V8 Engine Noise Reduction: Techniques and Benefits

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Noise Background and Objectives

V8 engines have been a cornerstone of automotive engineering since their inception in the early 20th century. Known for their power and distinctive sound, these engines have been widely used in high-performance vehicles, luxury cars, and even some trucks. However, as environmental concerns and consumer preferences have evolved, the focus has shifted towards reducing noise pollution and improving overall vehicle comfort.

The development of V8 engines has seen significant advancements in terms of power output and efficiency. Yet, the inherent design of these engines, with their eight cylinders arranged in a V-shape, contributes to their characteristic noise profile. This noise, while appealing to some enthusiasts, has become a challenge in the context of modern automotive design and urban living.

The primary sources of noise in V8 engines include combustion processes, mechanical movements of pistons and valves, and exhaust systems. As regulations on vehicle noise emissions have become more stringent globally, manufacturers have been compelled to address these issues while maintaining the performance attributes that V8 engines are known for.

The objectives of V8 engine noise reduction are multifaceted. Firstly, there is a need to comply with increasingly strict noise regulations in various markets. This involves reducing both internal and external noise levels to meet legal requirements. Secondly, there is a growing consumer demand for quieter, more refined driving experiences, even in high-performance vehicles.

Another key objective is to achieve noise reduction without significantly compromising the engine's performance or increasing its weight. This presents a complex engineering challenge, as many traditional noise reduction techniques can add weight or reduce engine efficiency. Additionally, for some market segments, preserving a degree of the V8's characteristic sound is important, as it is part of the brand identity and appeal of certain vehicles.

The evolution of noise reduction techniques in V8 engines has been driven by advancements in materials science, computer-aided design, and acoustic engineering. From the use of sound-absorbing materials to the development of active noise control systems, the field has seen a range of innovative approaches. The goal is not just to dampen noise, but to sculpt the acoustic profile of the engine to create a more pleasant auditory experience.

As we look towards the future, the objectives for V8 engine noise reduction are likely to become even more ambitious. With the rise of electric and hybrid vehicles setting new standards for quiet operation, the challenge for V8 engines is to remain relevant in a changing automotive landscape. This may involve integrating hybrid technologies or developing entirely new approaches to internal combustion engine design that can deliver the power of a V8 with significantly reduced noise levels.

The development of V8 engines has seen significant advancements in terms of power output and efficiency. Yet, the inherent design of these engines, with their eight cylinders arranged in a V-shape, contributes to their characteristic noise profile. This noise, while appealing to some enthusiasts, has become a challenge in the context of modern automotive design and urban living.

The primary sources of noise in V8 engines include combustion processes, mechanical movements of pistons and valves, and exhaust systems. As regulations on vehicle noise emissions have become more stringent globally, manufacturers have been compelled to address these issues while maintaining the performance attributes that V8 engines are known for.

The objectives of V8 engine noise reduction are multifaceted. Firstly, there is a need to comply with increasingly strict noise regulations in various markets. This involves reducing both internal and external noise levels to meet legal requirements. Secondly, there is a growing consumer demand for quieter, more refined driving experiences, even in high-performance vehicles.

Another key objective is to achieve noise reduction without significantly compromising the engine's performance or increasing its weight. This presents a complex engineering challenge, as many traditional noise reduction techniques can add weight or reduce engine efficiency. Additionally, for some market segments, preserving a degree of the V8's characteristic sound is important, as it is part of the brand identity and appeal of certain vehicles.

The evolution of noise reduction techniques in V8 engines has been driven by advancements in materials science, computer-aided design, and acoustic engineering. From the use of sound-absorbing materials to the development of active noise control systems, the field has seen a range of innovative approaches. The goal is not just to dampen noise, but to sculpt the acoustic profile of the engine to create a more pleasant auditory experience.

As we look towards the future, the objectives for V8 engine noise reduction are likely to become even more ambitious. With the rise of electric and hybrid vehicles setting new standards for quiet operation, the challenge for V8 engines is to remain relevant in a changing automotive landscape. This may involve integrating hybrid technologies or developing entirely new approaches to internal combustion engine design that can deliver the power of a V8 with significantly reduced noise levels.

Market Demand for Quieter V8 Engines

The market demand for quieter V8 engines has been steadily increasing in recent years, driven by a combination of consumer preferences, regulatory pressures, and technological advancements. Luxury vehicle manufacturers and performance car enthusiasts have long valued the power and distinctive sound of V8 engines. However, there is a growing desire for a more refined and less intrusive driving experience, particularly in high-end vehicles where comfort is paramount.

Consumer surveys indicate that noise reduction is becoming a key factor in purchasing decisions for premium vehicles. A significant portion of luxury car buyers now prioritize cabin quietness alongside traditional factors like performance and design. This shift in consumer preferences has prompted automakers to invest heavily in noise reduction technologies for their V8 engines.

Environmental regulations and noise pollution laws in many countries have also contributed to the demand for quieter engines. Urban areas, in particular, have implemented stricter noise limits for vehicles, pushing manufacturers to develop quieter powertrains to comply with these regulations while maintaining the performance characteristics of V8 engines.

The automotive industry has responded to this market demand by introducing various noise reduction technologies. Active noise control systems, which use sound waves to cancel out engine noise, have gained popularity in high-end vehicles. Additionally, advanced sound insulation materials and redesigned exhaust systems have been employed to reduce engine noise without compromising performance.

The aftermarket sector has also seen growth in products designed to reduce V8 engine noise. Performance enthusiasts are increasingly seeking solutions that allow them to enjoy the power of their V8 engines while minimizing noise pollution, especially for daily driving in urban environments.

Market analysis suggests that the global market for automotive noise, vibration, and harshness (NVH) solutions is expanding rapidly, with a significant portion attributed to V8 engine applications. This growth is expected to continue as consumers become more aware of the benefits of quieter engines and as regulations become more stringent.

Manufacturers are recognizing the potential for differentiation in the market through superior noise reduction technologies. Quieter V8 engines are becoming a selling point, particularly in the luxury and sports car segments where buyers are willing to pay a premium for enhanced comfort without sacrificing performance.

As the automotive industry transitions towards electrification, there is also a growing demand for hybrid powertrains that incorporate V8 engines. These systems require sophisticated noise reduction techniques to manage the interplay between electric and combustion power sources, further driving innovation in this field.

Consumer surveys indicate that noise reduction is becoming a key factor in purchasing decisions for premium vehicles. A significant portion of luxury car buyers now prioritize cabin quietness alongside traditional factors like performance and design. This shift in consumer preferences has prompted automakers to invest heavily in noise reduction technologies for their V8 engines.

Environmental regulations and noise pollution laws in many countries have also contributed to the demand for quieter engines. Urban areas, in particular, have implemented stricter noise limits for vehicles, pushing manufacturers to develop quieter powertrains to comply with these regulations while maintaining the performance characteristics of V8 engines.

The automotive industry has responded to this market demand by introducing various noise reduction technologies. Active noise control systems, which use sound waves to cancel out engine noise, have gained popularity in high-end vehicles. Additionally, advanced sound insulation materials and redesigned exhaust systems have been employed to reduce engine noise without compromising performance.

The aftermarket sector has also seen growth in products designed to reduce V8 engine noise. Performance enthusiasts are increasingly seeking solutions that allow them to enjoy the power of their V8 engines while minimizing noise pollution, especially for daily driving in urban environments.

Market analysis suggests that the global market for automotive noise, vibration, and harshness (NVH) solutions is expanding rapidly, with a significant portion attributed to V8 engine applications. This growth is expected to continue as consumers become more aware of the benefits of quieter engines and as regulations become more stringent.

Manufacturers are recognizing the potential for differentiation in the market through superior noise reduction technologies. Quieter V8 engines are becoming a selling point, particularly in the luxury and sports car segments where buyers are willing to pay a premium for enhanced comfort without sacrificing performance.

As the automotive industry transitions towards electrification, there is also a growing demand for hybrid powertrains that incorporate V8 engines. These systems require sophisticated noise reduction techniques to manage the interplay between electric and combustion power sources, further driving innovation in this field.

Current Noise Reduction Challenges in V8 Engines

V8 engines, known for their power and performance, continue to face significant noise reduction challenges. One of the primary issues is the inherent design of these engines, which involves eight cylinders arranged in a V-shape. This configuration, while efficient for power generation, creates complex vibration patterns that contribute to increased noise levels.

The combustion process in V8 engines generates substantial mechanical noise. The rapid firing sequence of eight cylinders produces a characteristic rumble that, while appealing to some enthusiasts, can be problematic in terms of regulatory compliance and consumer comfort. Addressing this fundamental source of noise without compromising engine performance remains a significant challenge for engineers.

Another major hurdle is the management of high-frequency noise emissions. V8 engines typically operate at higher RPMs compared to smaller engines, resulting in increased high-frequency noise that can be particularly irritating to the human ear. Developing effective solutions to attenuate these high-frequency components without adding excessive weight or complexity to the engine is an ongoing challenge.

The intake and exhaust systems of V8 engines also contribute significantly to overall noise levels. The large volume of air being drawn in and expelled creates turbulence and pressure waves that translate into noise. Designing intake and exhaust systems that effectively reduce noise while maintaining optimal engine breathing and performance is a delicate balancing act.

Heat management in V8 engines poses another challenge for noise reduction efforts. The substantial heat generated by these powerful engines can cause thermal expansion and contraction of components, leading to additional noise sources. Developing materials and designs that can withstand high temperatures while minimizing thermal-induced noise is an area of ongoing research and development.

Furthermore, the integration of noise reduction technologies with other engine systems presents its own set of challenges. For instance, the implementation of turbochargers or superchargers, common in modern V8 engines, introduces additional noise sources that must be addressed. Balancing the need for forced induction with noise reduction goals requires innovative engineering solutions.

Lastly, the automotive industry's push towards electrification and hybrid powertrains introduces new complexities in V8 engine noise reduction. As these engines are increasingly paired with electric motors in hybrid configurations, managing the transition between combustion and electric power modes while maintaining a consistent and pleasant sound profile becomes a critical challenge for engineers and acousticians.

The combustion process in V8 engines generates substantial mechanical noise. The rapid firing sequence of eight cylinders produces a characteristic rumble that, while appealing to some enthusiasts, can be problematic in terms of regulatory compliance and consumer comfort. Addressing this fundamental source of noise without compromising engine performance remains a significant challenge for engineers.

Another major hurdle is the management of high-frequency noise emissions. V8 engines typically operate at higher RPMs compared to smaller engines, resulting in increased high-frequency noise that can be particularly irritating to the human ear. Developing effective solutions to attenuate these high-frequency components without adding excessive weight or complexity to the engine is an ongoing challenge.

The intake and exhaust systems of V8 engines also contribute significantly to overall noise levels. The large volume of air being drawn in and expelled creates turbulence and pressure waves that translate into noise. Designing intake and exhaust systems that effectively reduce noise while maintaining optimal engine breathing and performance is a delicate balancing act.

Heat management in V8 engines poses another challenge for noise reduction efforts. The substantial heat generated by these powerful engines can cause thermal expansion and contraction of components, leading to additional noise sources. Developing materials and designs that can withstand high temperatures while minimizing thermal-induced noise is an area of ongoing research and development.

Furthermore, the integration of noise reduction technologies with other engine systems presents its own set of challenges. For instance, the implementation of turbochargers or superchargers, common in modern V8 engines, introduces additional noise sources that must be addressed. Balancing the need for forced induction with noise reduction goals requires innovative engineering solutions.

Lastly, the automotive industry's push towards electrification and hybrid powertrains introduces new complexities in V8 engine noise reduction. As these engines are increasingly paired with electric motors in hybrid configurations, managing the transition between combustion and electric power modes while maintaining a consistent and pleasant sound profile becomes a critical challenge for engineers and acousticians.

Existing V8 Engine Noise Reduction Solutions

01 Noise reduction systems for V8 engines

Various systems and methods are employed to reduce noise generated by V8 engines. These may include sound-absorbing materials, active noise control systems, and specially designed exhaust systems. Such solutions aim to minimize engine noise while maintaining performance.- Noise reduction systems for V8 engines: Various systems and methods are employed to reduce noise in V8 engines. These can include sound-absorbing materials, active noise control systems, and specially designed exhaust systems. Such solutions aim to minimize engine noise while maintaining performance.

- Engine component design for noise reduction: Specific design modifications to engine components can help reduce noise in V8 engines. This includes optimizing the shape and material of pistons, crankshafts, and engine blocks to minimize vibrations and resonance that contribute to noise.

- Exhaust system modifications for noise control: Modifications to the exhaust system can significantly impact V8 engine noise. This includes the use of specialized mufflers, resonators, and exhaust pipe designs to attenuate sound waves and reduce overall noise levels.

- Electronic noise cancellation techniques: Advanced electronic systems are used to actively cancel out unwanted engine noise. These systems use microphones to detect noise patterns and generate counter-waves through speakers, effectively reducing perceived engine noise inside the vehicle cabin.

- Vibration damping and isolation methods: Various techniques are employed to dampen and isolate engine vibrations, which are a significant source of noise. This includes the use of specialized engine mounts, damping materials, and isolation systems to prevent vibrations from propagating through the vehicle structure.

02 Engine component design for noise reduction

Specific design modifications to engine components can help reduce noise in V8 engines. This includes optimizing the shape and material of pistons, crankshafts, and cylinder heads to minimize vibrations and resonance that contribute to engine noise.Expand Specific Solutions03 Exhaust system modifications for noise control

Modifications to the exhaust system play a crucial role in managing V8 engine noise. This may involve the use of specialized mufflers, resonators, and exhaust pipe designs to attenuate sound waves and reduce overall noise levels without compromising engine performance.Expand Specific Solutions04 Electronic noise cancellation techniques

Advanced electronic systems are used to actively cancel or mask V8 engine noise. These may include sound wave analysis, generation of counter-phase sounds, and adaptive algorithms to dynamically adjust noise cancellation based on engine operating conditions.Expand Specific Solutions05 Vibration isolation and damping methods

Various techniques are employed to isolate and dampen engine vibrations, which are a significant source of noise in V8 engines. This includes the use of specialized engine mounts, dampers, and isolation materials to minimize the transmission of vibrations to the vehicle body and cabin.Expand Specific Solutions

Key Players in V8 Engine Noise Reduction Industry

The V8 engine noise reduction technology market is in a mature stage, with significant competition among established players. The global market size for automotive noise reduction solutions is substantial, driven by increasing consumer demand for quieter vehicles and stricter noise regulations. Major automotive manufacturers like Ford, GM, BMW, and Nissan are actively investing in noise reduction technologies, while specialized companies such as Tula Technology focus on innovative software solutions. The technology's maturity is evident from the involvement of diverse players, including traditional automakers, suppliers like Delphi and Hitachi Astemo, and research institutions. However, there's ongoing innovation, particularly in areas like active noise control and cylinder deactivation, indicating potential for further market growth and technological advancements.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Active Noise Control (ANC) system specifically designed for V8 engines. This system utilizes strategically placed microphones to detect engine noise and generates opposing sound waves through the vehicle's audio system to cancel out unwanted frequencies. Ford's ANC technology is particularly effective at reducing low-frequency rumble associated with V8 engines, improving cabin comfort without compromising the engine's distinctive sound character[1]. The system is adaptive, continuously adjusting to changes in engine speed and load, ensuring optimal noise reduction across various driving conditions[2]. Additionally, Ford has implemented advanced engine mount designs that incorporate hydraulic chambers and electronic controls to actively counteract engine vibrations, further reducing noise transmission to the vehicle interior[3].

Strengths: Highly effective at reducing low-frequency noise; adaptive to various driving conditions; preserves desirable engine sound characteristics. Weaknesses: Requires complex integration with vehicle audio system; may add cost and weight to the vehicle.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a multi-faceted approach to V8 engine noise reduction, combining both active and passive technologies. Their Dynamic Fuel Management (DFM) system, which can deactivate up to seven cylinders in a V8 engine, not only improves fuel efficiency but also contributes to noise reduction by minimizing the number of active cylinders during light load conditions[4]. GM has also developed an advanced exhaust valve system that modulates exhaust flow to reduce noise at specific frequencies. This system uses electronically controlled valves in the exhaust stream to create destructive interference, effectively canceling out certain exhaust tones[5]. Furthermore, GM employs a sophisticated engine encapsulation strategy, using multi-layer acoustic materials and targeted insulation to contain engine noise at its source[6].

Strengths: Comprehensive approach addressing multiple noise sources; fuel efficiency benefits alongside noise reduction; effective across various engine operating conditions. Weaknesses: Complex systems may increase maintenance complexity; potential for increased vehicle weight due to additional components.

Core Innovations in V8 Engine Noise Reduction

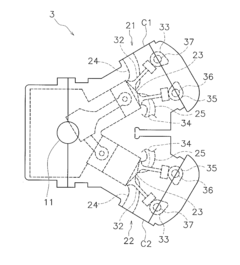

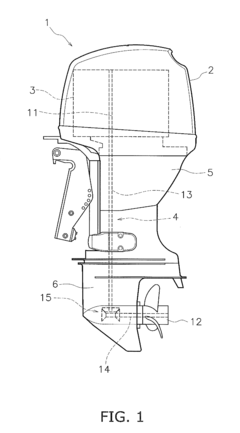

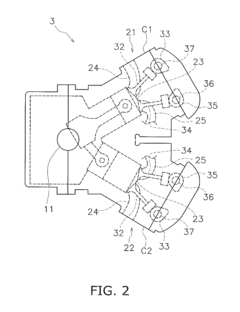

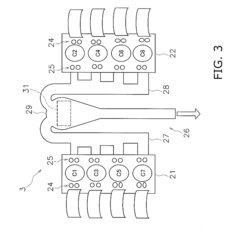

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

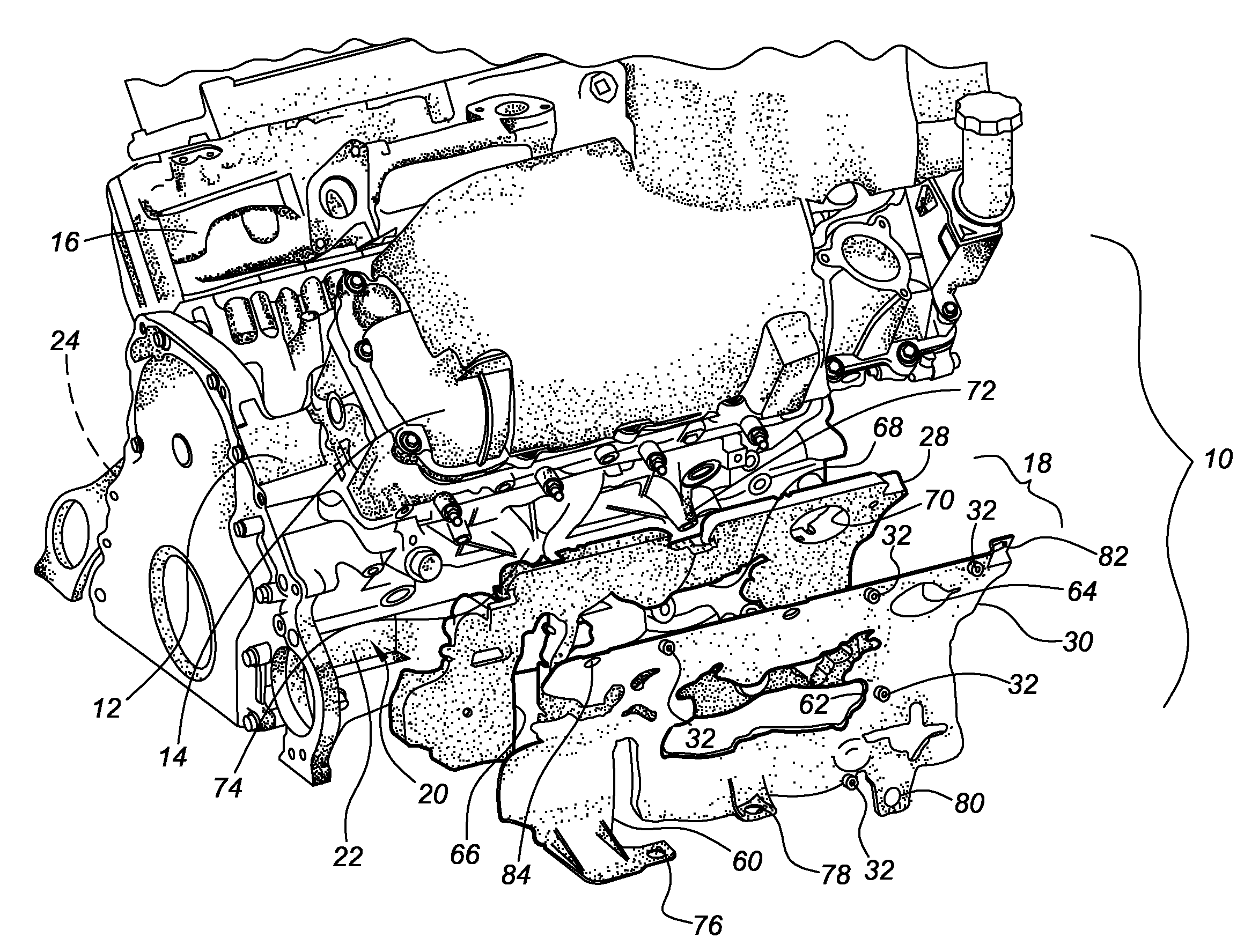

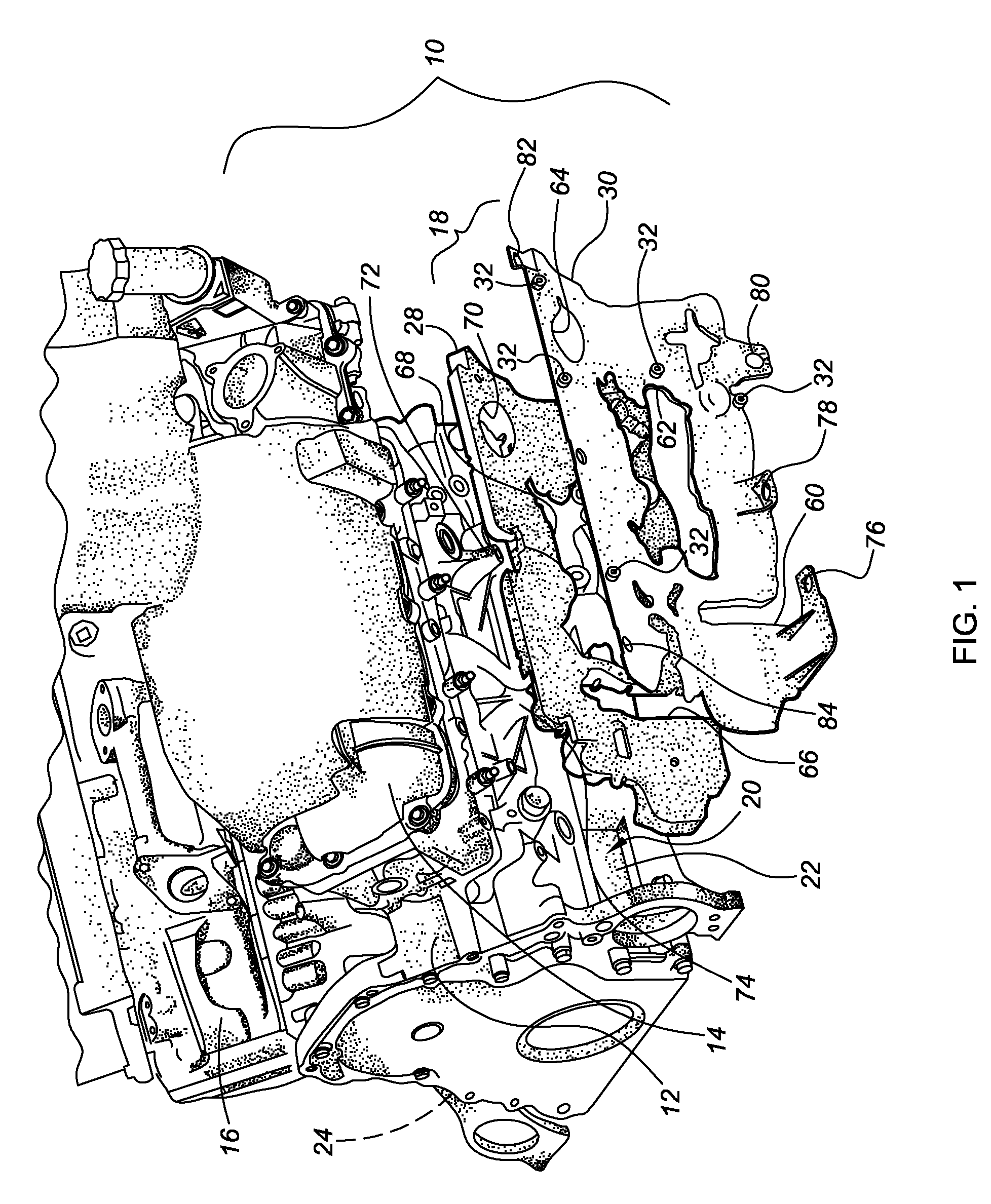

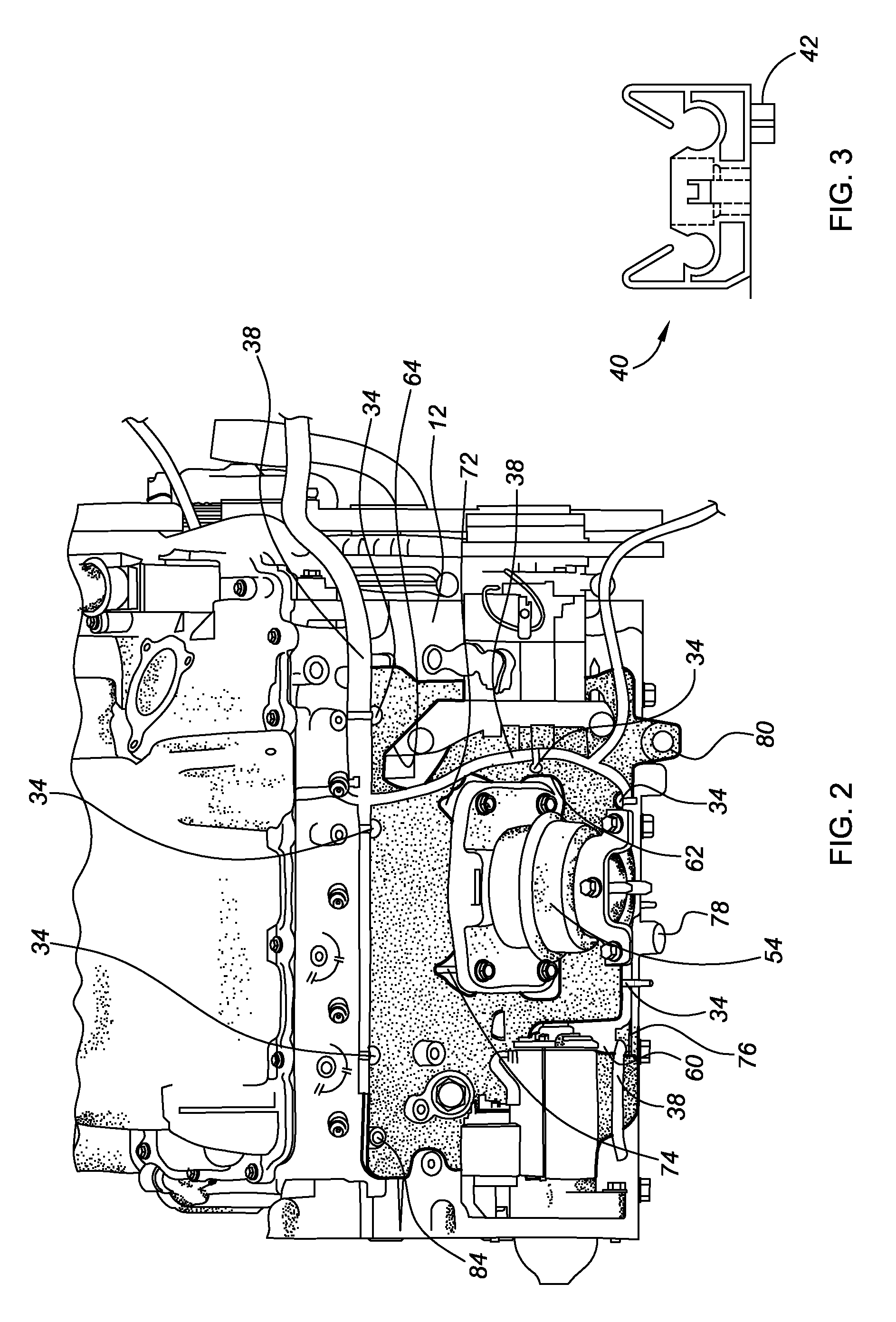

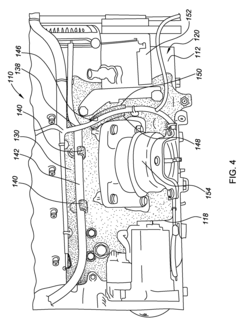

Acoustic Side Cover for an Engine

PatentInactiveUS20090056668A1

Innovation

- A multi-layer side cover for engines featuring a compliant acoustic-absorbing inner layer and a rigid outer shell layer that acts as an acoustic barrier, reducing the need for bosses and supporting engine components, thereby minimizing noise while optimizing mass and fuel efficiency.

Environmental Impact of V8 Engine Noise Reduction

The reduction of noise from V8 engines has significant environmental implications, extending beyond the immediate benefits to drivers and passengers. As urban areas continue to expand and vehicle usage increases, the cumulative impact of engine noise on the environment has become a growing concern for policymakers, environmentalists, and the automotive industry.

One of the primary environmental benefits of V8 engine noise reduction is the mitigation of noise pollution in urban and suburban areas. Excessive noise from vehicles, particularly those with powerful V8 engines, can disrupt local ecosystems, affecting wildlife behavior and breeding patterns. By implementing advanced noise reduction techniques, such as improved exhaust systems and engine encapsulation, the overall ambient noise levels in populated areas can be significantly reduced.

This reduction in noise pollution has cascading effects on human health and well-being. Studies have shown that prolonged exposure to high levels of traffic noise can lead to increased stress, sleep disturbances, and cardiovascular issues among residents living near busy roads. By minimizing V8 engine noise, these health risks can be mitigated, potentially leading to improved quality of life and reduced healthcare costs for affected communities.

Furthermore, the environmental impact of V8 engine noise reduction extends to the realm of urban planning and development. As noise levels decrease, areas previously considered unsuitable for residential or commercial development due to proximity to high-traffic roads may become viable. This could lead to more efficient land use and potentially reduce urban sprawl, indirectly contributing to conservation efforts and reduced carbon emissions associated with longer commutes.

The automotive industry's focus on V8 engine noise reduction also drives innovation in materials science and engineering. The development of advanced sound-absorbing materials and noise-canceling technologies not only benefits vehicle occupants but can find applications in other industries, such as construction and manufacturing, further reducing overall environmental noise pollution.

Additionally, the pursuit of quieter V8 engines often aligns with efforts to improve fuel efficiency and reduce emissions. Many noise reduction techniques, such as optimizing combustion processes and improving engine design, can lead to more efficient engine operation. This synergy between noise reduction and improved environmental performance underscores the holistic approach needed in addressing automotive environmental impacts.

In conclusion, the environmental impact of V8 engine noise reduction is multifaceted, encompassing improvements in ecosystem health, human well-being, urban development, and technological innovation. As automotive manufacturers continue to invest in noise reduction technologies, the broader environmental benefits are likely to become increasingly apparent, contributing to more sustainable and livable urban environments.

One of the primary environmental benefits of V8 engine noise reduction is the mitigation of noise pollution in urban and suburban areas. Excessive noise from vehicles, particularly those with powerful V8 engines, can disrupt local ecosystems, affecting wildlife behavior and breeding patterns. By implementing advanced noise reduction techniques, such as improved exhaust systems and engine encapsulation, the overall ambient noise levels in populated areas can be significantly reduced.

This reduction in noise pollution has cascading effects on human health and well-being. Studies have shown that prolonged exposure to high levels of traffic noise can lead to increased stress, sleep disturbances, and cardiovascular issues among residents living near busy roads. By minimizing V8 engine noise, these health risks can be mitigated, potentially leading to improved quality of life and reduced healthcare costs for affected communities.

Furthermore, the environmental impact of V8 engine noise reduction extends to the realm of urban planning and development. As noise levels decrease, areas previously considered unsuitable for residential or commercial development due to proximity to high-traffic roads may become viable. This could lead to more efficient land use and potentially reduce urban sprawl, indirectly contributing to conservation efforts and reduced carbon emissions associated with longer commutes.

The automotive industry's focus on V8 engine noise reduction also drives innovation in materials science and engineering. The development of advanced sound-absorbing materials and noise-canceling technologies not only benefits vehicle occupants but can find applications in other industries, such as construction and manufacturing, further reducing overall environmental noise pollution.

Additionally, the pursuit of quieter V8 engines often aligns with efforts to improve fuel efficiency and reduce emissions. Many noise reduction techniques, such as optimizing combustion processes and improving engine design, can lead to more efficient engine operation. This synergy between noise reduction and improved environmental performance underscores the holistic approach needed in addressing automotive environmental impacts.

In conclusion, the environmental impact of V8 engine noise reduction is multifaceted, encompassing improvements in ecosystem health, human well-being, urban development, and technological innovation. As automotive manufacturers continue to invest in noise reduction technologies, the broader environmental benefits are likely to become increasingly apparent, contributing to more sustainable and livable urban environments.

Cost-Benefit Analysis of Noise Reduction Techniques

The cost-benefit analysis of noise reduction techniques for V8 engines is a critical aspect of automotive engineering and design. This analysis involves evaluating the financial implications of implementing various noise reduction methods against the potential benefits they offer.

One of the primary considerations in this analysis is the cost of materials and manufacturing processes required for noise reduction. Advanced sound-absorbing materials, such as acoustic foams and composite panels, can significantly increase production costs. Similarly, redesigning engine components or incorporating additional insulation layers may require substantial investments in tooling and production line modifications.

Labor costs associated with the implementation of noise reduction techniques must also be factored in. This includes the time and expertise required for research and development, as well as the additional assembly time needed for more complex noise reduction systems. Training costs for workers to handle new materials or assembly processes should also be considered.

On the benefit side, reduced engine noise can lead to improved customer satisfaction and potentially increased sales. A quieter V8 engine may be perceived as more refined and luxurious, allowing manufacturers to command higher prices or gain a competitive edge in the market. This could result in increased revenue and market share, offsetting the initial investment in noise reduction technologies.

Regulatory compliance is another crucial factor in the cost-benefit equation. As noise emission standards become more stringent, investing in effective noise reduction techniques can help manufacturers avoid costly fines and ensure their vehicles remain compliant across various markets. This proactive approach can save significant expenses in the long run and maintain the company's ability to sell in key markets.

Fuel efficiency implications must also be weighed. Some noise reduction techniques, such as adding weight through insulation, may negatively impact fuel economy. However, other methods, like improving engine design for smoother operation, could potentially enhance efficiency. The long-term cost savings or additional expenses related to fuel consumption should be carefully calculated and factored into the overall analysis.

Maintenance and warranty costs are additional considerations. While some noise reduction techniques may increase the complexity of engine systems and potentially lead to higher maintenance costs, others could result in reduced wear and tear, extending the engine's lifespan and decreasing warranty claims. This balance must be carefully evaluated to determine the true long-term financial impact of noise reduction measures.

In conclusion, a comprehensive cost-benefit analysis of V8 engine noise reduction techniques requires a multifaceted approach, considering immediate costs, long-term financial implications, regulatory factors, and potential market advantages. This analysis is essential for automotive manufacturers to make informed decisions that balance engineering innovation with economic viability.

One of the primary considerations in this analysis is the cost of materials and manufacturing processes required for noise reduction. Advanced sound-absorbing materials, such as acoustic foams and composite panels, can significantly increase production costs. Similarly, redesigning engine components or incorporating additional insulation layers may require substantial investments in tooling and production line modifications.

Labor costs associated with the implementation of noise reduction techniques must also be factored in. This includes the time and expertise required for research and development, as well as the additional assembly time needed for more complex noise reduction systems. Training costs for workers to handle new materials or assembly processes should also be considered.

On the benefit side, reduced engine noise can lead to improved customer satisfaction and potentially increased sales. A quieter V8 engine may be perceived as more refined and luxurious, allowing manufacturers to command higher prices or gain a competitive edge in the market. This could result in increased revenue and market share, offsetting the initial investment in noise reduction technologies.

Regulatory compliance is another crucial factor in the cost-benefit equation. As noise emission standards become more stringent, investing in effective noise reduction techniques can help manufacturers avoid costly fines and ensure their vehicles remain compliant across various markets. This proactive approach can save significant expenses in the long run and maintain the company's ability to sell in key markets.

Fuel efficiency implications must also be weighed. Some noise reduction techniques, such as adding weight through insulation, may negatively impact fuel economy. However, other methods, like improving engine design for smoother operation, could potentially enhance efficiency. The long-term cost savings or additional expenses related to fuel consumption should be carefully calculated and factored into the overall analysis.

Maintenance and warranty costs are additional considerations. While some noise reduction techniques may increase the complexity of engine systems and potentially lead to higher maintenance costs, others could result in reduced wear and tear, extending the engine's lifespan and decreasing warranty claims. This balance must be carefully evaluated to determine the true long-term financial impact of noise reduction measures.

In conclusion, a comprehensive cost-benefit analysis of V8 engine noise reduction techniques requires a multifaceted approach, considering immediate costs, long-term financial implications, regulatory factors, and potential market advantages. This analysis is essential for automotive manufacturers to make informed decisions that balance engineering innovation with economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!