V8 Engine Contribution to Circular Economic Models

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Sustainability Goals

The V8 engine, a cornerstone of automotive engineering, has undergone significant evolution since its inception. This evolution has been driven by the need for improved performance, fuel efficiency, and, more recently, sustainability. As global concerns about environmental impact and resource depletion have grown, the automotive industry has been compelled to align its development goals with circular economic models.

The journey of the V8 engine towards sustainability began with incremental improvements in fuel efficiency and emissions reduction. Early efforts focused on optimizing combustion processes, reducing friction, and enhancing thermal efficiency. These advancements led to notable reductions in fuel consumption and emissions without compromising the power and performance that V8 engines are known for.

As environmental regulations became more stringent, engine designers turned their attention to more radical innovations. The introduction of variable valve timing, cylinder deactivation, and direct fuel injection systems marked significant milestones in V8 engine evolution. These technologies allowed for dynamic adjustment of engine operation, optimizing performance and efficiency based on driving conditions.

The push towards sustainability has also led to the exploration of alternative fuels and hybrid technologies in V8 engines. Flex-fuel V8 engines capable of running on ethanol blends have been developed, reducing dependence on fossil fuels. Additionally, mild hybrid systems have been integrated into V8 powertrains, recuperating energy during braking and providing electric assist during acceleration, further improving fuel economy.

Recent years have seen a shift towards more comprehensive sustainability goals in V8 engine development. Manufacturers are now focusing on the entire lifecycle of the engine, from production to end-of-life. This holistic approach includes the use of recycled materials in engine components, design for disassembly to facilitate easier recycling, and the development of remanufacturing processes to extend engine life.

The future of V8 engine evolution is closely tied to circular economic principles. Research is underway to develop bio-based lubricants and coolants, reducing the environmental impact of engine operation. Advanced materials research is exploring the use of lightweight, recyclable alloys that can maintain the durability required for high-performance engines while reducing the overall environmental footprint.

As the automotive industry transitions towards electrification, the role of V8 engines in sustainable mobility is being redefined. Some manufacturers are exploring the potential of hydrogen-powered V8 engines as a zero-emission alternative, while others are investigating synthetic fuels produced from renewable sources. These innovations aim to preserve the cultural and performance aspects of V8 engines while aligning with long-term sustainability goals.

The journey of the V8 engine towards sustainability began with incremental improvements in fuel efficiency and emissions reduction. Early efforts focused on optimizing combustion processes, reducing friction, and enhancing thermal efficiency. These advancements led to notable reductions in fuel consumption and emissions without compromising the power and performance that V8 engines are known for.

As environmental regulations became more stringent, engine designers turned their attention to more radical innovations. The introduction of variable valve timing, cylinder deactivation, and direct fuel injection systems marked significant milestones in V8 engine evolution. These technologies allowed for dynamic adjustment of engine operation, optimizing performance and efficiency based on driving conditions.

The push towards sustainability has also led to the exploration of alternative fuels and hybrid technologies in V8 engines. Flex-fuel V8 engines capable of running on ethanol blends have been developed, reducing dependence on fossil fuels. Additionally, mild hybrid systems have been integrated into V8 powertrains, recuperating energy during braking and providing electric assist during acceleration, further improving fuel economy.

Recent years have seen a shift towards more comprehensive sustainability goals in V8 engine development. Manufacturers are now focusing on the entire lifecycle of the engine, from production to end-of-life. This holistic approach includes the use of recycled materials in engine components, design for disassembly to facilitate easier recycling, and the development of remanufacturing processes to extend engine life.

The future of V8 engine evolution is closely tied to circular economic principles. Research is underway to develop bio-based lubricants and coolants, reducing the environmental impact of engine operation. Advanced materials research is exploring the use of lightweight, recyclable alloys that can maintain the durability required for high-performance engines while reducing the overall environmental footprint.

As the automotive industry transitions towards electrification, the role of V8 engines in sustainable mobility is being redefined. Some manufacturers are exploring the potential of hydrogen-powered V8 engines as a zero-emission alternative, while others are investigating synthetic fuels produced from renewable sources. These innovations aim to preserve the cultural and performance aspects of V8 engines while aligning with long-term sustainability goals.

Circular Economy Market Demand in Automotive Sector

The automotive industry is experiencing a significant shift towards circular economy principles, driven by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable products. This transition is creating a substantial market demand for circular economy solutions in the automotive sector, particularly in relation to engine technologies such as the V8 engine.

The global automotive circular economy market is projected to grow rapidly in the coming years, with a focus on reducing waste, improving resource efficiency, and extending product lifecycles. This growth is fueled by stringent environmental regulations, such as the European Union's End-of-Life Vehicles Directive, which mandates higher recycling rates for vehicles and their components.

In the context of V8 engines, there is a growing demand for remanufacturing and refurbishing services. These processes allow for the extension of engine life, reducing the need for new production and minimizing waste. The market for remanufactured V8 engines is expanding, as automotive manufacturers and consumers recognize the economic and environmental benefits of this approach.

Additionally, there is an increasing interest in designing V8 engines with circular economy principles in mind from the outset. This includes using more recyclable materials, modular designs that facilitate easier repair and component replacement, and incorporating advanced technologies that improve fuel efficiency and reduce emissions over the engine's lifecycle.

The automotive sector is also seeing a rise in demand for closed-loop material systems for V8 engines and other vehicle components. This involves recovering and recycling materials from end-of-life vehicles to be used in the production of new engines and parts, reducing the reliance on virgin materials and minimizing environmental impact.

Furthermore, there is a growing market for innovative business models that support circular economy principles in the automotive sector. These include engine leasing programs, where manufacturers retain ownership of the V8 engine and are responsible for its maintenance, repair, and eventual recycling. Such models align with the circular economy concept by incentivizing manufacturers to design for longevity and recyclability.

The demand for circular economy solutions in the automotive sector extends beyond just the V8 engine to encompass the entire vehicle lifecycle. This holistic approach is creating new opportunities for businesses that can provide comprehensive circular economy services, from design and manufacturing to end-of-life management.

As awareness of environmental issues continues to grow, consumers are increasingly factoring sustainability into their purchasing decisions. This trend is driving demand for vehicles and engines that are produced and operated in line with circular economy principles, further reinforcing the market potential for circular economy solutions in the automotive sector.

The global automotive circular economy market is projected to grow rapidly in the coming years, with a focus on reducing waste, improving resource efficiency, and extending product lifecycles. This growth is fueled by stringent environmental regulations, such as the European Union's End-of-Life Vehicles Directive, which mandates higher recycling rates for vehicles and their components.

In the context of V8 engines, there is a growing demand for remanufacturing and refurbishing services. These processes allow for the extension of engine life, reducing the need for new production and minimizing waste. The market for remanufactured V8 engines is expanding, as automotive manufacturers and consumers recognize the economic and environmental benefits of this approach.

Additionally, there is an increasing interest in designing V8 engines with circular economy principles in mind from the outset. This includes using more recyclable materials, modular designs that facilitate easier repair and component replacement, and incorporating advanced technologies that improve fuel efficiency and reduce emissions over the engine's lifecycle.

The automotive sector is also seeing a rise in demand for closed-loop material systems for V8 engines and other vehicle components. This involves recovering and recycling materials from end-of-life vehicles to be used in the production of new engines and parts, reducing the reliance on virgin materials and minimizing environmental impact.

Furthermore, there is a growing market for innovative business models that support circular economy principles in the automotive sector. These include engine leasing programs, where manufacturers retain ownership of the V8 engine and are responsible for its maintenance, repair, and eventual recycling. Such models align with the circular economy concept by incentivizing manufacturers to design for longevity and recyclability.

The demand for circular economy solutions in the automotive sector extends beyond just the V8 engine to encompass the entire vehicle lifecycle. This holistic approach is creating new opportunities for businesses that can provide comprehensive circular economy services, from design and manufacturing to end-of-life management.

As awareness of environmental issues continues to grow, consumers are increasingly factoring sustainability into their purchasing decisions. This trend is driving demand for vehicles and engines that are produced and operated in line with circular economy principles, further reinforcing the market potential for circular economy solutions in the automotive sector.

V8 Engine Challenges in Circular Economy

The V8 engine, a cornerstone of automotive technology, faces significant challenges in adapting to circular economic models. These challenges stem from the engine's complex design, material composition, and traditional manufacturing processes, which have historically prioritized performance and efficiency over recyclability and reusability.

One of the primary obstacles is the engine's multi-material construction. V8 engines typically incorporate a variety of metals, alloys, and composite materials, each chosen for specific properties such as strength, heat resistance, or weight reduction. This diverse material mix complicates end-of-life disassembly and recycling processes, as different materials often require separate recycling streams.

The intricate design of V8 engines, with numerous interconnected components, presents another hurdle. Many parts are designed for permanent assembly or are difficult to separate without damage, hindering the potential for refurbishment or component reuse. This design philosophy, while optimizing performance and durability, conflicts with circular economy principles that emphasize easy disassembly and modular design for repair and remanufacturing.

Lubricants and coolants used in V8 engines pose environmental challenges. These fluids, essential for engine operation, often contain harmful substances that require special handling and disposal. Developing bio-based or recyclable alternatives that maintain performance standards is a significant technical challenge.

The manufacturing processes for V8 engines, which often involve energy-intensive methods and generate substantial waste, are another area of concern. Transitioning to more sustainable production techniques while maintaining the high precision and quality required for these complex engines is a formidable task.

Adapting V8 engines to use alternative, more sustainable fuels presents both technical and infrastructure challenges. While some progress has been made with biofuels and synthetic fuels, widespread adoption requires overcoming issues related to engine compatibility, fuel distribution networks, and consumer acceptance.

The longevity and durability of V8 engines, while generally positive attributes, can paradoxically hinder the adoption of newer, more environmentally friendly technologies. The long service life of these engines means that older, less efficient models remain in use for extended periods, slowing the overall transition to more sustainable alternatives.

Lastly, the cultural and market positioning of V8 engines as symbols of power and performance creates resistance to change. Convincing consumers and manufacturers to prioritize sustainability over traditional performance metrics requires a significant shift in marketing strategies and consumer preferences.

One of the primary obstacles is the engine's multi-material construction. V8 engines typically incorporate a variety of metals, alloys, and composite materials, each chosen for specific properties such as strength, heat resistance, or weight reduction. This diverse material mix complicates end-of-life disassembly and recycling processes, as different materials often require separate recycling streams.

The intricate design of V8 engines, with numerous interconnected components, presents another hurdle. Many parts are designed for permanent assembly or are difficult to separate without damage, hindering the potential for refurbishment or component reuse. This design philosophy, while optimizing performance and durability, conflicts with circular economy principles that emphasize easy disassembly and modular design for repair and remanufacturing.

Lubricants and coolants used in V8 engines pose environmental challenges. These fluids, essential for engine operation, often contain harmful substances that require special handling and disposal. Developing bio-based or recyclable alternatives that maintain performance standards is a significant technical challenge.

The manufacturing processes for V8 engines, which often involve energy-intensive methods and generate substantial waste, are another area of concern. Transitioning to more sustainable production techniques while maintaining the high precision and quality required for these complex engines is a formidable task.

Adapting V8 engines to use alternative, more sustainable fuels presents both technical and infrastructure challenges. While some progress has been made with biofuels and synthetic fuels, widespread adoption requires overcoming issues related to engine compatibility, fuel distribution networks, and consumer acceptance.

The longevity and durability of V8 engines, while generally positive attributes, can paradoxically hinder the adoption of newer, more environmentally friendly technologies. The long service life of these engines means that older, less efficient models remain in use for extended periods, slowing the overall transition to more sustainable alternatives.

Lastly, the cultural and market positioning of V8 engines as symbols of power and performance creates resistance to change. Convincing consumers and manufacturers to prioritize sustainability over traditional performance metrics requires a significant shift in marketing strategies and consumer preferences.

Current Circular Solutions for V8 Engines

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved balance, and higher power output compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems may include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output. These systems compress the intake air, allowing more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are used to optimize V8 engine performance across different operating conditions.

- Cooling and Lubrication Systems: Efficient cooling and lubrication systems are essential for V8 engine reliability and performance. Advanced cooling systems may include precision coolant flow control, while lubrication systems often feature high-pressure oil pumps and advanced filtration. These systems help maintain optimal operating temperatures and reduce friction, contributing to engine longevity and performance.

- Engine Management and Control Systems: Sophisticated engine management and control systems are integral to modern V8 engines. These systems monitor and adjust various engine parameters in real-time, optimizing performance, fuel efficiency, and emissions. Advanced sensors, electronic control units, and software algorithms work together to ensure optimal engine operation across a wide range of driving conditions.

02 Fuel Injection and Combustion Systems

Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems may include direct injection, variable valve timing, and advanced ignition control. Improvements in fuel delivery and combustion efficiency help to increase power output while reducing emissions and fuel consumption in V8 engines.Expand Specific Solutions03 Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, are often used in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and generating more power. Various designs and configurations of turbochargers and superchargers are employed to optimize V8 engine performance across different operating conditions.Expand Specific Solutions04 Cooling and Lubrication Systems

Effective cooling and lubrication systems are essential for V8 engine reliability and longevity. Advanced cooling systems may include precision coolant flow control, while lubrication systems often feature high-pressure oil pumps and advanced filtration. These systems help manage the high heat and stress generated by high-performance V8 engines.Expand Specific Solutions05 Engine Management and Control Systems

Sophisticated engine management and control systems are integral to modern V8 engines. These systems optimize various engine parameters, including fuel injection, ignition timing, and valve actuation, based on real-time operating conditions. Advanced sensors and electronic control units enable precise control over engine performance, emissions, and fuel efficiency.Expand Specific Solutions

Key Players in V8 Engine Circular Economy

The V8 engine's contribution to circular economic models is at a nascent stage, with the market still developing and technology in early phases of adaptation. The automotive industry, led by companies like Honda, BMW, GM, and Toyota, is exploring ways to integrate circular principles into V8 engine design and production. These efforts aim to enhance resource efficiency and reduce environmental impact. However, the market size remains limited, as traditional linear models still dominate. The technology's maturity varies among players, with some companies like Ford and Nissan making notable progress in sustainable V8 engine innovations. Overall, the industry is in a transition phase, balancing performance demands with circular economy goals.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive approach to incorporating V8 engines into circular economic models. Their strategy includes designing engines for easier disassembly and remanufacturing, utilizing recycled materials in engine components, and implementing advanced recycling techniques for end-of-life engines. GM's V8 engines now feature up to 17% recycled aluminum content [1], reducing the need for virgin materials. The company has also established a closed-loop recycling system for engine components, where used parts are collected, reprocessed, and reintegrated into new engines, significantly reducing waste and energy consumption [2]. Additionally, GM has invested in advanced technologies for more efficient engine remanufacturing, extending the lifespan of V8 engines and reducing the overall environmental impact [3].

Strengths: Comprehensive approach to circularity, established recycling infrastructure, and advanced remanufacturing capabilities. Weaknesses: Potential higher initial costs and complexity in managing the circular supply chain.

Toyota Motor Corp.

Technical Solution: Toyota has made significant strides in integrating V8 engines into circular economic models through its "Toyota Global 100 Dismantlers" project. This initiative focuses on proper dismantling and recycling of vehicles, including V8 engines, to maximize resource recovery and minimize waste. Toyota's approach includes designing V8 engines with easily separable components, using recycled materials in engine production, and implementing advanced recycling technologies. The company has achieved a 99% recovery rate for end-of-life vehicles, including engines [4]. Toyota's V8 engines now incorporate up to 20% recycled aluminum, reducing the environmental impact of production [5]. Furthermore, Toyota has developed a unique process for recycling rare earth elements from hybrid vehicle motors, which can be applied to V8 engine components, further enhancing the circular economy approach [6].

Strengths: High recovery rate for end-of-life vehicles, innovative recycling technologies, and global dismantling network. Weaknesses: Potential challenges in scaling up recycling processes for all markets and ensuring consistent quality of recycled materials.

Innovative Circular Technologies for V8 Engines

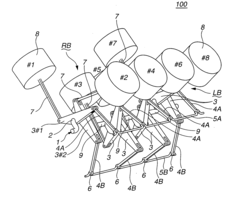

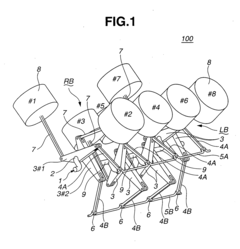

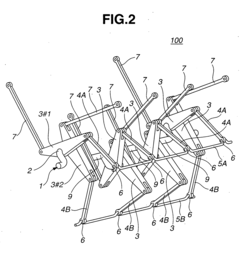

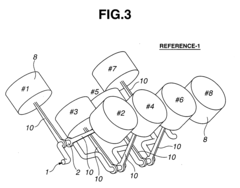

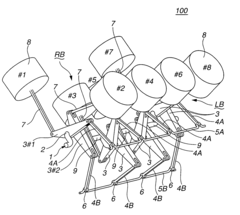

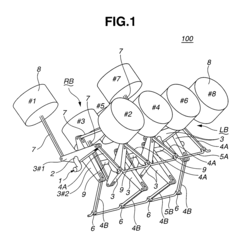

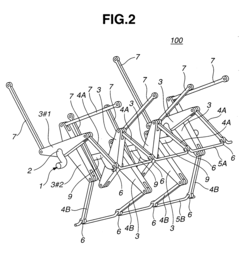

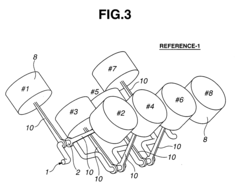

V-type 8-cylinder four cycle internal combustion engine

PatentInactiveUS20050263115A1

Innovation

- A V-type 8-cylinder four cycle internal combustion engine design incorporating a double link type piston-crank mechanism with a single plane type crankshaft and control links, where each piston is connected through upper and lower links to a crank pin, allowing for adjustable lower link attitudes to vary the compression ratio and reduce secondary vibration components, while maintaining balanced inertial forces and optimized firing intervals.

V-type 8-cylinder four cycle internal combustion engine

PatentInactiveUS7100548B2

Innovation

- A V-type 8-cylinder four cycle internal combustion engine design incorporating a double link type piston-crank mechanism with a single plane type crankshaft and control links, where each piston is connected through upper and lower links to a crank pin, allowing for adjustable lower link attitudes to vary the piston stroke and compression ratio, thereby reducing secondary vibration and optimizing firing intervals.

Environmental Impact Assessment of V8 Engines

The environmental impact assessment of V8 engines is a critical component in evaluating their contribution to circular economic models. These powerful engines, known for their high performance and distinctive sound, have long been associated with significant environmental concerns due to their fuel consumption and emissions.

V8 engines typically produce higher levels of carbon dioxide (CO2) and other greenhouse gases compared to smaller, more fuel-efficient engines. This contributes to climate change and air pollution, particularly in urban areas where vehicle emissions are concentrated. The production of these engines also requires substantial resources, including metals and energy-intensive manufacturing processes, which further adds to their environmental footprint.

However, recent advancements in engine technology have led to improvements in V8 efficiency. Modern V8 engines often incorporate features such as variable valve timing, direct fuel injection, and cylinder deactivation, which can reduce fuel consumption and emissions under certain driving conditions. These improvements, while significant, still leave V8 engines with a larger environmental impact than many smaller engine configurations.

The lifecycle assessment of V8 engines reveals additional environmental considerations. The extraction and processing of raw materials for engine components, as well as the energy-intensive manufacturing processes, contribute to the overall environmental impact. End-of-life disposal and recycling of V8 engines also present challenges, as they contain various materials that require proper handling to minimize environmental harm.

In the context of circular economic models, V8 engines present both challenges and opportunities. The durability and longevity of well-maintained V8 engines can contribute to extended product lifecycles, aligning with circular economy principles. Additionally, the potential for remanufacturing and refurbishing V8 engines offers a pathway to reduce waste and conserve resources.

Efforts to improve the environmental performance of V8 engines include research into alternative fuels, such as biofuels or synthetic fuels, which could potentially reduce their carbon footprint. Hybrid systems that combine V8 engines with electric motors are another avenue being explored to balance performance with improved efficiency and reduced emissions.

As regulatory pressures increase and consumer preferences shift towards more environmentally friendly options, the future of V8 engines in a circular economy context remains uncertain. Manufacturers are faced with the challenge of balancing the performance characteristics that V8 engines are known for with the imperative to reduce environmental impact and align with sustainability goals.

V8 engines typically produce higher levels of carbon dioxide (CO2) and other greenhouse gases compared to smaller, more fuel-efficient engines. This contributes to climate change and air pollution, particularly in urban areas where vehicle emissions are concentrated. The production of these engines also requires substantial resources, including metals and energy-intensive manufacturing processes, which further adds to their environmental footprint.

However, recent advancements in engine technology have led to improvements in V8 efficiency. Modern V8 engines often incorporate features such as variable valve timing, direct fuel injection, and cylinder deactivation, which can reduce fuel consumption and emissions under certain driving conditions. These improvements, while significant, still leave V8 engines with a larger environmental impact than many smaller engine configurations.

The lifecycle assessment of V8 engines reveals additional environmental considerations. The extraction and processing of raw materials for engine components, as well as the energy-intensive manufacturing processes, contribute to the overall environmental impact. End-of-life disposal and recycling of V8 engines also present challenges, as they contain various materials that require proper handling to minimize environmental harm.

In the context of circular economic models, V8 engines present both challenges and opportunities. The durability and longevity of well-maintained V8 engines can contribute to extended product lifecycles, aligning with circular economy principles. Additionally, the potential for remanufacturing and refurbishing V8 engines offers a pathway to reduce waste and conserve resources.

Efforts to improve the environmental performance of V8 engines include research into alternative fuels, such as biofuels or synthetic fuels, which could potentially reduce their carbon footprint. Hybrid systems that combine V8 engines with electric motors are another avenue being explored to balance performance with improved efficiency and reduced emissions.

As regulatory pressures increase and consumer preferences shift towards more environmentally friendly options, the future of V8 engines in a circular economy context remains uncertain. Manufacturers are faced with the challenge of balancing the performance characteristics that V8 engines are known for with the imperative to reduce environmental impact and align with sustainability goals.

Policy Frameworks for Automotive Circularity

The development of policy frameworks for automotive circularity is crucial in promoting sustainable practices within the automotive industry, particularly concerning V8 engines and their contribution to circular economic models. These frameworks aim to create a regulatory environment that encourages manufacturers, consumers, and other stakeholders to adopt circular economy principles throughout the vehicle lifecycle.

One key aspect of these policy frameworks is the implementation of extended producer responsibility (EPR) programs. These initiatives hold manufacturers accountable for the entire lifecycle of their products, including V8 engines, from production to end-of-life management. By placing the onus on producers, EPR programs incentivize the design of more durable, repairable, and recyclable engines, aligning with circular economy principles.

Another important element is the establishment of stringent emissions standards and fuel efficiency regulations. These policies drive innovation in V8 engine design, pushing manufacturers to develop more efficient and environmentally friendly powertrains. As a result, engines become more resource-efficient and potentially more suitable for remanufacturing and recycling processes, contributing to the circular economy.

Policy frameworks also often include incentives for the adoption of circular practices in the automotive sector. This may involve tax breaks or subsidies for companies that implement remanufacturing programs for V8 engines or develop innovative recycling technologies. Such incentives can stimulate investment in circular economy infrastructure and technologies, fostering a more sustainable automotive industry.

Furthermore, these frameworks typically incorporate regulations on end-of-life vehicle management. This includes mandates for proper dismantling, recycling, and disposal of vehicles and their components, including V8 engines. By setting clear guidelines and targets for material recovery and recycling rates, policymakers can ensure that valuable resources from engines are recaptured and reintegrated into the production cycle.

Standardization of parts and materials used in V8 engines is another critical aspect addressed by policy frameworks. By promoting the use of standardized, easily recyclable materials and modular design principles, policymakers can facilitate easier disassembly, repair, and recycling of engines, enhancing their circularity potential.

Lastly, policy frameworks often include provisions for data sharing and transparency. This may involve requirements for manufacturers to disclose information about the materials used in their V8 engines, their recyclability, and the environmental impact of their production processes. Such transparency enables better decision-making by consumers and recyclers, supporting the overall circular economy ecosystem in the automotive sector.

One key aspect of these policy frameworks is the implementation of extended producer responsibility (EPR) programs. These initiatives hold manufacturers accountable for the entire lifecycle of their products, including V8 engines, from production to end-of-life management. By placing the onus on producers, EPR programs incentivize the design of more durable, repairable, and recyclable engines, aligning with circular economy principles.

Another important element is the establishment of stringent emissions standards and fuel efficiency regulations. These policies drive innovation in V8 engine design, pushing manufacturers to develop more efficient and environmentally friendly powertrains. As a result, engines become more resource-efficient and potentially more suitable for remanufacturing and recycling processes, contributing to the circular economy.

Policy frameworks also often include incentives for the adoption of circular practices in the automotive sector. This may involve tax breaks or subsidies for companies that implement remanufacturing programs for V8 engines or develop innovative recycling technologies. Such incentives can stimulate investment in circular economy infrastructure and technologies, fostering a more sustainable automotive industry.

Furthermore, these frameworks typically incorporate regulations on end-of-life vehicle management. This includes mandates for proper dismantling, recycling, and disposal of vehicles and their components, including V8 engines. By setting clear guidelines and targets for material recovery and recycling rates, policymakers can ensure that valuable resources from engines are recaptured and reintegrated into the production cycle.

Standardization of parts and materials used in V8 engines is another critical aspect addressed by policy frameworks. By promoting the use of standardized, easily recyclable materials and modular design principles, policymakers can facilitate easier disassembly, repair, and recycling of engines, enhancing their circularity potential.

Lastly, policy frameworks often include provisions for data sharing and transparency. This may involve requirements for manufacturers to disclose information about the materials used in their V8 engines, their recyclability, and the environmental impact of their production processes. Such transparency enables better decision-making by consumers and recyclers, supporting the overall circular economy ecosystem in the automotive sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!