V8 Engine Newer Models: Trends and Predictions

JUL 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine, a stalwart of automotive engineering, has undergone significant evolution since its inception. This iconic powerplant has been a cornerstone of performance and efficiency in the automotive industry for decades. As we examine the trends and predictions for newer V8 engine models, it's crucial to understand the historical context and the objectives driving its continued development.

The journey of the V8 engine began in the early 20th century, with its widespread adoption in the 1930s and 1940s. Initially prized for its smooth power delivery and compact design, the V8 quickly became synonymous with American muscle cars and high-performance vehicles. Over the years, it has adapted to changing market demands, environmental regulations, and technological advancements.

In recent decades, the primary objectives for V8 engine development have shifted dramatically. While power output remains a key focus, engineers are now equally concerned with fuel efficiency, emissions reduction, and overall sustainability. This paradigm shift has led to the integration of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation.

The trend towards electrification has also significantly impacted V8 engine development. Many manufacturers are exploring hybrid V8 powertrains, combining the traditional internal combustion engine with electric motors to boost performance while reducing fuel consumption and emissions. This hybridization represents a critical stepping stone in the evolution of the V8, potentially extending its relevance in an increasingly electrified automotive landscape.

Looking forward, the objectives for V8 engine development are multifaceted. Engineers are striving to push the boundaries of thermal efficiency, aiming to extract maximum power from each drop of fuel while minimizing waste heat. There's also a growing emphasis on materials science, with research into lighter, stronger alloys that can withstand higher combustion pressures and temperatures.

Another key objective is the exploration of alternative fuels. Some manufacturers are developing V8 engines capable of running on hydrogen or synthetic fuels, potentially offering a more sustainable future for this engine configuration. These efforts align with the broader industry goal of reducing carbon footprints while maintaining the performance characteristics that V8 enthusiasts cherish.

As we predict the future of V8 engines, it's clear that adaptability will be crucial. The ability to meet stringent emissions standards while delivering the power and character expected of a V8 will determine its longevity. Advanced control systems, innovative combustion strategies, and integration with electrification technologies are likely to play pivotal roles in shaping the next generation of V8 engines.

The journey of the V8 engine began in the early 20th century, with its widespread adoption in the 1930s and 1940s. Initially prized for its smooth power delivery and compact design, the V8 quickly became synonymous with American muscle cars and high-performance vehicles. Over the years, it has adapted to changing market demands, environmental regulations, and technological advancements.

In recent decades, the primary objectives for V8 engine development have shifted dramatically. While power output remains a key focus, engineers are now equally concerned with fuel efficiency, emissions reduction, and overall sustainability. This paradigm shift has led to the integration of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation.

The trend towards electrification has also significantly impacted V8 engine development. Many manufacturers are exploring hybrid V8 powertrains, combining the traditional internal combustion engine with electric motors to boost performance while reducing fuel consumption and emissions. This hybridization represents a critical stepping stone in the evolution of the V8, potentially extending its relevance in an increasingly electrified automotive landscape.

Looking forward, the objectives for V8 engine development are multifaceted. Engineers are striving to push the boundaries of thermal efficiency, aiming to extract maximum power from each drop of fuel while minimizing waste heat. There's also a growing emphasis on materials science, with research into lighter, stronger alloys that can withstand higher combustion pressures and temperatures.

Another key objective is the exploration of alternative fuels. Some manufacturers are developing V8 engines capable of running on hydrogen or synthetic fuels, potentially offering a more sustainable future for this engine configuration. These efforts align with the broader industry goal of reducing carbon footprints while maintaining the performance characteristics that V8 enthusiasts cherish.

As we predict the future of V8 engines, it's clear that adaptability will be crucial. The ability to meet stringent emissions standards while delivering the power and character expected of a V8 will determine its longevity. Advanced control systems, innovative combustion strategies, and integration with electrification technologies are likely to play pivotal roles in shaping the next generation of V8 engines.

Market Demand Analysis for V8 Engines

The market demand for V8 engines has been undergoing significant shifts in recent years, driven by a complex interplay of factors including environmental regulations, consumer preferences, and technological advancements. Despite the growing trend towards electrification and downsizing in the automotive industry, V8 engines continue to maintain a strong presence in certain market segments.

In the luxury and high-performance vehicle sectors, V8 engines remain highly sought after for their distinctive power delivery and characteristic sound. Brands such as Mercedes-AMG, BMW M, and Audi RS continue to offer V8 options in their flagship models, catering to enthusiasts who prioritize performance and driving experience. The demand for V8-powered sports cars and muscle cars also remains robust, particularly in markets like North America where these vehicles hold cultural significance.

However, the overall market for V8 engines has been contracting due to stringent emissions regulations and the push for improved fuel efficiency. Many automakers have been phasing out V8 options in their mainstream models, replacing them with turbocharged six-cylinder or even four-cylinder engines that offer comparable power outputs with better fuel economy.

The commercial vehicle sector presents a mixed picture for V8 engine demand. While there's a trend towards more efficient powertrains in light-duty trucks, heavy-duty pickup trucks and commercial vehicles still rely on V8 engines for their torque and towing capabilities. This segment continues to provide a steady demand for V8 engines, especially in North America.

Emerging markets, particularly in regions with less stringent emissions regulations, are showing increased interest in V8-powered vehicles as symbols of luxury and status. This trend is partially offsetting the decline in traditional markets, although it's not expected to reverse the overall downward trajectory.

The aftermarket and performance tuning industries continue to support demand for V8 engines, with enthusiasts and custom builders seeking these powerplants for their projects. This niche market, while relatively small, contributes to the ongoing relevance of V8 technology.

Looking ahead, the market for V8 engines is expected to become increasingly specialized. As mainstream vehicles transition to smaller engines or electric powertrains, V8s are likely to be reserved for high-end performance vehicles, luxury flagships, and specific commercial applications. Manufacturers are investing in technologies to make V8 engines more efficient and compliant with future emissions standards, potentially extending their viability in the market.

In the luxury and high-performance vehicle sectors, V8 engines remain highly sought after for their distinctive power delivery and characteristic sound. Brands such as Mercedes-AMG, BMW M, and Audi RS continue to offer V8 options in their flagship models, catering to enthusiasts who prioritize performance and driving experience. The demand for V8-powered sports cars and muscle cars also remains robust, particularly in markets like North America where these vehicles hold cultural significance.

However, the overall market for V8 engines has been contracting due to stringent emissions regulations and the push for improved fuel efficiency. Many automakers have been phasing out V8 options in their mainstream models, replacing them with turbocharged six-cylinder or even four-cylinder engines that offer comparable power outputs with better fuel economy.

The commercial vehicle sector presents a mixed picture for V8 engine demand. While there's a trend towards more efficient powertrains in light-duty trucks, heavy-duty pickup trucks and commercial vehicles still rely on V8 engines for their torque and towing capabilities. This segment continues to provide a steady demand for V8 engines, especially in North America.

Emerging markets, particularly in regions with less stringent emissions regulations, are showing increased interest in V8-powered vehicles as symbols of luxury and status. This trend is partially offsetting the decline in traditional markets, although it's not expected to reverse the overall downward trajectory.

The aftermarket and performance tuning industries continue to support demand for V8 engines, with enthusiasts and custom builders seeking these powerplants for their projects. This niche market, while relatively small, contributes to the ongoing relevance of V8 technology.

Looking ahead, the market for V8 engines is expected to become increasingly specialized. As mainstream vehicles transition to smaller engines or electric powertrains, V8s are likely to be reserved for high-end performance vehicles, luxury flagships, and specific commercial applications. Manufacturers are investing in technologies to make V8 engines more efficient and compliant with future emissions standards, potentially extending their viability in the market.

Current V8 Technology and Challenges

V8, Google's open-source high-performance JavaScript and WebAssembly engine, has undergone significant advancements in recent years. However, it still faces several challenges in keeping pace with the evolving demands of modern web applications and the increasing complexity of JavaScript codebases.

One of the primary challenges for V8 is optimizing performance for large-scale applications. As web applications grow in size and complexity, V8 must continually improve its compilation and execution strategies to maintain fast load times and smooth runtime performance. This includes enhancing just-in-time (JIT) compilation techniques, improving garbage collection algorithms, and optimizing memory usage.

Another significant challenge is balancing the trade-offs between startup time and peak performance. V8 employs various optimization techniques, such as inline caching and adaptive compilation, but must carefully manage when and how these optimizations are applied to avoid negatively impacting initial page load times.

The rapid evolution of JavaScript and its ecosystem presents ongoing challenges for V8. New language features, APIs, and programming paradigms require continuous updates to the engine's parsing, compilation, and optimization systems. This includes supporting modern JavaScript syntax, optimizing for functional programming patterns, and efficiently handling asynchronous operations.

WebAssembly support is another area where V8 faces both opportunities and challenges. While WebAssembly offers near-native performance for web applications, integrating it seamlessly with JavaScript and optimizing its execution within the V8 engine requires ongoing research and development.

Security remains a critical concern for V8, particularly as it is used in various environments beyond web browsers, such as server-side JavaScript runtimes. Protecting against potential vulnerabilities, such as side-channel attacks and memory corruption issues, requires constant vigilance and updates to the engine's security model.

Energy efficiency is an emerging challenge for V8, especially on mobile devices. Optimizing the engine to reduce power consumption while maintaining performance is crucial for improving battery life and user experience on portable devices.

Lastly, V8 faces the challenge of maintaining compatibility with older JavaScript code while pushing forward with optimizations for modern programming practices. This backward compatibility requirement can sometimes limit the potential for more aggressive optimizations or architectural changes.

As V8 continues to evolve, addressing these challenges will be crucial for maintaining its position as a leading JavaScript engine and supporting the next generation of web applications and JavaScript-based technologies.

One of the primary challenges for V8 is optimizing performance for large-scale applications. As web applications grow in size and complexity, V8 must continually improve its compilation and execution strategies to maintain fast load times and smooth runtime performance. This includes enhancing just-in-time (JIT) compilation techniques, improving garbage collection algorithms, and optimizing memory usage.

Another significant challenge is balancing the trade-offs between startup time and peak performance. V8 employs various optimization techniques, such as inline caching and adaptive compilation, but must carefully manage when and how these optimizations are applied to avoid negatively impacting initial page load times.

The rapid evolution of JavaScript and its ecosystem presents ongoing challenges for V8. New language features, APIs, and programming paradigms require continuous updates to the engine's parsing, compilation, and optimization systems. This includes supporting modern JavaScript syntax, optimizing for functional programming patterns, and efficiently handling asynchronous operations.

WebAssembly support is another area where V8 faces both opportunities and challenges. While WebAssembly offers near-native performance for web applications, integrating it seamlessly with JavaScript and optimizing its execution within the V8 engine requires ongoing research and development.

Security remains a critical concern for V8, particularly as it is used in various environments beyond web browsers, such as server-side JavaScript runtimes. Protecting against potential vulnerabilities, such as side-channel attacks and memory corruption issues, requires constant vigilance and updates to the engine's security model.

Energy efficiency is an emerging challenge for V8, especially on mobile devices. Optimizing the engine to reduce power consumption while maintaining performance is crucial for improving battery life and user experience on portable devices.

Lastly, V8 faces the challenge of maintaining compatibility with older JavaScript code while pushing forward with optimizations for modern programming practices. This backward compatibility requirement can sometimes limit the potential for more aggressive optimizations or architectural changes.

As V8 continues to evolve, addressing these challenges will be crucial for maintaining its position as a leading JavaScript engine and supporting the next generation of web applications and JavaScript-based technologies.

Current V8 Engine Design Solutions

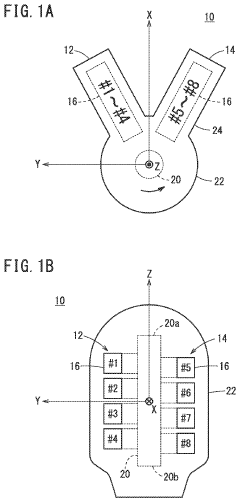

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are continuously optimized to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved balance, and higher power output compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Efficiency and Emissions Control: Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.

- Performance Enhancement and Tuning: Various methods and components are used to enhance V8 engine performance. These may include turbocharging, supercharging, high-flow intake and exhaust systems, and engine management system tuning. Performance enhancements aim to increase horsepower, torque, and overall engine responsiveness.

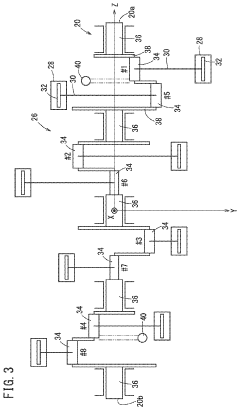

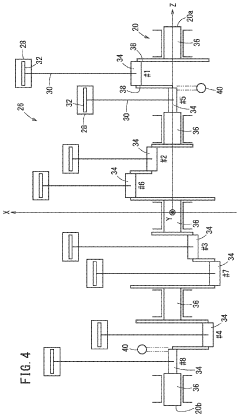

- Cooling and Lubrication Systems: Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Advanced cooling systems may incorporate precision coolant flow control, while lubrication systems often feature high-capacity oil pumps and sophisticated oil filtration. These systems help manage the high heat and stress generated by V8 engines during operation.

- Manufacturing and Assembly Techniques: Specialized manufacturing and assembly techniques are employed in V8 engine production. These may include precision machining of engine blocks and components, advanced casting methods, and automated assembly processes. Such techniques ensure consistent quality, tight tolerances, and optimal performance of V8 engines.

02 Fuel Injection and Combustion Systems

Modern V8 engines employ advanced fuel injection and combustion systems to improve fuel efficiency and reduce emissions. These systems may include direct injection, variable valve timing, and cylinder deactivation technologies. Innovations in this area focus on optimizing fuel-air mixture, combustion timing, and exhaust gas recirculation to meet stringent environmental regulations while maintaining high performance.Expand Specific Solutions03 Turbocharging and Supercharging

To increase power output and efficiency, many V8 engines incorporate forced induction systems such as turbochargers or superchargers. These systems compress the intake air, allowing more fuel to be burned and generating more power from the same engine displacement. Recent developments focus on reducing turbo lag, improving boost control, and integrating electric compressors for enhanced performance across the entire RPM range.Expand Specific Solutions04 Engine Block and Component Materials

Advancements in materials science have led to the use of lightweight, high-strength materials in V8 engine construction. Aluminum alloys, composite materials, and advanced steel formulations are used for engine blocks, cylinder heads, and internal components to reduce weight while maintaining durability. These materials help improve power-to-weight ratios and overall vehicle efficiency.Expand Specific Solutions05 Cooling and Lubrication Systems

Efficient cooling and lubrication are crucial for V8 engine performance and longevity. Innovations in this area include advanced coolant formulations, precision oil delivery systems, and integrated thermal management solutions. These improvements help maintain optimal operating temperatures, reduce friction, and extend engine life while supporting high-performance applications.Expand Specific Solutions

Major V8 Engine Manufacturers

The V8 engine market is in a mature stage, with established players and ongoing innovation. The global market size for V8 engines is substantial, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines are well-developed but evolving to meet efficiency and emissions standards. Key players like BMW, Toyota, Honda, GM, and Nissan are investing in V8 engine refinements, focusing on power output, fuel efficiency, and emissions reduction. Emerging trends include hybridization and electrification integration, with companies like Mercedes-Benz and Ford exploring these avenues to enhance V8 performance while addressing environmental concerns.

Bayerische Motoren Werke AG

Technical Solution: BMW's latest V8 engine models incorporate advanced technologies to meet future emission standards while maintaining high performance. The company has developed a new 4.4-liter twin-turbo V8 engine, codenamed S68, which features a cross-bank exhaust manifold, redesigned turbochargers, and a reinforced crankshaft drive[1]. This engine also integrates a 48V mild-hybrid system, improving fuel efficiency and reducing emissions[2]. BMW has implemented a cylinder deactivation system, allowing the engine to run on four cylinders during low-load conditions, further enhancing fuel economy[3]. The company is also exploring the use of sustainable fuels in their V8 engines to reduce carbon footprint without compromising performance[4].

Strengths: High performance combined with improved efficiency, advanced emissions control technologies, and compatibility with sustainable fuels. Weaknesses: Complexity of the engine design may lead to higher production costs and potential maintenance challenges.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V8 engine development focuses on balancing power with efficiency and reliability. The company's latest V8 engines, such as the 5.7-liter iForce V8, incorporate dual VVT-i (Variable Valve Timing with intelligence) technology, which optimizes valve timing for improved performance and fuel efficiency[1]. Toyota has also implemented D-4S direct injection system in their V8 engines, allowing for precise fuel delivery and better combustion control[2]. To address emissions concerns, Toyota is developing a new twin-turbo V8 engine with a smaller displacement, reportedly around 4.0 liters, which aims to deliver V8 performance with improved fuel economy[3]. Additionally, Toyota is exploring hydrogen combustion technology for V8 engines, as demonstrated in their experimental hydrogen-powered Corolla race car, which could potentially be applied to larger V8 engines in the future[4].

Strengths: Renowned reliability, advanced fuel injection and valve timing technologies, and innovative research into alternative fuels for V8 engines. Weaknesses: Relatively conservative approach to V8 development compared to some competitors, potentially lagging in power output.

Key V8 Engine Innovations

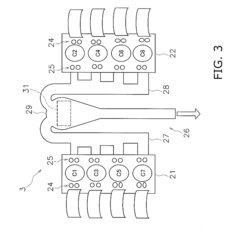

V8 engine

PatentActiveUS20230109196A1

Innovation

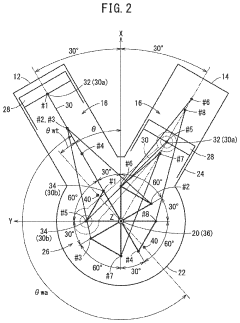

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

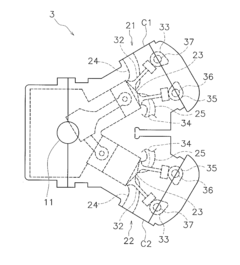

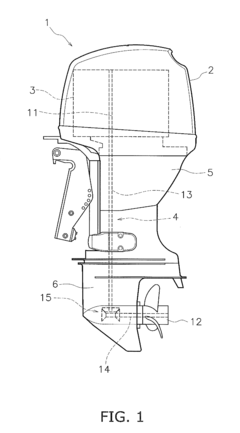

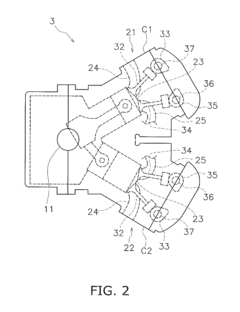

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

Environmental Regulations Impact

Environmental regulations have become increasingly stringent in recent years, significantly impacting the development and production of V8 engines. These regulations, primarily focused on reducing emissions and improving fuel efficiency, have forced manufacturers to adapt their V8 engine designs to meet new standards.

One of the most notable impacts has been the implementation of stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States. These standards have led to the widespread adoption of technologies like direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines. These innovations help reduce fuel consumption and emissions while maintaining performance levels.

The push for improved fuel economy has also resulted in the development of more efficient V8 engines. Manufacturers have been exploring ways to downsize V8 engines without sacrificing power output. This has led to the introduction of smaller displacement V8s with forced induction, typically using turbochargers or superchargers to maintain or even increase power output while reducing fuel consumption.

Another significant trend influenced by environmental regulations is the integration of hybrid technology with V8 engines. Many luxury and high-performance vehicle manufacturers are now combining V8 engines with electric motors to create hybrid powertrains. This approach allows for improved fuel efficiency and reduced emissions during city driving while still providing the power and performance expected from a V8 engine.

The impact of environmental regulations has also accelerated research and development in alternative fuels for V8 engines. Some manufacturers are exploring the use of sustainable biofuels or synthetic fuels that can significantly reduce carbon emissions without requiring major modifications to existing V8 engine designs.

Looking ahead, the continued tightening of environmental regulations is likely to further shape the future of V8 engines. We can expect to see more advanced technologies being integrated into V8 designs, such as improved thermal management systems, advanced materials for weight reduction, and more sophisticated engine control units to optimize performance and efficiency.

However, it's important to note that these regulations are also pushing some manufacturers to consider phasing out V8 engines in favor of smaller, more efficient powertrains or fully electric alternatives. This shift is particularly evident in markets with the most stringent environmental regulations, where the long-term viability of V8 engines is being called into question.

One of the most notable impacts has been the implementation of stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States. These standards have led to the widespread adoption of technologies like direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines. These innovations help reduce fuel consumption and emissions while maintaining performance levels.

The push for improved fuel economy has also resulted in the development of more efficient V8 engines. Manufacturers have been exploring ways to downsize V8 engines without sacrificing power output. This has led to the introduction of smaller displacement V8s with forced induction, typically using turbochargers or superchargers to maintain or even increase power output while reducing fuel consumption.

Another significant trend influenced by environmental regulations is the integration of hybrid technology with V8 engines. Many luxury and high-performance vehicle manufacturers are now combining V8 engines with electric motors to create hybrid powertrains. This approach allows for improved fuel efficiency and reduced emissions during city driving while still providing the power and performance expected from a V8 engine.

The impact of environmental regulations has also accelerated research and development in alternative fuels for V8 engines. Some manufacturers are exploring the use of sustainable biofuels or synthetic fuels that can significantly reduce carbon emissions without requiring major modifications to existing V8 engine designs.

Looking ahead, the continued tightening of environmental regulations is likely to further shape the future of V8 engines. We can expect to see more advanced technologies being integrated into V8 designs, such as improved thermal management systems, advanced materials for weight reduction, and more sophisticated engine control units to optimize performance and efficiency.

However, it's important to note that these regulations are also pushing some manufacturers to consider phasing out V8 engines in favor of smaller, more efficient powertrains or fully electric alternatives. This shift is particularly evident in markets with the most stringent environmental regulations, where the long-term viability of V8 engines is being called into question.

V8 Performance vs Efficiency Trade-offs

The evolution of V8 engine technology has led to a continuous balancing act between performance and efficiency. As newer models emerge, engineers face the challenge of maximizing power output while simultaneously improving fuel economy and reducing emissions. This trade-off is at the heart of modern V8 engine design and development.

Recent trends in V8 engine design have focused on downsizing and turbocharging. By reducing engine displacement and adding forced induction, manufacturers can maintain or even increase power output while improving fuel efficiency. However, this approach often comes at the cost of the characteristic V8 sound and immediate throttle response that enthusiasts cherish.

Another significant development is the implementation of cylinder deactivation technology. This allows V8 engines to operate on fewer cylinders under light load conditions, substantially improving fuel economy. The trade-off here is the complexity of the system and potential long-term reliability concerns.

Variable valve timing and lift systems have become increasingly sophisticated in newer V8 models. These systems offer improved performance across a wider range of engine speeds and load conditions. However, they add complexity and cost to the engine design, potentially impacting long-term maintenance requirements.

Direct fuel injection has become standard in modern V8 engines, offering better fuel atomization and more precise control over the combustion process. This technology improves both performance and efficiency but can lead to carbon buildup issues on intake valves, requiring additional maintenance.

The integration of hybrid systems with V8 engines represents a significant shift in the performance-efficiency paradigm. Electric motors can provide instant torque and fill in power gaps, allowing for smaller, more efficient V8 engines without sacrificing overall performance. The trade-off is increased weight and complexity, as well as higher initial costs.

Looking forward, the development of V8 engines is likely to focus on further refinement of these technologies, with an emphasis on reducing friction losses, improving thermal efficiency, and optimizing combustion processes. The challenge will be to maintain the distinctive character and performance of V8 engines while meeting increasingly stringent emissions regulations and efficiency demands.

Recent trends in V8 engine design have focused on downsizing and turbocharging. By reducing engine displacement and adding forced induction, manufacturers can maintain or even increase power output while improving fuel efficiency. However, this approach often comes at the cost of the characteristic V8 sound and immediate throttle response that enthusiasts cherish.

Another significant development is the implementation of cylinder deactivation technology. This allows V8 engines to operate on fewer cylinders under light load conditions, substantially improving fuel economy. The trade-off here is the complexity of the system and potential long-term reliability concerns.

Variable valve timing and lift systems have become increasingly sophisticated in newer V8 models. These systems offer improved performance across a wider range of engine speeds and load conditions. However, they add complexity and cost to the engine design, potentially impacting long-term maintenance requirements.

Direct fuel injection has become standard in modern V8 engines, offering better fuel atomization and more precise control over the combustion process. This technology improves both performance and efficiency but can lead to carbon buildup issues on intake valves, requiring additional maintenance.

The integration of hybrid systems with V8 engines represents a significant shift in the performance-efficiency paradigm. Electric motors can provide instant torque and fill in power gaps, allowing for smaller, more efficient V8 engines without sacrificing overall performance. The trade-off is increased weight and complexity, as well as higher initial costs.

Looking forward, the development of V8 engines is likely to focus on further refinement of these technologies, with an emphasis on reducing friction losses, improving thermal efficiency, and optimizing combustion processes. The challenge will be to maintain the distinctive character and performance of V8 engines while meeting increasingly stringent emissions regulations and efficiency demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!