V8 Engine Influence on Future-Ready Automotive Models

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine has been a cornerstone of automotive engineering since its inception in the early 20th century. Its evolution has been marked by significant technological advancements, reflecting the changing demands of the automotive industry and consumer preferences. Initially designed for high-performance applications, the V8 engine has undergone numerous iterations to improve efficiency, power output, and environmental compatibility.

The development of V8 engines has been driven by several key objectives. Primarily, manufacturers have sought to increase power and torque while simultaneously reducing fuel consumption and emissions. This balancing act has led to innovations in materials science, combustion technology, and engine management systems. The integration of advanced electronic control units (ECUs) and variable valve timing has allowed for more precise control over engine performance, adapting to various driving conditions in real-time.

Another significant objective in V8 engine evolution has been the reduction of weight and size. As automotive designs have become more aerodynamic and space-efficient, engine designers have had to create more compact V8 units without sacrificing performance. This has resulted in the development of aluminum block engines, reduced displacement through turbocharging, and more efficient cooling systems.

The pursuit of reliability and durability has also been a constant theme in V8 engine development. Engineers have focused on improving lubrication systems, enhancing thermal management, and developing more robust components to withstand the high stresses associated with performance engines. This has led to the widespread adoption of technologies such as direct fuel injection and variable displacement systems, which allow engines to operate more efficiently across a broader range of conditions.

In recent years, the objectives for V8 engine development have expanded to include compatibility with hybrid and electrification technologies. This has resulted in the creation of "mild hybrid" V8 systems that incorporate electric motors to boost efficiency and performance. Additionally, some manufacturers are exploring the use of sustainable fuels and advanced combustion techniques to further reduce the environmental impact of V8 engines.

Looking towards the future, the evolution of V8 engines is likely to focus on maintaining their relevance in an increasingly electrified automotive landscape. Objectives may include further improvements in thermal efficiency, integration with more advanced hybrid systems, and the potential use of hydrogen or synthetic fuels. The challenge for engineers will be to preserve the characteristic power and sound of V8 engines while meeting ever-stricter emissions regulations and fuel economy standards.

The development of V8 engines has been driven by several key objectives. Primarily, manufacturers have sought to increase power and torque while simultaneously reducing fuel consumption and emissions. This balancing act has led to innovations in materials science, combustion technology, and engine management systems. The integration of advanced electronic control units (ECUs) and variable valve timing has allowed for more precise control over engine performance, adapting to various driving conditions in real-time.

Another significant objective in V8 engine evolution has been the reduction of weight and size. As automotive designs have become more aerodynamic and space-efficient, engine designers have had to create more compact V8 units without sacrificing performance. This has resulted in the development of aluminum block engines, reduced displacement through turbocharging, and more efficient cooling systems.

The pursuit of reliability and durability has also been a constant theme in V8 engine development. Engineers have focused on improving lubrication systems, enhancing thermal management, and developing more robust components to withstand the high stresses associated with performance engines. This has led to the widespread adoption of technologies such as direct fuel injection and variable displacement systems, which allow engines to operate more efficiently across a broader range of conditions.

In recent years, the objectives for V8 engine development have expanded to include compatibility with hybrid and electrification technologies. This has resulted in the creation of "mild hybrid" V8 systems that incorporate electric motors to boost efficiency and performance. Additionally, some manufacturers are exploring the use of sustainable fuels and advanced combustion techniques to further reduce the environmental impact of V8 engines.

Looking towards the future, the evolution of V8 engines is likely to focus on maintaining their relevance in an increasingly electrified automotive landscape. Objectives may include further improvements in thermal efficiency, integration with more advanced hybrid systems, and the potential use of hydrogen or synthetic fuels. The challenge for engineers will be to preserve the characteristic power and sound of V8 engines while meeting ever-stricter emissions regulations and fuel economy standards.

Market Demand Analysis for V8-Powered Vehicles

The market demand for V8-powered vehicles has undergone significant shifts in recent years, influenced by various factors including environmental concerns, fuel efficiency regulations, and changing consumer preferences. Despite these challenges, there remains a niche but passionate market for V8 engines, particularly in high-performance and luxury segments.

In the performance car market, V8 engines continue to be highly sought after by enthusiasts and collectors. Sports cars and muscle cars equipped with V8 powerplants maintain a strong appeal, with manufacturers like Ford, Chevrolet, and Dodge still offering V8 options in their flagship performance models. These vehicles cater to a dedicated customer base that values the distinctive sound, power delivery, and emotional connection associated with V8 engines.

The luxury car segment also demonstrates ongoing demand for V8-powered vehicles. Premium brands such as Mercedes-Benz, BMW, and Audi continue to offer V8 engines in their high-end models, appealing to customers who prioritize prestige, comfort, and effortless performance. In this segment, V8 engines are often seen as a symbol of luxury and engineering excellence.

However, the overall market trend shows a gradual decline in V8 engine demand across mainstream vehicle categories. This shift is primarily driven by increasingly stringent emissions regulations and a growing focus on fuel efficiency. Many automakers are downsizing their engine offerings, replacing V8s with turbocharged V6 or even four-cylinder engines that deliver comparable performance with improved fuel economy.

The SUV and truck markets present a mixed picture for V8 engines. While there is still demand for V8-powered full-size trucks and large SUVs, particularly in North America, this segment is also experiencing a transition towards more fuel-efficient powertrains. Some manufacturers are introducing hybrid and electric options in these traditionally V8-dominated categories.

Looking at regional variations, North America remains the strongest market for V8-powered vehicles, followed by the Middle East. European and Asian markets show a more pronounced shift away from V8 engines, with stricter emissions standards and higher fuel costs driving consumer preferences towards smaller, more efficient engines.

The future market demand for V8 engines is likely to be influenced by advancements in electrification and alternative fuels. As battery technology improves and electric vehicles become more prevalent, the role of V8 engines may evolve. Some manufacturers are exploring ways to combine V8 power with hybrid systems, aiming to preserve the character of V8 engines while meeting future emissions standards.

In the performance car market, V8 engines continue to be highly sought after by enthusiasts and collectors. Sports cars and muscle cars equipped with V8 powerplants maintain a strong appeal, with manufacturers like Ford, Chevrolet, and Dodge still offering V8 options in their flagship performance models. These vehicles cater to a dedicated customer base that values the distinctive sound, power delivery, and emotional connection associated with V8 engines.

The luxury car segment also demonstrates ongoing demand for V8-powered vehicles. Premium brands such as Mercedes-Benz, BMW, and Audi continue to offer V8 engines in their high-end models, appealing to customers who prioritize prestige, comfort, and effortless performance. In this segment, V8 engines are often seen as a symbol of luxury and engineering excellence.

However, the overall market trend shows a gradual decline in V8 engine demand across mainstream vehicle categories. This shift is primarily driven by increasingly stringent emissions regulations and a growing focus on fuel efficiency. Many automakers are downsizing their engine offerings, replacing V8s with turbocharged V6 or even four-cylinder engines that deliver comparable performance with improved fuel economy.

The SUV and truck markets present a mixed picture for V8 engines. While there is still demand for V8-powered full-size trucks and large SUVs, particularly in North America, this segment is also experiencing a transition towards more fuel-efficient powertrains. Some manufacturers are introducing hybrid and electric options in these traditionally V8-dominated categories.

Looking at regional variations, North America remains the strongest market for V8-powered vehicles, followed by the Middle East. European and Asian markets show a more pronounced shift away from V8 engines, with stricter emissions standards and higher fuel costs driving consumer preferences towards smaller, more efficient engines.

The future market demand for V8 engines is likely to be influenced by advancements in electrification and alternative fuels. As battery technology improves and electric vehicles become more prevalent, the role of V8 engines may evolve. Some manufacturers are exploring ways to combine V8 power with hybrid systems, aiming to preserve the character of V8 engines while meeting future emissions standards.

V8 Technology: Current State and Challenges

The current state of V8 engine technology in the automotive industry is characterized by a complex interplay of technological advancements and environmental challenges. V8 engines, known for their power and performance, continue to be a significant component in high-end vehicles and sports cars. However, they face increasing scrutiny due to stringent emissions regulations and the global push towards more fuel-efficient and environmentally friendly vehicles.

One of the primary challenges facing V8 technology is the need to improve fuel efficiency while maintaining performance. Manufacturers have implemented various strategies to address this, including cylinder deactivation, direct fuel injection, and turbocharging. These technologies have allowed V8 engines to achieve better fuel economy without sacrificing the power output that consumers expect from this engine configuration.

Another significant challenge is meeting increasingly strict emissions standards. V8 engines, due to their larger displacement and higher fuel consumption, typically produce more emissions than smaller engine configurations. This has led to the development of advanced exhaust after-treatment systems and the integration of hybrid technologies to reduce overall emissions.

The geographical distribution of V8 technology development is primarily concentrated in regions with a strong automotive industry presence, such as North America, Germany, and Japan. However, emerging markets like China are also becoming increasingly important in V8 engine development, particularly as luxury car markets expand in these regions.

A key technological hurdle for V8 engines is weight reduction. As vehicles become heavier due to additional safety features and comfort amenities, engine weight becomes a critical factor in overall vehicle efficiency. Manufacturers are exploring the use of lightweight materials and innovative design techniques to reduce the mass of V8 engines without compromising structural integrity or performance.

The integration of V8 engines with electric powertrains presents both a challenge and an opportunity. Hybrid V8 systems are being developed to provide the best of both worlds – the performance of a V8 with the efficiency gains of electrification. However, balancing the complexity of these systems with reliability and cost-effectiveness remains a significant engineering challenge.

Looking ahead, the future of V8 technology in automotive applications is uncertain. While there is ongoing development to make V8 engines more efficient and environmentally friendly, the industry-wide shift towards electrification poses a significant threat to their long-term viability. Manufacturers must navigate the delicate balance between meeting consumer demand for high-performance vehicles and adhering to increasingly stringent environmental regulations.

One of the primary challenges facing V8 technology is the need to improve fuel efficiency while maintaining performance. Manufacturers have implemented various strategies to address this, including cylinder deactivation, direct fuel injection, and turbocharging. These technologies have allowed V8 engines to achieve better fuel economy without sacrificing the power output that consumers expect from this engine configuration.

Another significant challenge is meeting increasingly strict emissions standards. V8 engines, due to their larger displacement and higher fuel consumption, typically produce more emissions than smaller engine configurations. This has led to the development of advanced exhaust after-treatment systems and the integration of hybrid technologies to reduce overall emissions.

The geographical distribution of V8 technology development is primarily concentrated in regions with a strong automotive industry presence, such as North America, Germany, and Japan. However, emerging markets like China are also becoming increasingly important in V8 engine development, particularly as luxury car markets expand in these regions.

A key technological hurdle for V8 engines is weight reduction. As vehicles become heavier due to additional safety features and comfort amenities, engine weight becomes a critical factor in overall vehicle efficiency. Manufacturers are exploring the use of lightweight materials and innovative design techniques to reduce the mass of V8 engines without compromising structural integrity or performance.

The integration of V8 engines with electric powertrains presents both a challenge and an opportunity. Hybrid V8 systems are being developed to provide the best of both worlds – the performance of a V8 with the efficiency gains of electrification. However, balancing the complexity of these systems with reliability and cost-effectiveness remains a significant engineering challenge.

Looking ahead, the future of V8 technology in automotive applications is uncertain. While there is ongoing development to make V8 engines more efficient and environmentally friendly, the industry-wide shift towards electrification poses a significant threat to their long-term viability. Manufacturers must navigate the delicate balance between meeting consumer demand for high-performance vehicles and adhering to increasingly stringent environmental regulations.

Current V8 Engine Design Solutions

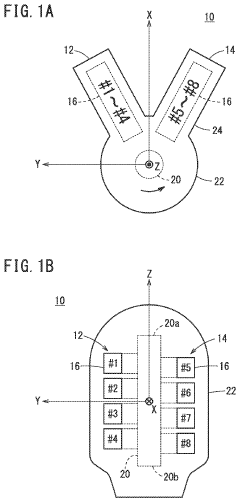

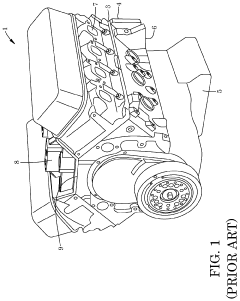

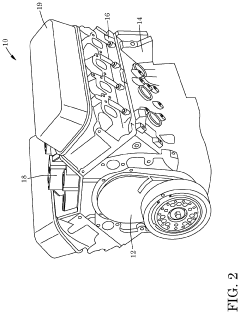

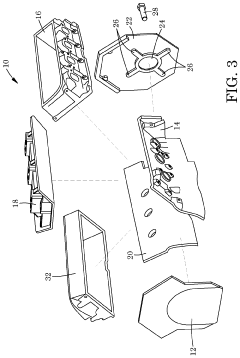

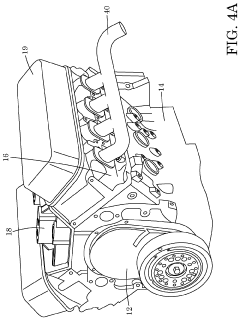

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems may include direct injection, variable valve timing, and advanced ignition control. Improvements in fuel delivery and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output. These systems compress the intake air, allowing for more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are used to optimize V8 engine performance across different operating conditions.

- Cooling and Lubrication Systems: Efficient cooling and lubrication systems are essential for V8 engine reliability and performance. Advanced cooling systems may include precision coolant flow control, while lubrication systems often feature high-pressure oil pumps and advanced filtration. These systems help maintain optimal operating temperatures and reduce friction, contributing to engine longevity and performance.

- Engine Management and Control Systems: Sophisticated engine management and control systems are integral to modern V8 engines. These systems monitor and adjust various engine parameters in real-time, optimizing performance, fuel efficiency, and emissions. Advanced sensors, electronic control units, and software algorithms work together to ensure optimal engine operation across a wide range of driving conditions.

02 Fuel Efficiency and Emissions Control

Modern V8 engines incorporate advanced technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.Expand Specific Solutions03 Performance Enhancement Technologies

Various technologies are employed to enhance the performance of V8 engines. These may include turbocharging, supercharging, intercooling, and advanced engine management systems. Such technologies aim to increase power output, improve torque characteristics, and enhance overall engine efficiency.Expand Specific Solutions04 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine performance and longevity. Advanced cooling systems may include precision-controlled electric water pumps, optimized coolant flow paths, and efficient heat exchangers. Lubrication systems are designed to ensure proper oil distribution to all critical engine components, even under high-performance conditions.Expand Specific Solutions05 Manufacturing and Assembly Techniques

Innovative manufacturing and assembly techniques are employed in the production of V8 engines. These may include advanced casting methods for engine blocks and heads, precision machining processes, and automated assembly lines. Such techniques aim to improve production efficiency, enhance quality control, and reduce manufacturing costs.Expand Specific Solutions

Key Players in V8 Engine Manufacturing

The V8 engine's influence on future-ready automotive models is shaping a competitive landscape characterized by rapid technological advancements and shifting market dynamics. The industry is in a transitional phase, with traditional automotive giants like Toyota, Honda, and BMW facing challenges from emerging players such as Hyundai, Kia, and innovative startups. The global market for V8-powered vehicles remains significant, though evolving emissions regulations are driving manufacturers to explore more efficient alternatives. Technologically, companies like GM, Ford, and Nissan are investing heavily in V8 engine optimization, focusing on improved fuel efficiency and performance while also developing hybrid and electric powertrains to meet future demands.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has been developing innovative V8 engine technologies for their future-ready automotive models. Their latest V8 engine design incorporates direct injection and multi-point injection systems, optimizing fuel delivery for improved performance and efficiency[2]. Hyundai's V8 engines also feature a high-pressure exhaust gas recirculation (EGR) system, which helps reduce nitrogen oxide emissions and improve fuel economy[4]. The company has implemented advanced thermal management systems in their V8 engines, allowing for faster warm-up times and reduced friction losses[6]. Hyundai is also exploring the use of lightweight materials and compact designs in their V8 engines to improve power-to-weight ratios and vehicle dynamics[8].

Strengths: Advanced emission control technologies, improved thermal efficiency, and focus on weight reduction. Weaknesses: Limited experience in V8 production compared to some competitors, and potential challenges in market perception for high-performance engines.

GM Global Technology Operations LLC

Technical Solution: GM has been a pioneer in V8 engine technology for future-ready automotive models. Their latest V8 engines feature Dynamic Fuel Management, an advanced cylinder deactivation system that can operate on as few as two cylinders for maximum efficiency[1]. GM has also implemented a stop/start technology in their V8 engines, further improving fuel economy in urban driving conditions[3]. The company's V8 engines incorporate advanced materials such as aluminum blocks and heads, reducing weight while maintaining durability[5]. GM is also developing a new generation of small-block V8 engines that are compatible with various alternative fuels, including E85 ethanol blends[7]. Additionally, GM is exploring the integration of mild hybrid systems with their V8 engines to meet future emission standards while preserving performance[9].

Strengths: Long history of V8 development, advanced fuel management systems, and compatibility with alternative fuels. Weaknesses: Potential challenges in meeting future emission standards without significant redesigns, and higher production costs compared to smaller engines.

Innovative V8 Technologies and Patents

V8 engine

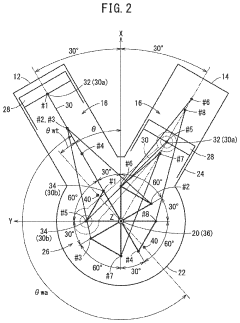

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Kit for transforming a hot rod into an electric car

PatentActiveUS20210122336A1

Innovation

- A kit comprising a faux transmission housing and castings that house an electric motor, designed to mimic the appearance of a V8 engine, including a bell housing, timing cover casting, side castings, and intake manifold casting, which can be easily assembled to conceal the electric motor and resemble a gasoline engine.

Environmental Regulations Impact on V8 Engines

Environmental regulations have become a significant factor influencing the future of V8 engines in automotive models. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, the traditional V8 engine faces increasing challenges. These regulations aim to reduce greenhouse gas emissions and improve air quality, putting pressure on automakers to adapt their engine designs or explore alternative powertrains.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been progressively tightened, requiring manufacturers to achieve higher fleet-wide fuel efficiency. This has led to a decline in the production and use of V8 engines, particularly in mainstream vehicles. Similarly, the European Union has implemented stringent CO2 emissions targets, forcing automakers to reconsider their engine lineup and invest in more efficient technologies.

China, the world's largest automotive market, has also introduced ambitious emissions reduction goals. The country's plan to ban the sale of new internal combustion engine vehicles by 2035 has accelerated the shift towards electric and hybrid powertrains, further challenging the viability of V8 engines in future automotive models.

The impact of these regulations on V8 engines is multifaceted. Manufacturers are exploring various strategies to comply with emissions standards while maintaining performance. One approach is the implementation of advanced technologies such as cylinder deactivation, direct injection, and turbocharging to improve fuel efficiency and reduce emissions. However, these solutions often come at the cost of increased complexity and higher production expenses.

Another consequence of environmental regulations is the shift towards downsized engines. Many automakers are replacing V8 engines with smaller, turbocharged V6 or even four-cylinder engines that can deliver comparable power output with improved fuel economy. This trend is particularly evident in the luxury and performance car segments, where V8 engines were once ubiquitous.

The rise of electrification presents both a challenge and an opportunity for V8 engines. While pure electric vehicles are gaining market share, some manufacturers are exploring hybrid powertrains that combine V8 engines with electric motors. This approach allows for improved fuel efficiency and reduced emissions while retaining the characteristic sound and power delivery of a V8 engine.

Despite these challenges, V8 engines continue to have a place in certain market segments, particularly in high-performance vehicles, luxury cars, and some truck applications. However, their long-term viability will depend on continued technological advancements and the ability to meet increasingly stringent environmental regulations.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been progressively tightened, requiring manufacturers to achieve higher fleet-wide fuel efficiency. This has led to a decline in the production and use of V8 engines, particularly in mainstream vehicles. Similarly, the European Union has implemented stringent CO2 emissions targets, forcing automakers to reconsider their engine lineup and invest in more efficient technologies.

China, the world's largest automotive market, has also introduced ambitious emissions reduction goals. The country's plan to ban the sale of new internal combustion engine vehicles by 2035 has accelerated the shift towards electric and hybrid powertrains, further challenging the viability of V8 engines in future automotive models.

The impact of these regulations on V8 engines is multifaceted. Manufacturers are exploring various strategies to comply with emissions standards while maintaining performance. One approach is the implementation of advanced technologies such as cylinder deactivation, direct injection, and turbocharging to improve fuel efficiency and reduce emissions. However, these solutions often come at the cost of increased complexity and higher production expenses.

Another consequence of environmental regulations is the shift towards downsized engines. Many automakers are replacing V8 engines with smaller, turbocharged V6 or even four-cylinder engines that can deliver comparable power output with improved fuel economy. This trend is particularly evident in the luxury and performance car segments, where V8 engines were once ubiquitous.

The rise of electrification presents both a challenge and an opportunity for V8 engines. While pure electric vehicles are gaining market share, some manufacturers are exploring hybrid powertrains that combine V8 engines with electric motors. This approach allows for improved fuel efficiency and reduced emissions while retaining the characteristic sound and power delivery of a V8 engine.

Despite these challenges, V8 engines continue to have a place in certain market segments, particularly in high-performance vehicles, luxury cars, and some truck applications. However, their long-term viability will depend on continued technological advancements and the ability to meet increasingly stringent environmental regulations.

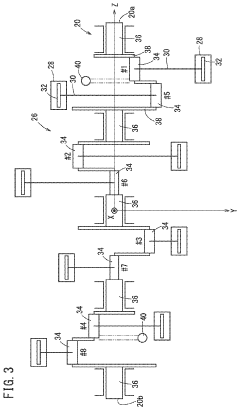

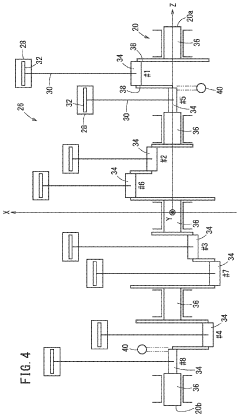

V8 Integration with Hybrid Systems

The integration of V8 engines with hybrid systems represents a significant evolution in automotive engineering, blending the power and performance of traditional internal combustion engines with the efficiency and environmental benefits of electric propulsion. This synergy aims to address the growing demand for vehicles that offer both high performance and improved fuel economy.

In hybrid V8 configurations, the electric motor typically supplements the V8 engine during acceleration and low-speed driving, reducing fuel consumption and emissions. During deceleration and braking, regenerative systems capture kinetic energy to recharge the battery, further enhancing overall efficiency. This integration allows for a reduction in engine size without compromising performance, as the electric motor can provide additional torque when needed.

Advanced hybrid V8 systems often incorporate sophisticated power management algorithms that optimize the balance between the gasoline engine and electric motor. These systems can seamlessly switch between power sources or combine them based on driving conditions, load requirements, and battery charge levels. Some configurations allow for pure electric driving at low speeds or for short distances, providing flexibility in urban environments.

The integration process presents several engineering challenges, including weight distribution, thermal management, and packaging constraints. Engineers must carefully design the hybrid system to maintain the V8's characteristic sound and performance while significantly improving fuel efficiency. This often involves redesigning engine mounts, modifying the transmission, and integrating complex cooling systems to manage heat from both the engine and electric components.

Manufacturers are exploring various hybrid V8 architectures, including parallel, series, and power-split systems. Parallel hybrids, where both the V8 engine and electric motor can directly power the wheels, are common in performance-oriented applications. Series hybrids, where the V8 engine acts primarily as a generator for the electric drive system, are less common but offer potential for extended-range electric vehicles with V8 power plants.

The integration of V8 engines with hybrid systems is not limited to passenger vehicles. Luxury SUVs, high-performance sports cars, and even some commercial vehicles are adopting this technology to meet stringent emissions regulations while maintaining the power output expected from V8 engines. This trend is likely to continue as automakers strive to balance performance with environmental responsibility in their future-ready models.

In hybrid V8 configurations, the electric motor typically supplements the V8 engine during acceleration and low-speed driving, reducing fuel consumption and emissions. During deceleration and braking, regenerative systems capture kinetic energy to recharge the battery, further enhancing overall efficiency. This integration allows for a reduction in engine size without compromising performance, as the electric motor can provide additional torque when needed.

Advanced hybrid V8 systems often incorporate sophisticated power management algorithms that optimize the balance between the gasoline engine and electric motor. These systems can seamlessly switch between power sources or combine them based on driving conditions, load requirements, and battery charge levels. Some configurations allow for pure electric driving at low speeds or for short distances, providing flexibility in urban environments.

The integration process presents several engineering challenges, including weight distribution, thermal management, and packaging constraints. Engineers must carefully design the hybrid system to maintain the V8's characteristic sound and performance while significantly improving fuel efficiency. This often involves redesigning engine mounts, modifying the transmission, and integrating complex cooling systems to manage heat from both the engine and electric components.

Manufacturers are exploring various hybrid V8 architectures, including parallel, series, and power-split systems. Parallel hybrids, where both the V8 engine and electric motor can directly power the wheels, are common in performance-oriented applications. Series hybrids, where the V8 engine acts primarily as a generator for the electric drive system, are less common but offer potential for extended-range electric vehicles with V8 power plants.

The integration of V8 engines with hybrid systems is not limited to passenger vehicles. Luxury SUVs, high-performance sports cars, and even some commercial vehicles are adopting this technology to meet stringent emissions regulations while maintaining the power output expected from V8 engines. This trend is likely to continue as automakers strive to balance performance with environmental responsibility in their future-ready models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!