V8 Engine Role in Redefining Fuel Economy Metrics

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Efficiency Goals

The V8 engine has played a pivotal role in shaping the automotive industry since its inception in the early 20th century. Initially designed for high-performance applications, V8 engines have undergone significant evolution to meet changing market demands and regulatory requirements, particularly in the realm of fuel economy. This technological journey reflects the industry's ongoing pursuit of balancing power with efficiency.

The development of V8 engines has been marked by several key milestones. In the 1950s and 1960s, V8s were synonymous with American muscle cars, prioritizing raw power over fuel efficiency. However, the oil crises of the 1970s sparked a shift towards more fuel-efficient designs. This led to the introduction of technologies such as electronic fuel injection and variable valve timing in the 1980s and 1990s, which significantly improved both performance and fuel economy.

In recent years, the focus on fuel economy has intensified due to stricter emissions regulations and growing environmental concerns. This has driven manufacturers to explore innovative solutions for V8 engines, including cylinder deactivation, direct injection, and turbocharging. These advancements have allowed V8 engines to maintain their performance characteristics while substantially reducing fuel consumption.

The current technological landscape presents both challenges and opportunities for V8 engine development. The primary goal is to further enhance fuel efficiency without compromising the power and torque that V8 engines are known for. This involves pushing the boundaries of materials science, combustion efficiency, and powertrain integration.

Looking ahead, the evolution of V8 engines is likely to be influenced by emerging technologies such as hybrid powertrains and advanced engine management systems. The integration of electric motors with V8 engines offers the potential for significant improvements in fuel economy while preserving the distinctive performance attributes of V8 powerplants.

As the automotive industry transitions towards electrification, the role of V8 engines in redefining fuel economy metrics becomes increasingly complex. The challenge lies in developing V8 engines that can meet stringent fuel economy standards while still appealing to enthusiasts and specific market segments that value the unique characteristics of these powerplants.

In conclusion, the evolution of V8 engines and their efficiency goals represent a dynamic interplay between technological innovation, market demands, and regulatory pressures. The ongoing development of these engines continues to push the boundaries of what is possible in terms of combining high performance with improved fuel economy, shaping the future of automotive engineering.

The development of V8 engines has been marked by several key milestones. In the 1950s and 1960s, V8s were synonymous with American muscle cars, prioritizing raw power over fuel efficiency. However, the oil crises of the 1970s sparked a shift towards more fuel-efficient designs. This led to the introduction of technologies such as electronic fuel injection and variable valve timing in the 1980s and 1990s, which significantly improved both performance and fuel economy.

In recent years, the focus on fuel economy has intensified due to stricter emissions regulations and growing environmental concerns. This has driven manufacturers to explore innovative solutions for V8 engines, including cylinder deactivation, direct injection, and turbocharging. These advancements have allowed V8 engines to maintain their performance characteristics while substantially reducing fuel consumption.

The current technological landscape presents both challenges and opportunities for V8 engine development. The primary goal is to further enhance fuel efficiency without compromising the power and torque that V8 engines are known for. This involves pushing the boundaries of materials science, combustion efficiency, and powertrain integration.

Looking ahead, the evolution of V8 engines is likely to be influenced by emerging technologies such as hybrid powertrains and advanced engine management systems. The integration of electric motors with V8 engines offers the potential for significant improvements in fuel economy while preserving the distinctive performance attributes of V8 powerplants.

As the automotive industry transitions towards electrification, the role of V8 engines in redefining fuel economy metrics becomes increasingly complex. The challenge lies in developing V8 engines that can meet stringent fuel economy standards while still appealing to enthusiasts and specific market segments that value the unique characteristics of these powerplants.

In conclusion, the evolution of V8 engines and their efficiency goals represent a dynamic interplay between technological innovation, market demands, and regulatory pressures. The ongoing development of these engines continues to push the boundaries of what is possible in terms of combining high performance with improved fuel economy, shaping the future of automotive engineering.

Market Demand for High-Performance Fuel-Efficient Engines

The market demand for high-performance fuel-efficient engines has been steadily increasing in recent years, driven by a combination of regulatory pressures, consumer preferences, and environmental concerns. As governments worldwide implement stricter fuel economy standards and emissions regulations, automakers are compelled to develop engines that deliver both power and efficiency. This has led to a growing interest in advanced V8 engine technologies that can redefine traditional fuel economy metrics.

Consumer preferences have shifted towards vehicles that offer a balance of performance and fuel efficiency. While there remains a strong market for high-performance vehicles, buyers are increasingly conscious of fuel costs and environmental impact. This has created a unique demand for engines that can deliver the power and prestige associated with V8 configurations while also providing improved fuel economy.

The global market for high-performance fuel-efficient engines is projected to grow significantly over the next decade. This growth is particularly pronounced in developed markets such as North America and Europe, where stringent regulations are driving innovation in engine technology. Emerging markets are also showing increased interest in these advanced engines as urban air quality concerns become more prominent.

In the luxury and sports car segments, where V8 engines have traditionally been a hallmark of performance, manufacturers are investing heavily in technologies that can maintain or enhance power output while substantially improving fuel efficiency. This includes advancements in direct injection, variable valve timing, cylinder deactivation, and turbocharging.

The commercial vehicle sector is another area where demand for high-performance fuel-efficient engines is growing. Fleet operators are seeking ways to reduce operating costs through improved fuel economy without sacrificing the power needed for heavy-duty applications. This has led to increased interest in V8 engines that can deliver both torque and efficiency for trucks and large SUVs.

As the automotive industry moves towards electrification, there is also a growing market for hybrid powertrains that incorporate high-efficiency V8 engines. These systems aim to bridge the gap between traditional internal combustion engines and fully electric vehicles, offering consumers a transitional technology that combines familiar performance characteristics with improved fuel economy.

The demand for high-performance fuel-efficient engines is also driving innovation in materials and manufacturing processes. Lightweight materials and advanced production techniques are being employed to reduce engine weight and improve thermal efficiency, further contributing to overall vehicle fuel economy.

Consumer preferences have shifted towards vehicles that offer a balance of performance and fuel efficiency. While there remains a strong market for high-performance vehicles, buyers are increasingly conscious of fuel costs and environmental impact. This has created a unique demand for engines that can deliver the power and prestige associated with V8 configurations while also providing improved fuel economy.

The global market for high-performance fuel-efficient engines is projected to grow significantly over the next decade. This growth is particularly pronounced in developed markets such as North America and Europe, where stringent regulations are driving innovation in engine technology. Emerging markets are also showing increased interest in these advanced engines as urban air quality concerns become more prominent.

In the luxury and sports car segments, where V8 engines have traditionally been a hallmark of performance, manufacturers are investing heavily in technologies that can maintain or enhance power output while substantially improving fuel efficiency. This includes advancements in direct injection, variable valve timing, cylinder deactivation, and turbocharging.

The commercial vehicle sector is another area where demand for high-performance fuel-efficient engines is growing. Fleet operators are seeking ways to reduce operating costs through improved fuel economy without sacrificing the power needed for heavy-duty applications. This has led to increased interest in V8 engines that can deliver both torque and efficiency for trucks and large SUVs.

As the automotive industry moves towards electrification, there is also a growing market for hybrid powertrains that incorporate high-efficiency V8 engines. These systems aim to bridge the gap between traditional internal combustion engines and fully electric vehicles, offering consumers a transitional technology that combines familiar performance characteristics with improved fuel economy.

The demand for high-performance fuel-efficient engines is also driving innovation in materials and manufacturing processes. Lightweight materials and advanced production techniques are being employed to reduce engine weight and improve thermal efficiency, further contributing to overall vehicle fuel economy.

Current V8 Technology and Fuel Economy Challenges

V8 engines have long been synonymous with power and performance, but in recent years, they have faced significant challenges in meeting increasingly stringent fuel economy standards. The current state of V8 technology reflects a delicate balance between maintaining the engine's characteristic high output and addressing the pressing need for improved efficiency.

Modern V8 engines employ a range of advanced technologies to enhance fuel economy. Variable valve timing and lift systems allow for optimized air intake and exhaust across different engine speeds and loads. Direct fuel injection provides more precise control over the combustion process, improving both power output and fuel efficiency. Cylinder deactivation technology, which allows the engine to run on fewer cylinders during light load conditions, has become a common feature in many V8 engines, significantly reducing fuel consumption during highway cruising.

Despite these advancements, V8 engines still face considerable challenges in meeting fuel economy metrics. Their inherently larger displacement and higher number of cylinders result in greater mechanical friction and pumping losses compared to smaller engines. This fundamental design characteristic makes it difficult for V8s to achieve the same level of efficiency as their smaller counterparts, particularly in urban driving conditions with frequent stops and starts.

The weight of V8 engines also poses a challenge to overall vehicle fuel economy. Their larger size and increased number of components contribute to a higher curb weight, which in turn requires more energy to propel the vehicle. This creates a cycle where more powerful engines are needed to maintain performance, further exacerbating fuel consumption issues.

Emissions regulations present another significant hurdle for V8 engines. The higher fuel consumption inherently leads to increased CO2 emissions, making it challenging to meet increasingly strict environmental standards. This has led some manufacturers to explore alternative technologies such as turbocharging and hybridization to maintain V8-level performance while improving efficiency.

The automotive industry's shift towards electrification has put additional pressure on V8 technology. As electric and hybrid powertrains become more prevalent, the role of V8 engines in mainstream vehicles is being reevaluated. Manufacturers are faced with the challenge of justifying the continued development and production of V8 engines in a market increasingly focused on sustainability and reduced environmental impact.

In response to these challenges, some automakers are exploring innovative solutions such as integrating mild hybrid systems with V8 engines to provide electric assist during acceleration and enable more aggressive engine start-stop systems. Others are investigating advanced materials and manufacturing techniques to reduce engine weight and improve thermal efficiency. However, these solutions often come with increased complexity and cost, raising questions about the long-term viability of V8 engines in a rapidly evolving automotive landscape.

Modern V8 engines employ a range of advanced technologies to enhance fuel economy. Variable valve timing and lift systems allow for optimized air intake and exhaust across different engine speeds and loads. Direct fuel injection provides more precise control over the combustion process, improving both power output and fuel efficiency. Cylinder deactivation technology, which allows the engine to run on fewer cylinders during light load conditions, has become a common feature in many V8 engines, significantly reducing fuel consumption during highway cruising.

Despite these advancements, V8 engines still face considerable challenges in meeting fuel economy metrics. Their inherently larger displacement and higher number of cylinders result in greater mechanical friction and pumping losses compared to smaller engines. This fundamental design characteristic makes it difficult for V8s to achieve the same level of efficiency as their smaller counterparts, particularly in urban driving conditions with frequent stops and starts.

The weight of V8 engines also poses a challenge to overall vehicle fuel economy. Their larger size and increased number of components contribute to a higher curb weight, which in turn requires more energy to propel the vehicle. This creates a cycle where more powerful engines are needed to maintain performance, further exacerbating fuel consumption issues.

Emissions regulations present another significant hurdle for V8 engines. The higher fuel consumption inherently leads to increased CO2 emissions, making it challenging to meet increasingly strict environmental standards. This has led some manufacturers to explore alternative technologies such as turbocharging and hybridization to maintain V8-level performance while improving efficiency.

The automotive industry's shift towards electrification has put additional pressure on V8 technology. As electric and hybrid powertrains become more prevalent, the role of V8 engines in mainstream vehicles is being reevaluated. Manufacturers are faced with the challenge of justifying the continued development and production of V8 engines in a market increasingly focused on sustainability and reduced environmental impact.

In response to these challenges, some automakers are exploring innovative solutions such as integrating mild hybrid systems with V8 engines to provide electric assist during acceleration and enable more aggressive engine start-stop systems. Others are investigating advanced materials and manufacturing techniques to reduce engine weight and improve thermal efficiency. However, these solutions often come with increased complexity and cost, raising questions about the long-term viability of V8 engines in a rapidly evolving automotive landscape.

Advanced V8 Fuel Economy Enhancement Techniques

01 Engine design optimization

Improving V8 engine fuel economy through design modifications, such as cylinder deactivation, variable valve timing, and advanced combustion chamber designs. These optimizations can reduce fuel consumption while maintaining performance.- Engine design optimization: Improving V8 engine fuel economy through design modifications, such as optimizing cylinder configuration, valve timing, and combustion chamber geometry. These enhancements can lead to more efficient fuel burning and reduced energy losses, ultimately improving overall fuel efficiency.

- Fuel injection and management systems: Implementing advanced fuel injection and management systems to enhance V8 engine fuel economy. This includes precise fuel metering, direct injection technologies, and intelligent control systems that optimize fuel delivery based on engine load and operating conditions.

- Variable displacement technology: Utilizing variable displacement or cylinder deactivation technology in V8 engines to improve fuel economy. This allows the engine to operate on fewer cylinders during low-load conditions, reducing fuel consumption without sacrificing performance when needed.

- Friction reduction and lubrication improvements: Enhancing V8 engine fuel economy by reducing internal friction and improving lubrication. This includes using advanced materials, surface treatments, and optimized lubricants to minimize energy losses due to friction between moving parts.

- Engine monitoring and diagnostics: Implementing advanced engine monitoring and diagnostic systems to maintain optimal V8 engine performance and fuel economy. These systems can detect inefficiencies, provide real-time feedback, and suggest maintenance or adjustments to ensure the engine operates at peak efficiency.

02 Fuel injection and management systems

Implementing advanced fuel injection and management systems to enhance V8 engine fuel efficiency. This includes direct injection, precise fuel metering, and electronic control units that optimize fuel delivery based on driving conditions.Expand Specific Solutions03 Lubrication and friction reduction

Developing improved lubrication systems and low-friction components to reduce energy losses in V8 engines. This can include advanced oil formulations, surface treatments, and bearing designs to minimize friction and improve overall efficiency.Expand Specific Solutions04 Exhaust gas recirculation and thermal management

Utilizing exhaust gas recirculation (EGR) systems and advanced thermal management techniques to improve V8 engine fuel economy. These methods can help reduce pumping losses, optimize combustion temperatures, and increase overall engine efficiency.Expand Specific Solutions05 Engine monitoring and control systems

Implementing advanced engine monitoring and control systems to optimize V8 engine performance and fuel economy. This includes sensors, onboard diagnostics, and adaptive control algorithms that continuously adjust engine parameters for maximum efficiency.Expand Specific Solutions

Major V8 Engine Manufacturers and Market Dynamics

The V8 engine's role in redefining fuel economy metrics is at a mature stage of development, with a significant market presence and ongoing technological advancements. The global automotive engine market, valued at over $70 billion, continues to grow, driven by demand for fuel-efficient vehicles. Major players like Ford, GM, Toyota, and Delphi Technology are investing heavily in V8 engine optimization, focusing on advanced fuel injection systems, lightweight materials, and cylinder deactivation technologies. These companies are also exploring hybrid V8 configurations to meet stringent emissions standards while maintaining performance. The competitive landscape is characterized by continuous innovation and strategic partnerships to enhance fuel economy without compromising power output.

Ford Global Technologies LLC

Technical Solution: Ford has developed the Ti-VCT (Twin Independent Variable Camshaft Timing) technology for their V8 engines, which allows for independent control of intake and exhaust valve timing. This system can improve fuel economy by up to 4.5% compared to non-VCT engines[7]. Ford has also implemented cylinder deactivation in their V8 engines, allowing them to run on four cylinders during light load conditions, significantly improving fuel efficiency. The company's latest V8 engines feature direct fuel injection and high compression ratios, typically around 12:1, to maximize combustion efficiency[8]. Ford has also developed a plasma transferred wire arc (PTWA) coating technology for cylinder bores in their V8 engines, reducing friction and improving fuel economy[9].

Strengths: Versatile technology applicable across various engine sizes, good balance of performance and efficiency, innovative friction reduction techniques. Weaknesses: Relatively modest fuel economy gains compared to some competitors, potential reliability concerns with complex systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed a Dynamic Skip Fire (DSF) technology for V8 engines, which selectively deactivates cylinders based on driving conditions. This system can improve fuel economy by up to 15% compared to traditional V8 engines[1]. The technology uses sophisticated algorithms to determine which cylinders to deactivate and when, allowing for seamless transitions between different firing patterns. GM has also integrated this technology with their eAssist mild hybrid system, further enhancing fuel efficiency in their V8-powered vehicles[2]. Additionally, GM has implemented advanced thermal management systems in their V8 engines, optimizing engine temperature for improved combustion efficiency and reduced fuel consumption[3].

Strengths: Significant fuel economy improvements, seamless operation, compatibility with hybrid systems. Weaknesses: Increased complexity, potential durability concerns over long-term use, higher initial cost.

Innovative V8 Fuel Efficiency Patents and Research

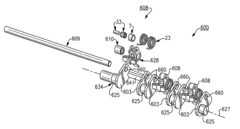

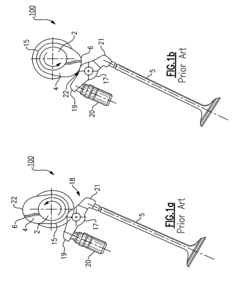

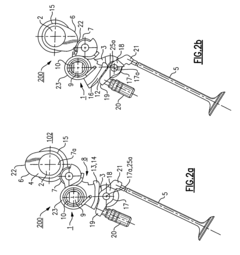

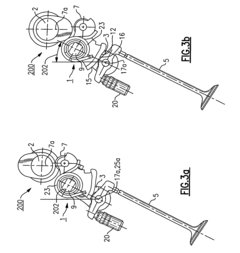

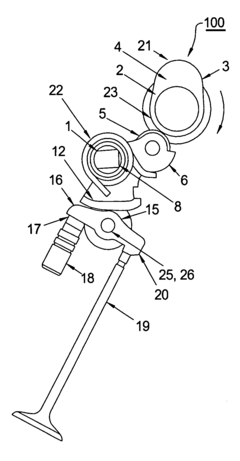

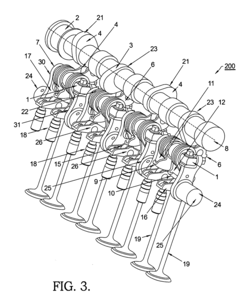

System for variable valvetrain actuation

PatentInactiveUS7409934B2

Innovation

- A simplified VVA system using a single rotary actuator per bank of valves, with a hardened steel rocker subassembly and a one-piece control shaft that varies valve lift, duration, and phasing without being mounted on the engine camshaft, utilizing needle roller bearings and a worm gear drive for precise control.

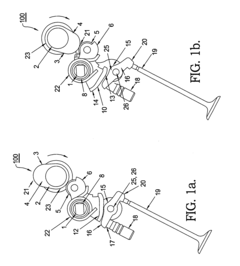

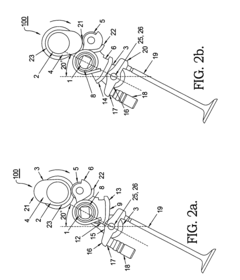

Variable valve actuation system having a crank-based actuation transmission

PatentInactiveUS20080141960A1

Innovation

- A simplified mechanical VVA system using a single electrical rotary actuator and a secondary crank mechanism with an eccentric transmission to vary valve lift, duration, and phasing, eliminating the need for multiple frame structures and parasitic loads, and reducing the number of mechanical parts for easier assembly and reduced power consumption.

Environmental Regulations Impact on V8 Engine Development

Environmental regulations have played a significant role in shaping the development trajectory of V8 engines, particularly in the context of fuel economy metrics. Over the past few decades, governments worldwide have implemented increasingly stringent emissions standards and fuel efficiency requirements, forcing automakers to adapt their V8 engine designs to meet these new regulations.

The introduction of Corporate Average Fuel Economy (CAFE) standards in the United States in 1975 marked a turning point for V8 engine development. These standards set specific fuel efficiency targets for vehicle fleets, compelling manufacturers to improve the fuel economy of their V8 engines or face financial penalties. This regulatory pressure led to the implementation of various technological innovations, such as electronic fuel injection systems and variable valve timing, to enhance the efficiency of V8 engines without sacrificing performance.

In Europe, the implementation of Euro emissions standards has had a profound impact on V8 engine development. Each successive iteration of these standards has imposed stricter limits on pollutant emissions, particularly nitrogen oxides (NOx) and particulate matter. This has led to the widespread adoption of advanced exhaust after-treatment systems, including catalytic converters and particulate filters, in V8-powered vehicles.

The global push towards reducing greenhouse gas emissions has further intensified the regulatory pressure on V8 engines. Many countries have introduced carbon dioxide (CO2) emission targets, which directly correlate with fuel consumption. This has spurred the development of technologies such as cylinder deactivation, where a V8 engine can operate on fewer cylinders under light load conditions to improve fuel efficiency.

More recently, the shift towards electrification has posed new challenges for V8 engine development. Regulations promoting the adoption of electric and hybrid vehicles have forced manufacturers to reconsider the role of V8 engines in their product lineups. Some automakers have responded by developing hybrid V8 powertrains, combining the traditional appeal of the V8 with electric assistance to meet stricter fuel economy and emissions standards.

The impact of environmental regulations on V8 engine development has not been limited to technological advancements. It has also influenced market dynamics and consumer preferences. As fuel economy became a more prominent consideration for buyers, manufacturers have had to balance the performance characteristics of V8 engines with their environmental impact, leading to shifts in marketing strategies and product positioning.

Looking ahead, the future of V8 engine development will continue to be shaped by evolving environmental regulations. As governments worldwide set increasingly ambitious targets for reducing vehicle emissions and improving fuel efficiency, the V8 engine faces ongoing challenges in maintaining its relevance in the automotive landscape. This regulatory environment will likely drive further innovations in V8 technology, potentially leading to more efficient and environmentally friendly iterations of this iconic engine configuration.

The introduction of Corporate Average Fuel Economy (CAFE) standards in the United States in 1975 marked a turning point for V8 engine development. These standards set specific fuel efficiency targets for vehicle fleets, compelling manufacturers to improve the fuel economy of their V8 engines or face financial penalties. This regulatory pressure led to the implementation of various technological innovations, such as electronic fuel injection systems and variable valve timing, to enhance the efficiency of V8 engines without sacrificing performance.

In Europe, the implementation of Euro emissions standards has had a profound impact on V8 engine development. Each successive iteration of these standards has imposed stricter limits on pollutant emissions, particularly nitrogen oxides (NOx) and particulate matter. This has led to the widespread adoption of advanced exhaust after-treatment systems, including catalytic converters and particulate filters, in V8-powered vehicles.

The global push towards reducing greenhouse gas emissions has further intensified the regulatory pressure on V8 engines. Many countries have introduced carbon dioxide (CO2) emission targets, which directly correlate with fuel consumption. This has spurred the development of technologies such as cylinder deactivation, where a V8 engine can operate on fewer cylinders under light load conditions to improve fuel efficiency.

More recently, the shift towards electrification has posed new challenges for V8 engine development. Regulations promoting the adoption of electric and hybrid vehicles have forced manufacturers to reconsider the role of V8 engines in their product lineups. Some automakers have responded by developing hybrid V8 powertrains, combining the traditional appeal of the V8 with electric assistance to meet stricter fuel economy and emissions standards.

The impact of environmental regulations on V8 engine development has not been limited to technological advancements. It has also influenced market dynamics and consumer preferences. As fuel economy became a more prominent consideration for buyers, manufacturers have had to balance the performance characteristics of V8 engines with their environmental impact, leading to shifts in marketing strategies and product positioning.

Looking ahead, the future of V8 engine development will continue to be shaped by evolving environmental regulations. As governments worldwide set increasingly ambitious targets for reducing vehicle emissions and improving fuel efficiency, the V8 engine faces ongoing challenges in maintaining its relevance in the automotive landscape. This regulatory environment will likely drive further innovations in V8 technology, potentially leading to more efficient and environmentally friendly iterations of this iconic engine configuration.

V8 Engine Hybridization and Electrification Prospects

The hybridization and electrification of V8 engines represent a significant shift in the automotive industry's approach to balancing performance and fuel economy. As stricter emissions regulations and increasing consumer demand for more efficient vehicles continue to shape the market, manufacturers are exploring innovative ways to maintain the power and appeal of V8 engines while improving their environmental impact.

One of the primary approaches to V8 engine hybridization involves integrating electric motors into the powertrain. This configuration allows for the electric motor to assist the V8 engine during acceleration and low-speed driving, significantly reducing fuel consumption in urban environments. Additionally, regenerative braking systems can capture and store energy typically lost during deceleration, further enhancing overall efficiency.

Advanced hybrid systems for V8 engines often incorporate plug-in capabilities, enabling pure electric driving for short distances. This feature is particularly beneficial for reducing emissions in city centers and providing flexibility for drivers who primarily engage in short commutes. The combination of electric and V8 power also allows for improved torque delivery, enhancing the overall driving experience while maintaining the characteristic sound and feel of a V8 engine.

Electrification prospects for V8 engines extend beyond hybridization to full electric conversions. Some manufacturers are exploring the possibility of creating electric powertrains that mimic the power delivery and driving characteristics of V8 engines. This approach aims to preserve the emotional appeal of V8-powered vehicles while transitioning to zero-emission propulsion systems.

The development of high-performance battery technologies and power electronics is crucial for the successful electrification of V8 engines. Advancements in these areas will enable electric powertrains to match or exceed the output of traditional V8 engines while offering improved efficiency and reduced environmental impact. Moreover, the integration of artificial intelligence and machine learning algorithms can optimize power distribution between electric and combustion components in hybrid systems, further enhancing performance and efficiency.

As the automotive industry continues to evolve, the future of V8 engines lies in their ability to adapt to changing market demands and regulatory requirements. The hybridization and electrification of these iconic powerplants represent a promising path forward, allowing manufacturers to preserve the legacy of V8 performance while embracing more sustainable technologies.

One of the primary approaches to V8 engine hybridization involves integrating electric motors into the powertrain. This configuration allows for the electric motor to assist the V8 engine during acceleration and low-speed driving, significantly reducing fuel consumption in urban environments. Additionally, regenerative braking systems can capture and store energy typically lost during deceleration, further enhancing overall efficiency.

Advanced hybrid systems for V8 engines often incorporate plug-in capabilities, enabling pure electric driving for short distances. This feature is particularly beneficial for reducing emissions in city centers and providing flexibility for drivers who primarily engage in short commutes. The combination of electric and V8 power also allows for improved torque delivery, enhancing the overall driving experience while maintaining the characteristic sound and feel of a V8 engine.

Electrification prospects for V8 engines extend beyond hybridization to full electric conversions. Some manufacturers are exploring the possibility of creating electric powertrains that mimic the power delivery and driving characteristics of V8 engines. This approach aims to preserve the emotional appeal of V8-powered vehicles while transitioning to zero-emission propulsion systems.

The development of high-performance battery technologies and power electronics is crucial for the successful electrification of V8 engines. Advancements in these areas will enable electric powertrains to match or exceed the output of traditional V8 engines while offering improved efficiency and reduced environmental impact. Moreover, the integration of artificial intelligence and machine learning algorithms can optimize power distribution between electric and combustion components in hybrid systems, further enhancing performance and efficiency.

As the automotive industry continues to evolve, the future of V8 engines lies in their ability to adapt to changing market demands and regulatory requirements. The hybridization and electrification of these iconic powerplants represent a promising path forward, allowing manufacturers to preserve the legacy of V8 performance while embracing more sustainable technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!