V8 Engine Troubleshooting: Diagnosing Common Issues

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Overview and Diagnostic Goals

The V8 engine, a powerful and efficient internal combustion engine design, has been a cornerstone of automotive engineering for decades. Its configuration, featuring eight cylinders arranged in a V-shape, offers a balance of power, compactness, and smoothness that has made it popular in various applications, from high-performance sports cars to luxury vehicles and even some trucks.

As automotive technology continues to evolve, the V8 engine faces new challenges and opportunities. The industry's shift towards electrification and stricter emissions regulations has prompted manufacturers to focus on improving V8 efficiency and reducing environmental impact. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging, all aimed at enhancing performance while minimizing fuel consumption and emissions.

Despite these advancements, V8 engines remain complex systems that can experience a range of issues. Common problems include oil leaks, misfires, excessive fuel consumption, and reduced performance. These issues can stem from various sources, including wear and tear on components, electronic system malfunctions, or improper maintenance. As such, effective troubleshooting and diagnostics are crucial for maintaining V8 engine performance and longevity.

The primary goal of V8 engine diagnostics is to accurately identify and resolve issues that affect engine performance, efficiency, and reliability. This process involves a systematic approach to problem-solving, utilizing both traditional mechanical knowledge and modern diagnostic tools. Technicians must be adept at interpreting engine data, recognizing symptoms, and correlating them with potential causes.

Advanced diagnostic equipment plays a vital role in modern V8 engine troubleshooting. On-board diagnostic (OBD) systems, scan tools, and engine analyzers provide valuable insights into engine performance parameters, allowing technicians to quickly pinpoint issues that might otherwise require extensive manual inspection. These tools can read error codes, monitor real-time data streams, and even perform advanced tests on specific engine systems.

However, effective diagnostics go beyond just reading codes. It requires a deep understanding of V8 engine architecture, fuel systems, ignition systems, and the intricate interplay between mechanical and electronic components. Technicians must also stay updated on the latest V8 engine technologies and manufacturer-specific diagnostic procedures to ensure accurate problem identification and resolution.

As V8 engines continue to evolve, so too must diagnostic techniques and tools. The integration of more sophisticated electronic control systems and the potential for hybrid V8 configurations present new challenges for troubleshooting. Future diagnostic goals may include developing more predictive maintenance capabilities, leveraging artificial intelligence for faster and more accurate problem identification, and creating more user-friendly diagnostic interfaces for both professional technicians and vehicle owners.

As automotive technology continues to evolve, the V8 engine faces new challenges and opportunities. The industry's shift towards electrification and stricter emissions regulations has prompted manufacturers to focus on improving V8 efficiency and reducing environmental impact. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging, all aimed at enhancing performance while minimizing fuel consumption and emissions.

Despite these advancements, V8 engines remain complex systems that can experience a range of issues. Common problems include oil leaks, misfires, excessive fuel consumption, and reduced performance. These issues can stem from various sources, including wear and tear on components, electronic system malfunctions, or improper maintenance. As such, effective troubleshooting and diagnostics are crucial for maintaining V8 engine performance and longevity.

The primary goal of V8 engine diagnostics is to accurately identify and resolve issues that affect engine performance, efficiency, and reliability. This process involves a systematic approach to problem-solving, utilizing both traditional mechanical knowledge and modern diagnostic tools. Technicians must be adept at interpreting engine data, recognizing symptoms, and correlating them with potential causes.

Advanced diagnostic equipment plays a vital role in modern V8 engine troubleshooting. On-board diagnostic (OBD) systems, scan tools, and engine analyzers provide valuable insights into engine performance parameters, allowing technicians to quickly pinpoint issues that might otherwise require extensive manual inspection. These tools can read error codes, monitor real-time data streams, and even perform advanced tests on specific engine systems.

However, effective diagnostics go beyond just reading codes. It requires a deep understanding of V8 engine architecture, fuel systems, ignition systems, and the intricate interplay between mechanical and electronic components. Technicians must also stay updated on the latest V8 engine technologies and manufacturer-specific diagnostic procedures to ensure accurate problem identification and resolution.

As V8 engines continue to evolve, so too must diagnostic techniques and tools. The integration of more sophisticated electronic control systems and the potential for hybrid V8 configurations present new challenges for troubleshooting. Future diagnostic goals may include developing more predictive maintenance capabilities, leveraging artificial intelligence for faster and more accurate problem identification, and creating more user-friendly diagnostic interfaces for both professional technicians and vehicle owners.

Market Demand for V8 Engine Maintenance

The market demand for V8 engine maintenance has been steadily growing in recent years, driven by several key factors. Firstly, the increasing complexity of modern V8 engines has created a need for specialized diagnostic and repair services. As these engines incorporate more advanced technologies such as direct injection, variable valve timing, and turbocharging, the expertise required to maintain them has also increased.

The automotive aftermarket sector has seen a significant uptick in demand for V8 engine maintenance services, particularly in regions with a high concentration of performance and luxury vehicles. This trend is further amplified by the growing average age of vehicles on the road, with many V8-equipped cars now reaching the stage where major maintenance and repairs are necessary.

In the commercial sector, the demand for V8 engine maintenance is largely driven by the trucking and heavy equipment industries. V8 engines are commonly used in these applications due to their power and reliability, and the need for regular maintenance to ensure optimal performance and longevity is critical for fleet operators.

The rise of performance tuning and modification culture has also contributed to the market demand. Enthusiasts and professionals alike seek specialized services to diagnose issues, improve performance, and maintain highly tuned V8 engines. This niche market segment has seen substantial growth, particularly in urban areas and regions with a strong car culture.

Environmental regulations and fuel efficiency standards have paradoxically increased the demand for V8 engine maintenance. As manufacturers strive to meet these standards while maintaining performance, V8 engines have become more sophisticated, requiring more frequent and specialized maintenance to ensure they operate within compliance parameters.

The advent of advanced diagnostic tools and techniques has also shaped the market. Workshops and technicians equipped with state-of-the-art diagnostic equipment are in high demand, as they can more accurately and efficiently troubleshoot complex V8 engine issues. This has led to a segmentation in the market, with specialized V8 engine maintenance centers commanding premium prices for their expertise and technology.

Lastly, the global supply chain disruptions and economic uncertainties have influenced consumer behavior, with many vehicle owners opting to maintain and repair their existing V8-equipped vehicles rather than replacing them. This trend has further bolstered the demand for comprehensive V8 engine maintenance services across various market segments.

The automotive aftermarket sector has seen a significant uptick in demand for V8 engine maintenance services, particularly in regions with a high concentration of performance and luxury vehicles. This trend is further amplified by the growing average age of vehicles on the road, with many V8-equipped cars now reaching the stage where major maintenance and repairs are necessary.

In the commercial sector, the demand for V8 engine maintenance is largely driven by the trucking and heavy equipment industries. V8 engines are commonly used in these applications due to their power and reliability, and the need for regular maintenance to ensure optimal performance and longevity is critical for fleet operators.

The rise of performance tuning and modification culture has also contributed to the market demand. Enthusiasts and professionals alike seek specialized services to diagnose issues, improve performance, and maintain highly tuned V8 engines. This niche market segment has seen substantial growth, particularly in urban areas and regions with a strong car culture.

Environmental regulations and fuel efficiency standards have paradoxically increased the demand for V8 engine maintenance. As manufacturers strive to meet these standards while maintaining performance, V8 engines have become more sophisticated, requiring more frequent and specialized maintenance to ensure they operate within compliance parameters.

The advent of advanced diagnostic tools and techniques has also shaped the market. Workshops and technicians equipped with state-of-the-art diagnostic equipment are in high demand, as they can more accurately and efficiently troubleshoot complex V8 engine issues. This has led to a segmentation in the market, with specialized V8 engine maintenance centers commanding premium prices for their expertise and technology.

Lastly, the global supply chain disruptions and economic uncertainties have influenced consumer behavior, with many vehicle owners opting to maintain and repair their existing V8-equipped vehicles rather than replacing them. This trend has further bolstered the demand for comprehensive V8 engine maintenance services across various market segments.

Current Challenges in V8 Engine Diagnostics

V8 engine diagnostics face several significant challenges in the current automotive landscape. One of the primary issues is the increasing complexity of modern V8 engines, which incorporate advanced technologies such as direct injection, variable valve timing, and turbocharging. These sophisticated systems make it more difficult for technicians to isolate and identify problems accurately.

The integration of electronic control units (ECUs) and multiple sensors in V8 engines has led to a surge in potential failure points. Diagnosing issues related to these electronic components often requires specialized equipment and expertise, which may not be readily available in all service centers. This complexity can lead to misdiagnosis or incomplete repairs, resulting in recurring problems and customer dissatisfaction.

Another challenge is the interpretation of diagnostic trouble codes (DTCs). While these codes provide valuable information, they often indicate symptoms rather than root causes. Technicians must possess a deep understanding of engine systems and their interdependencies to accurately interpret these codes and perform effective troubleshooting.

The rapid evolution of V8 engine technology also presents a challenge in keeping diagnostic tools and procedures up-to-date. As manufacturers introduce new engine variants and control strategies, diagnostic equipment and technician training must evolve in tandem. This constant need for updates and education can strain resources and lead to knowledge gaps in the service industry.

Environmental factors and emission regulations add another layer of complexity to V8 engine diagnostics. Technicians must be aware of how various components interact to maintain optimal performance while meeting stringent emission standards. Identifying issues that affect emissions without compromising engine performance requires a delicate balance and comprehensive understanding of the entire powertrain system.

Intermittent faults pose a particular challenge in V8 engine diagnostics. These issues may not consistently trigger warning lights or store fault codes, making them difficult to replicate and diagnose in a workshop environment. Technicians often struggle to identify and resolve these elusive problems, leading to prolonged diagnostic times and increased costs.

The increasing use of proprietary technologies and manufacturer-specific diagnostic procedures further complicates the diagnostic process. Independent repair shops may face limitations in accessing certain diagnostic information or specialized tools, potentially impacting their ability to service V8 engines effectively across different brands and models.

The integration of electronic control units (ECUs) and multiple sensors in V8 engines has led to a surge in potential failure points. Diagnosing issues related to these electronic components often requires specialized equipment and expertise, which may not be readily available in all service centers. This complexity can lead to misdiagnosis or incomplete repairs, resulting in recurring problems and customer dissatisfaction.

Another challenge is the interpretation of diagnostic trouble codes (DTCs). While these codes provide valuable information, they often indicate symptoms rather than root causes. Technicians must possess a deep understanding of engine systems and their interdependencies to accurately interpret these codes and perform effective troubleshooting.

The rapid evolution of V8 engine technology also presents a challenge in keeping diagnostic tools and procedures up-to-date. As manufacturers introduce new engine variants and control strategies, diagnostic equipment and technician training must evolve in tandem. This constant need for updates and education can strain resources and lead to knowledge gaps in the service industry.

Environmental factors and emission regulations add another layer of complexity to V8 engine diagnostics. Technicians must be aware of how various components interact to maintain optimal performance while meeting stringent emission standards. Identifying issues that affect emissions without compromising engine performance requires a delicate balance and comprehensive understanding of the entire powertrain system.

Intermittent faults pose a particular challenge in V8 engine diagnostics. These issues may not consistently trigger warning lights or store fault codes, making them difficult to replicate and diagnose in a workshop environment. Technicians often struggle to identify and resolve these elusive problems, leading to prolonged diagnostic times and increased costs.

The increasing use of proprietary technologies and manufacturer-specific diagnostic procedures further complicates the diagnostic process. Independent repair shops may face limitations in accessing certain diagnostic information or specialized tools, potentially impacting their ability to service V8 engines effectively across different brands and models.

Existing V8 Engine Troubleshooting Methods

01 Engine diagnostic systems

Advanced diagnostic systems for V8 engines utilize sensors and computer algorithms to detect and analyze engine performance issues. These systems can monitor various parameters such as fuel consumption, exhaust emissions, and engine temperature to identify potential problems and suggest appropriate troubleshooting steps.- Engine diagnostic systems: Advanced diagnostic systems for V8 engines utilize sensors and computer algorithms to detect and analyze engine performance issues. These systems can monitor various parameters such as fuel consumption, emissions, and overall engine efficiency, providing real-time data for troubleshooting and maintenance.

- Fault code analysis and interpretation: Specialized software and databases are used to interpret fault codes generated by V8 engine control units. These tools help mechanics and technicians quickly identify specific issues, streamlining the troubleshooting process and reducing diagnostic time.

- Predictive maintenance techniques: Predictive maintenance approaches for V8 engines involve analyzing historical data and current engine performance metrics to forecast potential failures. This proactive method helps prevent unexpected breakdowns and optimizes maintenance schedules, improving overall engine reliability.

- Vibration analysis for engine troubleshooting: Vibration analysis techniques are employed to detect abnormalities in V8 engine operation. By measuring and analyzing vibration patterns, technicians can identify issues such as misalignments, worn components, or imbalances, allowing for targeted repairs and adjustments.

- Remote diagnostics and monitoring: Remote diagnostic systems enable real-time monitoring and troubleshooting of V8 engines from a distance. These systems use telematics and cloud-based platforms to transmit engine data, allowing for quick identification of issues and remote assistance in diagnosing problems.

02 Vibration analysis for engine troubleshooting

Vibration analysis techniques are employed to diagnose V8 engine issues by detecting abnormal vibrations that may indicate problems with engine components. This method can help identify issues such as misfires, bearing wear, or imbalanced rotating parts, allowing for targeted troubleshooting and maintenance.Expand Specific Solutions03 Fuel system diagnostics

Specialized tools and methods for diagnosing fuel system issues in V8 engines, including fuel injector testing, fuel pressure analysis, and fuel quality assessment. These techniques help identify problems related to fuel delivery, combustion efficiency, and engine performance.Expand Specific Solutions04 Electronic control unit (ECU) troubleshooting

Methods for diagnosing and resolving issues related to the engine's electronic control unit, including software updates, error code analysis, and sensor calibration. These techniques are crucial for addressing modern V8 engine problems that are often related to electronic systems and control modules.Expand Specific Solutions05 Predictive maintenance for V8 engines

Implementation of predictive maintenance strategies using data analytics and machine learning algorithms to forecast potential engine failures and schedule maintenance activities proactively. This approach helps prevent unexpected breakdowns and optimize engine performance over time.Expand Specific Solutions

Key Players in V8 Engine Manufacturing and Diagnostics

The V8 engine troubleshooting market is in a mature stage, with a well-established global presence and significant market size. The technology is highly developed, with major players like Weichai Power, Robert Bosch GmbH, and Honda Motor Co., Ltd. offering advanced diagnostic solutions. The competitive landscape is characterized by a mix of automotive manufacturers, component suppliers, and specialized diagnostic equipment providers. Companies such as Snap-On, Inc. and Delphi International Operations Luxembourg SARL are at the forefront of developing sophisticated diagnostic tools, while automakers like Toyota Motor Corp. and Hyundai Motor Co., Ltd. integrate advanced troubleshooting capabilities into their vehicles. The market continues to evolve with the integration of AI and IoT technologies, driving innovation in predictive maintenance and real-time diagnostics.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced diagnostic tools and software for V8 engine troubleshooting. Their KTS series diagnostic testers use intelligent troubleshooting algorithms to quickly identify common V8 engine issues[1]. The system integrates with Bosch's ESI[tronic] 2.0 software, which provides comprehensive vehicle data and guided diagnostic procedures specific to V8 engines[2]. This combination allows technicians to efficiently diagnose problems such as misfires, fuel injection issues, and sensor malfunctions. Bosch's solution also includes real-time data analysis and graphing capabilities, enabling technicians to visualize engine performance parameters and identify anomalies more easily[3].

Strengths: Comprehensive diagnostic coverage, integration with extensive vehicle database, and user-friendly interface. Weaknesses: Potentially higher cost compared to generic tools, and may require regular software updates.

Snap-On, Inc.

Technical Solution: Snap-On's approach to V8 engine troubleshooting centers around their VERUS® Edge diagnostic and information system. This tool combines advanced scanner functionality with a vast database of OEM-specific information for V8 engines[4]. The system features Fast-Track® Intelligent Diagnostics, which guides technicians through a logical diagnostic process, reducing guesswork and improving efficiency[5]. For V8-specific issues, such as cylinder deactivation problems or variable valve timing faults, the tool provides detailed component information, wiring diagrams, and known-good waveforms. Snap-On's solution also incorporates SureTrack®, a community-based troubleshooting database that includes real-world fixes and tips from experienced technicians[6].

Strengths: Intuitive user interface, extensive knowledge base, and community-driven troubleshooting support. Weaknesses: Subscription-based model for some features may increase long-term costs.

Advanced Diagnostic Technologies for V8 Engines

Engine diagnostic device and engine power-generation system

PatentWO2025083964A1

Innovation

- An engine diagnostic device that calculates the total work amount and theoretical work amount using actual engine rotation speed, output, and fuel flow command values, allowing for rapid diagnosis of engine abnormalities.

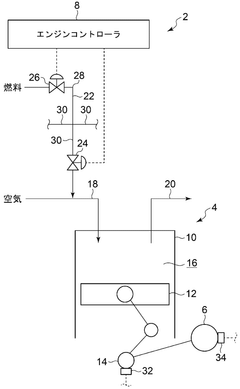

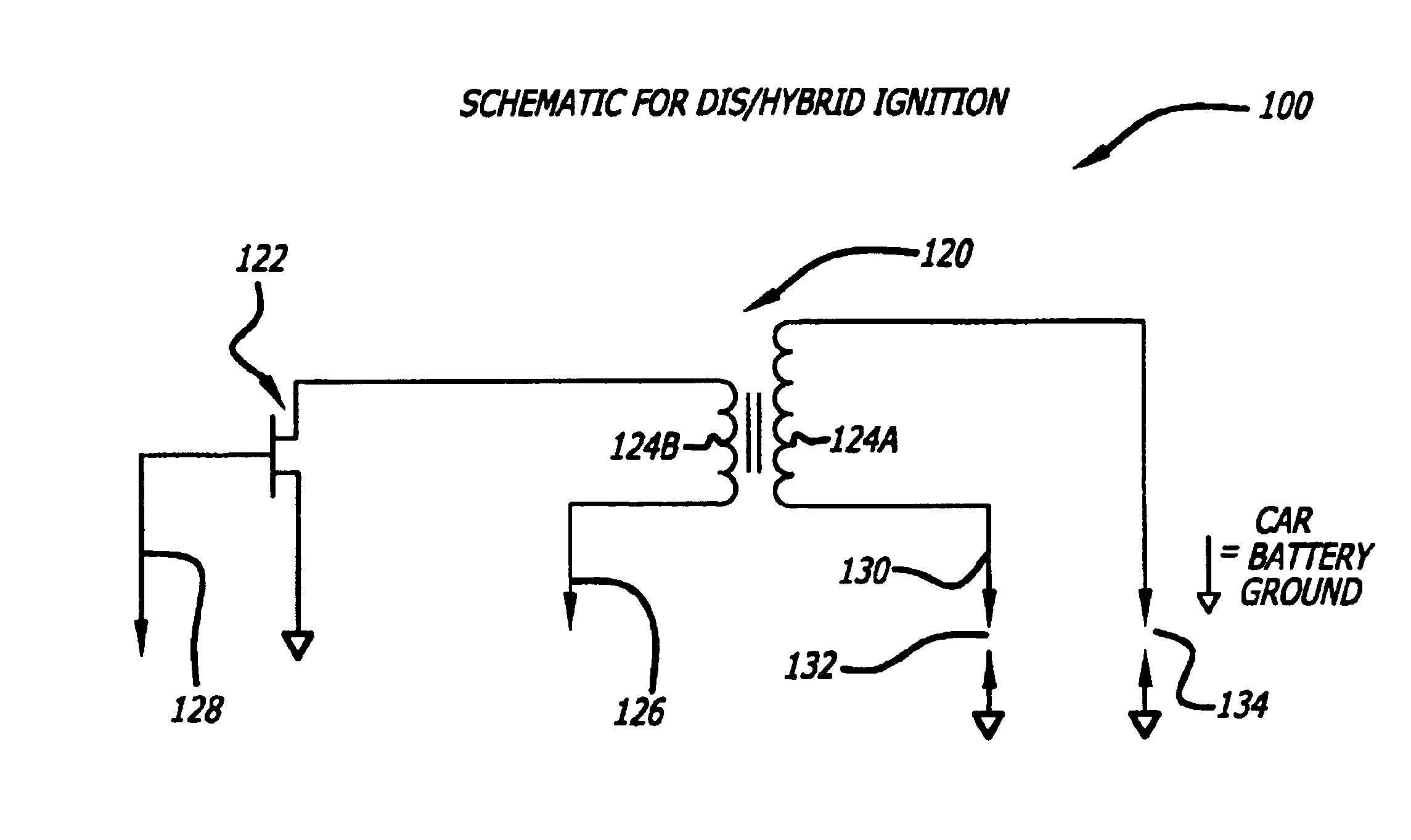

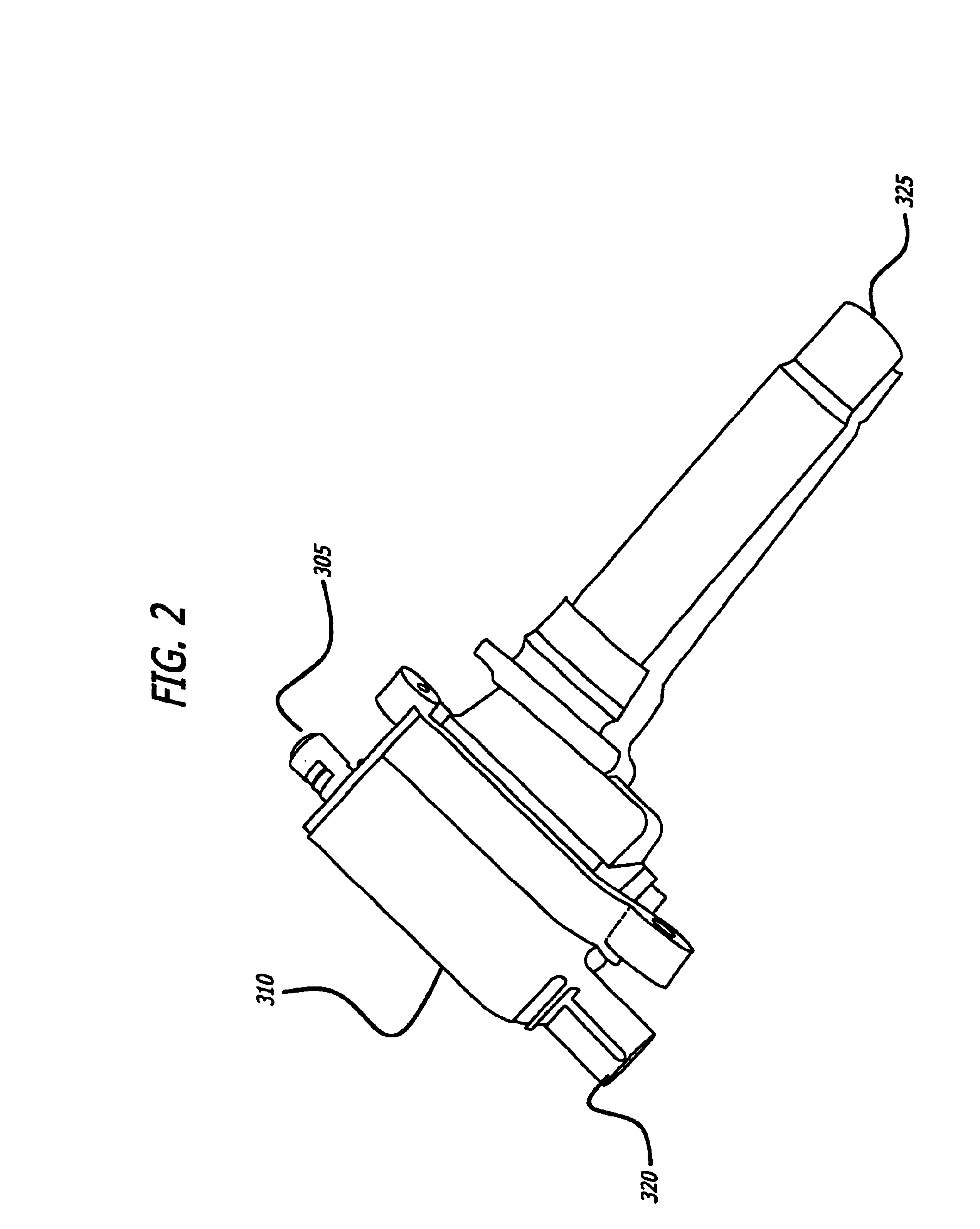

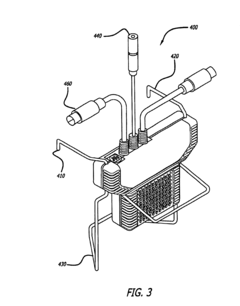

Efficient diagnosis of faulty distributorless and hybrid ignition systems

PatentInactiveUS6940284B2

Innovation

- A method involving the sequential disconnection and reconnection of primary connectors in distributorless or hybrid ignition systems to identify faulty cylinder pairs by observing changes in misfiring or roughness, followed by measuring firing line voltage to pinpoint the faulty cylinder using devices like SNAP ON VANTAGE MT2400 or SNAP ON DIS TESTER MT2700.

Environmental Impact of V8 Engine Maintenance

The environmental impact of V8 engine maintenance is a critical consideration in the automotive industry, particularly as global concerns about climate change and environmental sustainability continue to grow. Regular maintenance of V8 engines is essential for optimal performance and longevity, but it also has significant environmental implications that must be addressed.

One of the primary environmental concerns associated with V8 engine maintenance is the disposal of used engine oil and other fluids. These substances contain harmful contaminants that can pollute soil and water sources if not properly managed. Proper collection and recycling of used oil and coolants are crucial to minimize environmental damage. Many service centers and auto parts stores now offer recycling programs for these materials, helping to reduce their environmental impact.

Air pollution is another significant issue related to V8 engine maintenance. Poorly maintained engines can produce higher levels of emissions, including carbon monoxide, nitrogen oxides, and particulate matter. Regular tune-ups and maintenance can help ensure that V8 engines operate at peak efficiency, reducing harmful emissions and improving fuel economy. This not only benefits the environment but also extends the life of the engine and improves overall vehicle performance.

The production and disposal of replacement parts also contribute to the environmental footprint of V8 engine maintenance. Manufacturing new components requires energy and resources, while discarded parts can end up in landfills if not properly recycled. Encouraging the use of remanufactured or recycled parts can help reduce the demand for new components and minimize waste.

Chemical cleaners and degreasers used in engine maintenance can also have negative environmental effects if not handled properly. Many of these products contain volatile organic compounds (VOCs) that contribute to air pollution and can be harmful to human health. The automotive industry is increasingly moving towards more environmentally friendly cleaning solutions, including water-based and biodegradable products, to mitigate these impacts.

Proper disposal of waste materials generated during V8 engine maintenance is crucial for environmental protection. This includes not only used fluids and parts but also contaminated rags, filters, and packaging materials. Implementing comprehensive waste management practices in automotive service centers can significantly reduce the environmental impact of these activities.

As environmental regulations become more stringent, the automotive industry is developing new technologies and practices to reduce the environmental impact of V8 engine maintenance. This includes the development of more durable engine components that require less frequent replacement, as well as advanced diagnostic tools that can identify potential issues before they lead to more significant problems and increased emissions.

One of the primary environmental concerns associated with V8 engine maintenance is the disposal of used engine oil and other fluids. These substances contain harmful contaminants that can pollute soil and water sources if not properly managed. Proper collection and recycling of used oil and coolants are crucial to minimize environmental damage. Many service centers and auto parts stores now offer recycling programs for these materials, helping to reduce their environmental impact.

Air pollution is another significant issue related to V8 engine maintenance. Poorly maintained engines can produce higher levels of emissions, including carbon monoxide, nitrogen oxides, and particulate matter. Regular tune-ups and maintenance can help ensure that V8 engines operate at peak efficiency, reducing harmful emissions and improving fuel economy. This not only benefits the environment but also extends the life of the engine and improves overall vehicle performance.

The production and disposal of replacement parts also contribute to the environmental footprint of V8 engine maintenance. Manufacturing new components requires energy and resources, while discarded parts can end up in landfills if not properly recycled. Encouraging the use of remanufactured or recycled parts can help reduce the demand for new components and minimize waste.

Chemical cleaners and degreasers used in engine maintenance can also have negative environmental effects if not handled properly. Many of these products contain volatile organic compounds (VOCs) that contribute to air pollution and can be harmful to human health. The automotive industry is increasingly moving towards more environmentally friendly cleaning solutions, including water-based and biodegradable products, to mitigate these impacts.

Proper disposal of waste materials generated during V8 engine maintenance is crucial for environmental protection. This includes not only used fluids and parts but also contaminated rags, filters, and packaging materials. Implementing comprehensive waste management practices in automotive service centers can significantly reduce the environmental impact of these activities.

As environmental regulations become more stringent, the automotive industry is developing new technologies and practices to reduce the environmental impact of V8 engine maintenance. This includes the development of more durable engine components that require less frequent replacement, as well as advanced diagnostic tools that can identify potential issues before they lead to more significant problems and increased emissions.

V8 Engine Diagnostic Training and Certification

V8 Engine Diagnostic Training and Certification programs are essential for automotive technicians to develop the necessary skills and knowledge for effectively troubleshooting and repairing V8 engines. These programs typically cover a comprehensive range of topics, including engine fundamentals, advanced diagnostic techniques, and the latest technological advancements in V8 engine design.

The training curriculum often begins with a thorough review of V8 engine architecture and operating principles. This foundational knowledge is crucial for understanding the complex interactions between various engine components and systems. Participants learn about the unique characteristics of V8 engines, such as their firing order, crankshaft design, and valve timing mechanisms.

As the program progresses, technicians are introduced to advanced diagnostic tools and equipment specifically designed for V8 engine troubleshooting. This includes familiarization with computerized diagnostic systems, oscilloscopes, and specialized testing equipment. Hands-on training sessions allow participants to gain practical experience in using these tools to identify and diagnose common V8 engine issues.

A significant portion of the training focuses on interpreting diagnostic data and developing systematic problem-solving approaches. Technicians learn to analyze engine performance data, read and interpret fault codes, and perform comprehensive system checks. This includes training on how to diagnose issues related to fuel injection systems, ignition systems, and engine management computers specific to V8 engines.

The certification process typically involves both theoretical examinations and practical assessments. Theoretical tests evaluate the technician's understanding of V8 engine principles, diagnostic procedures, and relevant safety protocols. Practical assessments challenge technicians to diagnose and repair simulated V8 engine faults within specified time limits, demonstrating their ability to apply their knowledge in real-world scenarios.

Many training programs also incorporate modules on emerging technologies in V8 engine design, such as direct injection systems, variable valve timing, and cylinder deactivation. This ensures that certified technicians are prepared to work on the latest V8 engine models and can adapt to future technological advancements.

Upon successful completion of the training and certification process, technicians receive industry-recognized credentials that validate their expertise in V8 engine diagnostics. These certifications often require periodic renewal through continuing education courses, ensuring that technicians stay updated with the latest developments in V8 engine technology and diagnostic techniques.

The training curriculum often begins with a thorough review of V8 engine architecture and operating principles. This foundational knowledge is crucial for understanding the complex interactions between various engine components and systems. Participants learn about the unique characteristics of V8 engines, such as their firing order, crankshaft design, and valve timing mechanisms.

As the program progresses, technicians are introduced to advanced diagnostic tools and equipment specifically designed for V8 engine troubleshooting. This includes familiarization with computerized diagnostic systems, oscilloscopes, and specialized testing equipment. Hands-on training sessions allow participants to gain practical experience in using these tools to identify and diagnose common V8 engine issues.

A significant portion of the training focuses on interpreting diagnostic data and developing systematic problem-solving approaches. Technicians learn to analyze engine performance data, read and interpret fault codes, and perform comprehensive system checks. This includes training on how to diagnose issues related to fuel injection systems, ignition systems, and engine management computers specific to V8 engines.

The certification process typically involves both theoretical examinations and practical assessments. Theoretical tests evaluate the technician's understanding of V8 engine principles, diagnostic procedures, and relevant safety protocols. Practical assessments challenge technicians to diagnose and repair simulated V8 engine faults within specified time limits, demonstrating their ability to apply their knowledge in real-world scenarios.

Many training programs also incorporate modules on emerging technologies in V8 engine design, such as direct injection systems, variable valve timing, and cylinder deactivation. This ensures that certified technicians are prepared to work on the latest V8 engine models and can adapt to future technological advancements.

Upon successful completion of the training and certification process, technicians receive industry-recognized credentials that validate their expertise in V8 engine diagnostics. These certifications often require periodic renewal through continuing education courses, ensuring that technicians stay updated with the latest developments in V8 engine technology and diagnostic techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!