V8 Engine Fluid Dynamics: Explore Latest Findings

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Fluid Dynamics Background and Objectives

V8 engines have been a cornerstone of automotive engineering since their inception in the early 20th century. These powerful and efficient engines have undergone significant evolution, with fluid dynamics playing a crucial role in their performance optimization. The study of fluid dynamics in V8 engines encompasses the complex interactions between air, fuel, and exhaust gases within the engine's combustion chambers and associated systems.

The primary objective of exploring the latest findings in V8 engine fluid dynamics is to enhance engine efficiency, power output, and environmental performance. As global regulations on emissions and fuel economy become increasingly stringent, understanding and optimizing fluid flow within these engines has become more critical than ever. Recent advancements in computational fluid dynamics (CFD) and experimental techniques have opened new avenues for research and development in this field.

One of the key areas of focus in V8 engine fluid dynamics is the improvement of intake and exhaust systems. The design of intake manifolds, ports, and valves significantly influences the engine's volumetric efficiency and overall performance. Similarly, optimizing exhaust flow can lead to reduced back pressure and improved scavenging, resulting in better engine breathing and increased power output.

Another crucial aspect is the study of in-cylinder fluid dynamics during the combustion process. Understanding the complex turbulent flows, fuel-air mixing, and flame propagation within the combustion chamber is essential for developing more efficient and cleaner-burning engines. Advanced laser-based diagnostic techniques and high-fidelity simulations have provided unprecedented insights into these phenomena.

The integration of forced induction systems, such as turbochargers and superchargers, has further complicated the fluid dynamics landscape of V8 engines. Optimizing the interaction between these systems and the engine's natural aspiration characteristics presents both challenges and opportunities for performance enhancement.

Recent trends in V8 engine development have also focused on the implementation of direct fuel injection systems. The fluid dynamics of fuel spray formation, atomization, and mixing with air in the combustion chamber have become critical areas of research, as they directly impact fuel efficiency and emissions.

As the automotive industry shifts towards electrification, the role of V8 engines is evolving. However, the principles of fluid dynamics remain relevant in hybrid powertrains and in the development of high-performance electric vehicles. The knowledge gained from V8 engine fluid dynamics research continues to inform the design of advanced cooling systems and aerodynamic packages for all types of vehicles.

The primary objective of exploring the latest findings in V8 engine fluid dynamics is to enhance engine efficiency, power output, and environmental performance. As global regulations on emissions and fuel economy become increasingly stringent, understanding and optimizing fluid flow within these engines has become more critical than ever. Recent advancements in computational fluid dynamics (CFD) and experimental techniques have opened new avenues for research and development in this field.

One of the key areas of focus in V8 engine fluid dynamics is the improvement of intake and exhaust systems. The design of intake manifolds, ports, and valves significantly influences the engine's volumetric efficiency and overall performance. Similarly, optimizing exhaust flow can lead to reduced back pressure and improved scavenging, resulting in better engine breathing and increased power output.

Another crucial aspect is the study of in-cylinder fluid dynamics during the combustion process. Understanding the complex turbulent flows, fuel-air mixing, and flame propagation within the combustion chamber is essential for developing more efficient and cleaner-burning engines. Advanced laser-based diagnostic techniques and high-fidelity simulations have provided unprecedented insights into these phenomena.

The integration of forced induction systems, such as turbochargers and superchargers, has further complicated the fluid dynamics landscape of V8 engines. Optimizing the interaction between these systems and the engine's natural aspiration characteristics presents both challenges and opportunities for performance enhancement.

Recent trends in V8 engine development have also focused on the implementation of direct fuel injection systems. The fluid dynamics of fuel spray formation, atomization, and mixing with air in the combustion chamber have become critical areas of research, as they directly impact fuel efficiency and emissions.

As the automotive industry shifts towards electrification, the role of V8 engines is evolving. However, the principles of fluid dynamics remain relevant in hybrid powertrains and in the development of high-performance electric vehicles. The knowledge gained from V8 engine fluid dynamics research continues to inform the design of advanced cooling systems and aerodynamic packages for all types of vehicles.

Market Demand for Advanced V8 Engine Technologies

The market demand for advanced V8 engine technologies has been steadily growing, driven by the automotive industry's pursuit of improved performance, fuel efficiency, and environmental sustainability. As consumers continue to seek powerful yet eco-friendly vehicles, manufacturers are investing heavily in research and development to enhance V8 engine capabilities.

One of the primary drivers of market demand is the need for increased fuel efficiency without compromising power output. This has led to the development of advanced fluid dynamics solutions in V8 engines, which optimize fuel-air mixture and combustion processes. The market for these technologies is expected to expand significantly in the coming years, as stricter emissions regulations and consumer preferences push manufacturers to innovate.

The performance vehicle segment, including luxury cars and high-end sports cars, remains a key market for advanced V8 engine technologies. These vehicles often serve as showcases for cutting-edge engineering, driving demand for sophisticated fluid dynamics solutions that can extract maximum power and efficiency from V8 engines.

Additionally, there is a growing market for V8 engines in commercial and industrial applications, such as in heavy-duty trucks and marine vessels. These sectors require robust and efficient power sources, creating opportunities for advanced V8 engine technologies that can deliver improved performance and reduced operating costs.

The aftermarket and tuning industry also contributes significantly to the demand for advanced V8 engine technologies. Enthusiasts and performance shops seek innovative solutions to enhance engine output and efficiency, creating a niche market for specialized fluid dynamics components and systems.

Geographically, North America and Europe remain the largest markets for advanced V8 engine technologies, due to their strong automotive industries and consumer preferences for high-performance vehicles. However, emerging markets in Asia-Pacific and the Middle East are showing increasing demand, driven by rising disposable incomes and a growing appetite for luxury and performance vehicles.

The market is also influenced by the broader trend towards electrification in the automotive industry. While this poses a long-term challenge to traditional combustion engines, it has paradoxically spurred innovation in V8 technology. Manufacturers are developing hybrid V8 powertrains and exploring ways to make these engines more competitive with electric alternatives, further driving demand for advanced fluid dynamics solutions.

One of the primary drivers of market demand is the need for increased fuel efficiency without compromising power output. This has led to the development of advanced fluid dynamics solutions in V8 engines, which optimize fuel-air mixture and combustion processes. The market for these technologies is expected to expand significantly in the coming years, as stricter emissions regulations and consumer preferences push manufacturers to innovate.

The performance vehicle segment, including luxury cars and high-end sports cars, remains a key market for advanced V8 engine technologies. These vehicles often serve as showcases for cutting-edge engineering, driving demand for sophisticated fluid dynamics solutions that can extract maximum power and efficiency from V8 engines.

Additionally, there is a growing market for V8 engines in commercial and industrial applications, such as in heavy-duty trucks and marine vessels. These sectors require robust and efficient power sources, creating opportunities for advanced V8 engine technologies that can deliver improved performance and reduced operating costs.

The aftermarket and tuning industry also contributes significantly to the demand for advanced V8 engine technologies. Enthusiasts and performance shops seek innovative solutions to enhance engine output and efficiency, creating a niche market for specialized fluid dynamics components and systems.

Geographically, North America and Europe remain the largest markets for advanced V8 engine technologies, due to their strong automotive industries and consumer preferences for high-performance vehicles. However, emerging markets in Asia-Pacific and the Middle East are showing increasing demand, driven by rising disposable incomes and a growing appetite for luxury and performance vehicles.

The market is also influenced by the broader trend towards electrification in the automotive industry. While this poses a long-term challenge to traditional combustion engines, it has paradoxically spurred innovation in V8 technology. Manufacturers are developing hybrid V8 powertrains and exploring ways to make these engines more competitive with electric alternatives, further driving demand for advanced fluid dynamics solutions.

Current Challenges in V8 Engine Fluid Dynamics

V8 engine fluid dynamics faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of modeling and simulating fluid flow within the engine's intricate geometry. The combustion chamber, intake and exhaust ports, and valve systems create a highly dynamic environment that is difficult to accurately represent in computational fluid dynamics (CFD) models.

Another challenge lies in the high-speed, turbulent nature of fluid flow within V8 engines. As engine speeds increase, the fluid behavior becomes increasingly chaotic and unpredictable, making it challenging to optimize performance and efficiency. This turbulence also affects fuel-air mixing, which is crucial for complete combustion and emissions control.

Heat management presents a significant hurdle in V8 engine fluid dynamics. The intense heat generated during combustion can lead to thermal stress on engine components and affect the properties of fluids within the system. Developing effective cooling strategies that maintain optimal operating temperatures without compromising performance is an ongoing challenge for engineers.

The pursuit of improved fuel efficiency and reduced emissions adds another layer of complexity to V8 engine fluid dynamics. Engineers must balance the need for power output with increasingly stringent environmental regulations, often requiring innovative approaches to fluid flow management and combustion optimization.

Advancements in materials science have introduced new challenges and opportunities in V8 engine fluid dynamics. Novel materials with different thermal and fluid interaction properties require reevaluation of existing fluid dynamics models and design principles.

The integration of forced induction systems, such as turbochargers and superchargers, introduces additional complexities in fluid dynamics. Managing the increased air flow and pressure while maintaining engine reliability and efficiency presents ongoing challenges for researchers and engineers.

As engine designs evolve to meet modern performance and efficiency standards, the interaction between fluid dynamics and other engine systems becomes increasingly important. This includes the interplay between fluid flow and variable valve timing systems, direct injection technologies, and advanced ignition systems.

Another challenge lies in the high-speed, turbulent nature of fluid flow within V8 engines. As engine speeds increase, the fluid behavior becomes increasingly chaotic and unpredictable, making it challenging to optimize performance and efficiency. This turbulence also affects fuel-air mixing, which is crucial for complete combustion and emissions control.

Heat management presents a significant hurdle in V8 engine fluid dynamics. The intense heat generated during combustion can lead to thermal stress on engine components and affect the properties of fluids within the system. Developing effective cooling strategies that maintain optimal operating temperatures without compromising performance is an ongoing challenge for engineers.

The pursuit of improved fuel efficiency and reduced emissions adds another layer of complexity to V8 engine fluid dynamics. Engineers must balance the need for power output with increasingly stringent environmental regulations, often requiring innovative approaches to fluid flow management and combustion optimization.

Advancements in materials science have introduced new challenges and opportunities in V8 engine fluid dynamics. Novel materials with different thermal and fluid interaction properties require reevaluation of existing fluid dynamics models and design principles.

The integration of forced induction systems, such as turbochargers and superchargers, introduces additional complexities in fluid dynamics. Managing the increased air flow and pressure while maintaining engine reliability and efficiency presents ongoing challenges for researchers and engineers.

As engine designs evolve to meet modern performance and efficiency standards, the interaction between fluid dynamics and other engine systems becomes increasingly important. This includes the interplay between fluid flow and variable valve timing systems, direct injection technologies, and advanced ignition systems.

Existing Fluid Dynamic Solutions for V8 Engines

01 Computational Fluid Dynamics (CFD) for V8 Engine Analysis

CFD techniques are employed to analyze and optimize fluid dynamics within V8 engines. This involves simulating airflow, combustion processes, and thermal management to improve engine performance and efficiency. Advanced modeling software is used to predict fluid behavior and identify areas for design enhancement.- Computational Fluid Dynamics (CFD) for V8 Engine Analysis: CFD techniques are employed to analyze and optimize fluid dynamics within V8 engines. This involves simulating airflow, combustion processes, and heat transfer to improve engine performance and efficiency. Advanced modeling software is used to visualize and predict fluid behavior under various operating conditions.

- Intake and Exhaust System Optimization: Optimization of intake and exhaust systems in V8 engines focuses on improving airflow characteristics. This includes designing efficient intake manifolds, optimizing valve timing, and enhancing exhaust gas flow. The goal is to maximize volumetric efficiency and reduce pumping losses, ultimately improving engine performance and fuel economy.

- Fuel Injection and Combustion Dynamics: Advanced fuel injection systems and combustion chamber designs are developed to enhance the fluid dynamics of fuel-air mixture in V8 engines. This includes optimizing spray patterns, improving fuel atomization, and managing in-cylinder air motion to achieve more efficient combustion and reduced emissions.

- Cooling System and Thermal Management: Innovative cooling systems and thermal management strategies are implemented to optimize fluid dynamics related to heat dissipation in V8 engines. This involves designing efficient coolant passages, improving coolant flow distribution, and implementing advanced temperature control mechanisms to maintain optimal operating temperatures and enhance overall engine efficiency.

- Lubrication System Optimization: Optimization of lubrication systems in V8 engines focuses on improving oil flow dynamics. This includes designing efficient oil passages, optimizing oil pump performance, and enhancing oil distribution to critical engine components. The goal is to reduce friction, improve engine durability, and maintain proper lubrication under various operating conditions.

02 Intake and Exhaust System Optimization

Optimization of intake and exhaust systems in V8 engines focuses on improving airflow characteristics. This includes designing efficient intake manifolds, optimizing valve timing, and enhancing exhaust gas flow. These improvements aim to increase engine power output and reduce fuel consumption.Expand Specific Solutions03 Fuel Injection and Combustion Dynamics

Advanced fuel injection systems and combustion chamber designs are developed to enhance the fluid dynamics of fuel-air mixture in V8 engines. This involves optimizing fuel spray patterns, improving mixture formation, and controlling combustion timing to increase efficiency and reduce emissions.Expand Specific Solutions04 Cooling System and Thermal Management

Innovative cooling systems and thermal management strategies are implemented to optimize fluid dynamics related to heat transfer in V8 engines. This includes advanced coolant flow designs, targeted cooling of critical components, and integration of thermal management with overall engine performance.Expand Specific Solutions05 Lubrication System Enhancements

Improvements in lubrication system design focus on optimizing oil flow dynamics within V8 engines. This involves developing efficient oil pumps, enhancing oil distribution channels, and implementing advanced filtration systems to reduce friction, improve engine longevity, and maintain optimal performance under various operating conditions.Expand Specific Solutions

Key Players in V8 Engine Development

The V8 engine fluid dynamics field is in a mature stage of development, with ongoing research focused on optimizing performance and efficiency. The market size is substantial, driven by the automotive industry's continuous demand for high-performance engines. Technologically, advancements are incremental rather than revolutionary. Key players like Toyota, Honda, and Mercedes-Benz are at the forefront, leveraging their extensive R&D capabilities. Universities such as Tianjin University and Nanjing University of Aeronautics & Astronautics contribute significant research. Specialized companies like BorgWarner and Infineum International provide innovative solutions in engine components and lubricants, respectively, further advancing the field.

Toyota Motor Corp.

Technical Solution: Toyota has made significant advancements in V8 engine fluid dynamics, focusing on improving efficiency and performance. Their latest findings include the development of a high-precision computational fluid dynamics (CFD) model that accurately simulates in-cylinder flow and combustion processes[1]. This model incorporates advanced turbulence modeling techniques and detailed chemical kinetics to predict fuel-air mixing, flame propagation, and emissions formation with unprecedented accuracy. Toyota has also implemented innovative cooling strategies, utilizing targeted coolant flow paths and advanced thermal management systems to optimize heat transfer and reduce friction losses in their V8 engines[2]. Additionally, they have explored the use of variable valve timing and lift systems to enhance volumetric efficiency and control in-cylinder flow patterns across a wide range of operating conditions[3].

Strengths: Highly accurate CFD modeling, advanced thermal management, and innovative valve control systems. Weaknesses: Potential increased complexity and cost of manufacturing, may require specialized maintenance.

BorgWarner, Inc.

Technical Solution: BorgWarner has made substantial progress in V8 engine fluid dynamics, particularly in the area of turbocharging and air management systems. Their latest findings include the development of advanced twin-scroll turbochargers specifically optimized for V8 engines, which significantly improve low-end torque and reduce turbo lag[1]. BorgWarner has also introduced innovative variable geometry turbocharger designs that adapt to changing engine conditions, enhancing overall efficiency and performance across a broad operating range[2]. In addition, they have developed sophisticated exhaust gas recirculation (EGR) systems that precisely control the flow of exhaust gases back into the combustion chamber, reducing emissions and improving fuel economy[3]. BorgWarner's research has also led to the creation of advanced intake manifold designs with variable runner lengths and flow control valves, optimizing air flow dynamics for different engine speeds and loads[4].

Strengths: Cutting-edge turbocharging technology, adaptive air management systems, and expertise in exhaust gas recirculation. Weaknesses: Potential increased complexity and cost of components, may require more frequent maintenance due to advanced technologies.

Core Innovations in V8 Engine Fluid Dynamics

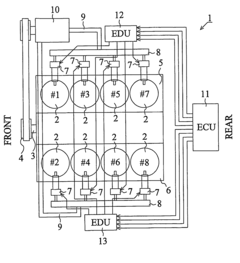

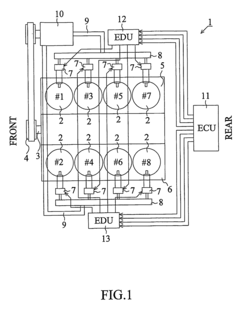

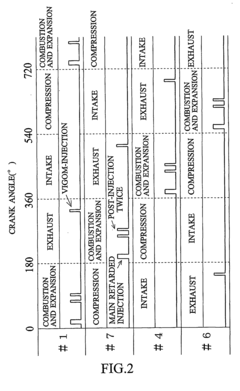

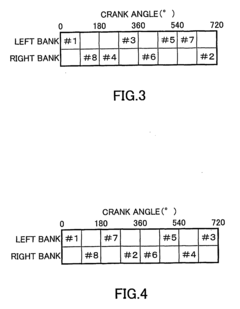

Eight-cylinder engine

PatentInactiveUS20070034177A1

Innovation

- The engine is configured with two valve drive units, where one drives fuel injection valves for cylinders with combustion and expansion strokes at equal intervals (1st, 3rd, 5th, and 7th cylinders) and the other for cylinders with equal intervals (2nd, 4th, 6th, and 8th cylinders), mimicking the energization sequence of a four-cylinder engine to maintain consistent energization intervals.

Eight-cylinder engine

PatentInactiveEP1740812A1

Innovation

- The engine is configured with two valve drive units, where one drives fuel injection valves for cylinders with combustion and expansion strokes at equal intervals, and the other drives those at different intervals, mimicking the operation of a four-cylinder engine to maintain consistent energization intervals and allow sufficient charging time.

Environmental Impact of V8 Engine Technologies

The environmental impact of V8 engine technologies has been a subject of increasing concern in recent years. As automotive manufacturers strive to balance performance with sustainability, the ecological footprint of these powerful engines has come under scrutiny. V8 engines, known for their high output and distinctive sound, have traditionally been associated with higher fuel consumption and increased emissions compared to smaller engine configurations.

Recent advancements in V8 engine fluid dynamics have led to significant improvements in efficiency and environmental performance. Computational fluid dynamics (CFD) simulations have played a crucial role in optimizing combustion processes, reducing friction, and enhancing overall engine efficiency. These improvements have resulted in reduced fuel consumption and lower emissions of greenhouse gases and other pollutants.

One of the key areas of focus has been the development of more efficient cooling systems. Advanced fluid dynamics modeling has enabled engineers to design more effective coolant flow paths, reducing thermal stress on engine components and improving heat dissipation. This has led to better overall engine performance and longevity, indirectly contributing to sustainability by reducing the need for frequent replacements and repairs.

Innovations in lubricant technology, guided by fluid dynamics research, have also contributed to reducing the environmental impact of V8 engines. Low-viscosity oils, developed through extensive fluid dynamics testing, have shown promise in reducing internal friction and improving fuel efficiency. These advancements have the potential to significantly decrease the carbon footprint of V8-powered vehicles over their lifetime.

The integration of start-stop technology and cylinder deactivation systems in V8 engines has further enhanced their environmental credentials. Fluid dynamics research has been instrumental in optimizing these systems, ensuring smooth operation and maximizing fuel savings. By temporarily shutting down cylinders or the entire engine during idle periods, these technologies can substantially reduce emissions in urban driving conditions.

However, challenges remain in fully mitigating the environmental impact of V8 engines. The inherent size and power output of these engines continue to pose challenges in meeting increasingly stringent emissions regulations. As a result, many manufacturers are exploring hybrid and electric powertrains as alternatives or supplements to traditional V8 configurations.

In conclusion, while V8 engines still face environmental challenges, ongoing research in fluid dynamics has led to significant improvements in their ecological performance. These advancements demonstrate the potential for continued innovation in internal combustion engine technology, even as the automotive industry transitions towards more sustainable propulsion systems.

Recent advancements in V8 engine fluid dynamics have led to significant improvements in efficiency and environmental performance. Computational fluid dynamics (CFD) simulations have played a crucial role in optimizing combustion processes, reducing friction, and enhancing overall engine efficiency. These improvements have resulted in reduced fuel consumption and lower emissions of greenhouse gases and other pollutants.

One of the key areas of focus has been the development of more efficient cooling systems. Advanced fluid dynamics modeling has enabled engineers to design more effective coolant flow paths, reducing thermal stress on engine components and improving heat dissipation. This has led to better overall engine performance and longevity, indirectly contributing to sustainability by reducing the need for frequent replacements and repairs.

Innovations in lubricant technology, guided by fluid dynamics research, have also contributed to reducing the environmental impact of V8 engines. Low-viscosity oils, developed through extensive fluid dynamics testing, have shown promise in reducing internal friction and improving fuel efficiency. These advancements have the potential to significantly decrease the carbon footprint of V8-powered vehicles over their lifetime.

The integration of start-stop technology and cylinder deactivation systems in V8 engines has further enhanced their environmental credentials. Fluid dynamics research has been instrumental in optimizing these systems, ensuring smooth operation and maximizing fuel savings. By temporarily shutting down cylinders or the entire engine during idle periods, these technologies can substantially reduce emissions in urban driving conditions.

However, challenges remain in fully mitigating the environmental impact of V8 engines. The inherent size and power output of these engines continue to pose challenges in meeting increasingly stringent emissions regulations. As a result, many manufacturers are exploring hybrid and electric powertrains as alternatives or supplements to traditional V8 configurations.

In conclusion, while V8 engines still face environmental challenges, ongoing research in fluid dynamics has led to significant improvements in their ecological performance. These advancements demonstrate the potential for continued innovation in internal combustion engine technology, even as the automotive industry transitions towards more sustainable propulsion systems.

Regulatory Landscape for V8 Engine Emissions

The regulatory landscape for V8 engine emissions has become increasingly stringent in recent years, reflecting growing global concerns about environmental protection and climate change. Governments and regulatory bodies worldwide have implemented progressively stricter standards to reduce harmful emissions from internal combustion engines, including V8 engines.

In the United States, the Environmental Protection Agency (EPA) has established comprehensive regulations under the Clean Air Act. These regulations set specific limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). The Corporate Average Fuel Economy (CAFE) standards also indirectly impact V8 engine emissions by mandating improved fuel efficiency across manufacturers' vehicle fleets.

The European Union has implemented its own set of emissions standards, known as Euro standards. Currently, Euro 6 is in effect, with plans for Euro 7 on the horizon. These standards impose strict limits on emissions of NOx, CO, hydrocarbons, and PM. The EU has also introduced Real Driving Emissions (RDE) tests to ensure vehicles comply with emissions standards under real-world driving conditions.

China, as the world's largest automotive market, has adopted emissions standards similar to those in Europe. The China 6 standard, implemented in phases, sets ambitious targets for reducing vehicle emissions and improving air quality in urban areas.

To meet these regulatory requirements, manufacturers of V8 engines have had to invest heavily in advanced technologies. This includes the development of more efficient combustion processes, improved fuel injection systems, and sophisticated exhaust after-treatment technologies such as catalytic converters and particulate filters.

The regulatory landscape has also driven innovation in engine management systems. Advanced electronic control units (ECUs) and sensors are now essential components in modern V8 engines, allowing for real-time monitoring and adjustment of engine parameters to optimize performance while minimizing emissions.

Looking ahead, the regulatory trend is clearly moving towards even stricter emissions standards. Many countries have announced plans to phase out internal combustion engines entirely in favor of electric vehicles. This presents a significant challenge for V8 engine manufacturers, who must balance performance expectations with increasingly demanding environmental regulations.

In response, some manufacturers are exploring hybrid technologies that combine V8 engines with electric motors. This approach allows for improved fuel efficiency and reduced emissions while maintaining the power and character associated with V8 engines. However, the long-term viability of V8 engines in the face of tightening regulations remains uncertain, and manufacturers will need to continue innovating to meet future challenges.

In the United States, the Environmental Protection Agency (EPA) has established comprehensive regulations under the Clean Air Act. These regulations set specific limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). The Corporate Average Fuel Economy (CAFE) standards also indirectly impact V8 engine emissions by mandating improved fuel efficiency across manufacturers' vehicle fleets.

The European Union has implemented its own set of emissions standards, known as Euro standards. Currently, Euro 6 is in effect, with plans for Euro 7 on the horizon. These standards impose strict limits on emissions of NOx, CO, hydrocarbons, and PM. The EU has also introduced Real Driving Emissions (RDE) tests to ensure vehicles comply with emissions standards under real-world driving conditions.

China, as the world's largest automotive market, has adopted emissions standards similar to those in Europe. The China 6 standard, implemented in phases, sets ambitious targets for reducing vehicle emissions and improving air quality in urban areas.

To meet these regulatory requirements, manufacturers of V8 engines have had to invest heavily in advanced technologies. This includes the development of more efficient combustion processes, improved fuel injection systems, and sophisticated exhaust after-treatment technologies such as catalytic converters and particulate filters.

The regulatory landscape has also driven innovation in engine management systems. Advanced electronic control units (ECUs) and sensors are now essential components in modern V8 engines, allowing for real-time monitoring and adjustment of engine parameters to optimize performance while minimizing emissions.

Looking ahead, the regulatory trend is clearly moving towards even stricter emissions standards. Many countries have announced plans to phase out internal combustion engines entirely in favor of electric vehicles. This presents a significant challenge for V8 engine manufacturers, who must balance performance expectations with increasingly demanding environmental regulations.

In response, some manufacturers are exploring hybrid technologies that combine V8 engines with electric motors. This approach allows for improved fuel efficiency and reduced emissions while maintaining the power and character associated with V8 engines. However, the long-term viability of V8 engines in the face of tightening regulations remains uncertain, and manufacturers will need to continue innovating to meet future challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!