V8 Engine Role in Next-Gen Energy Efficiency Measures

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Efficiency Goals

The V8 engine has been a cornerstone of automotive technology for over a century, evolving significantly to meet changing demands for performance, efficiency, and environmental sustainability. Initially developed in the early 1900s, V8 engines quickly gained popularity due to their smooth operation and power output. Over the decades, they have undergone numerous refinements to address the growing need for fuel efficiency and reduced emissions.

In recent years, the focus on energy efficiency has intensified, driven by stricter environmental regulations and consumer demand for more economical vehicles. This has led to a new era in V8 engine development, with manufacturers exploring innovative technologies to enhance efficiency without compromising performance. Modern V8 engines incorporate advanced features such as direct fuel injection, variable valve timing, and cylinder deactivation to optimize fuel consumption and reduce emissions.

The evolution of V8 engines has been marked by several key milestones. The introduction of electronic fuel injection in the 1980s significantly improved fuel economy and engine control. In the 1990s and 2000s, the implementation of variable valve timing and lift systems further enhanced efficiency by optimizing engine breathing across different operating conditions. More recently, the adoption of turbocharging and supercharging has allowed for engine downsizing while maintaining or even increasing power output.

Looking ahead, the goals for V8 engine efficiency are ambitious and multifaceted. Manufacturers are targeting substantial improvements in fuel economy, aiming to achieve figures that were once thought impossible for high-displacement engines. This includes reducing fuel consumption by up to 20-30% compared to previous generations while maintaining or enhancing performance characteristics.

Emissions reduction is another critical objective, with engineers working to meet increasingly stringent global standards. This involves not only reducing CO2 emissions but also minimizing other pollutants such as NOx and particulate matter. Advanced exhaust after-treatment systems and improved combustion processes are key areas of focus to achieve these goals.

Furthermore, there is a growing emphasis on integrating V8 engines into hybrid powertrains. This approach aims to combine the traditional strengths of V8 engines with the efficiency benefits of electric propulsion. The goal is to create powertrains that offer the best of both worlds: the exhilarating performance of a V8 with significantly reduced fuel consumption and emissions.

As the automotive industry transitions towards electrification, the role of V8 engines is evolving. While they may become less common in mainstream vehicles, there is still a strong focus on developing highly efficient V8 engines for specific applications, such as performance vehicles, luxury cars, and certain commercial vehicles where their unique characteristics remain valuable.

In recent years, the focus on energy efficiency has intensified, driven by stricter environmental regulations and consumer demand for more economical vehicles. This has led to a new era in V8 engine development, with manufacturers exploring innovative technologies to enhance efficiency without compromising performance. Modern V8 engines incorporate advanced features such as direct fuel injection, variable valve timing, and cylinder deactivation to optimize fuel consumption and reduce emissions.

The evolution of V8 engines has been marked by several key milestones. The introduction of electronic fuel injection in the 1980s significantly improved fuel economy and engine control. In the 1990s and 2000s, the implementation of variable valve timing and lift systems further enhanced efficiency by optimizing engine breathing across different operating conditions. More recently, the adoption of turbocharging and supercharging has allowed for engine downsizing while maintaining or even increasing power output.

Looking ahead, the goals for V8 engine efficiency are ambitious and multifaceted. Manufacturers are targeting substantial improvements in fuel economy, aiming to achieve figures that were once thought impossible for high-displacement engines. This includes reducing fuel consumption by up to 20-30% compared to previous generations while maintaining or enhancing performance characteristics.

Emissions reduction is another critical objective, with engineers working to meet increasingly stringent global standards. This involves not only reducing CO2 emissions but also minimizing other pollutants such as NOx and particulate matter. Advanced exhaust after-treatment systems and improved combustion processes are key areas of focus to achieve these goals.

Furthermore, there is a growing emphasis on integrating V8 engines into hybrid powertrains. This approach aims to combine the traditional strengths of V8 engines with the efficiency benefits of electric propulsion. The goal is to create powertrains that offer the best of both worlds: the exhilarating performance of a V8 with significantly reduced fuel consumption and emissions.

As the automotive industry transitions towards electrification, the role of V8 engines is evolving. While they may become less common in mainstream vehicles, there is still a strong focus on developing highly efficient V8 engines for specific applications, such as performance vehicles, luxury cars, and certain commercial vehicles where their unique characteristics remain valuable.

Market Demand for Fuel-Efficient V8 Engines

The market demand for fuel-efficient V8 engines has been evolving rapidly in recent years, driven by a combination of regulatory pressures, consumer preferences, and technological advancements. As governments worldwide implement stricter emissions standards and fuel economy regulations, automakers are facing increasing pressure to improve the efficiency of their high-performance engines, including V8s.

In the luxury and performance vehicle segments, where V8 engines are most prevalent, there is a growing demand for powertrains that can deliver both high performance and improved fuel economy. This trend is particularly evident in markets such as North America and Europe, where consumers are seeking vehicles that offer the power and prestige of a V8 engine without compromising on fuel efficiency.

The automotive industry has witnessed a shift in consumer behavior, with a growing emphasis on environmental consciousness and operating costs. This has led to increased interest in fuel-efficient V8 engines among buyers who are unwilling to compromise on performance but are also mindful of their carbon footprint and fuel expenses.

Market research indicates that the global market for fuel-efficient V8 engines is expected to grow steadily over the next decade. This growth is attributed to the ongoing development of advanced technologies such as cylinder deactivation, direct injection, and turbocharging, which are enabling manufacturers to produce V8 engines that meet both performance and efficiency requirements.

In the sports car and high-performance vehicle segment, there is a strong demand for V8 engines that can deliver impressive power outputs while also meeting increasingly stringent emissions standards. This has led to the development of hybrid and mild-hybrid V8 powertrains, which are gaining traction in the market due to their ability to provide enhanced fuel efficiency without sacrificing the characteristic V8 sound and power delivery.

The commercial vehicle sector, particularly in heavy-duty trucks and large SUVs, also shows a significant demand for more fuel-efficient V8 engines. Fleet operators and businesses are increasingly looking for ways to reduce their fuel costs and environmental impact, creating a market opportunity for advanced V8 engine technologies in this segment.

As the automotive industry continues its transition towards electrification, there is a niche but persistent demand for fuel-efficient V8 engines in specialized applications and enthusiast markets. This includes high-end sports cars, luxury vehicles, and certain commercial applications where the unique characteristics of V8 engines remain highly valued.

In the luxury and performance vehicle segments, where V8 engines are most prevalent, there is a growing demand for powertrains that can deliver both high performance and improved fuel economy. This trend is particularly evident in markets such as North America and Europe, where consumers are seeking vehicles that offer the power and prestige of a V8 engine without compromising on fuel efficiency.

The automotive industry has witnessed a shift in consumer behavior, with a growing emphasis on environmental consciousness and operating costs. This has led to increased interest in fuel-efficient V8 engines among buyers who are unwilling to compromise on performance but are also mindful of their carbon footprint and fuel expenses.

Market research indicates that the global market for fuel-efficient V8 engines is expected to grow steadily over the next decade. This growth is attributed to the ongoing development of advanced technologies such as cylinder deactivation, direct injection, and turbocharging, which are enabling manufacturers to produce V8 engines that meet both performance and efficiency requirements.

In the sports car and high-performance vehicle segment, there is a strong demand for V8 engines that can deliver impressive power outputs while also meeting increasingly stringent emissions standards. This has led to the development of hybrid and mild-hybrid V8 powertrains, which are gaining traction in the market due to their ability to provide enhanced fuel efficiency without sacrificing the characteristic V8 sound and power delivery.

The commercial vehicle sector, particularly in heavy-duty trucks and large SUVs, also shows a significant demand for more fuel-efficient V8 engines. Fleet operators and businesses are increasingly looking for ways to reduce their fuel costs and environmental impact, creating a market opportunity for advanced V8 engine technologies in this segment.

As the automotive industry continues its transition towards electrification, there is a niche but persistent demand for fuel-efficient V8 engines in specialized applications and enthusiast markets. This includes high-end sports cars, luxury vehicles, and certain commercial applications where the unique characteristics of V8 engines remain highly valued.

Current V8 Technology and Efficiency Challenges

The V8 engine, a stalwart of automotive technology, faces significant challenges in meeting next-generation energy efficiency measures. Current V8 technology, while powerful and popular among enthusiasts, struggles to keep pace with increasingly stringent environmental regulations and the global push for reduced carbon emissions.

One of the primary challenges facing V8 engines is their inherently high fuel consumption. Traditional V8 designs, with their large displacement and multiple cylinders, consume more fuel than smaller, more efficient engines. This characteristic makes it difficult for V8-powered vehicles to meet ever-tightening fuel economy standards, particularly in urban driving conditions where stop-and-start traffic exacerbates fuel inefficiency.

Emissions control presents another significant hurdle for V8 engines. The higher fuel consumption translates directly to increased carbon dioxide emissions, a major contributor to greenhouse gases. Additionally, V8 engines typically produce higher levels of nitrogen oxides (NOx) and particulate matter, both of which are subject to strict regulatory limits in many countries.

Thermal efficiency is a critical area where V8 engines lag behind more modern designs. Current V8 technology often struggles to convert a high percentage of fuel energy into useful mechanical work, with much energy lost as heat. This inefficiency not only impacts fuel economy but also increases the cooling requirements of the engine, adding weight and complexity to the overall vehicle design.

The weight of V8 engines themselves poses another challenge to efficiency. Their larger size and higher number of components compared to smaller engines contribute to increased vehicle weight, which in turn requires more energy to move the vehicle, creating a cycle of inefficiency.

Advancements in turbocharging and direct injection have somewhat mitigated these issues, allowing for smaller displacement V8 engines that maintain power output while improving efficiency. However, these technologies also introduce additional complexity and potential reliability concerns.

The integration of hybrid systems with V8 engines has shown promise in addressing efficiency challenges. By combining electric motors with V8 power, manufacturers can improve low-speed efficiency and reduce overall fuel consumption. However, the added weight and complexity of hybrid systems present their own set of challenges in terms of cost, packaging, and weight distribution.

As the automotive industry shifts towards electrification, the role of V8 engines in mainstream vehicles is increasingly questioned. The inherent inefficiencies of internal combustion engines, particularly larger ones like V8s, become more pronounced when compared to the efficiency of electric powertrains.

In conclusion, while V8 engines continue to offer unparalleled performance and character, their current technology faces significant challenges in meeting future energy efficiency requirements. Overcoming these hurdles will require innovative engineering solutions and may ultimately lead to a redefinition of the V8's role in the automotive landscape.

One of the primary challenges facing V8 engines is their inherently high fuel consumption. Traditional V8 designs, with their large displacement and multiple cylinders, consume more fuel than smaller, more efficient engines. This characteristic makes it difficult for V8-powered vehicles to meet ever-tightening fuel economy standards, particularly in urban driving conditions where stop-and-start traffic exacerbates fuel inefficiency.

Emissions control presents another significant hurdle for V8 engines. The higher fuel consumption translates directly to increased carbon dioxide emissions, a major contributor to greenhouse gases. Additionally, V8 engines typically produce higher levels of nitrogen oxides (NOx) and particulate matter, both of which are subject to strict regulatory limits in many countries.

Thermal efficiency is a critical area where V8 engines lag behind more modern designs. Current V8 technology often struggles to convert a high percentage of fuel energy into useful mechanical work, with much energy lost as heat. This inefficiency not only impacts fuel economy but also increases the cooling requirements of the engine, adding weight and complexity to the overall vehicle design.

The weight of V8 engines themselves poses another challenge to efficiency. Their larger size and higher number of components compared to smaller engines contribute to increased vehicle weight, which in turn requires more energy to move the vehicle, creating a cycle of inefficiency.

Advancements in turbocharging and direct injection have somewhat mitigated these issues, allowing for smaller displacement V8 engines that maintain power output while improving efficiency. However, these technologies also introduce additional complexity and potential reliability concerns.

The integration of hybrid systems with V8 engines has shown promise in addressing efficiency challenges. By combining electric motors with V8 power, manufacturers can improve low-speed efficiency and reduce overall fuel consumption. However, the added weight and complexity of hybrid systems present their own set of challenges in terms of cost, packaging, and weight distribution.

As the automotive industry shifts towards electrification, the role of V8 engines in mainstream vehicles is increasingly questioned. The inherent inefficiencies of internal combustion engines, particularly larger ones like V8s, become more pronounced when compared to the efficiency of electric powertrains.

In conclusion, while V8 engines continue to offer unparalleled performance and character, their current technology faces significant challenges in meeting future energy efficiency requirements. Overcoming these hurdles will require innovative engineering solutions and may ultimately lead to a redefinition of the V8's role in the automotive landscape.

Current V8 Efficiency Enhancement Solutions

01 Improved combustion efficiency

V8 engines can achieve higher energy efficiency through optimized combustion processes. This includes advanced fuel injection systems, improved air intake designs, and enhanced combustion chamber geometries. These improvements lead to more complete fuel burning, reduced emissions, and increased power output.- Improved combustion efficiency: Various techniques are employed to enhance the combustion efficiency of V8 engines. These include optimizing fuel injection systems, improving air intake designs, and implementing advanced ignition timing control. Such improvements lead to better fuel utilization and increased overall energy efficiency.

- Thermal management systems: Advanced thermal management systems are integrated into V8 engines to regulate temperature and reduce energy losses. These systems may include intelligent cooling circuits, heat recovery mechanisms, and thermal insulation techniques, all contributing to improved energy efficiency and performance.

- Variable displacement technology: V8 engines incorporate variable displacement technology, allowing them to operate on fewer cylinders under light load conditions. This adaptive functionality significantly reduces fuel consumption and improves overall energy efficiency, particularly during highway cruising or low-demand situations.

- Friction reduction techniques: Various friction reduction techniques are applied to V8 engines to minimize energy losses. These may include advanced surface treatments, low-friction coatings, and optimized component designs. Reducing internal friction contributes to improved mechanical efficiency and overall engine performance.

- Electronic control systems: Sophisticated electronic control systems are implemented in V8 engines to optimize various parameters in real-time. These systems manage fuel injection, ignition timing, valve timing, and other critical functions to ensure optimal energy efficiency across different operating conditions.

02 Variable displacement technology

Implementing variable displacement technology in V8 engines allows for selective deactivation of cylinders during low-load conditions. This reduces fuel consumption and improves overall energy efficiency by operating the engine with fewer cylinders when full power is not required.Expand Specific Solutions03 Advanced thermal management

Enhancing thermal management in V8 engines can significantly improve energy efficiency. This includes optimizing coolant flow, implementing advanced heat recovery systems, and using thermal barrier coatings. Effective thermal management reduces energy losses and improves overall engine performance.Expand Specific Solutions04 Friction reduction techniques

Reducing friction within V8 engines can lead to improved energy efficiency. This involves using advanced lubricants, implementing low-friction coatings on engine components, and optimizing piston and ring designs. Minimizing friction losses results in better fuel economy and increased power output.Expand Specific Solutions05 Electronic control and monitoring systems

Implementing advanced electronic control and monitoring systems in V8 engines can optimize performance and energy efficiency. These systems can adjust engine parameters in real-time, manage fuel injection, control valve timing, and monitor various engine functions to ensure optimal operation under different conditions.Expand Specific Solutions

Major V8 Engine Manufacturers and Innovators

The V8 engine's role in next-generation energy efficiency measures is characterized by a competitive landscape in transition. The industry is moving from mature V8 technology towards more efficient alternatives, reflecting growing environmental concerns and stricter emissions regulations. Market size remains significant, but is gradually shrinking as automakers shift focus to hybrid and electric powertrains. Technologically, companies like Toyota, Ford, and BMW are at the forefront, developing advanced V8 engines with improved fuel efficiency and reduced emissions. However, emerging players such as Tesla and other electric vehicle manufacturers are challenging traditional V8 dominance, pushing the industry towards a more diverse and sustainable future.

Toyota Motor Corp.

Technical Solution: Toyota has developed a high-efficiency V8 engine that incorporates advanced technologies to improve fuel economy and reduce emissions. The engine features direct injection, variable valve timing, and cylinder deactivation[1]. Toyota's V8 engine employs a high compression ratio of 13:1, which improves thermal efficiency[2]. The company has also implemented a water-cooled exhaust gas recirculation (EGR) system to reduce NOx emissions and improve fuel efficiency[3]. Additionally, Toyota has integrated a start-stop system into their V8 engines, which automatically shuts off the engine when the vehicle is stationary, further reducing fuel consumption and emissions in urban driving conditions[4].

Strengths: High thermal efficiency, reduced emissions, and improved fuel economy. Weaknesses: Complexity of the system may lead to higher maintenance costs and potential reliability issues in the long term.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative V8 engine technology called "Plasma Coating Technology" for cylinder liners. This process replaces traditional iron cylinder liners with a thin plasma coating, reducing weight and improving heat transfer[1]. The company has also implemented advanced fuel injection systems, including direct injection and port fuel injection, to optimize fuel delivery and combustion efficiency[2]. Ford's V8 engines feature variable camshaft timing and cylinder deactivation, allowing for improved fuel economy under various driving conditions[3]. Additionally, Ford has integrated a twin-turbocharging system in some V8 models, which provides increased power output while maintaining fuel efficiency through downsizing[4].

Strengths: Lightweight design, improved heat management, and flexible power delivery. Weaknesses: Higher production costs and potential durability concerns with new coating technology.

Key Innovations in V8 Engine Efficiency

V engine

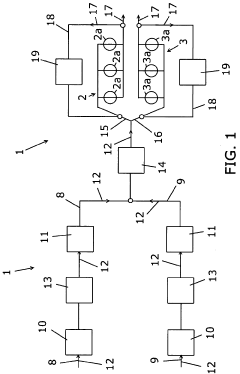

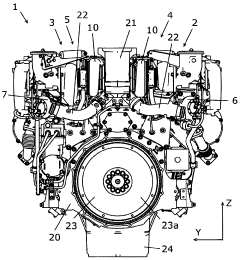

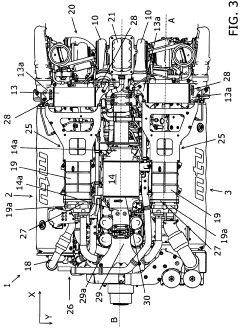

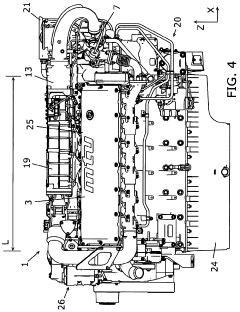

PatentWO2011054513A1

Innovation

- A V-engine design featuring a two-stage charging system with low-pressure and high-pressure exhaust gas turbochargers arranged above the main output element, incorporating an intermediate charge air cooler, main charge air cooler, exhaust gas recirculation, and a mixer element to optimize charge air flow and reduce emissions, while maintaining a compact layout.

V engine

PatentInactiveEP2496805A1

Innovation

- A V-type engine design featuring a two-stage charging system with low-pressure and high-pressure exhaust gas turbochargers, integrated charge air coolers, and exhaust gas recirculation, arranged to optimize space and reduce nitrogen oxide emissions through a specific layout of components such as turbochargers, coolers, and a mixer element.

Environmental Regulations Impact on V8 Engines

Environmental regulations have significantly impacted the development and future of V8 engines, particularly in the context of next-generation energy efficiency measures. These regulations, primarily aimed at reducing greenhouse gas emissions and improving fuel economy, have forced manufacturers to adapt their V8 engine designs or consider alternative powertrains.

In recent years, many countries have implemented stringent emissions standards, such as the European Union's Euro 6 and the United States' EPA Tier 3 regulations. These standards have set increasingly strict limits on pollutants like carbon dioxide, nitrogen oxides, and particulate matter. As a result, V8 engine manufacturers have had to invest heavily in advanced technologies to meet these requirements.

One of the primary strategies employed by manufacturers is the integration of advanced fuel injection systems and improved combustion chamber designs. These enhancements allow for more precise fuel delivery and better combustion efficiency, reducing emissions while maintaining performance. Additionally, many V8 engines now incorporate variable valve timing and cylinder deactivation technologies, which can selectively shut down cylinders during low-load conditions to improve fuel economy.

The implementation of turbocharging and supercharging has also become more prevalent in V8 engines. These forced induction systems allow for smaller displacement engines to produce comparable power to larger naturally aspirated units, while potentially reducing fuel consumption and emissions. This trend towards "downsizing" has led to the development of more compact V8 engines that can still deliver the performance expected from this configuration.

However, despite these advancements, the long-term viability of V8 engines in many markets is increasingly uncertain. Several countries have announced plans to ban the sale of new internal combustion engine vehicles in the coming decades. For instance, the United Kingdom has set a target to end the sale of new petrol and diesel cars by 2030, with hybrid vehicles following in 2035.

These regulatory pressures have led some manufacturers to shift their focus towards electrification. Many are developing hybrid V8 powertrains that combine the traditional engine with electric motors, offering improved efficiency and reduced emissions. Some luxury and performance car makers are even exploring fully electric alternatives to their V8-powered models.

The impact of environmental regulations on V8 engines extends beyond passenger vehicles. In the commercial and industrial sectors, where V8 engines are often used in heavy-duty applications, manufacturers are exploring alternative fuels such as hydrogen and biofuels to meet emissions targets while maintaining the power and torque characteristics of V8 engines.

In recent years, many countries have implemented stringent emissions standards, such as the European Union's Euro 6 and the United States' EPA Tier 3 regulations. These standards have set increasingly strict limits on pollutants like carbon dioxide, nitrogen oxides, and particulate matter. As a result, V8 engine manufacturers have had to invest heavily in advanced technologies to meet these requirements.

One of the primary strategies employed by manufacturers is the integration of advanced fuel injection systems and improved combustion chamber designs. These enhancements allow for more precise fuel delivery and better combustion efficiency, reducing emissions while maintaining performance. Additionally, many V8 engines now incorporate variable valve timing and cylinder deactivation technologies, which can selectively shut down cylinders during low-load conditions to improve fuel economy.

The implementation of turbocharging and supercharging has also become more prevalent in V8 engines. These forced induction systems allow for smaller displacement engines to produce comparable power to larger naturally aspirated units, while potentially reducing fuel consumption and emissions. This trend towards "downsizing" has led to the development of more compact V8 engines that can still deliver the performance expected from this configuration.

However, despite these advancements, the long-term viability of V8 engines in many markets is increasingly uncertain. Several countries have announced plans to ban the sale of new internal combustion engine vehicles in the coming decades. For instance, the United Kingdom has set a target to end the sale of new petrol and diesel cars by 2030, with hybrid vehicles following in 2035.

These regulatory pressures have led some manufacturers to shift their focus towards electrification. Many are developing hybrid V8 powertrains that combine the traditional engine with electric motors, offering improved efficiency and reduced emissions. Some luxury and performance car makers are even exploring fully electric alternatives to their V8-powered models.

The impact of environmental regulations on V8 engines extends beyond passenger vehicles. In the commercial and industrial sectors, where V8 engines are often used in heavy-duty applications, manufacturers are exploring alternative fuels such as hydrogen and biofuels to meet emissions targets while maintaining the power and torque characteristics of V8 engines.

V8 Engine Hybridization Potential

The hybridization potential of V8 engines represents a significant avenue for enhancing energy efficiency in next-generation vehicles. This approach combines the power and performance characteristics of traditional V8 engines with electric propulsion systems, offering a bridge between conventional internal combustion technology and fully electric powertrains.

V8 hybrid systems typically integrate one or more electric motors with the combustion engine, allowing for various operational modes. These include pure electric driving for short distances, engine assist during acceleration, and regenerative braking to recover energy. The electric components can be sized to provide substantial power boost, enabling downsizing of the V8 engine while maintaining or even improving overall performance.

One of the key advantages of V8 hybridization is the ability to significantly reduce fuel consumption and emissions, particularly in urban driving scenarios. The electric motors can handle low-speed operations and stop-start traffic, where traditional V8 engines are least efficient. During highway cruising, the V8 engine can operate at its optimal efficiency point, with the electric system providing additional power when needed for overtaking or climbing.

Advanced control strategies play a crucial role in maximizing the benefits of V8 hybridization. Sophisticated algorithms can continuously optimize the power split between the combustion engine and electric motors, based on driving conditions, battery state of charge, and driver inputs. This ensures the most efficient use of both power sources at all times.

The integration of hybrid technology with V8 engines also opens up possibilities for enhanced vehicle dynamics. Electric motors can provide instant torque, improving acceleration and responsiveness. Additionally, they can be used for torque vectoring, enhancing handling and stability, particularly in performance-oriented applications.

However, the hybridization of V8 engines also presents challenges. The added complexity of the hybrid system increases vehicle weight and cost. Packaging the electric components, especially the battery pack, can be challenging in existing vehicle architectures designed around traditional V8 powertrains. Moreover, balancing performance expectations with efficiency gains requires careful engineering and tuning.

Looking forward, the potential for V8 engine hybridization extends beyond traditional applications. High-performance vehicles, luxury SUVs, and even some light-duty trucks could benefit from this technology, offering a compromise between the emotional appeal of V8 engines and the increasing demand for improved fuel economy and reduced emissions.

V8 hybrid systems typically integrate one or more electric motors with the combustion engine, allowing for various operational modes. These include pure electric driving for short distances, engine assist during acceleration, and regenerative braking to recover energy. The electric components can be sized to provide substantial power boost, enabling downsizing of the V8 engine while maintaining or even improving overall performance.

One of the key advantages of V8 hybridization is the ability to significantly reduce fuel consumption and emissions, particularly in urban driving scenarios. The electric motors can handle low-speed operations and stop-start traffic, where traditional V8 engines are least efficient. During highway cruising, the V8 engine can operate at its optimal efficiency point, with the electric system providing additional power when needed for overtaking or climbing.

Advanced control strategies play a crucial role in maximizing the benefits of V8 hybridization. Sophisticated algorithms can continuously optimize the power split between the combustion engine and electric motors, based on driving conditions, battery state of charge, and driver inputs. This ensures the most efficient use of both power sources at all times.

The integration of hybrid technology with V8 engines also opens up possibilities for enhanced vehicle dynamics. Electric motors can provide instant torque, improving acceleration and responsiveness. Additionally, they can be used for torque vectoring, enhancing handling and stability, particularly in performance-oriented applications.

However, the hybridization of V8 engines also presents challenges. The added complexity of the hybrid system increases vehicle weight and cost. Packaging the electric components, especially the battery pack, can be challenging in existing vehicle architectures designed around traditional V8 powertrains. Moreover, balancing performance expectations with efficiency gains requires careful engineering and tuning.

Looking forward, the potential for V8 engine hybridization extends beyond traditional applications. High-performance vehicles, luxury SUVs, and even some light-duty trucks could benefit from this technology, offering a compromise between the emotional appeal of V8 engines and the increasing demand for improved fuel economy and reduced emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!