VVT Vs. VVL Advantages in B58 Engine Versatility

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine VVT/VVL Background and Objectives

The B58 engine, developed by BMW, represents a significant advancement in internal combustion engine technology. This inline-six turbocharged engine has gained prominence for its versatility and performance across various BMW models. At the heart of its adaptability are two key technologies: Variable Valve Timing (VVT) and Variable Valve Lift (VVL).

VVT technology allows for precise control of valve timing, adjusting the opening and closing of intake and exhaust valves based on engine speed and load. This capability enables the B58 engine to optimize performance, fuel efficiency, and emissions across a wide range of operating conditions. The system can advance or retard valve timing to enhance low-end torque, high-end power, or fuel economy as needed.

VVL, on the other hand, focuses on adjusting the lift of the valves, controlling how far they open. This technology complements VVT by allowing for variable airflow into the combustion chamber. By modulating valve lift, the B58 engine can fine-tune its breathing characteristics, further enhancing its adaptability to different driving scenarios and performance requirements.

The primary objective of implementing both VVT and VVL in the B58 engine is to create a highly versatile powerplant capable of meeting diverse performance demands while maintaining excellent fuel efficiency and emissions compliance. This dual approach allows BMW to use the B58 engine across multiple vehicle platforms, from sporty coupes to luxury sedans and even SUVs, with minimal modifications.

The evolution of these technologies in the B58 engine builds upon BMW's long-standing commitment to engine innovation. Previous generations of BMW engines, such as the N54 and N55, laid the groundwork for advanced valve control systems. The B58 represents the culmination of this development, integrating more sophisticated VVT and VVL systems to achieve unprecedented levels of engine versatility.

Looking forward, the implementation of VVT and VVL in the B58 engine sets the stage for future advancements in internal combustion engine technology. As emissions regulations become increasingly stringent and consumer demands for performance and efficiency continue to rise, the ability to precisely control valve operation becomes ever more critical. The B58's VVT and VVL systems provide a foundation for further refinements and potentially more advanced valve control strategies in future engine iterations.

VVT technology allows for precise control of valve timing, adjusting the opening and closing of intake and exhaust valves based on engine speed and load. This capability enables the B58 engine to optimize performance, fuel efficiency, and emissions across a wide range of operating conditions. The system can advance or retard valve timing to enhance low-end torque, high-end power, or fuel economy as needed.

VVL, on the other hand, focuses on adjusting the lift of the valves, controlling how far they open. This technology complements VVT by allowing for variable airflow into the combustion chamber. By modulating valve lift, the B58 engine can fine-tune its breathing characteristics, further enhancing its adaptability to different driving scenarios and performance requirements.

The primary objective of implementing both VVT and VVL in the B58 engine is to create a highly versatile powerplant capable of meeting diverse performance demands while maintaining excellent fuel efficiency and emissions compliance. This dual approach allows BMW to use the B58 engine across multiple vehicle platforms, from sporty coupes to luxury sedans and even SUVs, with minimal modifications.

The evolution of these technologies in the B58 engine builds upon BMW's long-standing commitment to engine innovation. Previous generations of BMW engines, such as the N54 and N55, laid the groundwork for advanced valve control systems. The B58 represents the culmination of this development, integrating more sophisticated VVT and VVL systems to achieve unprecedented levels of engine versatility.

Looking forward, the implementation of VVT and VVL in the B58 engine sets the stage for future advancements in internal combustion engine technology. As emissions regulations become increasingly stringent and consumer demands for performance and efficiency continue to rise, the ability to precisely control valve operation becomes ever more critical. The B58's VVT and VVL systems provide a foundation for further refinements and potentially more advanced valve control strategies in future engine iterations.

Market Demand for Engine Versatility

The market demand for engine versatility has been steadily increasing in recent years, driven by several key factors. Consumers are increasingly seeking vehicles that offer a balance of performance, fuel efficiency, and environmental sustainability. This shift in consumer preferences has led automakers to focus on developing engines that can adapt to various driving conditions and regulatory requirements.

The B58 engine, with its potential for incorporating both Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies, is positioned to meet these evolving market demands. VVT and VVL systems allow for greater control over engine performance, enabling manufacturers to optimize power output, fuel economy, and emissions across a wide range of operating conditions.

In the automotive industry, there is a growing trend towards downsizing engines while maintaining or improving performance. This trend is partly driven by stringent emissions regulations and fuel economy standards imposed by governments worldwide. The versatility offered by advanced valve control systems like VVT and VVL allows manufacturers to meet these regulatory requirements without sacrificing performance.

The premium and luxury vehicle segments, where the B58 engine is commonly used, have shown particular interest in engine versatility. Customers in these segments demand vehicles that can provide both exhilarating performance and refined, efficient operation for daily driving. The ability to seamlessly transition between these modes is a key selling point for many high-end vehicles.

Furthermore, the global push towards electrification has paradoxically increased the demand for versatile internal combustion engines. As automakers invest heavily in electric vehicle technology, they are also seeking to maximize the efficiency and performance of their conventional powertrains to remain competitive in the transitional period.

The aftermarket and tuning community also contribute to the demand for engine versatility. The adaptability of engines like the B58, especially when equipped with advanced valve control systems, provides a platform for enthusiasts and tuners to modify and enhance engine performance according to their preferences.

In emerging markets, where infrastructure and fuel quality can vary significantly, engine versatility is particularly valued. The ability to adapt to different fuel grades and driving conditions makes versatile engines like the B58 attractive options for global automotive platforms.

As the automotive industry continues to evolve, the demand for engine versatility is expected to grow further. Manufacturers that can offer engines capable of meeting diverse performance, efficiency, and emissions requirements across various markets and vehicle segments are likely to gain a competitive advantage in the coming years.

The B58 engine, with its potential for incorporating both Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies, is positioned to meet these evolving market demands. VVT and VVL systems allow for greater control over engine performance, enabling manufacturers to optimize power output, fuel economy, and emissions across a wide range of operating conditions.

In the automotive industry, there is a growing trend towards downsizing engines while maintaining or improving performance. This trend is partly driven by stringent emissions regulations and fuel economy standards imposed by governments worldwide. The versatility offered by advanced valve control systems like VVT and VVL allows manufacturers to meet these regulatory requirements without sacrificing performance.

The premium and luxury vehicle segments, where the B58 engine is commonly used, have shown particular interest in engine versatility. Customers in these segments demand vehicles that can provide both exhilarating performance and refined, efficient operation for daily driving. The ability to seamlessly transition between these modes is a key selling point for many high-end vehicles.

Furthermore, the global push towards electrification has paradoxically increased the demand for versatile internal combustion engines. As automakers invest heavily in electric vehicle technology, they are also seeking to maximize the efficiency and performance of their conventional powertrains to remain competitive in the transitional period.

The aftermarket and tuning community also contribute to the demand for engine versatility. The adaptability of engines like the B58, especially when equipped with advanced valve control systems, provides a platform for enthusiasts and tuners to modify and enhance engine performance according to their preferences.

In emerging markets, where infrastructure and fuel quality can vary significantly, engine versatility is particularly valued. The ability to adapt to different fuel grades and driving conditions makes versatile engines like the B58 attractive options for global automotive platforms.

As the automotive industry continues to evolve, the demand for engine versatility is expected to grow further. Manufacturers that can offer engines capable of meeting diverse performance, efficiency, and emissions requirements across various markets and vehicle segments are likely to gain a competitive advantage in the coming years.

VVT and VVL Technology Status and Challenges

Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies have become integral components in modern engine design, particularly in high-performance engines like BMW's B58. These technologies have evolved significantly over the past few decades, with continuous advancements in both mechanical and electronic control systems.

The current status of VVT and VVL technologies showcases their widespread adoption across various automotive manufacturers. VVT systems have become standard in most modern engines, offering improved fuel efficiency, reduced emissions, and enhanced performance across a wide range of engine speeds. VVL technology, while less ubiquitous, has gained traction in premium and performance-oriented vehicles due to its ability to further optimize engine breathing and power output.

Despite their widespread implementation, these technologies still face several challenges. One primary concern is the complexity of the systems, which can lead to increased manufacturing costs and potential reliability issues. The intricate mechanical components and sophisticated control algorithms require precise calibration and maintenance, potentially impacting long-term durability.

Another significant challenge lies in the integration of these technologies with emerging powertrain trends, such as hybridization and electrification. As the automotive industry shifts towards more sustainable solutions, adapting VVT and VVL systems to work seamlessly with electric motors and regenerative braking systems presents new engineering hurdles.

The pursuit of even greater efficiency gains poses another challenge. While current VVT and VVL systems offer substantial improvements over fixed valve timing and lift, there is ongoing research to develop more advanced systems that can provide even finer control over valve events. This includes the development of fully variable valve actuation systems that can independently control each valve's timing and lift.

Emissions regulations continue to tighten globally, pushing engineers to refine VVT and VVL technologies further. The challenge lies in optimizing these systems to meet stringent emissions standards without compromising performance or drivability. This often requires sophisticated engine management systems and advanced catalytic converters working in tandem with VVT and VVL.

In the context of BMW's B58 engine, the implementation of both VVT and VVL technologies has contributed significantly to its versatility. However, balancing the advantages of each system while managing complexity and cost remains an ongoing challenge. The B58's success in various BMW models demonstrates the potential of these technologies when effectively integrated, but also highlights the need for continuous innovation to address the evolving demands of the automotive industry.

The current status of VVT and VVL technologies showcases their widespread adoption across various automotive manufacturers. VVT systems have become standard in most modern engines, offering improved fuel efficiency, reduced emissions, and enhanced performance across a wide range of engine speeds. VVL technology, while less ubiquitous, has gained traction in premium and performance-oriented vehicles due to its ability to further optimize engine breathing and power output.

Despite their widespread implementation, these technologies still face several challenges. One primary concern is the complexity of the systems, which can lead to increased manufacturing costs and potential reliability issues. The intricate mechanical components and sophisticated control algorithms require precise calibration and maintenance, potentially impacting long-term durability.

Another significant challenge lies in the integration of these technologies with emerging powertrain trends, such as hybridization and electrification. As the automotive industry shifts towards more sustainable solutions, adapting VVT and VVL systems to work seamlessly with electric motors and regenerative braking systems presents new engineering hurdles.

The pursuit of even greater efficiency gains poses another challenge. While current VVT and VVL systems offer substantial improvements over fixed valve timing and lift, there is ongoing research to develop more advanced systems that can provide even finer control over valve events. This includes the development of fully variable valve actuation systems that can independently control each valve's timing and lift.

Emissions regulations continue to tighten globally, pushing engineers to refine VVT and VVL technologies further. The challenge lies in optimizing these systems to meet stringent emissions standards without compromising performance or drivability. This often requires sophisticated engine management systems and advanced catalytic converters working in tandem with VVT and VVL.

In the context of BMW's B58 engine, the implementation of both VVT and VVL technologies has contributed significantly to its versatility. However, balancing the advantages of each system while managing complexity and cost remains an ongoing challenge. The B58's success in various BMW models demonstrates the potential of these technologies when effectively integrated, but also highlights the need for continuous innovation to address the evolving demands of the automotive industry.

Current VVT and VVL Implementation in B58

01 Engine design adaptability

The B58 engine demonstrates versatility through its adaptable design, allowing for various applications across different vehicle models and performance requirements. This flexibility enables manufacturers to utilize the same base engine architecture for a range of automotive applications, reducing development costs and improving efficiency.- Engine Design Adaptability: The B58 engine demonstrates versatility through its adaptable design, allowing for various applications across different vehicle models and performance requirements. This flexibility enables manufacturers to utilize the same core engine architecture while tailoring specific components to meet diverse needs.

- Modular Component System: A key aspect of the B58 engine's versatility is its modular component system. This approach allows for easy customization and upgrades, enabling manufacturers to efficiently produce different engine variants with shared core components, reducing production costs and complexity.

- Turbocharging and Power Output Variability: The B58 engine's versatility is enhanced by its turbocharging capabilities, allowing for a wide range of power outputs. This feature enables the engine to be used in various vehicle types, from standard passenger cars to high-performance sports models, by adjusting boost pressure and other parameters.

- Fuel Efficiency and Emissions Compliance: Versatility in the B58 engine extends to its ability to meet various fuel efficiency standards and emissions regulations. Advanced technologies incorporated into the engine design allow for optimized fuel consumption and reduced emissions across different markets and vehicle applications.

- Integration with Hybrid Systems: The B58 engine demonstrates versatility through its compatibility with hybrid powertrains. This adaptability allows the engine to be integrated into various hybrid configurations, extending its use in eco-friendly vehicle models and meeting evolving market demands for electrification.

02 Modular components and customization

The engine's versatility is enhanced by its modular design, featuring interchangeable components that can be easily customized or upgraded. This approach allows for quick adaptation to different power output requirements and emissions standards, making the B58 engine suitable for diverse market demands.Expand Specific Solutions03 Advanced fuel management systems

Incorporating advanced fuel management systems contributes to the B58 engine's versatility. These systems allow for precise control of fuel injection and combustion processes, enabling the engine to operate efficiently under various conditions and meet different performance targets while maintaining compliance with emissions regulations.Expand Specific Solutions04 Turbocharging and power enhancement

The B58 engine's versatility is further improved through its turbocharging capabilities and power enhancement features. These technologies allow for significant power output increases while maintaining efficiency, making the engine suitable for both high-performance and economical applications.Expand Specific Solutions05 Integration with hybrid and electrification systems

The B58 engine demonstrates versatility in its ability to integrate with hybrid and electrification systems. This adaptability allows the engine to be used in various powertrain configurations, including mild hybrid, full hybrid, and plug-in hybrid vehicles, extending its relevance in the evolving automotive landscape.Expand Specific Solutions

Key Players in VVT/VVL Engine Technology

The competition in VVT (Variable Valve Timing) vs. VVL (Variable Valve Lift) for B58 engine versatility is in a mature stage, with established players like BMW, Toyota, and Ford leading the market. The global automotive VVT system market size is projected to reach $52 billion by 2025, driven by increasing demand for fuel-efficient vehicles. Technologically, both VVT and VVL systems are well-developed, with companies like BorgWarner, DENSO, and Continental Automotive Technologies offering advanced solutions. However, there's ongoing innovation in integrating these technologies for improved engine performance and efficiency, particularly in the context of hybrid and electric powertrains.

GM Global Technology Operations LLC

Technical Solution: GM's approach to VVT and VVL in their engines, including the B58-like configurations, focuses on a dual-independent system. This system allows for independent control of both intake and exhaust valve timing, optimizing engine performance across a wide range of operating conditions. GM's technology includes a cam phaser system that can adjust valve timing by up to 62 degrees[1], significantly improving low-end torque and high-end power. Additionally, GM has implemented a two-step valve lift system, which switches between low and high lift profiles based on engine load and speed, enhancing fuel efficiency and performance[2]. The company has also integrated this technology with direct injection and turbocharging to further improve engine versatility and efficiency.

Strengths: Improved fuel efficiency, enhanced low-end torque, and better high-end power. Weaknesses: Increased system complexity and potential for higher maintenance costs.

Ford Global Technologies LLC

Technical Solution: Ford's approach to VVT and VVL technology, applicable to engines similar to the B58, incorporates their Ti-VCT (Twin Independent Variable Camshaft Timing) system. This system allows for independent control of intake and exhaust valve timing, optimizing engine performance across various operating conditions. Ford has also developed a dual-mode crankshaft pulley that enables two distinct valve lift profiles, enhancing engine versatility[3]. In some applications, Ford combines VVT with cylinder deactivation technology, allowing the engine to shut down cylinders under light load conditions for improved fuel efficiency[4]. Ford's implementation also includes integration with EcoBoost technology, combining turbocharging and direct injection with VVT for enhanced power output and fuel economy.

Strengths: Improved fuel efficiency, enhanced power output, and flexibility across different engine loads. Weaknesses: Increased system complexity and potential for higher production costs.

Core Innovations in Valve Control Systems

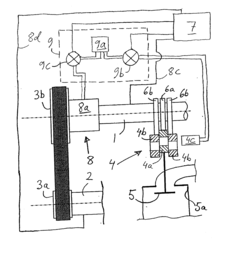

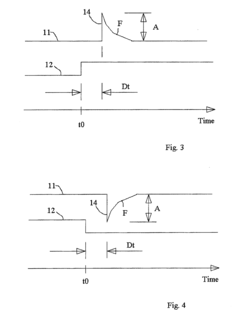

Internal combustion engine comprising a variable valve lift system and a variable valve timing system, and a method for such an engine

PatentInactiveUS20070113807A1

Innovation

- A method is implemented to control valve timing by sending a control pulsing signal to the VVT system actuator in response to valve lift mode shifts, using a controllable valve to counteract pressure changes and maintain consistent VVT position.

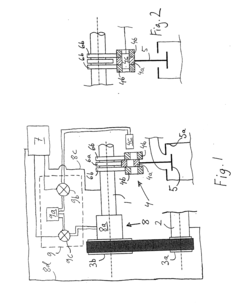

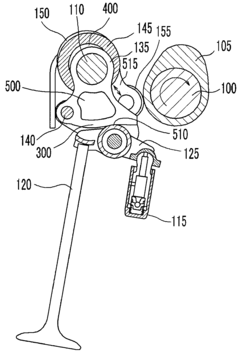

Continuously Variable Valve Lift Apparatus

PatentInactiveUS20100139588A1

Innovation

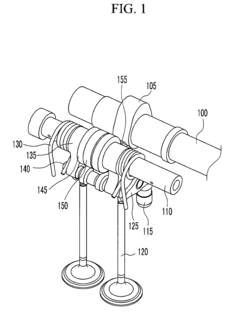

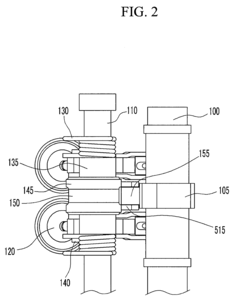

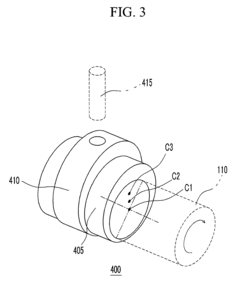

- A continuously variable valve lift apparatus featuring a control shaft, eccentric member, roller-type follower, and variable ring, which allows for adjustable valve lift and timing through a system of links and cams, enabling the valve lift amount and timing to be varied in response to engine speed, reducing fuel consumption and pumping losses.

Emissions Regulations Impact on Engine Design

Emissions regulations have become a driving force in shaping modern engine design, particularly in the context of the B58 engine's versatility and the comparison between Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies. As global environmental concerns intensify, regulatory bodies worldwide have implemented increasingly stringent emissions standards, compelling automotive manufacturers to innovate and adapt their engine designs.

The impact of these regulations on engine design is multifaceted, affecting various aspects of performance, efficiency, and environmental impact. One of the primary focuses has been on reducing harmful emissions, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. This has led to the development and implementation of advanced technologies like VVT and VVL, which offer greater control over engine operation and combustion processes.

In the case of the B58 engine, emissions regulations have necessitated a careful balance between performance and environmental compliance. The engine's design incorporates sophisticated systems to optimize fuel consumption and minimize emissions across a wide range of operating conditions. This adaptability is crucial in meeting diverse regulatory requirements across different markets and driving scenarios.

The choice between VVT and VVL technologies in the B58 engine is significantly influenced by emissions standards. VVT allows for precise control of valve timing, enabling better management of exhaust gas recirculation and combustion efficiency. This capability is particularly valuable in meeting NOx emission targets. On the other hand, VVL offers additional flexibility in controlling valve lift, which can further optimize engine breathing and reduce pumping losses, contributing to improved fuel efficiency and reduced CO2 emissions.

Emissions regulations have also pushed for the integration of advanced aftertreatment systems in engine design. The B58 engine, like many modern engines, incorporates catalytic converters, particulate filters, and other emission control devices. The effectiveness of these systems is closely tied to engine operation, making technologies like VVT and VVL crucial in ensuring optimal performance of the entire emissions control system.

Furthermore, the global nature of emissions regulations has necessitated a versatile engine design that can be adapted to meet varying standards across different markets. This has led to the development of modular engine architectures and flexible control strategies, allowing manufacturers to fine-tune engine performance and emissions characteristics for specific regulatory environments without fundamental redesigns.

In conclusion, emissions regulations have profoundly influenced the design philosophy behind engines like the B58, driving the adoption of advanced technologies such as VVT and VVL. These regulations continue to shape the evolution of engine design, pushing for ever-greater efficiency and cleaner operation while maintaining performance and versatility.

The impact of these regulations on engine design is multifaceted, affecting various aspects of performance, efficiency, and environmental impact. One of the primary focuses has been on reducing harmful emissions, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. This has led to the development and implementation of advanced technologies like VVT and VVL, which offer greater control over engine operation and combustion processes.

In the case of the B58 engine, emissions regulations have necessitated a careful balance between performance and environmental compliance. The engine's design incorporates sophisticated systems to optimize fuel consumption and minimize emissions across a wide range of operating conditions. This adaptability is crucial in meeting diverse regulatory requirements across different markets and driving scenarios.

The choice between VVT and VVL technologies in the B58 engine is significantly influenced by emissions standards. VVT allows for precise control of valve timing, enabling better management of exhaust gas recirculation and combustion efficiency. This capability is particularly valuable in meeting NOx emission targets. On the other hand, VVL offers additional flexibility in controlling valve lift, which can further optimize engine breathing and reduce pumping losses, contributing to improved fuel efficiency and reduced CO2 emissions.

Emissions regulations have also pushed for the integration of advanced aftertreatment systems in engine design. The B58 engine, like many modern engines, incorporates catalytic converters, particulate filters, and other emission control devices. The effectiveness of these systems is closely tied to engine operation, making technologies like VVT and VVL crucial in ensuring optimal performance of the entire emissions control system.

Furthermore, the global nature of emissions regulations has necessitated a versatile engine design that can be adapted to meet varying standards across different markets. This has led to the development of modular engine architectures and flexible control strategies, allowing manufacturers to fine-tune engine performance and emissions characteristics for specific regulatory environments without fundamental redesigns.

In conclusion, emissions regulations have profoundly influenced the design philosophy behind engines like the B58, driving the adoption of advanced technologies such as VVT and VVL. These regulations continue to shape the evolution of engine design, pushing for ever-greater efficiency and cleaner operation while maintaining performance and versatility.

Cost-Benefit Analysis of VVT vs VVL in B58

The cost-benefit analysis of Variable Valve Timing (VVT) versus Variable Valve Lift (VVL) in the BMW B58 engine reveals significant implications for both performance and economic considerations. VVT technology, already implemented in the B58, offers a more cost-effective solution with proven reliability and performance benefits. It allows for precise control of valve timing, improving engine efficiency across a wide range of operating conditions.

On the other hand, VVL technology presents potential advantages in terms of enhanced performance and fuel efficiency. However, its implementation comes with higher initial costs and increased complexity. The B58 engine, known for its versatility and robust design, would require substantial modifications to incorporate VVL, potentially affecting its reliability and manufacturing processes.

From a cost perspective, VVT maintains a clear advantage. The existing infrastructure and production processes for VVT in the B58 engine contribute to lower manufacturing costs and reduced complexity in the supply chain. Conversely, integrating VVL would necessitate significant investments in retooling production lines and retraining personnel, leading to higher unit costs.

Performance-wise, while VVL offers theoretical advantages in terms of power output and fuel efficiency, the real-world benefits may not justify the additional costs for the B58 engine. VVT already provides substantial performance gains, and the marginal improvements from VVL might not translate into a noticeable difference for most drivers.

Maintenance and long-term reliability also favor VVT. The simpler mechanism of VVT results in lower maintenance costs and potentially longer engine life. VVL's more complex system could lead to increased wear and tear, potentially resulting in higher maintenance expenses over the vehicle's lifetime.

Fuel efficiency improvements, a key selling point for VVL, must be carefully weighed against the increased production costs. While VVL can offer slightly better fuel economy, the difference may not be significant enough in the B58 engine to offset the higher manufacturing and retail costs.

In conclusion, the cost-benefit analysis leans towards maintaining VVT in the B58 engine. The proven technology, lower costs, and satisfactory performance improvements make it a more economically viable option. While VVL presents interesting possibilities, its benefits may not outweigh the substantial costs and potential risks associated with its implementation in the B58 platform.

On the other hand, VVL technology presents potential advantages in terms of enhanced performance and fuel efficiency. However, its implementation comes with higher initial costs and increased complexity. The B58 engine, known for its versatility and robust design, would require substantial modifications to incorporate VVL, potentially affecting its reliability and manufacturing processes.

From a cost perspective, VVT maintains a clear advantage. The existing infrastructure and production processes for VVT in the B58 engine contribute to lower manufacturing costs and reduced complexity in the supply chain. Conversely, integrating VVL would necessitate significant investments in retooling production lines and retraining personnel, leading to higher unit costs.

Performance-wise, while VVL offers theoretical advantages in terms of power output and fuel efficiency, the real-world benefits may not justify the additional costs for the B58 engine. VVT already provides substantial performance gains, and the marginal improvements from VVL might not translate into a noticeable difference for most drivers.

Maintenance and long-term reliability also favor VVT. The simpler mechanism of VVT results in lower maintenance costs and potentially longer engine life. VVL's more complex system could lead to increased wear and tear, potentially resulting in higher maintenance expenses over the vehicle's lifetime.

Fuel efficiency improvements, a key selling point for VVL, must be carefully weighed against the increased production costs. While VVL can offer slightly better fuel economy, the difference may not be significant enough in the B58 engine to offset the higher manufacturing and retail costs.

In conclusion, the cost-benefit analysis leans towards maintaining VVT in the B58 engine. The proven technology, lower costs, and satisfactory performance improvements make it a more economically viable option. While VVL presents interesting possibilities, its benefits may not outweigh the substantial costs and potential risks associated with its implementation in the B58 platform.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!