V8 Engine Commercial Applications: A Sector Review

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a powerful and efficient internal combustion engine configuration, has undergone significant evolution since its inception in the early 20th century. Initially developed for high-performance automobiles, the V8 engine has become a staple in various commercial applications due to its balance of power, torque, and reliability.

The evolution of V8 engines has been driven by several key objectives, including increased fuel efficiency, reduced emissions, and improved power-to-weight ratios. Early V8 engines were characterized by their large displacement and relatively low efficiency. However, as environmental concerns and fuel costs became more prominent, manufacturers began focusing on developing more compact and efficient V8 designs.

One of the most significant advancements in V8 technology has been the introduction of variable valve timing and lift systems. These innovations allow for optimized engine performance across a wide range of operating conditions, resulting in improved fuel economy and reduced emissions without sacrificing power output.

Another crucial development in V8 engine technology has been the widespread adoption of direct fuel injection systems. This technology enables more precise control over the fuel delivery process, leading to better combustion efficiency and reduced fuel consumption. Combined with turbocharging or supercharging, modern V8 engines can produce impressive power outputs from relatively small displacements.

The integration of advanced materials and manufacturing techniques has also played a vital role in V8 engine evolution. Lightweight alloys and composite materials have allowed for the creation of stronger, lighter engine components, contributing to overall vehicle efficiency and performance.

In recent years, the automotive industry's shift towards electrification has presented new challenges and opportunities for V8 engine development. Hybrid V8 powertrains have emerged as a transitional technology, combining the traditional benefits of V8 engines with electric motors to achieve improved fuel efficiency and reduced emissions.

Looking forward, the objectives for V8 engine development in commercial applications are likely to focus on further improvements in efficiency and emissions reduction. This may involve the integration of more advanced combustion technologies, such as homogeneous charge compression ignition (HCCI), as well as the continued refinement of hybrid and mild-hybrid systems.

As environmental regulations become increasingly stringent, V8 engine manufacturers will need to explore innovative solutions to meet these challenges while maintaining the performance characteristics that have made V8 engines popular in commercial applications. This may include the development of alternative fuel compatibility, such as hydrogen or synthetic fuels, to ensure the longevity of V8 technology in a changing energy landscape.

The evolution of V8 engines has been driven by several key objectives, including increased fuel efficiency, reduced emissions, and improved power-to-weight ratios. Early V8 engines were characterized by their large displacement and relatively low efficiency. However, as environmental concerns and fuel costs became more prominent, manufacturers began focusing on developing more compact and efficient V8 designs.

One of the most significant advancements in V8 technology has been the introduction of variable valve timing and lift systems. These innovations allow for optimized engine performance across a wide range of operating conditions, resulting in improved fuel economy and reduced emissions without sacrificing power output.

Another crucial development in V8 engine technology has been the widespread adoption of direct fuel injection systems. This technology enables more precise control over the fuel delivery process, leading to better combustion efficiency and reduced fuel consumption. Combined with turbocharging or supercharging, modern V8 engines can produce impressive power outputs from relatively small displacements.

The integration of advanced materials and manufacturing techniques has also played a vital role in V8 engine evolution. Lightweight alloys and composite materials have allowed for the creation of stronger, lighter engine components, contributing to overall vehicle efficiency and performance.

In recent years, the automotive industry's shift towards electrification has presented new challenges and opportunities for V8 engine development. Hybrid V8 powertrains have emerged as a transitional technology, combining the traditional benefits of V8 engines with electric motors to achieve improved fuel efficiency and reduced emissions.

Looking forward, the objectives for V8 engine development in commercial applications are likely to focus on further improvements in efficiency and emissions reduction. This may involve the integration of more advanced combustion technologies, such as homogeneous charge compression ignition (HCCI), as well as the continued refinement of hybrid and mild-hybrid systems.

As environmental regulations become increasingly stringent, V8 engine manufacturers will need to explore innovative solutions to meet these challenges while maintaining the performance characteristics that have made V8 engines popular in commercial applications. This may include the development of alternative fuel compatibility, such as hydrogen or synthetic fuels, to ensure the longevity of V8 technology in a changing energy landscape.

Market Demand Analysis for V8 Engines

The market demand for V8 engines has undergone significant shifts in recent years, driven by changing consumer preferences, environmental regulations, and technological advancements. Traditionally, V8 engines have been synonymous with high-performance vehicles, luxury cars, and heavy-duty trucks, valued for their power, torque, and distinctive sound. However, the automotive industry's landscape has evolved, impacting the demand for these engines.

In the passenger vehicle segment, there has been a noticeable decline in V8 engine demand. This trend is primarily attributed to the growing emphasis on fuel efficiency and reduced emissions. Many consumers are now opting for smaller, turbocharged engines that offer a balance between performance and fuel economy. Luxury car manufacturers, once heavily reliant on V8 engines to showcase their top-tier models, are increasingly turning to hybrid and electric powertrains to meet stringent emission standards while maintaining performance levels.

Despite this shift, certain niche markets continue to show strong demand for V8 engines. The sports car and high-performance vehicle sectors remain loyal to V8 powerplants, with enthusiasts and collectors valuing the raw power and emotional appeal these engines provide. Additionally, the muscle car revival in North America has sustained interest in V8 engines among a dedicated consumer base.

The commercial vehicle sector presents a more complex picture. Heavy-duty trucks and large SUVs still rely on V8 engines for their towing capacity and durability. In the United States, full-size pickup trucks equipped with V8 engines continue to be top sellers, reflecting the enduring demand in this segment. However, even in this market, there is growing competition from more efficient V6 engines and emerging electric alternatives.

Geographically, the demand for V8 engines varies significantly. North America remains the largest market, driven by the popularity of full-size trucks and performance vehicles. In contrast, European markets have seen a sharper decline due to stricter emission regulations and higher fuel costs. Emerging markets show mixed trends, with some regions experiencing growth in luxury vehicle sales that include V8 options, while others prioritize more affordable and efficient alternatives.

Looking ahead, the market for V8 engines is expected to face continued challenges. Tightening global emissions standards and the push towards electrification are likely to further reduce demand in many segments. However, opportunities remain in specialized applications where the V8's characteristics are still highly valued, such as in performance vehicles, certain commercial applications, and niche luxury markets.

In the passenger vehicle segment, there has been a noticeable decline in V8 engine demand. This trend is primarily attributed to the growing emphasis on fuel efficiency and reduced emissions. Many consumers are now opting for smaller, turbocharged engines that offer a balance between performance and fuel economy. Luxury car manufacturers, once heavily reliant on V8 engines to showcase their top-tier models, are increasingly turning to hybrid and electric powertrains to meet stringent emission standards while maintaining performance levels.

Despite this shift, certain niche markets continue to show strong demand for V8 engines. The sports car and high-performance vehicle sectors remain loyal to V8 powerplants, with enthusiasts and collectors valuing the raw power and emotional appeal these engines provide. Additionally, the muscle car revival in North America has sustained interest in V8 engines among a dedicated consumer base.

The commercial vehicle sector presents a more complex picture. Heavy-duty trucks and large SUVs still rely on V8 engines for their towing capacity and durability. In the United States, full-size pickup trucks equipped with V8 engines continue to be top sellers, reflecting the enduring demand in this segment. However, even in this market, there is growing competition from more efficient V6 engines and emerging electric alternatives.

Geographically, the demand for V8 engines varies significantly. North America remains the largest market, driven by the popularity of full-size trucks and performance vehicles. In contrast, European markets have seen a sharper decline due to stricter emission regulations and higher fuel costs. Emerging markets show mixed trends, with some regions experiencing growth in luxury vehicle sales that include V8 options, while others prioritize more affordable and efficient alternatives.

Looking ahead, the market for V8 engines is expected to face continued challenges. Tightening global emissions standards and the push towards electrification are likely to further reduce demand in many segments. However, opportunities remain in specialized applications where the V8's characteristics are still highly valued, such as in performance vehicles, certain commercial applications, and niche luxury markets.

V8 Technology Status and Challenges

The V8 engine, renowned for its power and efficiency, has seen significant advancements in recent years. However, its commercial applications face several challenges in the current technological landscape. The global push towards electrification and stringent emission regulations have put pressure on V8 engine manufacturers to innovate and adapt.

One of the primary challenges is meeting increasingly strict emissions standards. Many countries and regions have implemented or are planning to implement tighter regulations on vehicle emissions, particularly targeting high-performance engines like V8s. This has led to the development of more sophisticated fuel injection systems, improved exhaust gas recirculation technologies, and advanced catalytic converters. However, these solutions often come at the cost of increased complexity and higher production expenses.

Another significant challenge is the improvement of fuel efficiency without compromising performance. V8 engines are traditionally known for their high fuel consumption, which is becoming less acceptable in a market increasingly focused on sustainability. Manufacturers are exploring various technologies such as cylinder deactivation, variable valve timing, and advanced turbocharging to address this issue. While these technologies have shown promise, they also add to the overall cost and complexity of the engine.

The integration of hybrid technologies with V8 engines presents both an opportunity and a challenge. Hybrid V8 systems can potentially offer the best of both worlds – the power of a V8 with improved fuel efficiency and reduced emissions. However, the development and implementation of such systems require significant investment and engineering expertise.

From a manufacturing perspective, the decreasing demand for V8 engines in certain sectors poses a challenge to economies of scale. As more automakers shift towards smaller, turbocharged engines or electric powertrains, the production volumes for V8 engines may decrease, potentially leading to higher per-unit costs.

In terms of geographical distribution, the development and production of V8 engines remain concentrated in traditional automotive manufacturing hubs such as North America, Germany, and Japan. However, emerging markets, particularly China, are showing increased interest in high-performance engines, potentially shifting the landscape of V8 technology development.

Despite these challenges, V8 engines continue to find applications in specific sectors. They remain popular in high-performance sports cars, luxury vehicles, and certain types of trucks and SUVs. The challenge for manufacturers is to maintain the appeal of V8 engines in these niche markets while adapting to broader industry trends and regulatory pressures.

One of the primary challenges is meeting increasingly strict emissions standards. Many countries and regions have implemented or are planning to implement tighter regulations on vehicle emissions, particularly targeting high-performance engines like V8s. This has led to the development of more sophisticated fuel injection systems, improved exhaust gas recirculation technologies, and advanced catalytic converters. However, these solutions often come at the cost of increased complexity and higher production expenses.

Another significant challenge is the improvement of fuel efficiency without compromising performance. V8 engines are traditionally known for their high fuel consumption, which is becoming less acceptable in a market increasingly focused on sustainability. Manufacturers are exploring various technologies such as cylinder deactivation, variable valve timing, and advanced turbocharging to address this issue. While these technologies have shown promise, they also add to the overall cost and complexity of the engine.

The integration of hybrid technologies with V8 engines presents both an opportunity and a challenge. Hybrid V8 systems can potentially offer the best of both worlds – the power of a V8 with improved fuel efficiency and reduced emissions. However, the development and implementation of such systems require significant investment and engineering expertise.

From a manufacturing perspective, the decreasing demand for V8 engines in certain sectors poses a challenge to economies of scale. As more automakers shift towards smaller, turbocharged engines or electric powertrains, the production volumes for V8 engines may decrease, potentially leading to higher per-unit costs.

In terms of geographical distribution, the development and production of V8 engines remain concentrated in traditional automotive manufacturing hubs such as North America, Germany, and Japan. However, emerging markets, particularly China, are showing increased interest in high-performance engines, potentially shifting the landscape of V8 technology development.

Despite these challenges, V8 engines continue to find applications in specific sectors. They remain popular in high-performance sports cars, luxury vehicles, and certain types of trucks and SUVs. The challenge for manufacturers is to maintain the appeal of V8 engines in these niche markets while adapting to broader industry trends and regulatory pressures.

Current V8 Engine Solutions

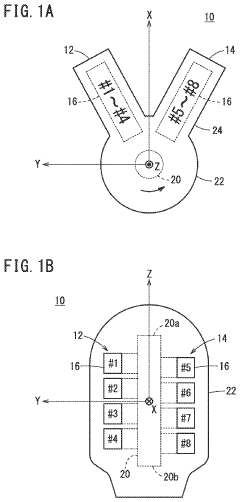

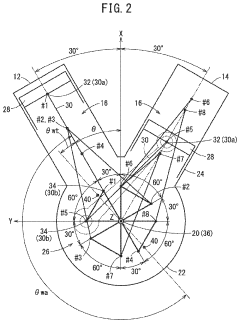

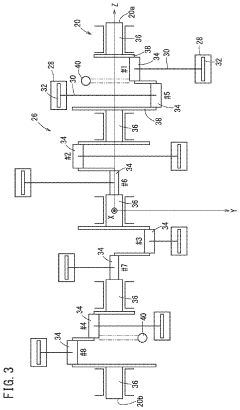

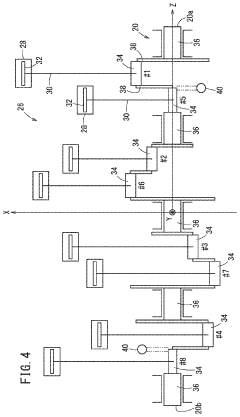

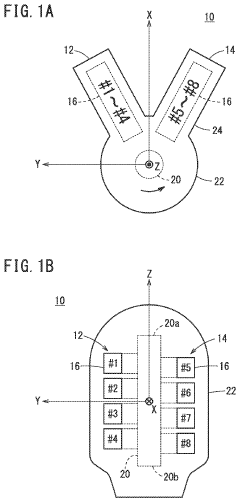

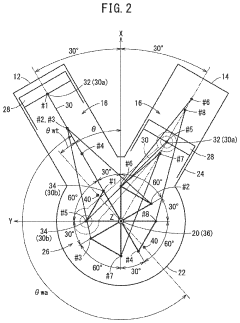

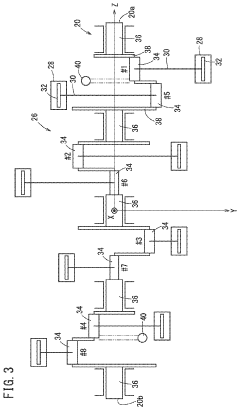

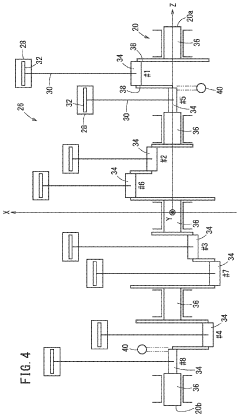

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems may include direct injection, variable valve timing, and advanced ignition control. Improvements in fuel delivery and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output. These systems compress the intake air, allowing more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are used to optimize V8 engine performance across different operating conditions.

- Engine Block and Cylinder Head Design: The design of V8 engine blocks and cylinder heads plays a crucial role in overall engine performance and durability. Advanced materials, casting techniques, and cooling systems are employed to optimize weight, strength, and heat dissipation. Innovations in cylinder head design, including variable valve lift and timing systems, contribute to improved engine efficiency and power output.

- Lubrication and Cooling Systems: Effective lubrication and cooling systems are essential for V8 engine reliability and performance. Advanced oil circulation systems, oil coolers, and precision-engineered coolant passages help maintain optimal operating temperatures and reduce friction. Innovations in these systems contribute to increased engine longevity, improved efficiency, and enhanced performance under various operating conditions.

02 Fuel Injection and Combustion Systems

Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery, air-fuel mixture formation, and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.Expand Specific Solutions03 Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output. These systems compress the intake air, allowing for increased fuel combustion and power generation. Various designs and configurations of turbochargers and superchargers are used to optimize performance across different engine speeds and load conditions.Expand Specific Solutions04 Engine Block and Component Materials

The choice of materials for V8 engine blocks, cylinder heads, pistons, and other components significantly impacts performance and durability. Advanced materials such as aluminum alloys, high-strength steel, and composite materials are used to reduce weight, improve heat dissipation, and enhance overall engine efficiency. Innovative manufacturing techniques are employed to produce these components with precise tolerances.Expand Specific Solutions05 Cooling and Lubrication Systems

Efficient cooling and lubrication systems are essential for V8 engine performance and longevity. Advanced cooling systems utilize optimized coolant flow paths, electric water pumps, and precision-controlled thermostats to maintain optimal operating temperatures. Lubrication systems employ high-performance oil pumps, advanced filtration, and oil cooling techniques to ensure proper lubrication and heat management across all engine components.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine commercial applications sector is in a mature stage of development, with a substantial global market size driven by automotive and industrial applications. The technology is well-established, with ongoing innovations focused on efficiency and emissions reduction. Key players like GM Global Technology Operations, Honda Motor Co., and Toyota Motor Corp. have extensive experience in V8 engine development and production. These companies, along with others such as BMW and Nissan, continue to refine V8 technology for high-performance vehicles and specialized applications. However, the sector faces challenges from the growing shift towards electrification and stricter emissions regulations, prompting manufacturers to explore hybrid V8 systems and alternative powertrains.

GM Global Technology Operations LLC

Technical Solution: GM has been at the forefront of V8 engine development for decades, particularly in the automotive sector. Their latest V8 engines, such as the 6.2L LT2 V8 used in the Corvette C8, showcase advanced technologies like Direct Fuel Injection, Variable Valve Timing, and Active Fuel Management[1]. These engines are designed to deliver high performance while meeting stringent emissions standards. GM's V8 engines also feature cylinder deactivation technology, allowing them to operate as a V4 under light load conditions, significantly improving fuel efficiency[2]. The company has invested heavily in lightweight materials and advanced manufacturing processes to reduce engine weight and improve power-to-weight ratios[3].

Strengths: High performance, fuel efficiency technologies, and extensive experience in V8 development. Weaknesses: Increasing focus on electric vehicles may limit future V8 development resources.

Honda Motor Co., Ltd.

Technical Solution: While Honda is not primarily known for V8 engines, they have developed notable V8 applications, particularly in the racing sector. Honda's most significant commercial V8 engine was the C32B, used in the Acura NSX from 1991 to 2005[4]. More recently, Honda has focused on V8 engines for racing applications, such as their IndyCar V8 engine. These racing engines incorporate advanced technologies like direct fuel injection, variable cam timing, and high-pressure fuel systems[5]. Honda's expertise in high-revving engines has been applied to their V8 designs, allowing for impressive power outputs in compact packages. The company has also explored hybrid V8 systems for potential future applications in high-performance vehicles[6].

Strengths: High-revving engine design, racing technology transfer, and hybrid integration potential. Weaknesses: Limited commercial V8 applications compared to competitors.

Core V8 Engine Innovations

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Environmental Regulations Impact

Environmental regulations have significantly impacted the commercial applications of V8 engines across various sectors. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, manufacturers have been compelled to adapt their V8 engine designs or explore alternative powertrains.

In the automotive industry, the impact has been particularly pronounced. Many automakers have reduced their V8 engine offerings in passenger vehicles, focusing instead on smaller, turbocharged engines or hybrid powertrains. This shift has been driven by the need to meet increasingly stringent Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other markets.

The commercial vehicle sector has also felt the effects of environmental regulations. While V8 engines remain popular in heavy-duty trucks and large SUVs, manufacturers have had to invest heavily in technologies to improve fuel efficiency and reduce emissions. This includes the development of advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies.

In the marine industry, V8 engines have faced challenges due to regulations such as the International Maritime Organization's (IMO) emissions standards. Manufacturers have responded by developing cleaner-burning V8 marine engines, often incorporating electronic fuel injection and catalytic converters to meet these requirements.

The stationary power generation sector has seen a shift away from V8 engines in favor of more environmentally friendly alternatives. However, V8 engines still find applications in backup power systems and remote locations where emissions regulations may be less stringent.

Racing and motorsports have also been affected by environmental concerns. While V8 engines continue to be used in certain racing categories, there has been a trend towards smaller engines and hybrid powertrains in high-profile series such as Formula 1.

To address these regulatory challenges, V8 engine manufacturers have invested in research and development to improve efficiency and reduce emissions. This includes the adoption of technologies such as direct fuel injection, turbocharging, and advanced engine management systems. Some manufacturers have also explored the use of alternative fuels, such as biofuels or hydrogen, to reduce the environmental impact of V8 engines.

Despite these efforts, the long-term future of V8 engines in commercial applications remains uncertain. As environmental regulations continue to tighten, manufacturers may need to further innovate or potentially phase out V8 engines in favor of more sustainable alternatives. This transition presents both challenges and opportunities for industries that have traditionally relied on V8 power.

In the automotive industry, the impact has been particularly pronounced. Many automakers have reduced their V8 engine offerings in passenger vehicles, focusing instead on smaller, turbocharged engines or hybrid powertrains. This shift has been driven by the need to meet increasingly stringent Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other markets.

The commercial vehicle sector has also felt the effects of environmental regulations. While V8 engines remain popular in heavy-duty trucks and large SUVs, manufacturers have had to invest heavily in technologies to improve fuel efficiency and reduce emissions. This includes the development of advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies.

In the marine industry, V8 engines have faced challenges due to regulations such as the International Maritime Organization's (IMO) emissions standards. Manufacturers have responded by developing cleaner-burning V8 marine engines, often incorporating electronic fuel injection and catalytic converters to meet these requirements.

The stationary power generation sector has seen a shift away from V8 engines in favor of more environmentally friendly alternatives. However, V8 engines still find applications in backup power systems and remote locations where emissions regulations may be less stringent.

Racing and motorsports have also been affected by environmental concerns. While V8 engines continue to be used in certain racing categories, there has been a trend towards smaller engines and hybrid powertrains in high-profile series such as Formula 1.

To address these regulatory challenges, V8 engine manufacturers have invested in research and development to improve efficiency and reduce emissions. This includes the adoption of technologies such as direct fuel injection, turbocharging, and advanced engine management systems. Some manufacturers have also explored the use of alternative fuels, such as biofuels or hydrogen, to reduce the environmental impact of V8 engines.

Despite these efforts, the long-term future of V8 engines in commercial applications remains uncertain. As environmental regulations continue to tighten, manufacturers may need to further innovate or potentially phase out V8 engines in favor of more sustainable alternatives. This transition presents both challenges and opportunities for industries that have traditionally relied on V8 power.

V8 Engine Efficiency Improvements

V8 engines have undergone significant efficiency improvements over the years, driven by the need for better fuel economy, reduced emissions, and enhanced performance. One of the key advancements has been the implementation of direct fuel injection systems. This technology allows for more precise control over fuel delivery, resulting in improved combustion efficiency and reduced fuel consumption.

Variable valve timing (VVT) has also played a crucial role in enhancing V8 engine efficiency. By adjusting the timing of valve opening and closing based on engine speed and load, VVT systems optimize engine performance across a wide range of operating conditions. This technology has contributed to improved fuel economy and reduced emissions without sacrificing power output.

Cylinder deactivation, also known as variable displacement, has become a common feature in modern V8 engines. This system allows the engine to shut down a portion of its cylinders during light load conditions, effectively reducing fuel consumption while maintaining smooth operation. When full power is required, all cylinders are reactivated seamlessly.

Turbocharging and supercharging technologies have been increasingly adopted in V8 engines to boost efficiency. These forced induction systems allow for smaller displacement engines to produce comparable power to larger naturally aspirated units, resulting in improved fuel economy and reduced emissions. The integration of advanced intercooling systems further enhances the efficiency of turbocharged and supercharged V8 engines.

Materials science has also contributed to V8 engine efficiency improvements. The use of lightweight materials such as aluminum alloys and composites in engine components has reduced overall engine weight, leading to improved power-to-weight ratios and fuel efficiency. Additionally, advanced coatings and surface treatments have been developed to reduce friction and wear within the engine, further enhancing efficiency and longevity.

Electronic engine management systems have become increasingly sophisticated, allowing for precise control over various engine parameters. These systems optimize fuel injection, ignition timing, and other variables in real-time, ensuring optimal efficiency across a wide range of operating conditions. The integration of adaptive learning algorithms has further improved engine performance and efficiency over time.

Variable valve timing (VVT) has also played a crucial role in enhancing V8 engine efficiency. By adjusting the timing of valve opening and closing based on engine speed and load, VVT systems optimize engine performance across a wide range of operating conditions. This technology has contributed to improved fuel economy and reduced emissions without sacrificing power output.

Cylinder deactivation, also known as variable displacement, has become a common feature in modern V8 engines. This system allows the engine to shut down a portion of its cylinders during light load conditions, effectively reducing fuel consumption while maintaining smooth operation. When full power is required, all cylinders are reactivated seamlessly.

Turbocharging and supercharging technologies have been increasingly adopted in V8 engines to boost efficiency. These forced induction systems allow for smaller displacement engines to produce comparable power to larger naturally aspirated units, resulting in improved fuel economy and reduced emissions. The integration of advanced intercooling systems further enhances the efficiency of turbocharged and supercharged V8 engines.

Materials science has also contributed to V8 engine efficiency improvements. The use of lightweight materials such as aluminum alloys and composites in engine components has reduced overall engine weight, leading to improved power-to-weight ratios and fuel efficiency. Additionally, advanced coatings and surface treatments have been developed to reduce friction and wear within the engine, further enhancing efficiency and longevity.

Electronic engine management systems have become increasingly sophisticated, allowing for precise control over various engine parameters. These systems optimize fuel injection, ignition timing, and other variables in real-time, ensuring optimal efficiency across a wide range of operating conditions. The integration of adaptive learning algorithms has further improved engine performance and efficiency over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!