V8 Engine Role in Transforming Cargo Logistics

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Objectives

The V8 engine has played a pivotal role in transforming cargo logistics over the past century. Initially developed in the early 1900s, this powerful internal combustion engine has undergone significant evolution, continuously adapting to meet the changing demands of the transportation industry. The primary objective of V8 engine development in cargo logistics has been to enhance efficiency, power, and reliability while reducing environmental impact.

In its early stages, V8 engines were primarily focused on delivering raw power to move heavy loads. As logistics operations expanded and became more complex, the objectives shifted towards improving fuel efficiency and reducing operational costs. This led to the integration of advanced technologies such as fuel injection systems, turbocharging, and variable valve timing, which significantly improved the engine's performance and fuel economy.

The advent of computerized engine management systems in the late 20th century marked a significant milestone in V8 engine evolution. These systems allowed for precise control over fuel delivery and ignition timing, resulting in optimized performance across various operating conditions. This technological leap not only improved efficiency but also paved the way for more sophisticated diagnostics and predictive maintenance capabilities, crucial for minimizing downtime in logistics operations.

Environmental concerns have become increasingly prominent in recent decades, driving the evolution of V8 engines towards cleaner and more sustainable operations. This has led to the development of advanced emission control technologies, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), to meet stringent environmental regulations while maintaining the power and reliability required for cargo transportation.

The latest frontier in V8 engine evolution for cargo logistics is the integration of hybrid and electric technologies. Many manufacturers are now developing hybrid V8 powertrains that combine the traditional internal combustion engine with electric motors. This approach aims to leverage the strengths of both technologies, providing the power and range of V8 engines while significantly reducing fuel consumption and emissions during urban operations or idling periods.

Looking forward, the objectives for V8 engine development in cargo logistics are multifaceted. There is a continued focus on improving fuel efficiency and reducing emissions to meet increasingly stringent environmental standards. Simultaneously, there is a push for enhanced power density, allowing for greater payload capacity without sacrificing performance. The integration of advanced materials and manufacturing techniques, such as 3D printing for complex components, is expected to play a crucial role in achieving these objectives.

Another key objective is the development of smart V8 engines that can adapt to various operating conditions and integrate seamlessly with fleet management systems. This includes the implementation of advanced sensors and artificial intelligence to optimize performance in real-time, predict maintenance needs, and provide valuable data for logistics planning and operations.

In its early stages, V8 engines were primarily focused on delivering raw power to move heavy loads. As logistics operations expanded and became more complex, the objectives shifted towards improving fuel efficiency and reducing operational costs. This led to the integration of advanced technologies such as fuel injection systems, turbocharging, and variable valve timing, which significantly improved the engine's performance and fuel economy.

The advent of computerized engine management systems in the late 20th century marked a significant milestone in V8 engine evolution. These systems allowed for precise control over fuel delivery and ignition timing, resulting in optimized performance across various operating conditions. This technological leap not only improved efficiency but also paved the way for more sophisticated diagnostics and predictive maintenance capabilities, crucial for minimizing downtime in logistics operations.

Environmental concerns have become increasingly prominent in recent decades, driving the evolution of V8 engines towards cleaner and more sustainable operations. This has led to the development of advanced emission control technologies, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), to meet stringent environmental regulations while maintaining the power and reliability required for cargo transportation.

The latest frontier in V8 engine evolution for cargo logistics is the integration of hybrid and electric technologies. Many manufacturers are now developing hybrid V8 powertrains that combine the traditional internal combustion engine with electric motors. This approach aims to leverage the strengths of both technologies, providing the power and range of V8 engines while significantly reducing fuel consumption and emissions during urban operations or idling periods.

Looking forward, the objectives for V8 engine development in cargo logistics are multifaceted. There is a continued focus on improving fuel efficiency and reducing emissions to meet increasingly stringent environmental standards. Simultaneously, there is a push for enhanced power density, allowing for greater payload capacity without sacrificing performance. The integration of advanced materials and manufacturing techniques, such as 3D printing for complex components, is expected to play a crucial role in achieving these objectives.

Another key objective is the development of smart V8 engines that can adapt to various operating conditions and integrate seamlessly with fleet management systems. This includes the implementation of advanced sensors and artificial intelligence to optimize performance in real-time, predict maintenance needs, and provide valuable data for logistics planning and operations.

Cargo Logistics Market Trends

The cargo logistics market is experiencing significant transformations driven by technological advancements and changing consumer demands. E-commerce growth has been a major catalyst, with global online retail sales projected to reach $6.5 trillion by 2023. This surge has led to increased demand for efficient last-mile delivery solutions and warehouse automation technologies.

Sustainability has become a key focus in the industry, with companies adopting eco-friendly practices to reduce their carbon footprint. This trend is reflected in the rising adoption of electric and hybrid vehicles for transportation, as well as the implementation of green warehousing solutions. The market is also seeing a shift towards circular logistics models, emphasizing the reuse and recycling of packaging materials.

Digitalization is reshaping the cargo logistics landscape, with the integration of Internet of Things (IoT) devices, artificial intelligence, and big data analytics. These technologies enable real-time tracking, predictive maintenance, and optimized route planning, leading to improved operational efficiency and cost reduction. The global logistics automation market is expected to grow at a CAGR of 11.5% from 2021 to 2026.

The COVID-19 pandemic has accelerated the adoption of contactless delivery methods and autonomous technologies in logistics. Drone deliveries and autonomous vehicles are gaining traction, with major companies investing heavily in these areas. The global autonomous last-mile delivery market is forecasted to reach $84.7 billion by 2030.

Urbanization and the rise of megacities are creating new challenges and opportunities for cargo logistics. The demand for urban logistics solutions, such as micro-fulfillment centers and smart lockers, is on the rise. Additionally, the concept of shared logistics is gaining popularity, allowing companies to optimize their resources and reduce costs through collaborative networks.

The increasing focus on supply chain resilience has led to the adoption of diversified sourcing strategies and the development of regional logistics hubs. This trend is particularly evident in the aftermath of global disruptions, as companies seek to mitigate risks and ensure business continuity.

Emerging technologies like blockchain and 3D printing are poised to further disrupt the cargo logistics market. Blockchain technology offers enhanced transparency and traceability in supply chains, while 3D printing has the potential to revolutionize on-demand manufacturing and reduce transportation needs.

Sustainability has become a key focus in the industry, with companies adopting eco-friendly practices to reduce their carbon footprint. This trend is reflected in the rising adoption of electric and hybrid vehicles for transportation, as well as the implementation of green warehousing solutions. The market is also seeing a shift towards circular logistics models, emphasizing the reuse and recycling of packaging materials.

Digitalization is reshaping the cargo logistics landscape, with the integration of Internet of Things (IoT) devices, artificial intelligence, and big data analytics. These technologies enable real-time tracking, predictive maintenance, and optimized route planning, leading to improved operational efficiency and cost reduction. The global logistics automation market is expected to grow at a CAGR of 11.5% from 2021 to 2026.

The COVID-19 pandemic has accelerated the adoption of contactless delivery methods and autonomous technologies in logistics. Drone deliveries and autonomous vehicles are gaining traction, with major companies investing heavily in these areas. The global autonomous last-mile delivery market is forecasted to reach $84.7 billion by 2030.

Urbanization and the rise of megacities are creating new challenges and opportunities for cargo logistics. The demand for urban logistics solutions, such as micro-fulfillment centers and smart lockers, is on the rise. Additionally, the concept of shared logistics is gaining popularity, allowing companies to optimize their resources and reduce costs through collaborative networks.

The increasing focus on supply chain resilience has led to the adoption of diversified sourcing strategies and the development of regional logistics hubs. This trend is particularly evident in the aftermath of global disruptions, as companies seek to mitigate risks and ensure business continuity.

Emerging technologies like blockchain and 3D printing are poised to further disrupt the cargo logistics market. Blockchain technology offers enhanced transparency and traceability in supply chains, while 3D printing has the potential to revolutionize on-demand manufacturing and reduce transportation needs.

V8 Engine Challenges in Logistics

The integration of V8 engines in cargo logistics presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the high initial investment required for upgrading existing fleets or purchasing new vehicles equipped with V8 engines. This financial burden can be particularly daunting for small and medium-sized logistics companies, potentially creating a barrier to entry and widening the gap between industry leaders and smaller players.

Fuel efficiency remains a critical concern in the logistics sector, and V8 engines are often associated with higher fuel consumption compared to their smaller counterparts. This challenge is exacerbated by fluctuating fuel prices and increasing environmental regulations, putting pressure on logistics companies to balance performance with sustainability. The need to optimize fuel efficiency without compromising power output requires continuous research and development in engine technology and fuel management systems.

Maintenance and repair costs for V8 engines can be substantially higher than those for smaller engines, due to their complexity and the specialized skills required for servicing. This increased maintenance burden can lead to longer vehicle downtime, potentially disrupting logistics operations and schedules. Additionally, the availability of skilled technicians capable of maintaining V8 engines may be limited in certain regions, further complicating the logistics of fleet management.

Environmental concerns pose another significant challenge for V8 engines in logistics. With stricter emissions regulations being implemented globally, logistics companies must ensure their V8-equipped vehicles comply with these standards. This often necessitates the integration of advanced emission control technologies, which can add to the overall cost and complexity of the vehicles. Balancing the power advantages of V8 engines with environmental responsibility remains an ongoing challenge for the industry.

The weight of V8 engines can also impact cargo capacity, as heavier engines may reduce the maximum payload of vehicles. This trade-off between engine power and cargo capacity requires careful consideration in fleet planning and route optimization. Logistics companies must evaluate whether the performance benefits of V8 engines outweigh the potential reduction in cargo-carrying capabilities for specific operational scenarios.

Adapting existing logistics infrastructure to accommodate V8-powered vehicles can present additional challenges. This may include upgrading fueling stations, modifying maintenance facilities, and retraining staff to handle these more powerful engines. The transition period can be disruptive and costly, requiring careful planning and phased implementation to minimize operational impacts.

Fuel efficiency remains a critical concern in the logistics sector, and V8 engines are often associated with higher fuel consumption compared to their smaller counterparts. This challenge is exacerbated by fluctuating fuel prices and increasing environmental regulations, putting pressure on logistics companies to balance performance with sustainability. The need to optimize fuel efficiency without compromising power output requires continuous research and development in engine technology and fuel management systems.

Maintenance and repair costs for V8 engines can be substantially higher than those for smaller engines, due to their complexity and the specialized skills required for servicing. This increased maintenance burden can lead to longer vehicle downtime, potentially disrupting logistics operations and schedules. Additionally, the availability of skilled technicians capable of maintaining V8 engines may be limited in certain regions, further complicating the logistics of fleet management.

Environmental concerns pose another significant challenge for V8 engines in logistics. With stricter emissions regulations being implemented globally, logistics companies must ensure their V8-equipped vehicles comply with these standards. This often necessitates the integration of advanced emission control technologies, which can add to the overall cost and complexity of the vehicles. Balancing the power advantages of V8 engines with environmental responsibility remains an ongoing challenge for the industry.

The weight of V8 engines can also impact cargo capacity, as heavier engines may reduce the maximum payload of vehicles. This trade-off between engine power and cargo capacity requires careful consideration in fleet planning and route optimization. Logistics companies must evaluate whether the performance benefits of V8 engines outweigh the potential reduction in cargo-carrying capabilities for specific operational scenarios.

Adapting existing logistics infrastructure to accommodate V8-powered vehicles can present additional challenges. This may include upgrading fueling stations, modifying maintenance facilities, and retraining staff to handle these more powerful engines. The transition period can be disruptive and costly, requiring careful planning and phased implementation to minimize operational impacts.

Current V8 Solutions for Logistics

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and balanced operation. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve timing, are optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased horsepower. Various designs and configurations of turbochargers and superchargers are used to optimize V8 engine performance.

- Cooling and Lubrication Systems: Effective cooling and lubrication systems are essential for V8 engine reliability and longevity. Advanced cooling systems manage engine temperature, while sophisticated lubrication systems ensure proper oil distribution to all moving parts. Innovations in these areas focus on improving heat dissipation, reducing friction, and enhancing overall engine efficiency.

- Engine Management and Control Systems: Modern V8 engines incorporate advanced electronic control units (ECUs) and sensors to optimize performance, fuel efficiency, and emissions. These systems manage various engine parameters, including fuel injection timing, ignition timing, and valve operation. Adaptive control algorithms and real-time monitoring contribute to improved engine responsiveness and overall performance.

02 Fuel Efficiency and Emissions Control

Modern V8 engines incorporate technologies to improve fuel efficiency and reduce emissions. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced exhaust gas recirculation systems. Such innovations help V8 engines meet stringent environmental regulations while maintaining high performance.Expand Specific Solutions03 Performance Enhancement and Tuning

Various methods and components are used to enhance V8 engine performance. These may include turbocharging, supercharging, high-flow intake and exhaust systems, and engine management system tuning. Performance enhancements aim to increase horsepower, torque, and overall engine responsiveness.Expand Specific Solutions04 Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for V8 engine reliability and longevity. Advanced cooling systems may include precision-controlled electric water pumps, improved radiator designs, and optimized coolant flow paths. Lubrication systems often feature high-capacity oil pumps, multi-stage filtration, and oil coolers to maintain proper engine temperatures and reduce wear.Expand Specific Solutions05 Manufacturing and Assembly Techniques

Innovative manufacturing and assembly techniques are employed in V8 engine production to improve quality, reduce weight, and enhance performance. These may include advanced casting methods for engine blocks and heads, precision machining processes, and the use of lightweight materials such as aluminum alloys. Assembly techniques focus on ensuring proper tolerances and reducing friction between moving parts.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine's role in transforming cargo logistics is at a mature stage of development, with a significant market size due to its widespread adoption in heavy-duty trucks and commercial vehicles. The technology's maturity is evident from the involvement of major automotive manufacturers like Honda, GM, BMW, and Nissan, who have refined V8 engine designs over decades. However, the industry is experiencing a shift towards more fuel-efficient and environmentally friendly alternatives, with companies like Hexagon Purus and Agility Fuel Systems focusing on alternative fuel technologies. This transition is driving innovation in V8 engine efficiency and performance, as traditional manufacturers compete with emerging technologies in the evolving cargo logistics landscape.

GM Global Technology Operations LLC

Technical Solution: GM has developed a V8 engine-based logistics solution that integrates advanced fuel efficiency technologies and smart connectivity features. Their V8 engines, such as the 6.2L V8 used in heavy-duty trucks, incorporate Dynamic Fuel Management (DFM) which can deactivate up to seven cylinders for improved fuel economy[1]. This technology, combined with GM's OnStar telematics system, allows for real-time monitoring of fuel consumption, route optimization, and predictive maintenance in cargo logistics operations[2]. The company has also implemented a start-stop technology in their V8 engines, which automatically shuts off the engine when the vehicle comes to a stop, further enhancing fuel efficiency in urban delivery scenarios[3].

Strengths: Advanced fuel management systems, integrated telematics for logistics optimization, and proven reliability in heavy-duty applications. Weaknesses: Higher initial cost compared to smaller engines, and potential complexity in maintenance due to advanced technologies.

Bayerische Motoren Werke AG

Technical Solution: BMW has applied its V8 engine expertise to cargo logistics through the development of efficient powertrains for commercial vehicles. Their TwinPower Turbo V8 technology, originally designed for high-performance cars, has been adapted for use in medium to heavy-duty trucks[4]. This engine features twin-scroll turbochargers and high-precision direct injection, delivering high torque at low RPMs, which is crucial for cargo hauling[5]. BMW has also integrated their V8 engines with mild hybrid systems, incorporating a 48V electric motor to assist the engine during acceleration and enable energy recovery during braking, significantly improving fuel efficiency in stop-and-go traffic common in urban logistics[6].

Strengths: High-performance engine technology adapted for commercial use, advanced fuel efficiency features, and integration with electrification. Weaknesses: Limited presence in the commercial vehicle market compared to traditional truck manufacturers.

V8 Innovations for Cargo Transport

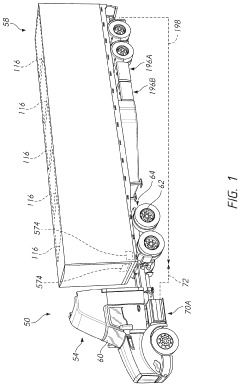

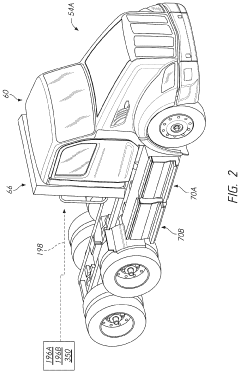

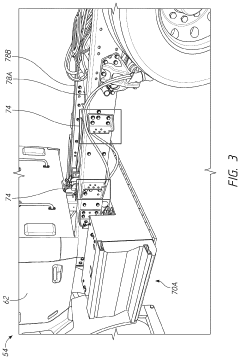

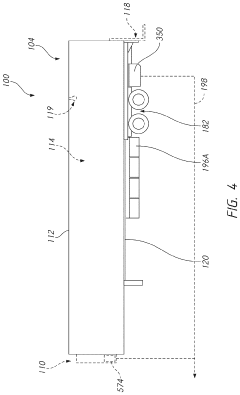

Battery and auxiliary components for vehicle trailer

PatentActiveUS11926207B2

Innovation

- A cargo trailer assembly is designed with a battery storage unit coupled externally to the chassis, featuring a modular power storage and distribution system that includes multiple battery assemblies, a thermal management system, and a power distribution unit, allowing for extended range operation, independent charging of the trailer unit, and efficient power management between the tractor and trailer units.

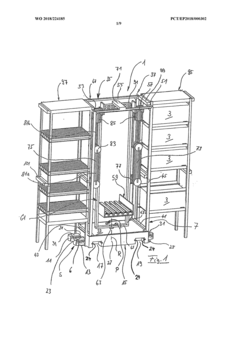

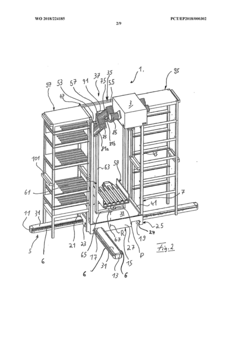

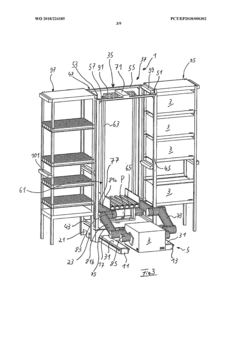

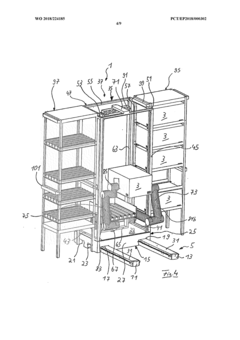

Logistics vehicle and base of a logistics vehicle

PatentWO2018224185A1

Innovation

- A logistics vehicle with a chassis and a supporting frame that can be independently operated, featuring a transfer robot with gripper arms and a modular design allowing for flexible positioning and movement, along with a transport pallet system that includes entry tunnels to absorb tilting moments, enabling efficient and stable transport and storage.

Environmental Impact of V8 Engines

The environmental impact of V8 engines in cargo logistics is a critical concern that requires careful consideration. These powerful engines, while efficient for heavy-duty transportation, contribute significantly to greenhouse gas emissions and air pollution. The combustion of fossil fuels in V8 engines releases carbon dioxide, nitrogen oxides, and particulate matter, which have detrimental effects on air quality and climate change.

In urban areas, where cargo logistics operations are concentrated, the emissions from V8 engines can exacerbate smog formation and contribute to respiratory health issues among local populations. The noise pollution generated by these engines also poses a challenge, particularly in densely populated areas or during night-time operations.

However, advancements in engine technology have led to improvements in fuel efficiency and emissions reduction for V8 engines. Modern V8 engines incorporate features such as direct fuel injection, variable valve timing, and cylinder deactivation, which help optimize fuel consumption and reduce emissions. Additionally, the implementation of exhaust after-treatment systems, including catalytic converters and diesel particulate filters, has further mitigated the environmental impact of these engines.

The logistics industry has been exploring alternative fuel options for V8 engines to reduce their carbon footprint. Biodiesel and synthetic fuels derived from renewable sources offer potential solutions, as they can be used in existing V8 engines with minimal modifications. These alternative fuels can significantly reduce lifecycle carbon emissions compared to traditional petroleum-based fuels.

Furthermore, the integration of hybrid and electric technologies with V8 engines has shown promise in reducing environmental impact. Hybrid powertrains that combine V8 engines with electric motors can improve fuel efficiency and reduce emissions, particularly in urban environments where stop-and-go traffic is common.

As regulations on emissions become more stringent globally, the cargo logistics industry is under pressure to adopt cleaner technologies. This has led to increased investment in research and development of more environmentally friendly propulsion systems, including the potential replacement of V8 engines with alternative powertrains in certain applications.

In conclusion, while V8 engines continue to play a crucial role in cargo logistics due to their power and reliability, their environmental impact remains a significant challenge. The industry's focus on technological advancements, alternative fuels, and hybrid solutions demonstrates a commitment to addressing these environmental concerns while maintaining the efficiency and performance required for cargo transportation.

In urban areas, where cargo logistics operations are concentrated, the emissions from V8 engines can exacerbate smog formation and contribute to respiratory health issues among local populations. The noise pollution generated by these engines also poses a challenge, particularly in densely populated areas or during night-time operations.

However, advancements in engine technology have led to improvements in fuel efficiency and emissions reduction for V8 engines. Modern V8 engines incorporate features such as direct fuel injection, variable valve timing, and cylinder deactivation, which help optimize fuel consumption and reduce emissions. Additionally, the implementation of exhaust after-treatment systems, including catalytic converters and diesel particulate filters, has further mitigated the environmental impact of these engines.

The logistics industry has been exploring alternative fuel options for V8 engines to reduce their carbon footprint. Biodiesel and synthetic fuels derived from renewable sources offer potential solutions, as they can be used in existing V8 engines with minimal modifications. These alternative fuels can significantly reduce lifecycle carbon emissions compared to traditional petroleum-based fuels.

Furthermore, the integration of hybrid and electric technologies with V8 engines has shown promise in reducing environmental impact. Hybrid powertrains that combine V8 engines with electric motors can improve fuel efficiency and reduce emissions, particularly in urban environments where stop-and-go traffic is common.

As regulations on emissions become more stringent globally, the cargo logistics industry is under pressure to adopt cleaner technologies. This has led to increased investment in research and development of more environmentally friendly propulsion systems, including the potential replacement of V8 engines with alternative powertrains in certain applications.

In conclusion, while V8 engines continue to play a crucial role in cargo logistics due to their power and reliability, their environmental impact remains a significant challenge. The industry's focus on technological advancements, alternative fuels, and hybrid solutions demonstrates a commitment to addressing these environmental concerns while maintaining the efficiency and performance required for cargo transportation.

V8 Fuel Efficiency Strategies

V8 engines have long been associated with power and performance in the automotive industry. However, in recent years, there has been a significant focus on improving their fuel efficiency to meet stricter environmental regulations and reduce operational costs in cargo logistics. Several strategies have been developed and implemented to enhance the fuel efficiency of V8 engines without compromising their power output.

One of the primary approaches to improving V8 fuel efficiency is through advanced engine management systems. These systems utilize sophisticated algorithms and sensors to optimize fuel injection timing, air-fuel mixture, and ignition timing in real-time. By precisely controlling these parameters, the engine can operate at peak efficiency across various driving conditions, resulting in reduced fuel consumption.

Cylinder deactivation technology has also emerged as a crucial fuel-saving strategy for V8 engines. This system allows the engine to temporarily shut down a set of cylinders during light load conditions, effectively operating as a smaller, more efficient engine. When additional power is required, all cylinders are reactivated seamlessly, providing the full power of the V8 configuration.

Turbocharging and supercharging technologies have been increasingly adopted to improve V8 fuel efficiency. These forced induction systems allow for downsizing of the engine while maintaining or even increasing power output. By compressing the intake air, these systems enable more efficient combustion and improved fuel economy, particularly in cargo logistics applications where consistent power delivery is essential.

Advanced materials and manufacturing techniques have contributed significantly to V8 fuel efficiency improvements. Lightweight materials such as aluminum and carbon fiber composites are being used to reduce engine weight, decreasing the overall vehicle mass and improving fuel economy. Additionally, precision manufacturing techniques have enabled tighter tolerances and improved surface finishes, reducing friction and enhancing engine efficiency.

Variable valve timing and lift systems have been refined to optimize engine breathing across a wide range of operating conditions. These systems allow for dynamic adjustment of valve timing and lift, improving combustion efficiency and reducing pumping losses. In cargo logistics applications, this technology can significantly enhance fuel economy during long-haul operations.

The integration of start-stop systems in V8 engines has become increasingly common, particularly in urban delivery scenarios. These systems automatically shut off the engine when the vehicle is stationary and restart it when motion is required, reducing fuel consumption and emissions during idle periods. While initially met with skepticism, advancements in battery technology and system refinement have made start-stop systems more reliable and effective in V8 applications.

One of the primary approaches to improving V8 fuel efficiency is through advanced engine management systems. These systems utilize sophisticated algorithms and sensors to optimize fuel injection timing, air-fuel mixture, and ignition timing in real-time. By precisely controlling these parameters, the engine can operate at peak efficiency across various driving conditions, resulting in reduced fuel consumption.

Cylinder deactivation technology has also emerged as a crucial fuel-saving strategy for V8 engines. This system allows the engine to temporarily shut down a set of cylinders during light load conditions, effectively operating as a smaller, more efficient engine. When additional power is required, all cylinders are reactivated seamlessly, providing the full power of the V8 configuration.

Turbocharging and supercharging technologies have been increasingly adopted to improve V8 fuel efficiency. These forced induction systems allow for downsizing of the engine while maintaining or even increasing power output. By compressing the intake air, these systems enable more efficient combustion and improved fuel economy, particularly in cargo logistics applications where consistent power delivery is essential.

Advanced materials and manufacturing techniques have contributed significantly to V8 fuel efficiency improvements. Lightweight materials such as aluminum and carbon fiber composites are being used to reduce engine weight, decreasing the overall vehicle mass and improving fuel economy. Additionally, precision manufacturing techniques have enabled tighter tolerances and improved surface finishes, reducing friction and enhancing engine efficiency.

Variable valve timing and lift systems have been refined to optimize engine breathing across a wide range of operating conditions. These systems allow for dynamic adjustment of valve timing and lift, improving combustion efficiency and reducing pumping losses. In cargo logistics applications, this technology can significantly enhance fuel economy during long-haul operations.

The integration of start-stop systems in V8 engines has become increasingly common, particularly in urban delivery scenarios. These systems automatically shut off the engine when the vehicle is stationary and restart it when motion is required, reducing fuel consumption and emissions during idle periods. While initially met with skepticism, advancements in battery technology and system refinement have made start-stop systems more reliable and effective in V8 applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!