V8 Engine Impact on Global Automotive Trends

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception in the early 20th century. Initially developed to provide more power and smoother operation than inline engines, the V8 configuration quickly became synonymous with performance and luxury in the automotive world.

In the 1930s and 1940s, V8 engines gained popularity in American automobiles, with brands like Ford and Cadillac leading the charge. These early V8s were characterized by their large displacement and relatively low-tech designs, focusing on raw power output rather than efficiency.

The 1950s and 1960s saw a surge in V8 engine development, particularly in the United States. This era, often referred to as the "Golden Age" of V8s, witnessed the introduction of high-performance variants like the Chrysler Hemi and Chevrolet's small-block V8. These engines not only powered iconic muscle cars but also influenced global automotive trends.

During the 1970s, the oil crisis and stricter emission regulations forced manufacturers to rethink V8 engine design. This led to a period of downsizing and the introduction of technologies like fuel injection and catalytic converters. Despite these challenges, V8 engines remained a staple in luxury cars and performance vehicles.

The 1980s and 1990s brought about a renaissance for V8 engines, with advancements in materials science and computer-aided design allowing for more efficient and powerful units. Overhead cam designs became more common, and variable valve timing was introduced to improve both performance and fuel economy.

In the 21st century, V8 engines have continued to evolve, embracing technologies such as direct injection, cylinder deactivation, and turbocharging. These innovations have allowed V8s to maintain their relevance in an era of increasing environmental concerns and fuel efficiency demands.

Recent years have seen a shift towards electrification, with hybrid V8 powertrains emerging as a bridge between traditional internal combustion engines and fully electric vehicles. This trend is particularly evident in high-performance and luxury segments, where manufacturers are striving to balance power output with reduced emissions.

Looking ahead, the future of V8 engines faces challenges from stricter emissions regulations and the push towards electrification. However, their cultural significance and performance capabilities ensure that V8s will likely continue to play a role in niche markets and specialized applications, albeit with continued focus on efficiency and environmental impact.

In the 1930s and 1940s, V8 engines gained popularity in American automobiles, with brands like Ford and Cadillac leading the charge. These early V8s were characterized by their large displacement and relatively low-tech designs, focusing on raw power output rather than efficiency.

The 1950s and 1960s saw a surge in V8 engine development, particularly in the United States. This era, often referred to as the "Golden Age" of V8s, witnessed the introduction of high-performance variants like the Chrysler Hemi and Chevrolet's small-block V8. These engines not only powered iconic muscle cars but also influenced global automotive trends.

During the 1970s, the oil crisis and stricter emission regulations forced manufacturers to rethink V8 engine design. This led to a period of downsizing and the introduction of technologies like fuel injection and catalytic converters. Despite these challenges, V8 engines remained a staple in luxury cars and performance vehicles.

The 1980s and 1990s brought about a renaissance for V8 engines, with advancements in materials science and computer-aided design allowing for more efficient and powerful units. Overhead cam designs became more common, and variable valve timing was introduced to improve both performance and fuel economy.

In the 21st century, V8 engines have continued to evolve, embracing technologies such as direct injection, cylinder deactivation, and turbocharging. These innovations have allowed V8s to maintain their relevance in an era of increasing environmental concerns and fuel efficiency demands.

Recent years have seen a shift towards electrification, with hybrid V8 powertrains emerging as a bridge between traditional internal combustion engines and fully electric vehicles. This trend is particularly evident in high-performance and luxury segments, where manufacturers are striving to balance power output with reduced emissions.

Looking ahead, the future of V8 engines faces challenges from stricter emissions regulations and the push towards electrification. However, their cultural significance and performance capabilities ensure that V8s will likely continue to play a role in niche markets and specialized applications, albeit with continued focus on efficiency and environmental impact.

Market Demand Analysis

The global automotive industry has witnessed a significant shift in market demand, with V8 engines playing a crucial role in shaping consumer preferences and industry trends. Despite the growing emphasis on fuel efficiency and environmental concerns, there remains a substantial market segment that values the power, performance, and prestige associated with V8 engines.

In the luxury and high-performance vehicle segments, V8 engines continue to be in high demand. Consumers in these markets prioritize acceleration, top speed, and overall driving experience, which V8 engines excel at delivering. This demand is particularly strong in regions with a robust car culture, such as North America, Europe, and the Middle East.

The sports car and muscle car markets have also maintained a steady demand for V8 engines. These vehicles cater to enthusiasts who appreciate the distinctive sound, power delivery, and heritage associated with V8 powerplants. Manufacturers like Ford, Chevrolet, and Dodge have capitalized on this demand by continuing to offer V8 options in their performance-oriented models.

However, the market for V8 engines is not without challenges. Stringent emissions regulations and increasing fuel economy standards have put pressure on automakers to improve the efficiency of V8 engines or explore alternative powertrains. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging to enhance the efficiency of V8 engines while maintaining their performance characteristics.

The luxury SUV and pickup truck segments have emerged as significant growth areas for V8 engines. As consumers gravitate towards larger vehicles, the need for powerful engines to move these heavier platforms has sustained the demand for V8 options. This trend is particularly evident in North America, where full-size trucks and SUVs dominate the market.

Emerging markets, particularly in Asia and the Middle East, have shown an increasing appetite for luxury vehicles equipped with V8 engines. The growing middle and upper classes in these regions view V8-powered vehicles as status symbols, driving demand for high-end automobiles from both domestic and international manufacturers.

The racing and motorsport industry continues to be a significant driver of V8 engine development and demand. Formula 1's use of V8 engines in the past and the ongoing popularity of V8 powerplants in various racing series have maintained the engine configuration's relevance and appeal among automotive enthusiasts.

While the overall automotive market is shifting towards electrification and smaller, more efficient engines, the V8 engine market has shown resilience. Manufacturers are adapting by developing hybrid V8 powertrains and exploring ways to make V8 engines more environmentally friendly without sacrificing the performance characteristics that consumers desire.

In the luxury and high-performance vehicle segments, V8 engines continue to be in high demand. Consumers in these markets prioritize acceleration, top speed, and overall driving experience, which V8 engines excel at delivering. This demand is particularly strong in regions with a robust car culture, such as North America, Europe, and the Middle East.

The sports car and muscle car markets have also maintained a steady demand for V8 engines. These vehicles cater to enthusiasts who appreciate the distinctive sound, power delivery, and heritage associated with V8 powerplants. Manufacturers like Ford, Chevrolet, and Dodge have capitalized on this demand by continuing to offer V8 options in their performance-oriented models.

However, the market for V8 engines is not without challenges. Stringent emissions regulations and increasing fuel economy standards have put pressure on automakers to improve the efficiency of V8 engines or explore alternative powertrains. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging to enhance the efficiency of V8 engines while maintaining their performance characteristics.

The luxury SUV and pickup truck segments have emerged as significant growth areas for V8 engines. As consumers gravitate towards larger vehicles, the need for powerful engines to move these heavier platforms has sustained the demand for V8 options. This trend is particularly evident in North America, where full-size trucks and SUVs dominate the market.

Emerging markets, particularly in Asia and the Middle East, have shown an increasing appetite for luxury vehicles equipped with V8 engines. The growing middle and upper classes in these regions view V8-powered vehicles as status symbols, driving demand for high-end automobiles from both domestic and international manufacturers.

The racing and motorsport industry continues to be a significant driver of V8 engine development and demand. Formula 1's use of V8 engines in the past and the ongoing popularity of V8 powerplants in various racing series have maintained the engine configuration's relevance and appeal among automotive enthusiasts.

While the overall automotive market is shifting towards electrification and smaller, more efficient engines, the V8 engine market has shown resilience. Manufacturers are adapting by developing hybrid V8 powertrains and exploring ways to make V8 engines more environmentally friendly without sacrificing the performance characteristics that consumers desire.

Technical Challenges

The V8 engine, a cornerstone of automotive engineering for decades, faces significant technical challenges in the context of global automotive trends. One of the primary hurdles is meeting increasingly stringent emissions regulations worldwide. As governments implement stricter standards to combat climate change, V8 engines struggle to achieve the required levels of fuel efficiency and reduced carbon emissions.

Fuel consumption remains a critical issue for V8 engines. Their inherently larger displacement and higher number of cylinders result in greater fuel consumption compared to smaller, more efficient engine configurations. This challenge is particularly pronounced in urban environments where stop-and-start traffic conditions prevail, leading to increased fuel usage and emissions.

The weight of V8 engines presents another technical obstacle. As automotive manufacturers strive for lighter vehicles to improve overall efficiency and performance, the substantial mass of V8 engines becomes a limiting factor. This weight not only affects fuel economy but also impacts vehicle dynamics and handling characteristics.

Thermal management poses a significant challenge for V8 engines, especially in high-performance applications. The increased heat generation from eight cylinders requires sophisticated cooling systems, which add complexity and weight to the vehicle. Balancing thermal efficiency with performance demands continues to be a technical hurdle for engineers.

Noise, vibration, and harshness (NVH) characteristics of V8 engines present ongoing challenges. While the distinctive sound of a V8 is often desirable, it can conflict with noise regulations and consumer preferences for quieter vehicles. Engineers must develop innovative solutions to dampen engine noise and vibrations without compromising the engine's performance or character.

The integration of advanced technologies, such as hybrid systems and cylinder deactivation, into V8 engines presents complex engineering challenges. These technologies aim to improve efficiency and emissions but require sophisticated control systems and careful integration to maintain the performance characteristics expected from V8 engines.

Manufacturing complexity and cost remain significant hurdles for V8 engines. The intricate design and higher number of components compared to smaller engines result in increased production costs and potential reliability issues. This challenge is particularly acute as the automotive industry shifts towards more cost-effective and simplified powertrain solutions.

Lastly, the industry-wide trend towards electrification poses an existential challenge for V8 engines. As automotive manufacturers invest heavily in electric vehicle technology, the long-term viability of V8 engines in mainstream vehicles is called into question. Engineers must find ways to justify the continued development and production of V8 engines in an increasingly electrified automotive landscape.

Fuel consumption remains a critical issue for V8 engines. Their inherently larger displacement and higher number of cylinders result in greater fuel consumption compared to smaller, more efficient engine configurations. This challenge is particularly pronounced in urban environments where stop-and-start traffic conditions prevail, leading to increased fuel usage and emissions.

The weight of V8 engines presents another technical obstacle. As automotive manufacturers strive for lighter vehicles to improve overall efficiency and performance, the substantial mass of V8 engines becomes a limiting factor. This weight not only affects fuel economy but also impacts vehicle dynamics and handling characteristics.

Thermal management poses a significant challenge for V8 engines, especially in high-performance applications. The increased heat generation from eight cylinders requires sophisticated cooling systems, which add complexity and weight to the vehicle. Balancing thermal efficiency with performance demands continues to be a technical hurdle for engineers.

Noise, vibration, and harshness (NVH) characteristics of V8 engines present ongoing challenges. While the distinctive sound of a V8 is often desirable, it can conflict with noise regulations and consumer preferences for quieter vehicles. Engineers must develop innovative solutions to dampen engine noise and vibrations without compromising the engine's performance or character.

The integration of advanced technologies, such as hybrid systems and cylinder deactivation, into V8 engines presents complex engineering challenges. These technologies aim to improve efficiency and emissions but require sophisticated control systems and careful integration to maintain the performance characteristics expected from V8 engines.

Manufacturing complexity and cost remain significant hurdles for V8 engines. The intricate design and higher number of components compared to smaller engines result in increased production costs and potential reliability issues. This challenge is particularly acute as the automotive industry shifts towards more cost-effective and simplified powertrain solutions.

Lastly, the industry-wide trend towards electrification poses an existential challenge for V8 engines. As automotive manufacturers invest heavily in electric vehicle technology, the long-term viability of V8 engines in mainstream vehicles is called into question. Engineers must find ways to justify the continued development and production of V8 engines in an increasingly electrified automotive landscape.

Current V8 Solutions

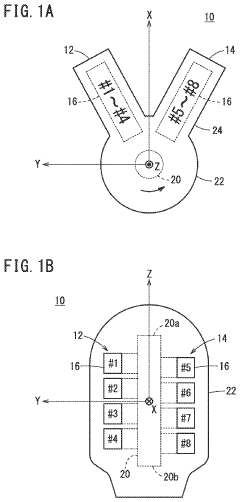

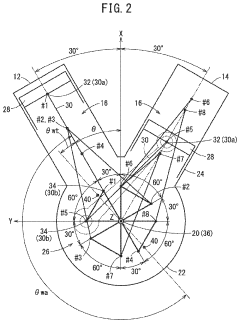

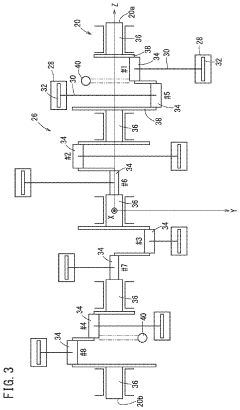

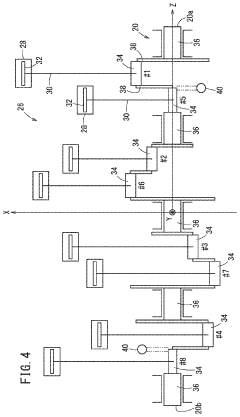

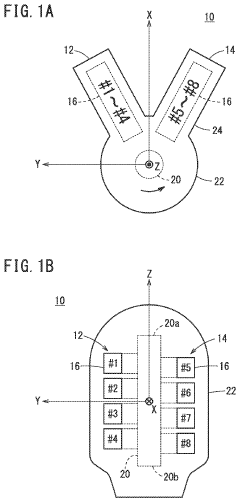

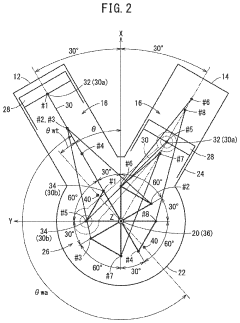

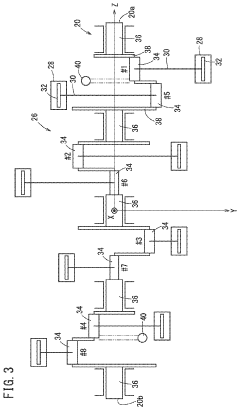

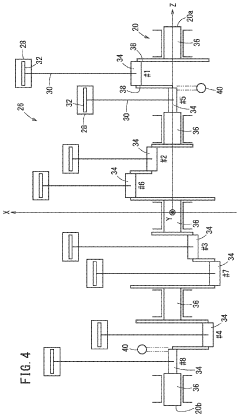

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.

- Performance Enhancement and Tuning: Various methods and components are used to enhance V8 engine performance. These may include turbocharging, supercharging, high-flow intake and exhaust systems, and engine management system tuning. Performance enhancements aim to increase power output, torque, and overall engine efficiency.

- Cooling and Lubrication Systems: Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Advanced cooling systems may include precision-controlled electric water pumps, optimized coolant flow paths, and efficient heat exchangers. Lubrication systems are designed to ensure proper oil distribution to all critical engine components, even under high-performance conditions.

- Manufacturing and Assembly Techniques: Innovative manufacturing and assembly techniques are employed in V8 engine production to improve quality, reduce weight, and enhance durability. These may include advanced casting methods, precision machining processes, and the use of lightweight materials such as aluminum alloys. Assembly techniques focus on ensuring proper component alignment and optimal clearances.

02 Fuel Injection and Combustion Systems

Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.Expand Specific Solutions03 Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased horsepower. Various designs and configurations of turbochargers and superchargers are used to optimize V8 engine performance across different operating conditions.Expand Specific Solutions04 Cooling and Lubrication Systems

Efficient cooling and lubrication systems are essential for V8 engine reliability and longevity. Advanced cooling systems manage engine temperature under high-performance conditions, while improved lubrication systems ensure proper oil distribution to critical components. These systems are designed to handle the increased heat and stress generated by high-output V8 engines.Expand Specific Solutions05 Materials and Manufacturing Techniques

Innovative materials and manufacturing techniques are employed in V8 engine production to enhance performance and durability. Lightweight alloys, advanced coatings, and precision manufacturing processes are used to reduce engine weight, improve heat dissipation, and increase component strength. These advancements contribute to improved power-to-weight ratios and overall engine efficiency.Expand Specific Solutions

Key Manufacturers

The V8 engine's impact on global automotive trends is characterized by a mature market with established players and evolving technology. The industry is in a transitional phase, balancing traditional V8 applications with emerging alternatives. Market size remains significant, particularly in high-performance and luxury segments. Technologically, companies like GM, Ford, Toyota, and Honda continue to refine V8 designs, focusing on efficiency and emissions. However, the shift towards electrification and stricter environmental regulations is challenging V8's long-term dominance, prompting manufacturers to explore hybrid and alternative powertrain solutions. This dynamic landscape is driving innovation and diversification among key players in the automotive sector.

GM Global Technology Operations LLC

Technical Solution: GM has been at the forefront of V8 engine development, particularly with their Small Block V8 series. Their latest V8 innovations focus on Dynamic Fuel Management (DFM) technology, which can deactivate up to seven cylinders for improved fuel efficiency[1]. GM's V8 engines also incorporate advanced materials and manufacturing techniques, such as aluminum block and heads, to reduce weight while maintaining durability[2]. The company has invested in cylinder deactivation systems that seamlessly transition between 4, 6, and 8-cylinder operation modes, optimizing performance and fuel economy based on driving conditions[3]. Additionally, GM has integrated start-stop technology and advanced thermal management systems into their V8 engines to further enhance efficiency and reduce emissions[4].

Strengths: Proven reliability, high performance, and adaptability to various vehicle types. Weaknesses: Higher fuel consumption compared to smaller engines, potential challenges in meeting stricter emission standards.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V8 engine technology focuses on balancing power with efficiency. Their latest V8 engines, such as those used in the Lexus lineup, feature dual VVT-i (Variable Valve Timing-intelligent) systems for both intake and exhaust valves, optimizing performance across the entire RPM range[1]. Toyota has also implemented D-4S direct injection technology, which combines direct and port fuel injection for improved fuel efficiency and reduced emissions[2]. The company's V8 engines often incorporate lightweight materials like aluminum alloy blocks and cylinder heads to reduce overall vehicle weight[3]. Toyota has been exploring hybrid V8 powertrains, integrating electric motors with traditional V8 engines to boost performance while improving fuel economy, particularly in their high-end vehicles and racing applications[4].

Strengths: Renowned reliability, smooth operation, and integration with hybrid systems. Weaknesses: Relatively conservative approach to performance compared to some competitors, potential for higher production costs due to quality standards.

Core V8 Innovations

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Emissions Regulations

Emissions regulations have played a pivotal role in shaping the global automotive landscape, particularly in relation to V8 engines. These regulations, aimed at reducing harmful emissions and improving air quality, have significantly influenced the design, production, and market presence of V8 engines worldwide.

In recent years, stringent emissions standards such as Euro 6 in Europe, Tier 3 in the United States, and China 6 in China have posed considerable challenges for V8 engine manufacturers. These regulations have set increasingly strict limits on pollutants like carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM), forcing automakers to adapt their V8 engines or face potential market exclusion.

The impact of these regulations on V8 engines has been multifaceted. Manufacturers have had to invest heavily in advanced technologies to meet emissions targets while maintaining performance. This has led to the widespread adoption of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines. Additionally, many automakers have incorporated turbocharging and supercharging to achieve better fuel efficiency without sacrificing power output.

Despite these advancements, the long-term viability of V8 engines in many markets has come into question. Some regions, particularly in Europe, have introduced or proposed bans on the sale of new internal combustion engine vehicles, including those with V8 engines, within the next decade or two. This has accelerated the shift towards electrification and alternative powertrains, with many manufacturers reducing their V8 engine offerings or phasing them out entirely in certain markets.

The emissions regulations have also led to a geographical shift in V8 engine production and consumption. While stricter regulations in Europe and parts of Asia have diminished the market for V8 engines, they remain popular in regions with more lenient emissions standards, such as the Middle East and certain parts of North America. This has resulted in a reconfiguration of global automotive production strategies, with some manufacturers focusing their V8 engine production on specific markets where demand remains strong.

Furthermore, the regulatory landscape has spurred innovation in V8 engine technology. Some manufacturers have explored hybrid V8 powertrains as a way to meet emissions standards while preserving the characteristic performance and sound of V8 engines. Others have invested in advanced materials and manufacturing techniques to reduce engine weight and improve efficiency, thereby meeting emissions targets without compromising on power output.

In conclusion, emissions regulations have fundamentally altered the trajectory of V8 engine development and deployment globally. While these engines continue to hold a significant place in certain market segments, their future is increasingly shaped by the need to comply with ever-tightening emissions standards, driving technological innovation and market adaptation in the automotive industry.

In recent years, stringent emissions standards such as Euro 6 in Europe, Tier 3 in the United States, and China 6 in China have posed considerable challenges for V8 engine manufacturers. These regulations have set increasingly strict limits on pollutants like carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM), forcing automakers to adapt their V8 engines or face potential market exclusion.

The impact of these regulations on V8 engines has been multifaceted. Manufacturers have had to invest heavily in advanced technologies to meet emissions targets while maintaining performance. This has led to the widespread adoption of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines. Additionally, many automakers have incorporated turbocharging and supercharging to achieve better fuel efficiency without sacrificing power output.

Despite these advancements, the long-term viability of V8 engines in many markets has come into question. Some regions, particularly in Europe, have introduced or proposed bans on the sale of new internal combustion engine vehicles, including those with V8 engines, within the next decade or two. This has accelerated the shift towards electrification and alternative powertrains, with many manufacturers reducing their V8 engine offerings or phasing them out entirely in certain markets.

The emissions regulations have also led to a geographical shift in V8 engine production and consumption. While stricter regulations in Europe and parts of Asia have diminished the market for V8 engines, they remain popular in regions with more lenient emissions standards, such as the Middle East and certain parts of North America. This has resulted in a reconfiguration of global automotive production strategies, with some manufacturers focusing their V8 engine production on specific markets where demand remains strong.

Furthermore, the regulatory landscape has spurred innovation in V8 engine technology. Some manufacturers have explored hybrid V8 powertrains as a way to meet emissions standards while preserving the characteristic performance and sound of V8 engines. Others have invested in advanced materials and manufacturing techniques to reduce engine weight and improve efficiency, thereby meeting emissions targets without compromising on power output.

In conclusion, emissions regulations have fundamentally altered the trajectory of V8 engine development and deployment globally. While these engines continue to hold a significant place in certain market segments, their future is increasingly shaped by the need to comply with ever-tightening emissions standards, driving technological innovation and market adaptation in the automotive industry.

Performance vs Efficiency

The V8 engine has long been a symbol of power and performance in the automotive industry. However, in recent years, the focus has shifted towards balancing performance with efficiency due to increasing environmental concerns and stricter emissions regulations. This shift has led to significant innovations in V8 engine technology, aiming to maintain the power output while improving fuel economy and reducing emissions.

One of the key advancements in V8 engine technology is the implementation of cylinder deactivation systems. This technology allows the engine to shut down a portion of its cylinders during light load conditions, effectively operating as a smaller, more fuel-efficient engine. When more power is needed, all cylinders can be reactivated seamlessly. This approach has enabled V8 engines to achieve fuel economy improvements of up to 15% in real-world driving conditions.

Another significant development is the integration of direct fuel injection systems in V8 engines. By precisely controlling the fuel delivery into the combustion chamber, direct injection improves fuel atomization and allows for higher compression ratios. This results in more efficient combustion, increased power output, and reduced fuel consumption. Some modern V8 engines equipped with direct injection have shown improvements in fuel efficiency of up to 12% compared to their port-injected counterparts.

Turbocharging and supercharging technologies have also played a crucial role in enhancing V8 engine performance while maintaining efficiency. These forced induction systems allow manufacturers to downsize V8 engines without sacrificing power output. For example, a turbocharged 4.0-liter V8 can now produce power levels comparable to naturally aspirated 6.0-liter V8 engines of the past, while consuming significantly less fuel.

Advanced materials and manufacturing techniques have contributed to weight reduction in V8 engines, further improving their efficiency. The use of lightweight alloys, such as aluminum and magnesium, for engine blocks and components has reduced overall engine weight by up to 25% in some cases. This weight reduction not only improves fuel efficiency but also enhances vehicle dynamics and performance.

The integration of start-stop systems in V8-powered vehicles has become increasingly common, offering additional fuel savings in urban driving conditions. These systems automatically shut off the engine when the vehicle comes to a stop and restart it when the driver releases the brake pedal. While the fuel savings may seem minimal per instance, they can accumulate to significant improvements in overall efficiency, especially in heavy traffic situations.

In conclusion, the evolution of V8 engine technology demonstrates a successful balance between performance and efficiency. Through innovative technologies and engineering solutions, manufacturers have managed to preserve the power and appeal of V8 engines while significantly improving their fuel economy and environmental impact. This ongoing development ensures that V8 engines remain relevant in an increasingly efficiency-focused automotive landscape.

One of the key advancements in V8 engine technology is the implementation of cylinder deactivation systems. This technology allows the engine to shut down a portion of its cylinders during light load conditions, effectively operating as a smaller, more fuel-efficient engine. When more power is needed, all cylinders can be reactivated seamlessly. This approach has enabled V8 engines to achieve fuel economy improvements of up to 15% in real-world driving conditions.

Another significant development is the integration of direct fuel injection systems in V8 engines. By precisely controlling the fuel delivery into the combustion chamber, direct injection improves fuel atomization and allows for higher compression ratios. This results in more efficient combustion, increased power output, and reduced fuel consumption. Some modern V8 engines equipped with direct injection have shown improvements in fuel efficiency of up to 12% compared to their port-injected counterparts.

Turbocharging and supercharging technologies have also played a crucial role in enhancing V8 engine performance while maintaining efficiency. These forced induction systems allow manufacturers to downsize V8 engines without sacrificing power output. For example, a turbocharged 4.0-liter V8 can now produce power levels comparable to naturally aspirated 6.0-liter V8 engines of the past, while consuming significantly less fuel.

Advanced materials and manufacturing techniques have contributed to weight reduction in V8 engines, further improving their efficiency. The use of lightweight alloys, such as aluminum and magnesium, for engine blocks and components has reduced overall engine weight by up to 25% in some cases. This weight reduction not only improves fuel efficiency but also enhances vehicle dynamics and performance.

The integration of start-stop systems in V8-powered vehicles has become increasingly common, offering additional fuel savings in urban driving conditions. These systems automatically shut off the engine when the vehicle comes to a stop and restart it when the driver releases the brake pedal. While the fuel savings may seem minimal per instance, they can accumulate to significant improvements in overall efficiency, especially in heavy traffic situations.

In conclusion, the evolution of V8 engine technology demonstrates a successful balance between performance and efficiency. Through innovative technologies and engineering solutions, manufacturers have managed to preserve the power and appeal of V8 engines while significantly improving their fuel economy and environmental impact. This ongoing development ensures that V8 engines remain relevant in an increasingly efficiency-focused automotive landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!