V8 Engine Influence on Automotive Safety Standards

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Safety Objectives

The V8 engine has been a cornerstone of automotive engineering since its inception in the early 20th century. Its evolution has been closely intertwined with the development of automotive safety standards, reflecting the industry's ongoing commitment to balancing performance with passenger protection. The primary objective of this technological progression has been to enhance engine efficiency and power output while simultaneously improving vehicle safety.

Initially, V8 engines were primarily focused on delivering raw power and speed, with little consideration for safety implications. However, as automotive safety became a growing concern in the mid-20th century, engine designers began to incorporate features that would contribute to overall vehicle safety. This shift in focus led to the development of more compact V8 designs, allowing for improved crumple zones and better weight distribution.

The introduction of electronic fuel injection systems in V8 engines marked a significant milestone in both performance and safety. These systems not only improved fuel efficiency and reduced emissions but also provided better engine control, which translated to enhanced vehicle stability and handling. This advancement directly contributed to the development of more sophisticated traction control and stability management systems.

As safety standards became more stringent, V8 engine designers faced the challenge of meeting increasingly strict emissions regulations while maintaining performance. This led to innovations such as variable valve timing, cylinder deactivation, and advanced engine management systems. These technologies not only improved fuel economy but also allowed for more precise control over engine output, contributing to safer acceleration and deceleration characteristics.

The integration of V8 engines with advanced driver assistance systems (ADAS) represents the latest frontier in automotive safety. Modern V8 engines are now designed to work in harmony with sensors and electronic control units, enabling features such as adaptive cruise control and emergency braking. This synergy between powerful engine performance and intelligent safety systems has set new benchmarks for automotive safety standards.

Looking forward, the evolution of V8 engines continues to be driven by the dual objectives of performance enhancement and safety improvement. Emerging technologies such as hybrid V8 systems and advanced materials are being explored to further reduce weight, improve efficiency, and enhance safety features. The ultimate goal is to create V8 engines that not only deliver exhilarating performance but also contribute significantly to the overall safety ecosystem of modern vehicles.

Initially, V8 engines were primarily focused on delivering raw power and speed, with little consideration for safety implications. However, as automotive safety became a growing concern in the mid-20th century, engine designers began to incorporate features that would contribute to overall vehicle safety. This shift in focus led to the development of more compact V8 designs, allowing for improved crumple zones and better weight distribution.

The introduction of electronic fuel injection systems in V8 engines marked a significant milestone in both performance and safety. These systems not only improved fuel efficiency and reduced emissions but also provided better engine control, which translated to enhanced vehicle stability and handling. This advancement directly contributed to the development of more sophisticated traction control and stability management systems.

As safety standards became more stringent, V8 engine designers faced the challenge of meeting increasingly strict emissions regulations while maintaining performance. This led to innovations such as variable valve timing, cylinder deactivation, and advanced engine management systems. These technologies not only improved fuel economy but also allowed for more precise control over engine output, contributing to safer acceleration and deceleration characteristics.

The integration of V8 engines with advanced driver assistance systems (ADAS) represents the latest frontier in automotive safety. Modern V8 engines are now designed to work in harmony with sensors and electronic control units, enabling features such as adaptive cruise control and emergency braking. This synergy between powerful engine performance and intelligent safety systems has set new benchmarks for automotive safety standards.

Looking forward, the evolution of V8 engines continues to be driven by the dual objectives of performance enhancement and safety improvement. Emerging technologies such as hybrid V8 systems and advanced materials are being explored to further reduce weight, improve efficiency, and enhance safety features. The ultimate goal is to create V8 engines that not only deliver exhilarating performance but also contribute significantly to the overall safety ecosystem of modern vehicles.

Market Demand for High-Performance Safe Vehicles

The automotive industry has witnessed a significant shift in consumer preferences towards high-performance vehicles that do not compromise on safety. This trend is driven by a combination of factors, including technological advancements, changing lifestyle preferences, and increased awareness of road safety.

Market research indicates a growing demand for vehicles that offer both power and advanced safety features. Consumers are no longer satisfied with choosing between performance and safety; they expect both in a single package. This demand is particularly strong in developed markets such as North America, Europe, and parts of Asia, where consumers have higher disposable incomes and a greater emphasis on personal safety.

The rise of electric vehicles (EVs) has also influenced this market trend. High-performance electric cars have demonstrated that it is possible to achieve impressive acceleration and top speeds while maintaining high safety standards. This has raised consumer expectations across the entire automotive sector, including for traditional internal combustion engine vehicles.

Safety regulations and crash test standards have become increasingly stringent in recent years, pushing automakers to innovate in both active and passive safety systems. Consumers are now more informed about safety ratings and features, making these aspects crucial selling points for high-performance vehicles.

The luxury and sports car segments have been quick to respond to this market demand. Many manufacturers are now incorporating advanced driver assistance systems (ADAS), improved structural designs, and innovative materials to enhance safety without compromising performance. This has led to the development of vehicles that can accelerate from 0-60 mph in under 3 seconds while still achieving top safety ratings.

Market analysts predict that the global high-performance vehicle market will continue to grow, with safety features playing a key role in purchasing decisions. The integration of V8 engines with cutting-edge safety technologies is expected to remain a focus for manufacturers catering to this segment.

However, challenges remain in balancing performance with safety and environmental concerns. Stricter emissions regulations and the shift towards electrification may impact the future of V8 engines in high-performance vehicles. Manufacturers will need to innovate to meet these challenges while satisfying the market demand for powerful, safe vehicles.

Market research indicates a growing demand for vehicles that offer both power and advanced safety features. Consumers are no longer satisfied with choosing between performance and safety; they expect both in a single package. This demand is particularly strong in developed markets such as North America, Europe, and parts of Asia, where consumers have higher disposable incomes and a greater emphasis on personal safety.

The rise of electric vehicles (EVs) has also influenced this market trend. High-performance electric cars have demonstrated that it is possible to achieve impressive acceleration and top speeds while maintaining high safety standards. This has raised consumer expectations across the entire automotive sector, including for traditional internal combustion engine vehicles.

Safety regulations and crash test standards have become increasingly stringent in recent years, pushing automakers to innovate in both active and passive safety systems. Consumers are now more informed about safety ratings and features, making these aspects crucial selling points for high-performance vehicles.

The luxury and sports car segments have been quick to respond to this market demand. Many manufacturers are now incorporating advanced driver assistance systems (ADAS), improved structural designs, and innovative materials to enhance safety without compromising performance. This has led to the development of vehicles that can accelerate from 0-60 mph in under 3 seconds while still achieving top safety ratings.

Market analysts predict that the global high-performance vehicle market will continue to grow, with safety features playing a key role in purchasing decisions. The integration of V8 engines with cutting-edge safety technologies is expected to remain a focus for manufacturers catering to this segment.

However, challenges remain in balancing performance with safety and environmental concerns. Stricter emissions regulations and the shift towards electrification may impact the future of V8 engines in high-performance vehicles. Manufacturers will need to innovate to meet these challenges while satisfying the market demand for powerful, safe vehicles.

V8 Engine Safety Challenges and Limitations

V8 engines, known for their power and performance, present unique safety challenges in automotive applications. The high output and torque of these engines can lead to increased risks of vehicle instability, especially during acceleration and cornering. This necessitates advanced traction control and stability management systems to ensure driver safety.

One significant limitation of V8 engines in terms of safety is their weight. The additional mass of these larger engines affects the vehicle's center of gravity, potentially compromising handling and increasing the risk of rollovers in certain situations. This challenge requires careful chassis design and weight distribution to maintain optimal vehicle dynamics.

Fuel efficiency is another concern that indirectly impacts safety. V8 engines typically consume more fuel than smaller engines, which can lead to increased emissions and environmental impact. This has prompted stricter emissions regulations, forcing manufacturers to implement advanced technologies like cylinder deactivation and direct injection to improve efficiency without compromising performance.

The complexity of V8 engines also presents maintenance challenges. More components mean a higher likelihood of mechanical failures, which could potentially lead to safety issues if not properly addressed. Regular maintenance becomes crucial, and advanced diagnostic systems are necessary to detect potential problems before they become safety hazards.

Heat management is a critical safety consideration for V8 engines. The substantial power output generates significant heat, requiring robust cooling systems to prevent overheating and potential engine failure. This challenge extends to the need for effective heat shielding to protect other vehicle components and occupants from excessive temperatures.

Noise and vibration are additional factors that can impact driver comfort and, by extension, safety. V8 engines typically produce more noise and vibration than smaller engines, which can lead to driver fatigue on long journeys. Manufacturers must invest in advanced noise, vibration, and harshness (NVH) reduction technologies to mitigate these effects.

The size of V8 engines also presents packaging challenges within the vehicle. This can impact crumple zone design and overall vehicle structure, potentially affecting crash performance. Engineers must carefully balance engine placement with structural integrity to ensure optimal safety in collision scenarios.

Lastly, the high performance capabilities of V8-powered vehicles can encourage more aggressive driving behaviors, potentially increasing the risk of accidents. This psychological aspect of V8 engine safety requires consideration in vehicle design and the implementation of advanced driver assistance systems to promote safer driving practices.

One significant limitation of V8 engines in terms of safety is their weight. The additional mass of these larger engines affects the vehicle's center of gravity, potentially compromising handling and increasing the risk of rollovers in certain situations. This challenge requires careful chassis design and weight distribution to maintain optimal vehicle dynamics.

Fuel efficiency is another concern that indirectly impacts safety. V8 engines typically consume more fuel than smaller engines, which can lead to increased emissions and environmental impact. This has prompted stricter emissions regulations, forcing manufacturers to implement advanced technologies like cylinder deactivation and direct injection to improve efficiency without compromising performance.

The complexity of V8 engines also presents maintenance challenges. More components mean a higher likelihood of mechanical failures, which could potentially lead to safety issues if not properly addressed. Regular maintenance becomes crucial, and advanced diagnostic systems are necessary to detect potential problems before they become safety hazards.

Heat management is a critical safety consideration for V8 engines. The substantial power output generates significant heat, requiring robust cooling systems to prevent overheating and potential engine failure. This challenge extends to the need for effective heat shielding to protect other vehicle components and occupants from excessive temperatures.

Noise and vibration are additional factors that can impact driver comfort and, by extension, safety. V8 engines typically produce more noise and vibration than smaller engines, which can lead to driver fatigue on long journeys. Manufacturers must invest in advanced noise, vibration, and harshness (NVH) reduction technologies to mitigate these effects.

The size of V8 engines also presents packaging challenges within the vehicle. This can impact crumple zone design and overall vehicle structure, potentially affecting crash performance. Engineers must carefully balance engine placement with structural integrity to ensure optimal safety in collision scenarios.

Lastly, the high performance capabilities of V8-powered vehicles can encourage more aggressive driving behaviors, potentially increasing the risk of accidents. This psychological aspect of V8 engine safety requires consideration in vehicle design and the implementation of advanced driver assistance systems to promote safer driving practices.

Current V8 Engine Safety Enhancement Solutions

01 Engine Block Safety Features

V8 engine safety standards include improvements to the engine block design. These features may involve reinforced structures, enhanced cooling systems, and optimized material selection to prevent cracking, overheating, and structural failures during operation. Such enhancements contribute to the overall safety and reliability of V8 engines.- Engine Block Safety Features: V8 engine safety standards include specific design features for the engine block to enhance overall safety. These features may include reinforced structures, improved cooling systems, and advanced materials to prevent overheating and potential failures during operation.

- Fuel System Safety Measures: Safety standards for V8 engines incorporate measures to ensure fuel system integrity. This includes robust fuel lines, secure connections, and advanced fuel injection systems to prevent leaks and minimize fire risks associated with high-performance engines.

- Exhaust System Safety Enhancements: V8 engine safety standards address exhaust system design to manage heat dissipation and reduce emissions. This involves the use of high-quality materials, efficient catalytic converters, and proper insulation to prevent heat-related hazards and ensure compliance with environmental regulations.

- Electronic Control and Monitoring Systems: Modern V8 engine safety standards incorporate advanced electronic control and monitoring systems. These systems include sensors and computerized management units that continuously monitor engine performance, detect potential issues, and implement safety measures to prevent damage or failure.

- Vibration and Noise Reduction Techniques: Safety standards for V8 engines emphasize vibration and noise reduction to enhance overall vehicle safety and driver comfort. This includes the use of advanced mounting systems, balanced components, and sound-dampening materials to minimize mechanical stress and improve engine longevity.

02 Fuel System Safety Measures

Safety standards for V8 engines incorporate advanced fuel system designs. These may include improved fuel injection systems, leak detection mechanisms, and pressure regulation devices. Such measures help prevent fuel-related accidents, ensure proper fuel distribution, and maintain optimal engine performance while adhering to safety regulations.Expand Specific Solutions03 Exhaust System Safety Enhancements

V8 engine safety standards address exhaust system improvements. These enhancements may involve advanced catalytic converters, heat shields, and noise reduction technologies. Such features aim to minimize harmful emissions, prevent heat-related hazards, and ensure compliance with environmental and safety regulations.Expand Specific Solutions04 Electronic Control and Monitoring Systems

Safety standards for V8 engines incorporate advanced electronic control and monitoring systems. These may include sensors for temperature, pressure, and performance parameters, as well as computerized engine management systems. Such technologies enable real-time monitoring, early detection of potential issues, and automatic adjustments to maintain safe operating conditions.Expand Specific Solutions05 Vibration and Noise Reduction Techniques

V8 engine safety standards address vibration and noise reduction. These techniques may involve advanced engine mounts, balancing mechanisms, and sound-dampening materials. Such measures aim to improve driver comfort, reduce fatigue, and minimize the risk of component failure due to excessive vibration, thereby enhancing overall vehicle safety.Expand Specific Solutions

Major Automotive V8 Engine Manufacturers

The V8 engine's influence on automotive safety standards has shaped a competitive landscape characterized by ongoing innovation and technological advancements. The market is in a mature stage, with established players like Toyota, Ford, and BMW leading the way. However, emerging companies and research institutions are also making significant contributions. The global automotive safety market is substantial, driven by increasing consumer awareness and stringent regulations. Technological maturity varies across different safety features, with some companies like NXP Semiconductors and Honda focusing on advanced driver assistance systems, while others like Yamaha and KYB Corp. concentrate on improving traditional safety components. The collaboration between automotive manufacturers, technology providers, and research institutions is accelerating the development of safer vehicles and more robust safety standards.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced V8 engine technologies that significantly influence automotive safety standards. Their V8 engines incorporate a Direct Injection 4-Stroke Gasoline Engine Superior Version (D-4S) system, which optimizes fuel injection for improved performance and efficiency[1]. This system contributes to better engine control and stability, enhancing overall vehicle safety. Toyota has also implemented Variable Valve Timing with intelligence (VVT-i) in their V8 engines, allowing for precise control of valve timing to optimize engine performance across various driving conditions[2]. This technology improves engine responsiveness and stability, contributing to safer vehicle operation. Additionally, Toyota's V8 engines feature advanced electronic control units (ECUs) that continuously monitor and adjust engine parameters, ensuring optimal performance and safety in real-time[3].

Strengths: Advanced fuel injection and valve timing technologies improve engine control and stability. Sophisticated ECUs enhance real-time safety monitoring. Weaknesses: Higher fuel consumption compared to smaller engines may limit adoption in some markets concerned with emissions standards.

Ford Global Technologies LLC

Technical Solution: Ford has made significant strides in V8 engine technology that impact automotive safety standards. Their EcoBoost V8 engines utilize twin-turbocharging and direct fuel injection to deliver high power output with improved fuel efficiency[1]. This technology allows for smaller, lighter engines without compromising performance, contributing to better vehicle handling and safety. Ford has also implemented advanced engine management systems in their V8 engines, including real-time cylinder deactivation technology[2]. This system can shut down specific cylinders under light load conditions, improving fuel efficiency while maintaining smooth operation and safety. Furthermore, Ford's V8 engines incorporate advanced materials and design techniques to reduce weight and improve durability, enhancing overall vehicle safety through better weight distribution and increased structural integrity[3].

Strengths: Twin-turbocharging and direct injection technologies offer high performance with improved efficiency. Advanced engine management systems enhance safety and fuel economy. Weaknesses: Complexity of turbocharging systems may lead to higher maintenance requirements and potential reliability concerns in some applications.

Key Innovations in V8 Engine Safety Systems

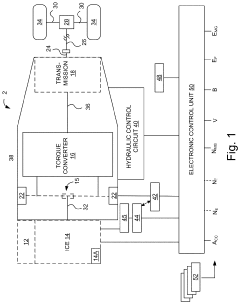

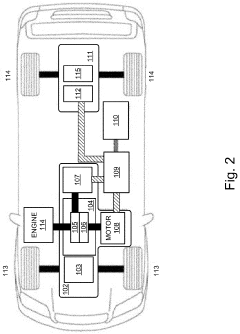

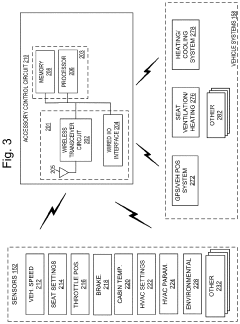

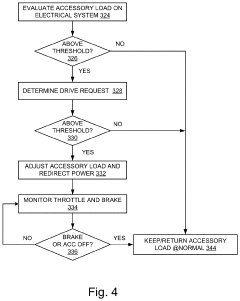

Systems and methods for accessory load adjustment to reduce engine noise

PatentActiveUS20210402975A1

Innovation

- A method and system for controlling a hybrid powertrain by adjusting the operation of vehicle accessories to reduce their electrical load on the batteries during high drive requests, redirecting saved power to the drive motor, which includes inhibiting components like the compressor or heating elements in the climate control system, while maintaining blower motor speed to minimize disruption.

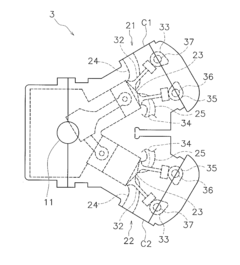

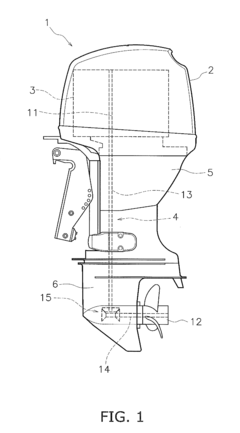

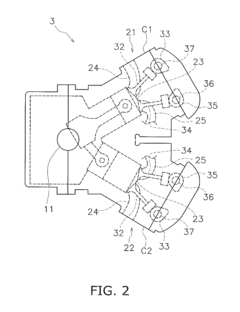

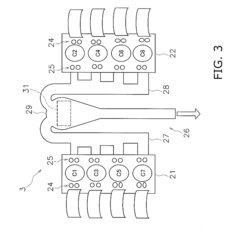

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

Environmental Impact of V8 Engines

The environmental impact of V8 engines has been a subject of increasing concern in recent years, as automotive manufacturers and regulatory bodies grapple with the need to balance performance with sustainability. V8 engines, known for their power and distinctive sound, have long been associated with high-performance vehicles and luxury cars. However, their larger displacement and higher fuel consumption have significant implications for the environment.

One of the primary environmental concerns associated with V8 engines is their higher carbon dioxide (CO2) emissions. These engines typically consume more fuel than their smaller counterparts, resulting in increased greenhouse gas emissions. This contributes to global warming and climate change, which have far-reaching consequences for ecosystems and human societies worldwide.

In addition to CO2 emissions, V8 engines also produce higher levels of other pollutants, such as nitrogen oxides (NOx) and particulate matter. These emissions can have detrimental effects on air quality, particularly in urban areas where vehicle concentrations are high. Poor air quality has been linked to various health issues, including respiratory problems and cardiovascular diseases.

The production and disposal of V8 engines also have environmental implications. These larger engines require more raw materials and energy to manufacture, leading to increased resource consumption and industrial emissions. At the end of their lifecycle, the disposal of V8 engines can pose challenges due to the presence of various metals and potentially hazardous materials.

In response to these environmental concerns, automotive manufacturers have been exploring ways to improve the efficiency of V8 engines. Technologies such as cylinder deactivation, direct injection, and turbocharging have been implemented to reduce fuel consumption and emissions while maintaining performance. Some manufacturers have also developed hybrid V8 powertrains, combining the traditional engine with electric motors to improve overall efficiency.

Despite these advancements, the trend in the automotive industry is moving towards smaller, more efficient engines and alternative powertrains. Many manufacturers are phasing out V8 engines in favor of turbocharged four- and six-cylinder engines that offer comparable performance with reduced environmental impact. The rise of electric vehicles is also challenging the future of V8 engines, as they offer zero tailpipe emissions and potentially lower overall environmental impact, depending on the source of electricity used for charging.

The environmental impact of V8 engines has led to stricter regulations in many countries, with emissions standards becoming increasingly stringent. This regulatory pressure, combined with changing consumer preferences and advancements in alternative technologies, is reshaping the automotive landscape and the role of V8 engines within it.

One of the primary environmental concerns associated with V8 engines is their higher carbon dioxide (CO2) emissions. These engines typically consume more fuel than their smaller counterparts, resulting in increased greenhouse gas emissions. This contributes to global warming and climate change, which have far-reaching consequences for ecosystems and human societies worldwide.

In addition to CO2 emissions, V8 engines also produce higher levels of other pollutants, such as nitrogen oxides (NOx) and particulate matter. These emissions can have detrimental effects on air quality, particularly in urban areas where vehicle concentrations are high. Poor air quality has been linked to various health issues, including respiratory problems and cardiovascular diseases.

The production and disposal of V8 engines also have environmental implications. These larger engines require more raw materials and energy to manufacture, leading to increased resource consumption and industrial emissions. At the end of their lifecycle, the disposal of V8 engines can pose challenges due to the presence of various metals and potentially hazardous materials.

In response to these environmental concerns, automotive manufacturers have been exploring ways to improve the efficiency of V8 engines. Technologies such as cylinder deactivation, direct injection, and turbocharging have been implemented to reduce fuel consumption and emissions while maintaining performance. Some manufacturers have also developed hybrid V8 powertrains, combining the traditional engine with electric motors to improve overall efficiency.

Despite these advancements, the trend in the automotive industry is moving towards smaller, more efficient engines and alternative powertrains. Many manufacturers are phasing out V8 engines in favor of turbocharged four- and six-cylinder engines that offer comparable performance with reduced environmental impact. The rise of electric vehicles is also challenging the future of V8 engines, as they offer zero tailpipe emissions and potentially lower overall environmental impact, depending on the source of electricity used for charging.

The environmental impact of V8 engines has led to stricter regulations in many countries, with emissions standards becoming increasingly stringent. This regulatory pressure, combined with changing consumer preferences and advancements in alternative technologies, is reshaping the automotive landscape and the role of V8 engines within it.

Regulatory Framework for V8 Engine Safety Standards

The regulatory framework for V8 engine safety standards has evolved significantly over the years, reflecting the changing landscape of automotive technology and safety concerns. Initially, regulations focused primarily on emissions control and fuel efficiency, with safety considerations being secondary. However, as vehicle safety became a more prominent issue, regulatory bodies began to implement more stringent safety standards specifically addressing high-performance engines like V8s.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a crucial role in setting and enforcing safety standards for V8 engines. These standards encompass various aspects, including crash protection, stability control, and occupant safety systems. The Federal Motor Vehicle Safety Standards (FMVSS) provide detailed requirements for vehicle manufacturers, with specific provisions related to engine design and performance.

European regulations, governed by the United Nations Economic Commission for Europe (UNECE), have also significantly impacted V8 engine safety standards. The Euro NCAP (New Car Assessment Programme) has been instrumental in pushing for higher safety standards, indirectly influencing V8 engine design to meet stringent crash test requirements and overall vehicle safety ratings.

One key area of focus in the regulatory framework is the management of engine power and torque in relation to vehicle dynamics. V8 engines, known for their high power output, have necessitated the development of advanced traction control and stability management systems. Regulations now mandate the inclusion of these systems in vehicles equipped with high-performance engines to ensure safe operation under various driving conditions.

Another critical aspect of the regulatory framework is the integration of V8 engines with advanced driver assistance systems (ADAS). Safety standards now require that engine management systems be compatible with and responsive to ADAS interventions, ensuring that the power delivery of V8 engines can be effectively modulated in emergency situations.

Fuel system safety has also been a significant focus of regulations pertaining to V8 engines. Standards have been established to ensure the integrity of fuel systems in crash scenarios, with specific requirements for high-performance engines that often operate at higher pressures and temperatures.

As environmental concerns have gained prominence, the regulatory framework has expanded to include emissions standards specifically tailored for high-performance engines. These regulations have driven innovations in V8 engine design, including the development of more efficient combustion processes and the integration of advanced exhaust after-treatment systems.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a crucial role in setting and enforcing safety standards for V8 engines. These standards encompass various aspects, including crash protection, stability control, and occupant safety systems. The Federal Motor Vehicle Safety Standards (FMVSS) provide detailed requirements for vehicle manufacturers, with specific provisions related to engine design and performance.

European regulations, governed by the United Nations Economic Commission for Europe (UNECE), have also significantly impacted V8 engine safety standards. The Euro NCAP (New Car Assessment Programme) has been instrumental in pushing for higher safety standards, indirectly influencing V8 engine design to meet stringent crash test requirements and overall vehicle safety ratings.

One key area of focus in the regulatory framework is the management of engine power and torque in relation to vehicle dynamics. V8 engines, known for their high power output, have necessitated the development of advanced traction control and stability management systems. Regulations now mandate the inclusion of these systems in vehicles equipped with high-performance engines to ensure safe operation under various driving conditions.

Another critical aspect of the regulatory framework is the integration of V8 engines with advanced driver assistance systems (ADAS). Safety standards now require that engine management systems be compatible with and responsive to ADAS interventions, ensuring that the power delivery of V8 engines can be effectively modulated in emergency situations.

Fuel system safety has also been a significant focus of regulations pertaining to V8 engines. Standards have been established to ensure the integrity of fuel systems in crash scenarios, with specific requirements for high-performance engines that often operate at higher pressures and temperatures.

As environmental concerns have gained prominence, the regulatory framework has expanded to include emissions standards specifically tailored for high-performance engines. These regulations have driven innovations in V8 engine design, including the development of more efficient combustion processes and the integration of advanced exhaust after-treatment systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!