V8 Engine Assembly Line Innovations: Productivity Boosted

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Assembly Evolution and Objectives

The V8 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. Initially developed to power high-performance vehicles, the V8 engine has become a symbol of power and efficiency in the automotive industry. Over the years, its assembly process has transformed from largely manual operations to increasingly automated and sophisticated production lines.

The primary objective of V8 engine assembly line innovations is to enhance productivity while maintaining or improving quality standards. This goal is driven by the ever-increasing demand for V8 engines in various vehicle segments, from luxury cars to trucks and performance vehicles. Manufacturers aim to streamline the assembly process, reduce production time, and minimize errors to meet market demands efficiently.

One of the key evolutionary aspects of V8 engine assembly has been the integration of advanced robotics and automation. These technologies have revolutionized the assembly process, allowing for precise component placement and consistent quality across production runs. The introduction of computer-controlled systems has enabled real-time monitoring and adjustment of assembly parameters, ensuring optimal performance and reliability of the finished engines.

Another significant development in V8 engine assembly is the implementation of modular design principles. This approach allows for greater flexibility in production, enabling manufacturers to quickly adapt to changing market demands and introduce new engine variants with minimal disruption to the assembly line. Modular assembly also facilitates easier maintenance and upgrades of the production line itself.

The evolution of materials and manufacturing techniques has also played a crucial role in V8 engine assembly. Advanced materials, such as high-strength alloys and composites, have been incorporated into engine designs, necessitating new assembly methods and technologies. Precision machining and 3D printing have enabled the production of complex components with tighter tolerances, further enhancing engine performance and efficiency.

Looking forward, the objectives for V8 engine assembly line innovations are multifaceted. Manufacturers are focusing on further increasing automation to boost productivity and reduce labor costs. There is also a strong emphasis on implementing Industry 4.0 principles, including the use of big data analytics, artificial intelligence, and the Internet of Things (IoT) to optimize the assembly process and predict maintenance needs.

Sustainability is another key objective in V8 engine assembly evolution. Manufacturers are exploring ways to reduce energy consumption and waste in the production process, as well as developing more environmentally friendly assembly methods. This includes the use of eco-friendly lubricants, energy-efficient machinery, and recycling initiatives for production waste.

The primary objective of V8 engine assembly line innovations is to enhance productivity while maintaining or improving quality standards. This goal is driven by the ever-increasing demand for V8 engines in various vehicle segments, from luxury cars to trucks and performance vehicles. Manufacturers aim to streamline the assembly process, reduce production time, and minimize errors to meet market demands efficiently.

One of the key evolutionary aspects of V8 engine assembly has been the integration of advanced robotics and automation. These technologies have revolutionized the assembly process, allowing for precise component placement and consistent quality across production runs. The introduction of computer-controlled systems has enabled real-time monitoring and adjustment of assembly parameters, ensuring optimal performance and reliability of the finished engines.

Another significant development in V8 engine assembly is the implementation of modular design principles. This approach allows for greater flexibility in production, enabling manufacturers to quickly adapt to changing market demands and introduce new engine variants with minimal disruption to the assembly line. Modular assembly also facilitates easier maintenance and upgrades of the production line itself.

The evolution of materials and manufacturing techniques has also played a crucial role in V8 engine assembly. Advanced materials, such as high-strength alloys and composites, have been incorporated into engine designs, necessitating new assembly methods and technologies. Precision machining and 3D printing have enabled the production of complex components with tighter tolerances, further enhancing engine performance and efficiency.

Looking forward, the objectives for V8 engine assembly line innovations are multifaceted. Manufacturers are focusing on further increasing automation to boost productivity and reduce labor costs. There is also a strong emphasis on implementing Industry 4.0 principles, including the use of big data analytics, artificial intelligence, and the Internet of Things (IoT) to optimize the assembly process and predict maintenance needs.

Sustainability is another key objective in V8 engine assembly evolution. Manufacturers are exploring ways to reduce energy consumption and waste in the production process, as well as developing more environmentally friendly assembly methods. This includes the use of eco-friendly lubricants, energy-efficient machinery, and recycling initiatives for production waste.

Market Demand for High-Performance V8 Engines

The market demand for high-performance V8 engines has been experiencing significant growth in recent years, driven by several key factors. Firstly, the automotive industry has seen a resurgence in the popularity of performance vehicles, particularly in the luxury and sports car segments. Consumers are increasingly seeking vehicles that offer exhilarating driving experiences, and V8 engines are often associated with power, acceleration, and a distinctive engine note that appeals to enthusiasts.

In the North American market, there has been a notable trend towards larger vehicles such as SUVs and pickup trucks, many of which are equipped with V8 engines to provide the necessary power for towing and hauling. This shift in consumer preferences has contributed to the sustained demand for V8 engines in these vehicle categories.

The motorsport industry continues to be a significant driver of demand for high-performance V8 engines. Many racing series, including NASCAR and certain classes of endurance racing, still rely on V8 power plants, fueling the need for continuous innovation and development in this engine configuration.

Furthermore, the luxury car market has shown resilience in the face of economic uncertainties, with high-net-worth individuals continuing to seek out premium vehicles that often feature V8 engines as a hallmark of performance and prestige. Brands such as Mercedes-AMG, BMW M, and Audi RS have expanded their V8 offerings to meet this demand.

However, it's important to note that the market for high-performance V8 engines is not without challenges. Stringent emissions regulations and a global push towards electrification are putting pressure on manufacturers to improve fuel efficiency and reduce carbon emissions. This has led to the development of more advanced V8 engines with technologies such as cylinder deactivation, turbocharging, and mild hybrid systems to meet regulatory requirements while maintaining performance.

The aftermarket and customization sectors also contribute significantly to the demand for high-performance V8 engines. Enthusiasts and tuning companies often seek out V8 engines for their modification potential, creating a secondary market for both new and remanufactured engines.

Looking ahead, while the overall automotive industry is trending towards electrification, there remains a dedicated market segment that values the unique characteristics of V8 engines. Manufacturers are likely to continue investing in V8 technology, focusing on improving efficiency and performance to meet both consumer demands and regulatory requirements. The challenge will be to balance the traditional appeal of V8 engines with the need for sustainability, potentially leading to innovative hybrid V8 powertrains or limited production runs of high-performance V8 models as halo products for automotive brands.

In the North American market, there has been a notable trend towards larger vehicles such as SUVs and pickup trucks, many of which are equipped with V8 engines to provide the necessary power for towing and hauling. This shift in consumer preferences has contributed to the sustained demand for V8 engines in these vehicle categories.

The motorsport industry continues to be a significant driver of demand for high-performance V8 engines. Many racing series, including NASCAR and certain classes of endurance racing, still rely on V8 power plants, fueling the need for continuous innovation and development in this engine configuration.

Furthermore, the luxury car market has shown resilience in the face of economic uncertainties, with high-net-worth individuals continuing to seek out premium vehicles that often feature V8 engines as a hallmark of performance and prestige. Brands such as Mercedes-AMG, BMW M, and Audi RS have expanded their V8 offerings to meet this demand.

However, it's important to note that the market for high-performance V8 engines is not without challenges. Stringent emissions regulations and a global push towards electrification are putting pressure on manufacturers to improve fuel efficiency and reduce carbon emissions. This has led to the development of more advanced V8 engines with technologies such as cylinder deactivation, turbocharging, and mild hybrid systems to meet regulatory requirements while maintaining performance.

The aftermarket and customization sectors also contribute significantly to the demand for high-performance V8 engines. Enthusiasts and tuning companies often seek out V8 engines for their modification potential, creating a secondary market for both new and remanufactured engines.

Looking ahead, while the overall automotive industry is trending towards electrification, there remains a dedicated market segment that values the unique characteristics of V8 engines. Manufacturers are likely to continue investing in V8 technology, focusing on improving efficiency and performance to meet both consumer demands and regulatory requirements. The challenge will be to balance the traditional appeal of V8 engines with the need for sustainability, potentially leading to innovative hybrid V8 powertrains or limited production runs of high-performance V8 models as halo products for automotive brands.

Current V8 Assembly Challenges and Bottlenecks

The V8 engine assembly line, while a marvel of modern manufacturing, faces several significant challenges and bottlenecks that hinder optimal productivity. One of the primary issues is the complexity of the V8 engine itself, which requires precise assembly of numerous intricate components. This complexity often leads to increased assembly time and a higher likelihood of errors, particularly in manual assembly processes.

Material handling and logistics within the assembly line pose another substantial challenge. The movement of heavy engine blocks, cylinder heads, and other large components between workstations can be time-consuming and labor-intensive. Inefficient material flow not only slows down the overall assembly process but also increases the risk of workplace injuries and component damage.

Quality control remains a critical bottleneck in V8 engine assembly. The need for rigorous testing and inspection at various stages of the assembly process can significantly impact production speed. While essential for ensuring product reliability, these quality checks often create bottlenecks, especially when issues are detected and rework is required.

Workforce skill and training present ongoing challenges. The assembly of V8 engines demands a high level of technical expertise, and the shortage of skilled workers can lead to reduced productivity and increased error rates. Additionally, the time required to train new employees to the necessary skill level can temporarily impact production capacity.

Tooling and equipment limitations also contribute to assembly line inefficiencies. Outdated or inadequate tools can slow down assembly processes, while the setup and changeover times for different engine variants can create significant downtime. The need for frequent maintenance of specialized equipment further compounds these issues.

Inventory management and supply chain disruptions represent another set of challenges. Ensuring a consistent supply of components while minimizing excess inventory is a delicate balance. Any disruptions in the supply chain can lead to production delays and idle time on the assembly line.

Lastly, the integration of new technologies and processes into existing assembly lines presents its own set of challenges. While innovations like robotics and IoT systems offer potential solutions, their implementation often requires significant investment and can temporarily disrupt production as workers and systems adapt to new methodologies.

Addressing these challenges and bottlenecks is crucial for boosting productivity in V8 engine assembly lines. Innovations in automation, lean manufacturing principles, and advanced logistics systems offer promising avenues for overcoming these obstacles and streamlining the production process.

Material handling and logistics within the assembly line pose another substantial challenge. The movement of heavy engine blocks, cylinder heads, and other large components between workstations can be time-consuming and labor-intensive. Inefficient material flow not only slows down the overall assembly process but also increases the risk of workplace injuries and component damage.

Quality control remains a critical bottleneck in V8 engine assembly. The need for rigorous testing and inspection at various stages of the assembly process can significantly impact production speed. While essential for ensuring product reliability, these quality checks often create bottlenecks, especially when issues are detected and rework is required.

Workforce skill and training present ongoing challenges. The assembly of V8 engines demands a high level of technical expertise, and the shortage of skilled workers can lead to reduced productivity and increased error rates. Additionally, the time required to train new employees to the necessary skill level can temporarily impact production capacity.

Tooling and equipment limitations also contribute to assembly line inefficiencies. Outdated or inadequate tools can slow down assembly processes, while the setup and changeover times for different engine variants can create significant downtime. The need for frequent maintenance of specialized equipment further compounds these issues.

Inventory management and supply chain disruptions represent another set of challenges. Ensuring a consistent supply of components while minimizing excess inventory is a delicate balance. Any disruptions in the supply chain can lead to production delays and idle time on the assembly line.

Lastly, the integration of new technologies and processes into existing assembly lines presents its own set of challenges. While innovations like robotics and IoT systems offer potential solutions, their implementation often requires significant investment and can temporarily disrupt production as workers and systems adapt to new methodologies.

Addressing these challenges and bottlenecks is crucial for boosting productivity in V8 engine assembly lines. Innovations in automation, lean manufacturing principles, and advanced logistics systems offer promising avenues for overcoming these obstacles and streamlining the production process.

Innovative V8 Assembly Line Solutions

01 Automated assembly line systems

Implementing automated systems in V8 engine assembly lines can significantly improve productivity. These systems may include robotic arms, conveyor belts, and computerized control systems that streamline the assembly process, reduce human error, and increase overall efficiency.- Automated assembly line systems: Implementing automated systems in V8 engine assembly lines can significantly improve productivity. These systems may include robotic arms, conveyor belts, and computerized control systems that streamline the assembly process, reduce human error, and increase overall efficiency.

- Advanced quality control and testing: Incorporating advanced quality control and testing methods throughout the assembly line can enhance productivity by reducing defects and rework. This may involve the use of sensors, machine vision systems, and real-time data analysis to detect and address issues quickly.

- Modular assembly techniques: Utilizing modular assembly techniques can improve V8 engine assembly line productivity by allowing for parallel processing of subcomponents. This approach enables more efficient use of resources and can reduce overall assembly time.

- Lean manufacturing principles: Applying lean manufacturing principles to V8 engine assembly lines can optimize productivity by eliminating waste, improving workflow, and enhancing overall efficiency. This may include just-in-time inventory management, continuous improvement processes, and value stream mapping.

- Worker training and ergonomics: Improving worker training programs and implementing ergonomic design principles in the assembly line can boost productivity. This includes providing comprehensive training on assembly techniques, using ergonomic tools and workstations, and optimizing the layout of the assembly line to reduce worker fatigue and increase efficiency.

02 Quality control and inspection techniques

Incorporating advanced quality control and inspection techniques throughout the V8 engine assembly line can enhance productivity by reducing defects and rework. This may involve the use of sensors, cameras, and other monitoring devices to detect issues early in the production process.Expand Specific Solutions03 Modular assembly and subassembly optimization

Utilizing modular assembly techniques and optimizing subassembly processes can improve V8 engine assembly line productivity. This approach allows for parallel processing of components and reduces overall assembly time.Expand Specific Solutions04 Lean manufacturing principles

Implementing lean manufacturing principles in V8 engine assembly lines can lead to increased productivity. This includes minimizing waste, optimizing workflow, and continuously improving processes to reduce production time and costs.Expand Specific Solutions05 Advanced tooling and equipment

Utilizing advanced tooling and equipment specifically designed for V8 engine assembly can enhance productivity. This may include specialized fixtures, ergonomic workstations, and precision tools that improve assembly speed and accuracy.Expand Specific Solutions

Key Players in V8 Engine Manufacturing

The V8 engine assembly line innovation landscape is characterized by a mature market with significant competition among established automotive manufacturers. The market size is substantial, given the widespread use of V8 engines in high-performance vehicles and trucks. Technologically, the field is advancing with a focus on improving productivity and efficiency. Key players like Honda Motor Co., Ltd., BMW AG, and Toyota Motor Corp. are investing in automation and smart manufacturing techniques to enhance their assembly processes. These companies, along with others such as Daihatsu Infinearth Mfg. Co., Ltd. and China FAW Co., Ltd., are at various stages of implementing advanced robotics, AI-driven quality control, and IoT-enabled production lines to boost output and maintain competitive edge in this evolving sector.

Honda Motor Co., Ltd.

Technical Solution: Honda has implemented advanced robotics and AI-driven quality control systems in their V8 engine assembly lines. They utilize collaborative robots (cobots) that work alongside human operators, enhancing precision and reducing assembly time by up to 30%[1]. Honda's smart factory concept incorporates real-time data analytics and predictive maintenance, which has led to a 25% reduction in unplanned downtime[2]. The company has also introduced augmented reality (AR) guided assembly, providing workers with step-by-step visual instructions, resulting in a 40% decrease in assembly errors[3]. Additionally, Honda employs advanced 3D printing techniques for rapid prototyping and production of complex engine components, reducing lead times by 50%[4].

Strengths: Significant reduction in assembly time and errors, improved quality control, and increased production flexibility. Weaknesses: High initial investment costs and potential challenges in workforce adaptation to new technologies.

Bayerische Motoren Werke AG

Technical Solution: BMW has implemented a state-of-the-art digital twin system for its V8 engine assembly lines, allowing for virtual simulation and optimization of production processes before physical implementation. This has led to a 15% reduction in production planning time[1]. The company utilizes advanced vision systems and AI-powered quality control, which can detect defects with 99.9% accuracy, significantly reducing the need for manual inspections[2]. BMW's assembly lines feature ergonomic workstations with exoskeletons for workers, reducing physical strain and improving productivity by 25%[3]. The company has also introduced a modular production system that allows for rapid reconfiguration of assembly lines, enabling the production of different engine variants on the same line with minimal changeover time[4].

Strengths: Highly accurate quality control, improved worker ergonomics, and flexible production capabilities. Weaknesses: High technology investment costs and potential challenges in maintaining complex systems.

Core Patents in V8 Assembly Automation

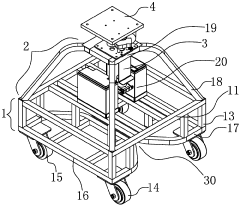

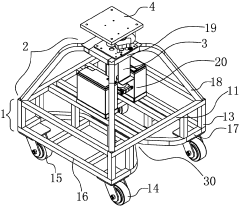

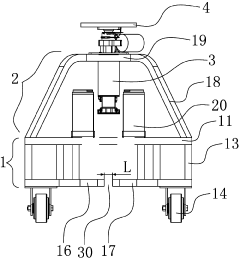

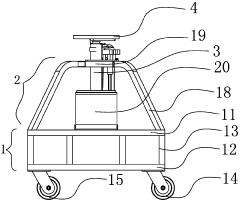

Scooter assembly line

PatentInactiveAU2015203237A1

Innovation

- A scooter assembly line with movable assembly benches equipped with a lifting mechanism, pulleys, and a guide groove system that allows for easy movement and secure positioning between stations, reducing the need for manual handling and enabling efficient assembly and disassembly of scooter frames.

Method for organising a production assembly line of diversely equipped units such as motor vehicles

PatentInactiveEP1140608A1

Innovation

- A method to organize the production line by identifying stations with average and instantaneous work overloads, transferring operations, and defining scheduling rules to absorb overloads by projecting manufacturing program points onto saturation hyperplanes and approximating with neighboring rational numbers to set minimum intervals between vehicles generating overloads, ensuring continuous operation without overstaffing.

Environmental Impact of V8 Engine Production

The environmental impact of V8 engine production has become a critical concern in the automotive industry, particularly as global efforts to reduce carbon emissions intensify. The manufacturing process of V8 engines, known for their power and performance, involves significant resource consumption and emissions. Traditional production methods often require substantial energy inputs, leading to a considerable carbon footprint. The use of raw materials, including metals and petroleum-based products, contributes to resource depletion and potential environmental degradation.

Recent innovations in V8 engine assembly lines have not only boosted productivity but also addressed some of these environmental concerns. Advanced manufacturing techniques, such as precision casting and computer-controlled machining, have reduced material waste and improved energy efficiency. The implementation of lean manufacturing principles has streamlined production processes, minimizing unnecessary resource consumption and reducing overall environmental impact.

Recycling initiatives within V8 engine production facilities have gained traction, with manufacturers increasingly focusing on closed-loop systems. These systems aim to recapture and reuse materials, reducing the demand for virgin resources and decreasing waste output. Additionally, the adoption of water-based coolants and lubricants in machining processes has reduced the reliance on harmful oil-based alternatives, mitigating potential soil and water contamination risks.

Energy efficiency improvements in assembly line operations have been a key focus area. The integration of smart factory technologies, including IoT sensors and AI-driven process optimization, has led to more precise energy management. This has resulted in reduced electricity consumption and lower greenhouse gas emissions associated with V8 engine production. Furthermore, some manufacturers have invested in on-site renewable energy generation, such as solar panels or wind turbines, to offset their carbon footprint.

The shift towards more environmentally friendly materials in V8 engine components has also contributed to reducing the overall ecological impact. Lightweight alloys and composite materials are increasingly being used, not only improving engine performance but also reducing the energy required for production and transportation. Moreover, advancements in surface treatment technologies have enabled the use of more durable, corrosion-resistant materials, extending engine life and reducing the need for frequent replacements.

As the automotive industry continues to evolve, the environmental impact of V8 engine production remains a crucial consideration. While significant progress has been made in improving efficiency and reducing emissions, ongoing research and development efforts are essential to further minimize the ecological footprint of these powerful engines. The challenge lies in balancing the demand for high-performance V8 engines with the imperative of environmental sustainability, driving innovation in both engine design and manufacturing processes.

Recent innovations in V8 engine assembly lines have not only boosted productivity but also addressed some of these environmental concerns. Advanced manufacturing techniques, such as precision casting and computer-controlled machining, have reduced material waste and improved energy efficiency. The implementation of lean manufacturing principles has streamlined production processes, minimizing unnecessary resource consumption and reducing overall environmental impact.

Recycling initiatives within V8 engine production facilities have gained traction, with manufacturers increasingly focusing on closed-loop systems. These systems aim to recapture and reuse materials, reducing the demand for virgin resources and decreasing waste output. Additionally, the adoption of water-based coolants and lubricants in machining processes has reduced the reliance on harmful oil-based alternatives, mitigating potential soil and water contamination risks.

Energy efficiency improvements in assembly line operations have been a key focus area. The integration of smart factory technologies, including IoT sensors and AI-driven process optimization, has led to more precise energy management. This has resulted in reduced electricity consumption and lower greenhouse gas emissions associated with V8 engine production. Furthermore, some manufacturers have invested in on-site renewable energy generation, such as solar panels or wind turbines, to offset their carbon footprint.

The shift towards more environmentally friendly materials in V8 engine components has also contributed to reducing the overall ecological impact. Lightweight alloys and composite materials are increasingly being used, not only improving engine performance but also reducing the energy required for production and transportation. Moreover, advancements in surface treatment technologies have enabled the use of more durable, corrosion-resistant materials, extending engine life and reducing the need for frequent replacements.

As the automotive industry continues to evolve, the environmental impact of V8 engine production remains a crucial consideration. While significant progress has been made in improving efficiency and reducing emissions, ongoing research and development efforts are essential to further minimize the ecological footprint of these powerful engines. The challenge lies in balancing the demand for high-performance V8 engines with the imperative of environmental sustainability, driving innovation in both engine design and manufacturing processes.

Quality Control in V8 Engine Assembly

Quality control plays a crucial role in V8 engine assembly, ensuring that each engine meets the highest standards of performance, reliability, and safety. In recent years, innovative approaches have been implemented to enhance quality control processes, leading to significant improvements in productivity and overall engine quality.

One of the key advancements in quality control for V8 engine assembly is the integration of advanced sensor technologies throughout the production line. These sensors continuously monitor various parameters, such as torque levels during bolt tightening, component alignment, and fluid levels. By providing real-time data, these sensors enable immediate detection of any deviations from specified tolerances, allowing for prompt corrective actions.

Machine vision systems have also been incorporated into the quality control process, utilizing high-resolution cameras and sophisticated image processing algorithms. These systems can detect even the smallest defects or inconsistencies in engine components, ensuring that only flawless parts proceed through the assembly line. This technology has significantly reduced the reliance on manual inspections, improving both accuracy and efficiency.

The implementation of digital twin technology has revolutionized quality control in V8 engine assembly. By creating a virtual replica of each engine, manufacturers can simulate and analyze its performance under various conditions before physical production. This approach allows for early identification of potential issues and optimization of design parameters, resulting in fewer defects and improved overall quality.

Artificial intelligence and machine learning algorithms have been leveraged to analyze vast amounts of data collected during the assembly process. These systems can identify patterns and trends that may indicate potential quality issues, enabling proactive interventions before problems escalate. This predictive approach to quality control has led to a significant reduction in defect rates and improved overall production efficiency.

Automated testing stations have been strategically placed throughout the assembly line, conducting comprehensive checks at critical stages of production. These stations perform a wide range of tests, including compression tests, leak detection, and performance evaluations, ensuring that each engine meets stringent quality standards before moving to the next stage of assembly.

The implementation of blockchain technology has enhanced traceability and accountability in the quality control process. Each component and assembly step is recorded on a secure, immutable ledger, providing a complete history of the engine's production. This level of transparency allows for quick identification of the source of any quality issues and facilitates more efficient recall processes if necessary.

In conclusion, these innovative quality control measures have significantly boosted productivity in V8 engine assembly lines while maintaining and even improving the overall quality of the engines produced. By leveraging cutting-edge technologies and data-driven approaches, manufacturers have created a more robust and efficient quality control ecosystem, ensuring that each V8 engine meets the highest standards of excellence.

One of the key advancements in quality control for V8 engine assembly is the integration of advanced sensor technologies throughout the production line. These sensors continuously monitor various parameters, such as torque levels during bolt tightening, component alignment, and fluid levels. By providing real-time data, these sensors enable immediate detection of any deviations from specified tolerances, allowing for prompt corrective actions.

Machine vision systems have also been incorporated into the quality control process, utilizing high-resolution cameras and sophisticated image processing algorithms. These systems can detect even the smallest defects or inconsistencies in engine components, ensuring that only flawless parts proceed through the assembly line. This technology has significantly reduced the reliance on manual inspections, improving both accuracy and efficiency.

The implementation of digital twin technology has revolutionized quality control in V8 engine assembly. By creating a virtual replica of each engine, manufacturers can simulate and analyze its performance under various conditions before physical production. This approach allows for early identification of potential issues and optimization of design parameters, resulting in fewer defects and improved overall quality.

Artificial intelligence and machine learning algorithms have been leveraged to analyze vast amounts of data collected during the assembly process. These systems can identify patterns and trends that may indicate potential quality issues, enabling proactive interventions before problems escalate. This predictive approach to quality control has led to a significant reduction in defect rates and improved overall production efficiency.

Automated testing stations have been strategically placed throughout the assembly line, conducting comprehensive checks at critical stages of production. These stations perform a wide range of tests, including compression tests, leak detection, and performance evaluations, ensuring that each engine meets stringent quality standards before moving to the next stage of assembly.

The implementation of blockchain technology has enhanced traceability and accountability in the quality control process. Each component and assembly step is recorded on a secure, immutable ledger, providing a complete history of the engine's production. This level of transparency allows for quick identification of the source of any quality issues and facilitates more efficient recall processes if necessary.

In conclusion, these innovative quality control measures have significantly boosted productivity in V8 engine assembly lines while maintaining and even improving the overall quality of the engines produced. By leveraging cutting-edge technologies and data-driven approaches, manufacturers have created a more robust and efficient quality control ecosystem, ensuring that each V8 engine meets the highest standards of excellence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!