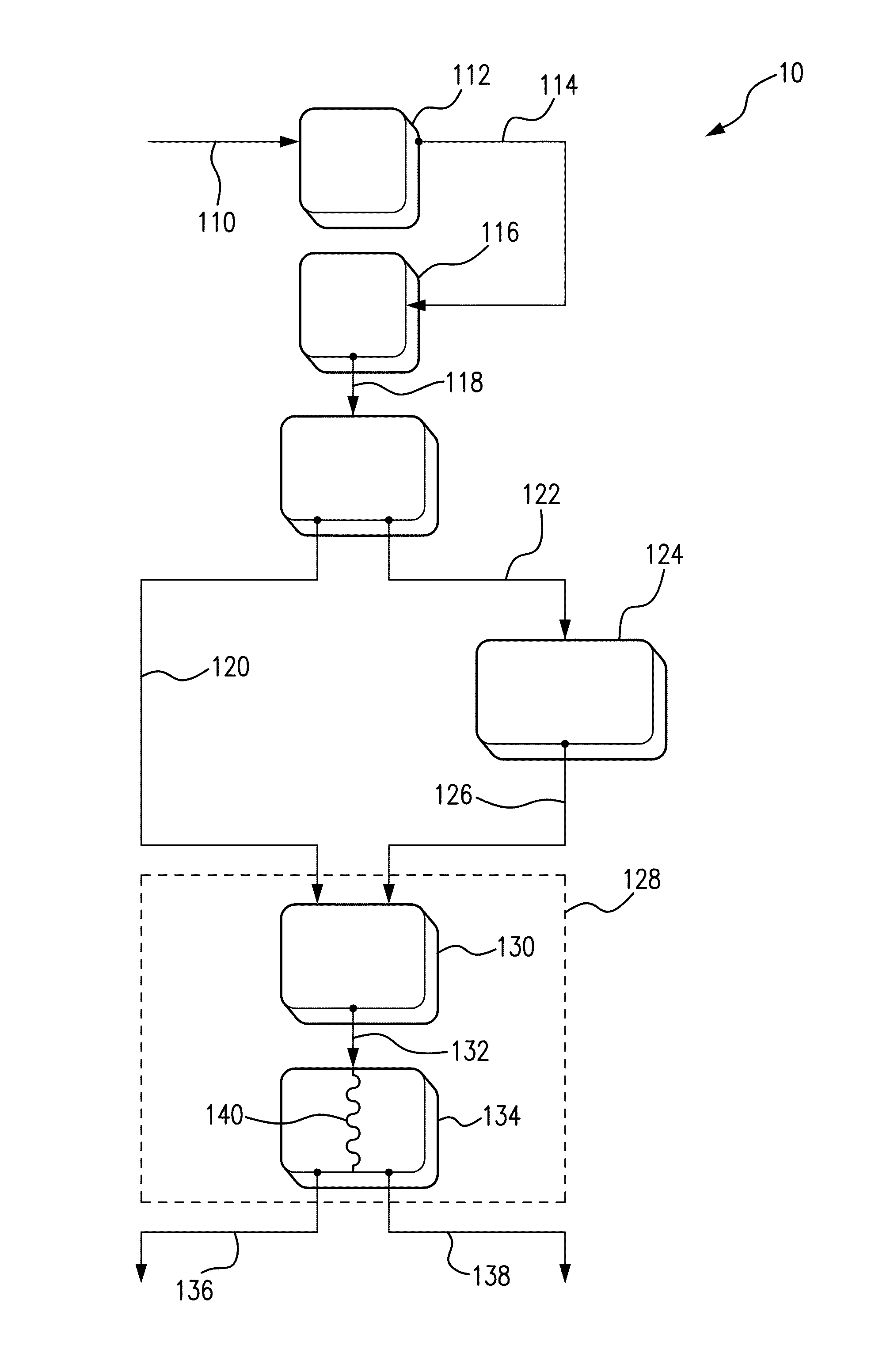

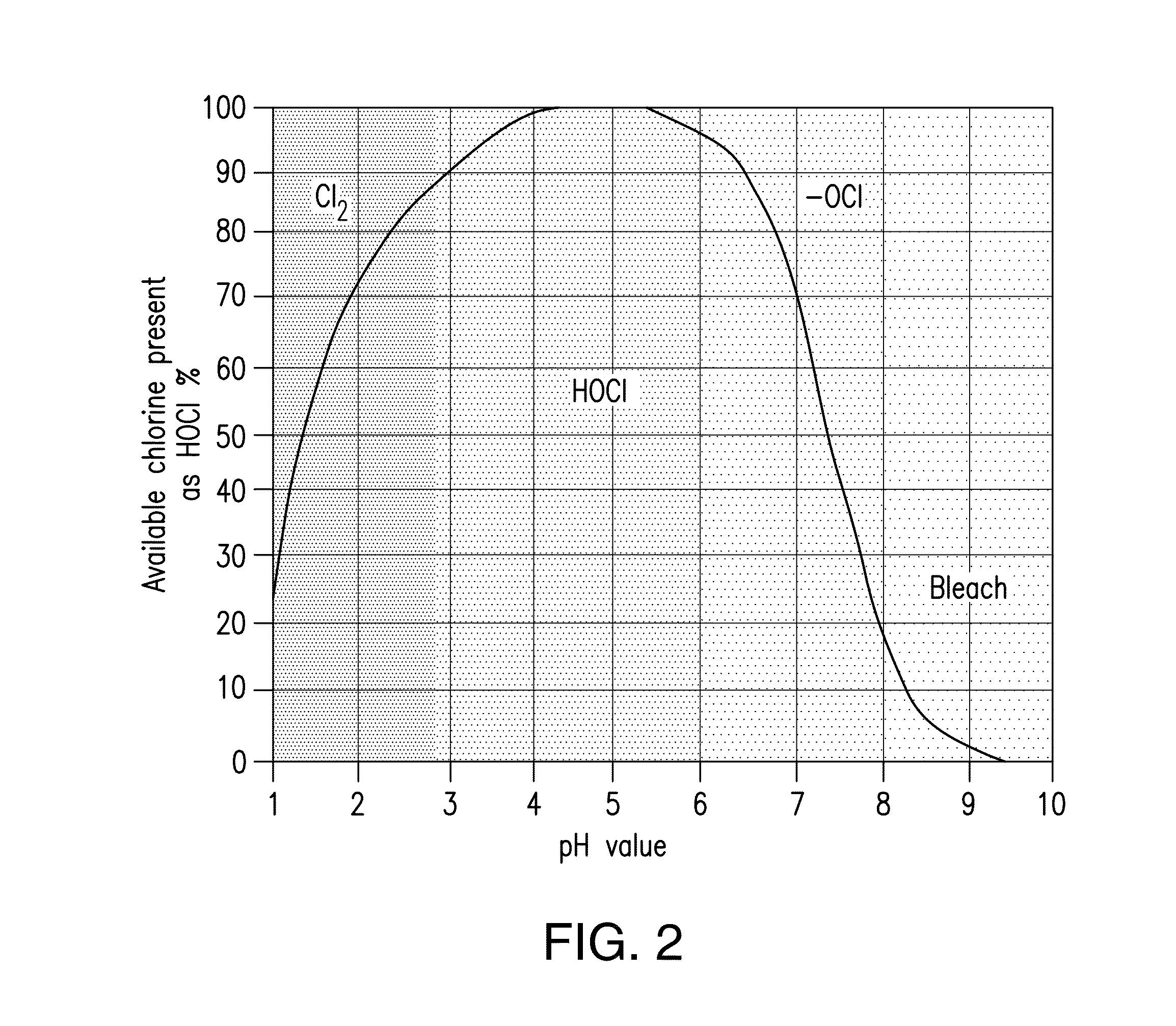

Research into novel production methods aims to create more stable forms of hypochlorous acid from the outset. This includes exploring electrochemical generation techniques, investigating the use of precursor compounds, and developing new synthesis pathways that result in inherently more stable hypochlorous acid solutions.Expand Specific Solutions

Key Industry Players

The market for hypochlorous acid shelf-life extension techniques is in a growth phase, driven by increasing demand for safe and effective disinfectants. The global market size is expanding, with applications across healthcare, food processing, and water treatment industries. Technologically, the field is advancing rapidly, with companies like WIAB WATER INNOVATION AB, Parasol Medical LLC, and Aquaox, Inc. leading innovation. These firms are developing proprietary formulations and delivery systems to enhance stability and efficacy. Established players such as Fresenius Medical Care and Zep, Inc. are also investing in R&D to improve product longevity. The competitive landscape is diverse, with both specialized biotech firms and larger chemical companies vying for market share through technological differentiation and product quality improvements.

WIAB WATER INNOVATION AB

Technical Solution: WIAB Water Innovation AB has focused on developing a unique electrolysis process that produces highly stable hypochlorous acid solutions. Their technology utilizes specialized electrode materials and precise control of electrolysis parameters to minimize the formation of byproducts that can reduce HOCl stability[11]. The company has also implemented an innovative bottling process that removes dissolved oxygen from the solution before packaging, significantly extending shelf life[12]. Additionally, WIAB has developed a proprietary additive package that helps maintain HOCl stability without affecting its antimicrobial efficacy.

Strengths: High-purity HOCl production, innovative oxygen removal process. Weaknesses: May require specialized production equipment, potential scalability challenges.

Aquaox, Inc.

Technical Solution: Aquaox has developed a patented electrolysis process to produce stable hypochlorous acid (HOCl) solutions with extended shelf life. Their technology utilizes a unique membrane-free electrolytic cell design and precise control of pH and oxidation-reduction potential (ORP) during production[1]. This results in HOCl solutions with concentrations up to 500 ppm and a shelf life of up to 12 months when stored in proper conditions[2]. The company has also implemented advanced packaging techniques, including UV-resistant bottles and air-tight seals, to further extend the stability of their HOCl products[3].

Strengths: Long shelf life, high concentration, patented production process. Weaknesses: May require specialized storage conditions, potentially higher production costs.

Innovative Stabilization Tech

Method for Producing Shelf Stable Hypochlorous Acid Solutions

PatentInactiveUS20150119245A1

Innovation

- A method involving the production of hypochlorous acid using high purity water from a combination of softening and reverse osmosis steps, followed by electrolysis with a bipolar membrane, and storage in opaque PET bottles or Nylon/PE bags, which significantly extends the shelf life to 24 months.

Method and system for preparing hypochlorous acid solutions with prolonged shelf-life

PatentInactiveUS20210235701A1

Innovation

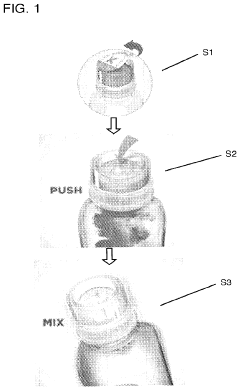

- A system using a dispensing device with a chlorine-containing powder or liquid that is safely measured and mixed with a receiving liquid to produce a shelf-stable Hypochlorous acid solution, maintaining a neutral pH and ensuring correct disinfection strength, eliminating user exposure to raw chemicals and ensuring safe disposal.

Regulatory Considerations

The regulatory landscape for Hypochlorous Acid (HOCl) and its shelf-life extension techniques is complex and varies across different regions and applications. In the United States, the Food and Drug Administration (FDA) regulates HOCl as an antimicrobial agent in food processing, medical devices, and certain consumer products. The Environmental Protection Agency (EPA) also oversees its use as a disinfectant and sanitizer.

For food applications, HOCl is generally recognized as safe (GRAS) when used as an antimicrobial agent in the production and preparation of whole or cut meat and poultry products. However, specific concentration limits and usage guidelines must be adhered to. In the European Union, the European Food Safety Authority (EFSA) has evaluated the safety of HOCl for various food-related applications, including as a processing aid for fruits and vegetables.

In the medical field, HOCl-based products are subject to stringent regulations, particularly when used in wound care or as medical device disinfectants. The FDA classifies these products based on their intended use and requires manufacturers to demonstrate safety and efficacy through clinical trials and rigorous testing protocols.

Regulatory considerations for shelf-life extension techniques of HOCl primarily focus on maintaining its stability and efficacy over time. Manufacturers must provide data on the product's shelf life, storage conditions, and any potential degradation products. The packaging materials used for HOCl products are also subject to regulatory scrutiny to ensure they do not interact with the active ingredient or compromise its stability.

Environmental regulations play a crucial role in the production and disposal of HOCl. While it is considered environmentally friendly due to its rapid breakdown into harmless components, manufacturers must still comply with local and national environmental protection laws regarding production processes and waste management.

As new shelf-life extension techniques emerge, regulatory bodies may require additional safety and efficacy data before approving their use. This could involve stability studies, toxicology assessments, and environmental impact evaluations. Companies developing novel preservation methods for HOCl must engage with regulatory agencies early in the development process to ensure compliance and streamline the approval pathway.

International harmonization efforts are underway to standardize regulations for HOCl across different countries, particularly in the context of its use as a disinfectant and sanitizer. These efforts aim to facilitate global trade and ensure consistent safety standards worldwide. However, companies operating in multiple markets must still navigate the nuances of regional regulatory requirements.

For food applications, HOCl is generally recognized as safe (GRAS) when used as an antimicrobial agent in the production and preparation of whole or cut meat and poultry products. However, specific concentration limits and usage guidelines must be adhered to. In the European Union, the European Food Safety Authority (EFSA) has evaluated the safety of HOCl for various food-related applications, including as a processing aid for fruits and vegetables.

In the medical field, HOCl-based products are subject to stringent regulations, particularly when used in wound care or as medical device disinfectants. The FDA classifies these products based on their intended use and requires manufacturers to demonstrate safety and efficacy through clinical trials and rigorous testing protocols.

Regulatory considerations for shelf-life extension techniques of HOCl primarily focus on maintaining its stability and efficacy over time. Manufacturers must provide data on the product's shelf life, storage conditions, and any potential degradation products. The packaging materials used for HOCl products are also subject to regulatory scrutiny to ensure they do not interact with the active ingredient or compromise its stability.

Environmental regulations play a crucial role in the production and disposal of HOCl. While it is considered environmentally friendly due to its rapid breakdown into harmless components, manufacturers must still comply with local and national environmental protection laws regarding production processes and waste management.

As new shelf-life extension techniques emerge, regulatory bodies may require additional safety and efficacy data before approving their use. This could involve stability studies, toxicology assessments, and environmental impact evaluations. Companies developing novel preservation methods for HOCl must engage with regulatory agencies early in the development process to ensure compliance and streamline the approval pathway.

International harmonization efforts are underway to standardize regulations for HOCl across different countries, particularly in the context of its use as a disinfectant and sanitizer. These efforts aim to facilitate global trade and ensure consistent safety standards worldwide. However, companies operating in multiple markets must still navigate the nuances of regional regulatory requirements.

Environmental Impact

The environmental impact of shelf-life extension techniques for Hypochlorous Acid (HOCl) is a critical consideration in the development and implementation of these technologies. As HOCl is increasingly used in various industries, including healthcare, food processing, and water treatment, the need for effective preservation methods has grown. However, these techniques must be evaluated not only for their efficacy but also for their potential effects on the environment.

One of the primary environmental concerns associated with HOCl shelf-life extension is the use of stabilizing agents. Many traditional stabilizers are synthetic chemicals that may persist in the environment long after their intended use. These compounds can accumulate in soil and water systems, potentially affecting aquatic ecosystems and terrestrial biodiversity. Recent trends in research have focused on developing more environmentally friendly stabilizers, such as natural polymers and plant-based compounds, which offer biodegradability and reduced ecological impact.

The packaging materials used in HOCl storage and distribution also play a significant role in environmental considerations. Conventional plastic packaging contributes to the global plastic waste problem, with many materials taking hundreds of years to decompose. Innovative approaches in packaging design are emerging, including the use of biodegradable plastics, recycled materials, and smart packaging technologies that extend shelf-life while minimizing environmental footprint.

Energy consumption is another crucial factor in assessing the environmental impact of HOCl shelf-life extension techniques. Some methods, such as refrigeration or controlled atmosphere storage, require significant energy inputs, contributing to greenhouse gas emissions. The trend towards more energy-efficient preservation technologies, including passive cooling systems and renewable energy-powered storage solutions, is gaining traction in the industry.

Water usage is a concern in the production and preservation of HOCl, particularly in regions facing water scarcity. Advanced water recycling and purification systems are being integrated into HOCl production facilities to minimize water consumption and reduce wastewater discharge. These closed-loop systems not only conserve water resources but also prevent the release of potentially harmful chemicals into the environment.

The disposal of expired or unused HOCl solutions presents another environmental challenge. Improper disposal can lead to soil and water contamination, affecting local ecosystems. To address this issue, there is a growing emphasis on developing on-site degradation methods that safely neutralize HOCl before disposal, as well as implementing more efficient production and inventory management systems to minimize waste.

As the demand for HOCl continues to grow, the environmental impact of its production, storage, and disposal becomes increasingly significant. The industry is responding with a shift towards more sustainable practices, driven by both regulatory pressures and consumer demand for environmentally responsible products. This trend is likely to continue, with future shelf-life extension techniques for HOCl focusing not only on efficacy and cost-effectiveness but also on minimizing ecological footprint throughout the product lifecycle.

One of the primary environmental concerns associated with HOCl shelf-life extension is the use of stabilizing agents. Many traditional stabilizers are synthetic chemicals that may persist in the environment long after their intended use. These compounds can accumulate in soil and water systems, potentially affecting aquatic ecosystems and terrestrial biodiversity. Recent trends in research have focused on developing more environmentally friendly stabilizers, such as natural polymers and plant-based compounds, which offer biodegradability and reduced ecological impact.

The packaging materials used in HOCl storage and distribution also play a significant role in environmental considerations. Conventional plastic packaging contributes to the global plastic waste problem, with many materials taking hundreds of years to decompose. Innovative approaches in packaging design are emerging, including the use of biodegradable plastics, recycled materials, and smart packaging technologies that extend shelf-life while minimizing environmental footprint.

Energy consumption is another crucial factor in assessing the environmental impact of HOCl shelf-life extension techniques. Some methods, such as refrigeration or controlled atmosphere storage, require significant energy inputs, contributing to greenhouse gas emissions. The trend towards more energy-efficient preservation technologies, including passive cooling systems and renewable energy-powered storage solutions, is gaining traction in the industry.

Water usage is a concern in the production and preservation of HOCl, particularly in regions facing water scarcity. Advanced water recycling and purification systems are being integrated into HOCl production facilities to minimize water consumption and reduce wastewater discharge. These closed-loop systems not only conserve water resources but also prevent the release of potentially harmful chemicals into the environment.

The disposal of expired or unused HOCl solutions presents another environmental challenge. Improper disposal can lead to soil and water contamination, affecting local ecosystems. To address this issue, there is a growing emphasis on developing on-site degradation methods that safely neutralize HOCl before disposal, as well as implementing more efficient production and inventory management systems to minimize waste.

As the demand for HOCl continues to grow, the environmental impact of its production, storage, and disposal becomes increasingly significant. The industry is responding with a shift towards more sustainable practices, driven by both regulatory pressures and consumer demand for environmentally responsible products. This trend is likely to continue, with future shelf-life extension techniques for HOCl focusing not only on efficacy and cost-effectiveness but also on minimizing ecological footprint throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!