V8 Engine Integration in Hydrogen Fuel Vehicles: Examined

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine and H2 Fuel Integration Background

The integration of V8 engines with hydrogen fuel technology represents a significant milestone in the evolution of automotive propulsion systems. This fusion aims to combine the power and performance characteristics of traditional V8 engines with the clean-burning properties of hydrogen fuel. The development of this technology can be traced back to the early 2000s when automotive manufacturers began exploring alternative fuel options to address growing environmental concerns and stricter emission regulations.

Initially, the focus was on adapting existing V8 engine designs to accommodate hydrogen fuel. This approach presented numerous challenges, including the need for significant modifications to fuel delivery systems, combustion chambers, and ignition timing. Early prototypes demonstrated the potential for high power output while dramatically reducing harmful emissions, particularly carbon dioxide.

As research progressed, engineers encountered several technical hurdles. One of the primary challenges was the lower energy density of hydrogen compared to gasoline, necessitating larger fuel tanks or more frequent refueling. Additionally, the high flame speed and wide flammability range of hydrogen required precise control over the fuel-air mixture to prevent pre-ignition and backfiring.

The evolution of this technology has been marked by several key milestones. In the mid-2000s, BMW introduced its Hydrogen 7 model, featuring a V12 engine capable of running on both hydrogen and gasoline. This dual-fuel approach served as a stepping stone towards full hydrogen integration in high-performance engines. Subsequently, other manufacturers, including Mercedes-Benz and Mazda, conducted extensive research and development in this field.

Recent advancements have focused on optimizing combustion efficiency, enhancing fuel storage solutions, and improving overall system integration. The development of advanced direct injection systems and sophisticated engine management software has played a crucial role in overcoming many of the initial challenges associated with hydrogen-powered V8 engines.

The current technological landscape sees a renewed interest in hydrogen fuel cell vehicles, which convert hydrogen into electricity to power electric motors. However, the integration of hydrogen fuel with internal combustion engines, particularly V8 configurations, continues to be an area of active research. This approach offers the potential to leverage existing manufacturing infrastructure while providing a bridge to zero-emission vehicles.

Looking forward, the integration of V8 engines with hydrogen fuel technology is expected to contribute significantly to the diversification of powertrain options in the automotive industry. As the world transitions towards more sustainable transportation solutions, this technology represents a promising avenue for maintaining high performance while drastically reducing environmental impact.

Initially, the focus was on adapting existing V8 engine designs to accommodate hydrogen fuel. This approach presented numerous challenges, including the need for significant modifications to fuel delivery systems, combustion chambers, and ignition timing. Early prototypes demonstrated the potential for high power output while dramatically reducing harmful emissions, particularly carbon dioxide.

As research progressed, engineers encountered several technical hurdles. One of the primary challenges was the lower energy density of hydrogen compared to gasoline, necessitating larger fuel tanks or more frequent refueling. Additionally, the high flame speed and wide flammability range of hydrogen required precise control over the fuel-air mixture to prevent pre-ignition and backfiring.

The evolution of this technology has been marked by several key milestones. In the mid-2000s, BMW introduced its Hydrogen 7 model, featuring a V12 engine capable of running on both hydrogen and gasoline. This dual-fuel approach served as a stepping stone towards full hydrogen integration in high-performance engines. Subsequently, other manufacturers, including Mercedes-Benz and Mazda, conducted extensive research and development in this field.

Recent advancements have focused on optimizing combustion efficiency, enhancing fuel storage solutions, and improving overall system integration. The development of advanced direct injection systems and sophisticated engine management software has played a crucial role in overcoming many of the initial challenges associated with hydrogen-powered V8 engines.

The current technological landscape sees a renewed interest in hydrogen fuel cell vehicles, which convert hydrogen into electricity to power electric motors. However, the integration of hydrogen fuel with internal combustion engines, particularly V8 configurations, continues to be an area of active research. This approach offers the potential to leverage existing manufacturing infrastructure while providing a bridge to zero-emission vehicles.

Looking forward, the integration of V8 engines with hydrogen fuel technology is expected to contribute significantly to the diversification of powertrain options in the automotive industry. As the world transitions towards more sustainable transportation solutions, this technology represents a promising avenue for maintaining high performance while drastically reducing environmental impact.

Market Analysis for H2 V8 Vehicles

The market for hydrogen-powered V8 vehicles represents a niche but potentially transformative segment within the automotive industry. As global efforts to reduce carbon emissions intensify, hydrogen fuel cell technology has emerged as a promising alternative to traditional internal combustion engines. The integration of V8 engines with hydrogen fuel systems combines the power and performance associated with V8 engines with the environmental benefits of zero-emission hydrogen technology.

Current market demand for hydrogen V8 vehicles is primarily driven by early adopters and environmentally conscious consumers seeking high-performance vehicles with a reduced carbon footprint. The luxury and sports car segments show particular interest in this technology, as it allows manufacturers to maintain the power output and driving experience expected from V8 engines while meeting increasingly stringent emissions regulations.

The potential market size for hydrogen V8 vehicles is closely tied to the development of hydrogen infrastructure and the overall adoption of hydrogen fuel cell technology in the automotive sector. While currently limited, the market is expected to grow as governments worldwide invest in hydrogen refueling stations and incentivize the adoption of zero-emission vehicles.

Industry trends indicate a gradual shift towards alternative powertrains, with hydrogen fuel cells gaining traction alongside battery electric vehicles. The hydrogen V8 market is positioned to capitalize on this trend, offering a unique value proposition that bridges the gap between traditional high-performance engines and clean energy solutions.

Market analysis reveals several key factors influencing the growth potential of hydrogen V8 vehicles. These include advancements in hydrogen storage technology, improvements in fuel cell efficiency, and the development of more cost-effective production methods for both hydrogen fuel and fuel cell systems. Additionally, the market's expansion is contingent upon overcoming challenges such as the high cost of hydrogen production and distribution, as well as consumer perceptions regarding the safety and reliability of hydrogen-powered vehicles.

The target demographic for hydrogen V8 vehicles primarily consists of affluent consumers, performance enthusiasts, and eco-conscious individuals who are willing to pay a premium for cutting-edge technology. Fleet operators in sectors requiring high-performance vehicles with zero emissions, such as luxury transportation services or specialized government agencies, also represent potential early adopters of this technology.

As the automotive industry continues to evolve, the market for hydrogen V8 vehicles is expected to play a significant role in shaping the future of high-performance, environmentally friendly transportation. The success of this market segment will largely depend on continued technological advancements, supportive government policies, and the ability of manufacturers to effectively communicate the benefits of hydrogen V8 technology to consumers.

Current market demand for hydrogen V8 vehicles is primarily driven by early adopters and environmentally conscious consumers seeking high-performance vehicles with a reduced carbon footprint. The luxury and sports car segments show particular interest in this technology, as it allows manufacturers to maintain the power output and driving experience expected from V8 engines while meeting increasingly stringent emissions regulations.

The potential market size for hydrogen V8 vehicles is closely tied to the development of hydrogen infrastructure and the overall adoption of hydrogen fuel cell technology in the automotive sector. While currently limited, the market is expected to grow as governments worldwide invest in hydrogen refueling stations and incentivize the adoption of zero-emission vehicles.

Industry trends indicate a gradual shift towards alternative powertrains, with hydrogen fuel cells gaining traction alongside battery electric vehicles. The hydrogen V8 market is positioned to capitalize on this trend, offering a unique value proposition that bridges the gap between traditional high-performance engines and clean energy solutions.

Market analysis reveals several key factors influencing the growth potential of hydrogen V8 vehicles. These include advancements in hydrogen storage technology, improvements in fuel cell efficiency, and the development of more cost-effective production methods for both hydrogen fuel and fuel cell systems. Additionally, the market's expansion is contingent upon overcoming challenges such as the high cost of hydrogen production and distribution, as well as consumer perceptions regarding the safety and reliability of hydrogen-powered vehicles.

The target demographic for hydrogen V8 vehicles primarily consists of affluent consumers, performance enthusiasts, and eco-conscious individuals who are willing to pay a premium for cutting-edge technology. Fleet operators in sectors requiring high-performance vehicles with zero emissions, such as luxury transportation services or specialized government agencies, also represent potential early adopters of this technology.

As the automotive industry continues to evolve, the market for hydrogen V8 vehicles is expected to play a significant role in shaping the future of high-performance, environmentally friendly transportation. The success of this market segment will largely depend on continued technological advancements, supportive government policies, and the ability of manufacturers to effectively communicate the benefits of hydrogen V8 technology to consumers.

Technical Challenges in V8 H2 Integration

The integration of V8 engines in hydrogen fuel vehicles presents several significant technical challenges that require innovative solutions. One of the primary obstacles is the adaptation of traditional V8 engine designs to accommodate hydrogen fuel. Hydrogen's unique combustion properties, including its high flame speed and wide flammability range, necessitate substantial modifications to the engine's combustion chamber, fuel injection systems, and ignition timing.

Another critical challenge lies in the materials used in V8 engines. Hydrogen's small molecular size can lead to increased permeation through conventional materials, potentially causing embrittlement and degradation of engine components. This necessitates the development and implementation of hydrogen-compatible materials throughout the engine system, including valves, seals, and fuel lines.

The thermal management of hydrogen-fueled V8 engines poses additional complexities. Hydrogen combustion produces higher temperatures compared to traditional fossil fuels, requiring enhanced cooling systems and heat-resistant materials to maintain engine integrity and performance. Engineers must also address the potential for pre-ignition and backfiring, which are more prevalent in hydrogen engines due to the fuel's low ignition energy.

Fuel storage and delivery systems present another set of challenges. The low energy density of hydrogen by volume necessitates high-pressure storage tanks or cryogenic systems, which must be seamlessly integrated with the V8 engine. This integration must ensure efficient fuel delivery while maintaining the vehicle's safety and performance characteristics.

Emissions control is a further area of concern. While hydrogen combustion primarily produces water vapor, NOx emissions can still occur due to high combustion temperatures. Developing effective catalytic converters and exhaust systems tailored for hydrogen V8 engines is crucial to meet stringent emissions standards.

The control systems and engine management software require significant recalibration to optimize hydrogen combustion in V8 engines. This includes adjusting air-fuel ratios, ignition timing, and valve timing to maximize efficiency and power output while ensuring smooth operation across various driving conditions.

Lastly, the integration of V8 hydrogen engines must address concerns related to noise, vibration, and harshness (NVH). The different combustion characteristics of hydrogen can alter the engine's sound profile and vibration patterns, necessitating redesigns in engine mounts, sound insulation, and overall vehicle structure to maintain the comfort and driving experience expected from V8-powered vehicles.

Another critical challenge lies in the materials used in V8 engines. Hydrogen's small molecular size can lead to increased permeation through conventional materials, potentially causing embrittlement and degradation of engine components. This necessitates the development and implementation of hydrogen-compatible materials throughout the engine system, including valves, seals, and fuel lines.

The thermal management of hydrogen-fueled V8 engines poses additional complexities. Hydrogen combustion produces higher temperatures compared to traditional fossil fuels, requiring enhanced cooling systems and heat-resistant materials to maintain engine integrity and performance. Engineers must also address the potential for pre-ignition and backfiring, which are more prevalent in hydrogen engines due to the fuel's low ignition energy.

Fuel storage and delivery systems present another set of challenges. The low energy density of hydrogen by volume necessitates high-pressure storage tanks or cryogenic systems, which must be seamlessly integrated with the V8 engine. This integration must ensure efficient fuel delivery while maintaining the vehicle's safety and performance characteristics.

Emissions control is a further area of concern. While hydrogen combustion primarily produces water vapor, NOx emissions can still occur due to high combustion temperatures. Developing effective catalytic converters and exhaust systems tailored for hydrogen V8 engines is crucial to meet stringent emissions standards.

The control systems and engine management software require significant recalibration to optimize hydrogen combustion in V8 engines. This includes adjusting air-fuel ratios, ignition timing, and valve timing to maximize efficiency and power output while ensuring smooth operation across various driving conditions.

Lastly, the integration of V8 hydrogen engines must address concerns related to noise, vibration, and harshness (NVH). The different combustion characteristics of hydrogen can alter the engine's sound profile and vibration patterns, necessitating redesigns in engine mounts, sound insulation, and overall vehicle structure to maintain the comfort and driving experience expected from V8-powered vehicles.

Current V8 H2 Integration Solutions

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include variable valve timing, direct fuel injection, cylinder deactivation, and advanced exhaust gas recirculation systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.

- Performance Enhancement Technologies: Various technologies are employed to enhance V8 engine performance. These may include turbocharging, supercharging, intercooling, and advanced engine management systems. Such technologies aim to increase power output, improve throttle response, and optimize overall engine performance across different operating conditions.

- Cooling and Lubrication Systems: Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Advanced cooling systems may incorporate precision coolant flow control, while lubrication systems often feature high-capacity oil pumps and sophisticated oil filtration. These systems help manage the high heat output and mechanical stresses associated with V8 engines.

- Manufacturing and Assembly Techniques: Specialized manufacturing and assembly techniques are employed in V8 engine production. These may include precision machining of engine blocks and components, advanced casting methods, and automated assembly processes. Such techniques aim to improve engine quality, consistency, and production efficiency while reducing manufacturing costs.

02 Fuel Injection and Combustion Systems

Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery and combustion efficiency help to enhance power output while reducing fuel consumption and emissions.Expand Specific Solutions03 Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to increase power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and generating more power from the same engine displacement. Various designs and configurations of turbochargers and superchargers are used to optimize performance across different operating conditions.Expand Specific Solutions04 Engine Block and Component Materials

The choice of materials for V8 engine blocks and components significantly impacts performance, durability, and weight. Advanced materials such as aluminum alloys, high-strength steels, and composite materials are used to reduce weight while maintaining strength. Innovations in manufacturing processes and material science contribute to improved engine efficiency and longevity.Expand Specific Solutions05 Cooling and Lubrication Systems

Effective cooling and lubrication systems are essential for V8 engine performance and longevity. Advanced cooling systems manage heat distribution and prevent overheating, while sophisticated lubrication systems ensure proper oil flow to all critical components. Innovations in these areas focus on improving efficiency, reducing friction, and extending engine life.Expand Specific Solutions

Key Players in H2 V8 Development

The integration of V8 engines in hydrogen fuel vehicles represents an emerging field in the automotive industry, currently in its early development stage. The market size is relatively small but growing, driven by increasing interest in alternative fuel technologies. The technical maturity varies among key players, with traditional automakers like Ford, Hyundai, and Toyota leading in hydrogen fuel cell technology. However, specialized companies such as ZeroAvia and Intelligent Energy are making significant strides in hydrogen-electric propulsion systems. The competitive landscape is diverse, with both established automotive giants and innovative startups vying for market share, indicating a dynamic and evolving sector with potential for rapid advancement in the coming years.

Ford Global Technologies LLC

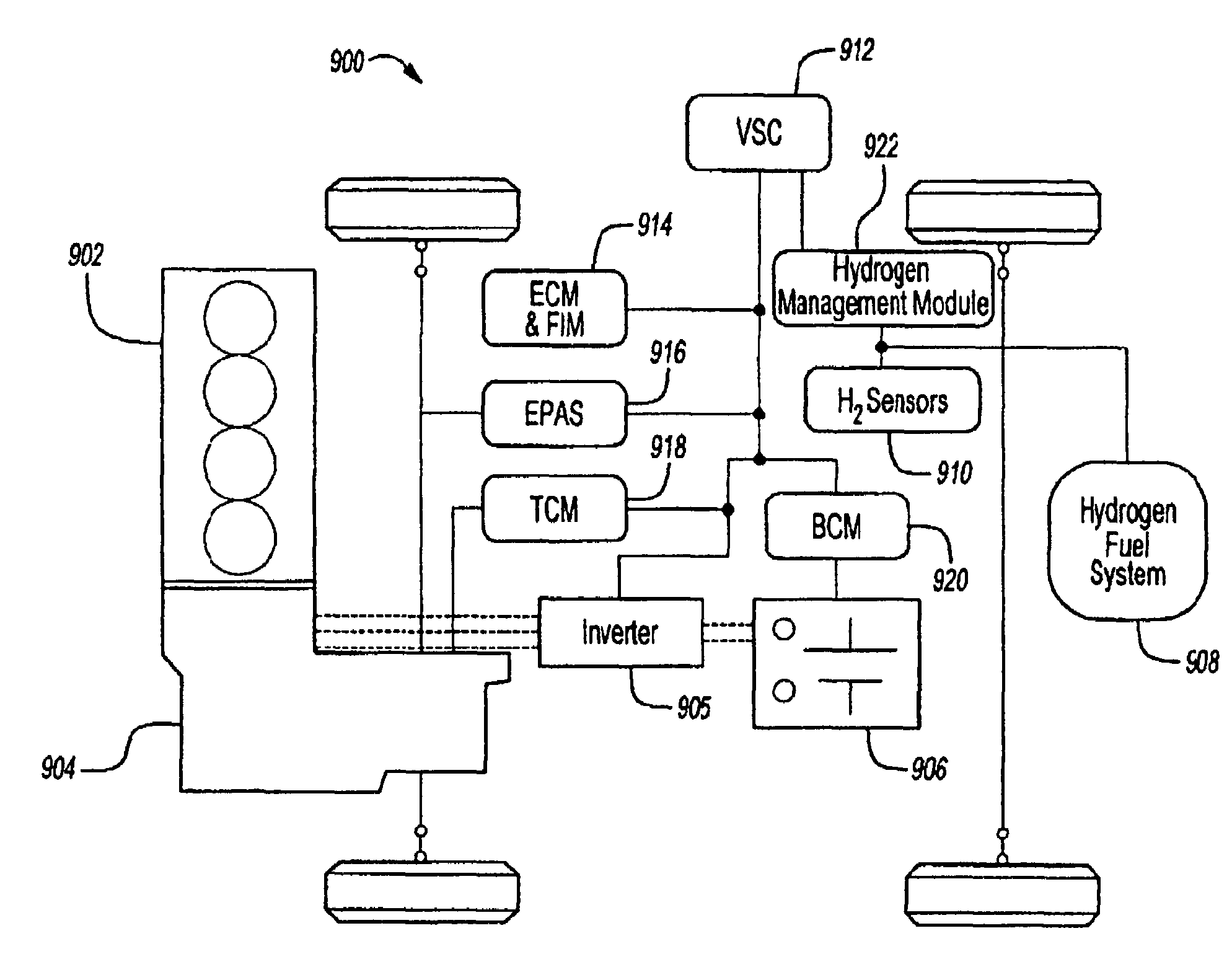

Technical Solution: Ford has developed a novel approach to integrating V8 engines with hydrogen fuel systems, focusing on direct injection technology. Their system utilizes a modified V8 engine with specialized hydrogen injectors and a high-pressure fuel delivery system. The engine's combustion chambers are redesigned to optimize hydrogen combustion, featuring a unique piston geometry and enhanced cooling systems. Ford's approach also incorporates advanced engine control units (ECUs) that precisely manage hydrogen injection timing and quantity, adapting to various driving conditions[1]. The system includes safety features such as hydrogen leak detection sensors and automatic shut-off valves. Ford has also implemented a regenerative braking system to improve overall vehicle efficiency, capturing and storing energy typically lost during deceleration[3].

Strengths: Leverages existing V8 engine architecture, potentially reducing manufacturing costs. Offers high power output while maintaining zero emissions. Weaknesses: May face challenges in hydrogen storage and distribution infrastructure. Potential concerns about the long-term durability of modified engine components.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's approach to integrating V8 engines in hydrogen fuel vehicles focuses on a hybrid system that combines a downsized V8 engine with hydrogen fuel cell technology. Their system utilizes a compact V8 engine optimized for hydrogen combustion, working in tandem with a fuel cell stack. The V8 engine is modified with specialized hydrogen injectors and a redesigned combustion chamber to maximize efficiency. Hyundai's innovative dual-power system allows the vehicle to switch between pure hydrogen combustion and fuel cell electric power, depending on driving conditions and power demands[2]. The company has also developed an advanced thermal management system to address the unique cooling requirements of this hybrid setup. Additionally, Hyundai has implemented a sophisticated control system that optimizes power distribution between the V8 engine and the fuel cell, ensuring maximum efficiency and performance[4].

Strengths: Offers flexibility in power sources, potentially improving range and performance. Combines benefits of both hydrogen combustion and fuel cell technologies. Weaknesses: Increased system complexity may lead to higher production costs and potential maintenance challenges. May face difficulties in balancing the size and weight of dual power systems.

Core Innovations in H2 V8 Technology

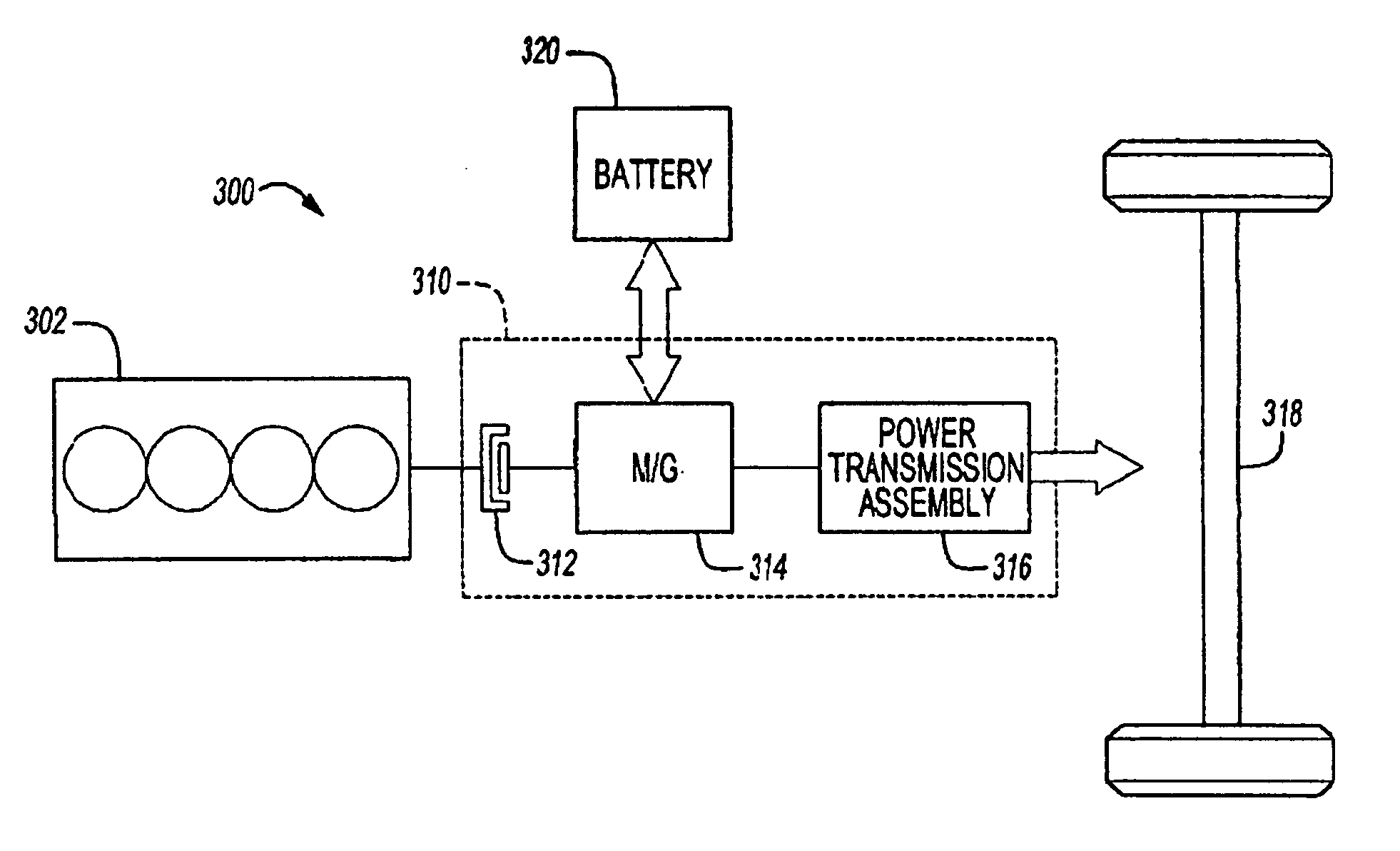

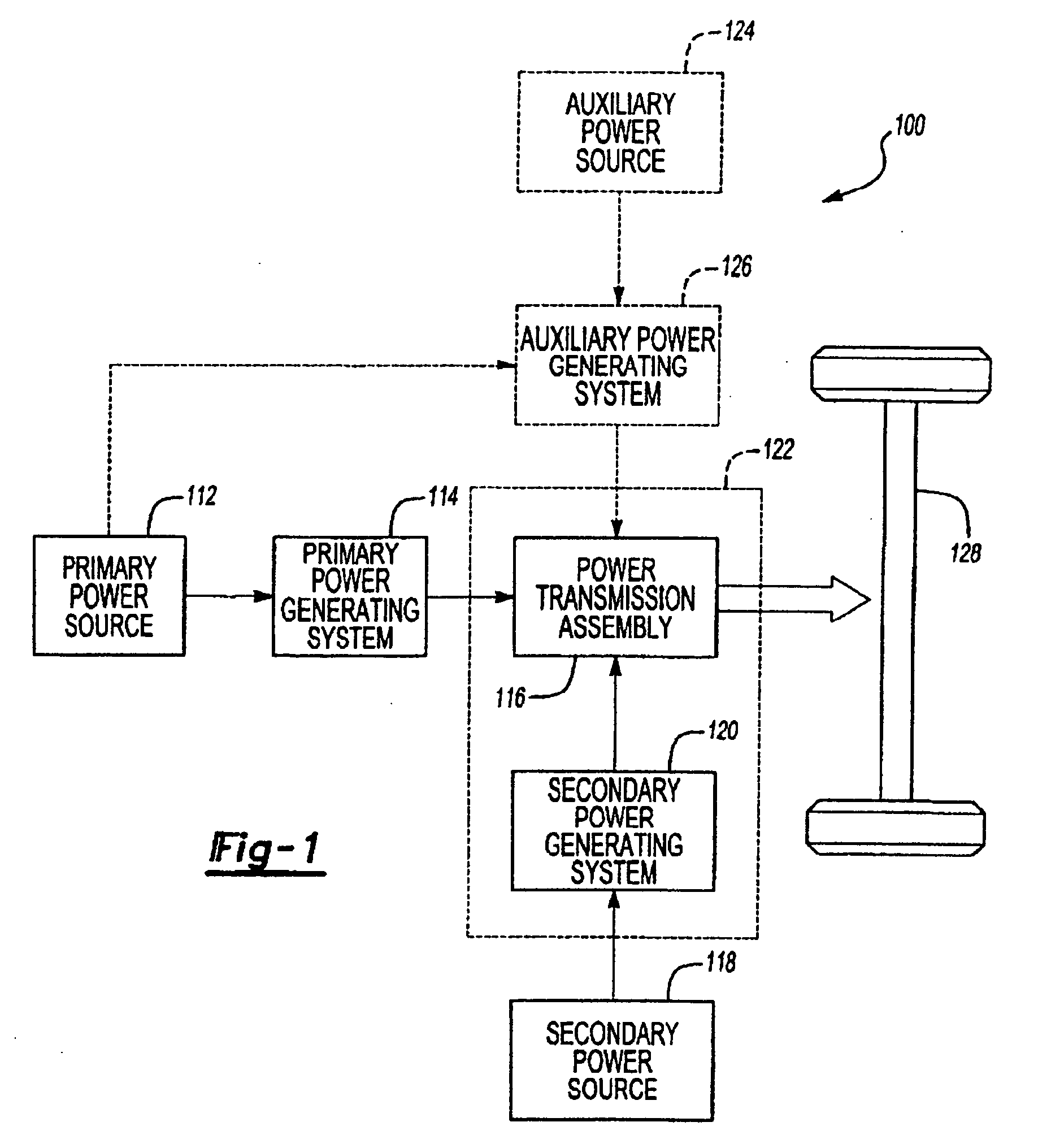

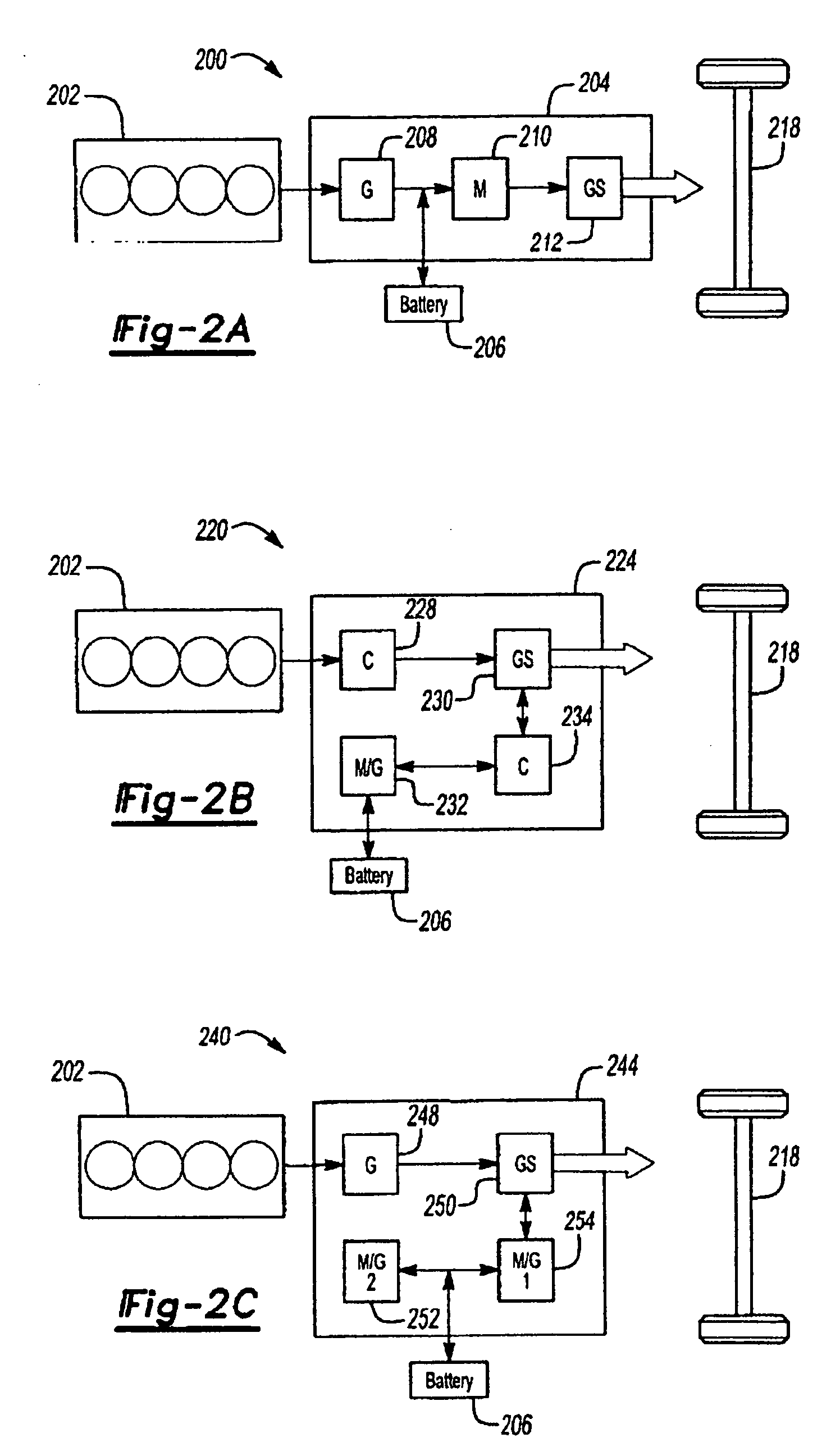

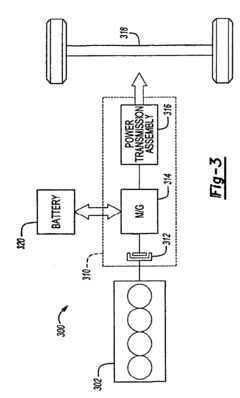

Hydrogen fuelled hybrid powertrain and vehicle

PatentInactiveUS7608011B2

Innovation

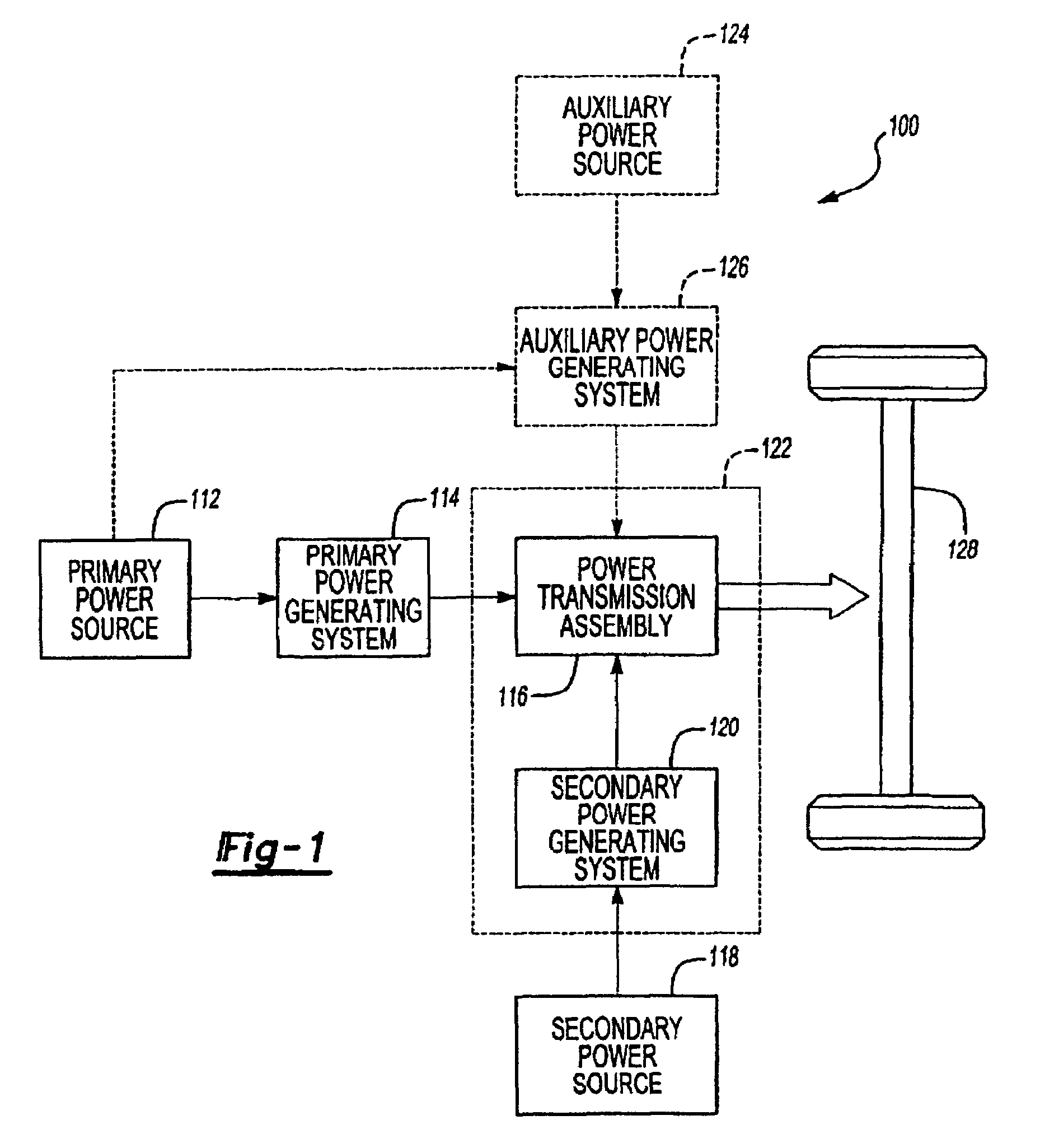

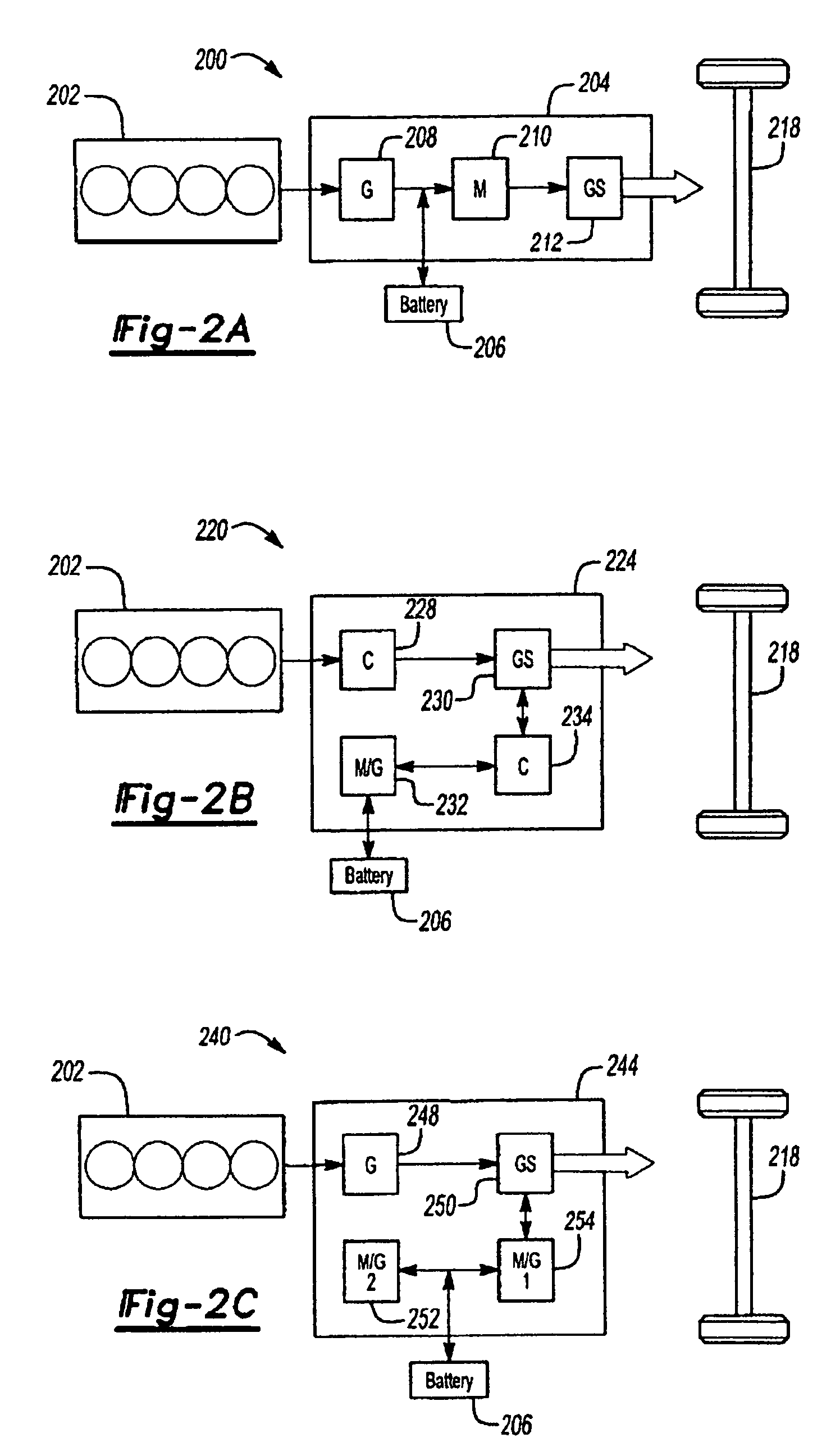

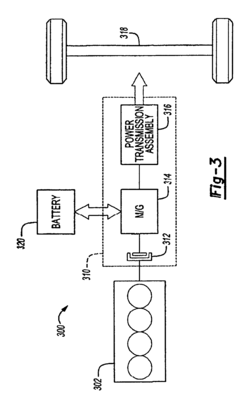

- A hybrid electric powertrain system that combines a hydrogen-fuelled internal combustion engine with an electric motor, utilizing supercharging and a disconnect clutch to enhance torque output, particularly at lower speeds, and incorporating a modular hybrid transmission system for improved performance and reduced emissions.

Hydrogen fuelled hybrid powertrain and vehicle

PatentInactiveUS20060174624A1

Innovation

- A hybrid powertrain system combining a hydrogen-fuelled internal combustion engine with an air charge boosting device and an electric torque generating system, utilizing a disconnect clutch and modular hybrid transmission to enhance torque output, particularly at lower speeds, and incorporating supercharging and intercooling to improve performance and reduce emissions.

Environmental Impact Assessment

The integration of V8 engines in hydrogen fuel vehicles presents a complex environmental impact scenario that requires careful assessment. While hydrogen fuel cells are often touted as a clean energy solution, the combination with traditional V8 engine architecture introduces unique environmental considerations.

Firstly, the emissions profile of this hybrid system differs significantly from conventional hydrogen fuel cell vehicles. V8 engines, known for their power output, typically produce higher levels of carbon dioxide and other greenhouse gases. However, when fueled by hydrogen, the primary exhaust product is water vapor. This shift in emissions composition necessitates a reevaluation of the vehicle's overall carbon footprint and its impact on local air quality.

The production and distribution of hydrogen fuel also play a crucial role in the environmental assessment. If the hydrogen is produced through electrolysis powered by renewable energy sources, the well-to-wheel emissions can be significantly lower than those of traditional fossil fuel vehicles. However, if the hydrogen is derived from natural gas reforming, which is currently the most common method, the environmental benefits may be diminished.

Another important factor to consider is the energy efficiency of the V8 engine when adapted for hydrogen combustion. Hydrogen has different combustion characteristics compared to gasoline, which may affect the engine's performance and efficiency. Any decrease in efficiency could lead to increased fuel consumption, potentially offsetting some of the environmental benefits of using hydrogen as a fuel source.

The manufacturing process of these hybrid vehicles also warrants examination. The production of V8 engines and their integration with hydrogen fuel systems may require additional resources and energy compared to standard hydrogen fuel cell vehicles. This could result in a higher embodied energy content and potentially greater environmental impact during the vehicle's production phase.

Furthermore, the end-of-life considerations for these vehicles must be addressed. The recycling and disposal of V8 engine components, combined with the specialized hydrogen fuel system, may present new challenges for waste management and resource recovery. Proper recycling protocols need to be established to minimize the environmental impact of decommissioned vehicles.

Lastly, the potential for hydrogen leakage and its atmospheric effects should be evaluated. While hydrogen is not a direct greenhouse gas, it can indirectly contribute to global warming through atmospheric chemistry interactions. Ensuring robust safety measures and leak prevention systems is crucial to mitigate any potential negative environmental impacts associated with hydrogen use in V8 engine vehicles.

Firstly, the emissions profile of this hybrid system differs significantly from conventional hydrogen fuel cell vehicles. V8 engines, known for their power output, typically produce higher levels of carbon dioxide and other greenhouse gases. However, when fueled by hydrogen, the primary exhaust product is water vapor. This shift in emissions composition necessitates a reevaluation of the vehicle's overall carbon footprint and its impact on local air quality.

The production and distribution of hydrogen fuel also play a crucial role in the environmental assessment. If the hydrogen is produced through electrolysis powered by renewable energy sources, the well-to-wheel emissions can be significantly lower than those of traditional fossil fuel vehicles. However, if the hydrogen is derived from natural gas reforming, which is currently the most common method, the environmental benefits may be diminished.

Another important factor to consider is the energy efficiency of the V8 engine when adapted for hydrogen combustion. Hydrogen has different combustion characteristics compared to gasoline, which may affect the engine's performance and efficiency. Any decrease in efficiency could lead to increased fuel consumption, potentially offsetting some of the environmental benefits of using hydrogen as a fuel source.

The manufacturing process of these hybrid vehicles also warrants examination. The production of V8 engines and their integration with hydrogen fuel systems may require additional resources and energy compared to standard hydrogen fuel cell vehicles. This could result in a higher embodied energy content and potentially greater environmental impact during the vehicle's production phase.

Furthermore, the end-of-life considerations for these vehicles must be addressed. The recycling and disposal of V8 engine components, combined with the specialized hydrogen fuel system, may present new challenges for waste management and resource recovery. Proper recycling protocols need to be established to minimize the environmental impact of decommissioned vehicles.

Lastly, the potential for hydrogen leakage and its atmospheric effects should be evaluated. While hydrogen is not a direct greenhouse gas, it can indirectly contribute to global warming through atmospheric chemistry interactions. Ensuring robust safety measures and leak prevention systems is crucial to mitigate any potential negative environmental impacts associated with hydrogen use in V8 engine vehicles.

Safety Regulations for H2 Vehicles

The integration of hydrogen fuel technology in vehicles necessitates stringent safety regulations to ensure public safety and promote widespread adoption. These regulations primarily focus on the unique properties of hydrogen as a fuel and the specific risks associated with its storage, handling, and use in vehicles.

Hydrogen fuel vehicles must comply with comprehensive crash safety standards to prevent fuel leakage and minimize the risk of fire or explosion in the event of a collision. These standards typically include requirements for robust fuel tank design, reinforced mounting systems, and fail-safe shut-off mechanisms. Additionally, manufacturers must demonstrate that hydrogen storage systems can withstand extreme temperatures, pressures, and impact forces without compromising safety.

Leak detection and prevention systems are crucial components of hydrogen vehicle safety regulations. Vehicles must be equipped with sophisticated sensors capable of detecting even minute hydrogen leaks and initiating automatic safety protocols. These systems often include multiple redundancies to ensure reliability and effectiveness in various operating conditions.

Refueling safety is another critical aspect of hydrogen vehicle regulations. Standardized fueling protocols, including nozzle designs and pressure ratings, are mandated to prevent accidents during the refueling process. Service station personnel must undergo specialized training to handle hydrogen safely and respond to potential emergencies.

Ventilation requirements for hydrogen vehicles are more stringent compared to conventional vehicles due to hydrogen's propensity to accumulate in enclosed spaces. Regulations typically mandate specific ventilation designs for vehicle cabins, engine compartments, and storage areas to prevent dangerous concentrations of hydrogen gas.

Electrical system safety is paramount in hydrogen fuel vehicles, given the potential for sparks to ignite hydrogen. Regulations often require intrinsically safe electrical components, proper insulation, and grounding systems to minimize the risk of electrical-induced ignition.

Maintenance and inspection protocols for hydrogen vehicles are typically more rigorous than those for conventional vehicles. Regular safety checks, specialized diagnostic tools, and certified technician training are mandated to ensure the ongoing safety and integrity of hydrogen fuel systems.

Public education and emergency response planning are integral components of hydrogen vehicle safety regulations. Manufacturers and operators are often required to provide comprehensive safety information to users and work closely with local emergency services to develop appropriate response strategies for hydrogen-related incidents.

As hydrogen fuel technology continues to evolve, safety regulations are regularly reviewed and updated to address new challenges and incorporate technological advancements. This ongoing process ensures that safety standards keep pace with the rapid development of hydrogen fuel vehicle technology, maintaining public confidence and supporting the growth of this emerging sector in the automotive industry.

Hydrogen fuel vehicles must comply with comprehensive crash safety standards to prevent fuel leakage and minimize the risk of fire or explosion in the event of a collision. These standards typically include requirements for robust fuel tank design, reinforced mounting systems, and fail-safe shut-off mechanisms. Additionally, manufacturers must demonstrate that hydrogen storage systems can withstand extreme temperatures, pressures, and impact forces without compromising safety.

Leak detection and prevention systems are crucial components of hydrogen vehicle safety regulations. Vehicles must be equipped with sophisticated sensors capable of detecting even minute hydrogen leaks and initiating automatic safety protocols. These systems often include multiple redundancies to ensure reliability and effectiveness in various operating conditions.

Refueling safety is another critical aspect of hydrogen vehicle regulations. Standardized fueling protocols, including nozzle designs and pressure ratings, are mandated to prevent accidents during the refueling process. Service station personnel must undergo specialized training to handle hydrogen safely and respond to potential emergencies.

Ventilation requirements for hydrogen vehicles are more stringent compared to conventional vehicles due to hydrogen's propensity to accumulate in enclosed spaces. Regulations typically mandate specific ventilation designs for vehicle cabins, engine compartments, and storage areas to prevent dangerous concentrations of hydrogen gas.

Electrical system safety is paramount in hydrogen fuel vehicles, given the potential for sparks to ignite hydrogen. Regulations often require intrinsically safe electrical components, proper insulation, and grounding systems to minimize the risk of electrical-induced ignition.

Maintenance and inspection protocols for hydrogen vehicles are typically more rigorous than those for conventional vehicles. Regular safety checks, specialized diagnostic tools, and certified technician training are mandated to ensure the ongoing safety and integrity of hydrogen fuel systems.

Public education and emergency response planning are integral components of hydrogen vehicle safety regulations. Manufacturers and operators are often required to provide comprehensive safety information to users and work closely with local emergency services to develop appropriate response strategies for hydrogen-related incidents.

As hydrogen fuel technology continues to evolve, safety regulations are regularly reviewed and updated to address new challenges and incorporate technological advancements. This ongoing process ensures that safety standards keep pace with the rapid development of hydrogen fuel vehicle technology, maintaining public confidence and supporting the growth of this emerging sector in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!