What New Fabrication Methods Enhance Scalability Of Capture Membranes

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Capture Membrane Fabrication Evolution and Objectives

Capture membrane technology has evolved significantly over the past several decades, transitioning from rudimentary filtration systems to sophisticated, highly selective separation platforms. The journey began in the 1960s with the development of basic cellulose acetate membranes for reverse osmosis applications, which laid the groundwork for more advanced capture membrane technologies. By the 1980s, polymeric membranes with improved selectivity emerged, followed by the introduction of composite membranes in the 1990s that combined multiple materials to enhance performance characteristics.

The early 2000s witnessed a paradigm shift with the integration of nanotechnology into membrane fabrication, enabling precise control over pore size and distribution. This period marked the beginning of nanoporous membranes, which offered unprecedented selectivity for specific molecules and contaminants. The subsequent decade saw the rise of biomimetic membranes inspired by natural biological systems, incorporating protein channels and aquaporins to achieve remarkable separation efficiency while minimizing energy consumption.

Recent years have been characterized by the development of stimuli-responsive membranes capable of adapting their properties in response to environmental changes, as well as the incorporation of advanced materials such as graphene, metal-organic frameworks (MOFs), and covalent organic frameworks (COFs). These innovations have dramatically expanded the application scope of capture membranes across industries including water purification, gas separation, pharmaceutical processing, and environmental remediation.

Despite these advancements, the primary challenge facing the field today is scalability. Laboratory-scale fabrication methods often fail to translate effectively to industrial production, creating a significant barrier to widespread adoption. Current objectives in capture membrane research are therefore centered on developing fabrication techniques that maintain nanoscale precision while enabling large-scale production at economically viable costs.

Key technical objectives include establishing continuous manufacturing processes that replace batch production, standardizing quality control metrics across different membrane types, and reducing the energy intensity of membrane fabrication. Additionally, there is a growing focus on sustainability, with efforts directed toward incorporating renewable materials and minimizing waste generation during production.

The ultimate goal is to develop a new generation of capture membranes that combine high selectivity, robust mechanical properties, and long-term stability with scalable manufacturing processes. This would enable their deployment in addressing global challenges such as water scarcity, air pollution, and resource recovery from waste streams. Success in this endeavor requires interdisciplinary collaboration between materials scientists, chemical engineers, process engineers, and environmental specialists to overcome the complex challenges associated with scaling precision nanofabrication techniques.

The early 2000s witnessed a paradigm shift with the integration of nanotechnology into membrane fabrication, enabling precise control over pore size and distribution. This period marked the beginning of nanoporous membranes, which offered unprecedented selectivity for specific molecules and contaminants. The subsequent decade saw the rise of biomimetic membranes inspired by natural biological systems, incorporating protein channels and aquaporins to achieve remarkable separation efficiency while minimizing energy consumption.

Recent years have been characterized by the development of stimuli-responsive membranes capable of adapting their properties in response to environmental changes, as well as the incorporation of advanced materials such as graphene, metal-organic frameworks (MOFs), and covalent organic frameworks (COFs). These innovations have dramatically expanded the application scope of capture membranes across industries including water purification, gas separation, pharmaceutical processing, and environmental remediation.

Despite these advancements, the primary challenge facing the field today is scalability. Laboratory-scale fabrication methods often fail to translate effectively to industrial production, creating a significant barrier to widespread adoption. Current objectives in capture membrane research are therefore centered on developing fabrication techniques that maintain nanoscale precision while enabling large-scale production at economically viable costs.

Key technical objectives include establishing continuous manufacturing processes that replace batch production, standardizing quality control metrics across different membrane types, and reducing the energy intensity of membrane fabrication. Additionally, there is a growing focus on sustainability, with efforts directed toward incorporating renewable materials and minimizing waste generation during production.

The ultimate goal is to develop a new generation of capture membranes that combine high selectivity, robust mechanical properties, and long-term stability with scalable manufacturing processes. This would enable their deployment in addressing global challenges such as water scarcity, air pollution, and resource recovery from waste streams. Success in this endeavor requires interdisciplinary collaboration between materials scientists, chemical engineers, process engineers, and environmental specialists to overcome the complex challenges associated with scaling precision nanofabrication techniques.

Market Analysis for Scalable Capture Membrane Technologies

The global market for capture membrane technologies has experienced significant growth in recent years, driven by increasing environmental regulations, water scarcity concerns, and industrial demand for efficient separation processes. The market size for advanced membrane technologies was valued at approximately $5.4 billion in 2022 and is projected to reach $8.2 billion by 2027, representing a compound annual growth rate of 8.7%.

Water treatment applications currently dominate the capture membrane market, accounting for nearly 45% of total demand. This segment is particularly strong in regions facing severe water stress, including parts of Asia-Pacific, Middle East, and North America. Industrial separation processes constitute the second-largest application segment at 30%, with pharmaceutical and biotechnology applications growing at the fastest rate among all segments.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Key market drivers include stringent environmental regulations regarding emissions and waste management, growing water scarcity concerns, and increasing industrial demand for high-purity separation processes. The push toward carbon capture technologies has created a new growth avenue for specialized membrane solutions, with this segment expected to grow at over 12% annually through 2027.

Customer requirements are evolving toward membranes with higher throughput, improved selectivity, and longer operational lifespans. End-users increasingly demand solutions that offer lower energy consumption and reduced operational costs, creating market opportunities for innovations in fabrication methods that enhance scalability while maintaining performance.

Market challenges include high initial capital investment requirements, technical limitations in existing membrane technologies, and competition from alternative separation technologies. The cost-performance ratio remains a critical factor influencing adoption rates, particularly in emerging economies.

The competitive landscape features both established players and innovative startups. Major companies like DuPont, 3M, Asahi Kasei, and Toray Industries hold significant market share, while specialized firms like Evonik, Pentair, and Membrane Technology and Research (MTR) focus on niche applications. Recent market activity shows increasing consolidation through mergers and acquisitions, as companies seek to expand their technological portfolios and geographical presence.

Water treatment applications currently dominate the capture membrane market, accounting for nearly 45% of total demand. This segment is particularly strong in regions facing severe water stress, including parts of Asia-Pacific, Middle East, and North America. Industrial separation processes constitute the second-largest application segment at 30%, with pharmaceutical and biotechnology applications growing at the fastest rate among all segments.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Key market drivers include stringent environmental regulations regarding emissions and waste management, growing water scarcity concerns, and increasing industrial demand for high-purity separation processes. The push toward carbon capture technologies has created a new growth avenue for specialized membrane solutions, with this segment expected to grow at over 12% annually through 2027.

Customer requirements are evolving toward membranes with higher throughput, improved selectivity, and longer operational lifespans. End-users increasingly demand solutions that offer lower energy consumption and reduced operational costs, creating market opportunities for innovations in fabrication methods that enhance scalability while maintaining performance.

Market challenges include high initial capital investment requirements, technical limitations in existing membrane technologies, and competition from alternative separation technologies. The cost-performance ratio remains a critical factor influencing adoption rates, particularly in emerging economies.

The competitive landscape features both established players and innovative startups. Major companies like DuPont, 3M, Asahi Kasei, and Toray Industries hold significant market share, while specialized firms like Evonik, Pentair, and Membrane Technology and Research (MTR) focus on niche applications. Recent market activity shows increasing consolidation through mergers and acquisitions, as companies seek to expand their technological portfolios and geographical presence.

Current Fabrication Limitations and Technical Barriers

Despite significant advancements in capture membrane technology, several critical fabrication limitations and technical barriers continue to impede large-scale implementation. Conventional membrane fabrication methods such as phase inversion, interfacial polymerization, and track-etching face substantial challenges when scaled beyond laboratory settings. These processes often suffer from inconsistent pore size distribution and membrane thickness when production volumes increase, directly compromising capture efficiency and selectivity.

Material limitations represent another significant barrier, as many high-performance capture membranes rely on expensive or difficult-to-source components. For instance, membranes incorporating noble metals or specialized polymers face prohibitive cost increases at industrial scales. Additionally, the complex chemical modifications required to enhance capture specificity often involve multi-step processes that are difficult to standardize across large production batches.

Equipment constraints further complicate scalability efforts. Many advanced fabrication techniques require specialized equipment operating under precisely controlled conditions. Techniques such as electrospinning for nanofiber membrane production demand consistent environmental parameters that become increasingly difficult to maintain as production area expands. Similarly, lithographic approaches used for creating precisely patterned capture surfaces face significant throughput limitations when scaled up.

Process integration challenges emerge when transitioning from batch to continuous manufacturing. Most laboratory-scale membrane fabrication relies on batch processes that are inherently difficult to convert to continuous production lines without sacrificing quality control. The sequential nature of membrane functionalization—often requiring multiple coating, washing, and drying steps—creates bottlenecks that dramatically reduce production efficiency at scale.

Quality control represents perhaps the most persistent technical barrier. As production volumes increase, detecting defects and ensuring uniform performance becomes exponentially more challenging. Current inspection technologies struggle to identify nanoscale imperfections across large membrane areas, leading to higher rejection rates and increased production costs. Non-destructive testing methods capable of validating membrane performance at industrial scales remain underdeveloped.

Environmental and regulatory considerations add another layer of complexity. Many traditional membrane fabrication processes utilize solvents and chemicals with significant environmental impacts. Scaling these processes requires substantial investment in containment and waste treatment systems, particularly as regulatory frameworks become increasingly stringent regarding chemical usage and disposal.

Lastly, the interdisciplinary nature of advanced capture membrane development creates knowledge transfer barriers. Innovations often emerge from specialized research environments with limited manufacturing expertise, creating significant challenges when translating laboratory successes to industrial production environments. This disconnect frequently results in promising technologies failing to achieve commercial viability despite excellent performance characteristics in controlled settings.

Material limitations represent another significant barrier, as many high-performance capture membranes rely on expensive or difficult-to-source components. For instance, membranes incorporating noble metals or specialized polymers face prohibitive cost increases at industrial scales. Additionally, the complex chemical modifications required to enhance capture specificity often involve multi-step processes that are difficult to standardize across large production batches.

Equipment constraints further complicate scalability efforts. Many advanced fabrication techniques require specialized equipment operating under precisely controlled conditions. Techniques such as electrospinning for nanofiber membrane production demand consistent environmental parameters that become increasingly difficult to maintain as production area expands. Similarly, lithographic approaches used for creating precisely patterned capture surfaces face significant throughput limitations when scaled up.

Process integration challenges emerge when transitioning from batch to continuous manufacturing. Most laboratory-scale membrane fabrication relies on batch processes that are inherently difficult to convert to continuous production lines without sacrificing quality control. The sequential nature of membrane functionalization—often requiring multiple coating, washing, and drying steps—creates bottlenecks that dramatically reduce production efficiency at scale.

Quality control represents perhaps the most persistent technical barrier. As production volumes increase, detecting defects and ensuring uniform performance becomes exponentially more challenging. Current inspection technologies struggle to identify nanoscale imperfections across large membrane areas, leading to higher rejection rates and increased production costs. Non-destructive testing methods capable of validating membrane performance at industrial scales remain underdeveloped.

Environmental and regulatory considerations add another layer of complexity. Many traditional membrane fabrication processes utilize solvents and chemicals with significant environmental impacts. Scaling these processes requires substantial investment in containment and waste treatment systems, particularly as regulatory frameworks become increasingly stringent regarding chemical usage and disposal.

Lastly, the interdisciplinary nature of advanced capture membrane development creates knowledge transfer barriers. Innovations often emerge from specialized research environments with limited manufacturing expertise, creating significant challenges when translating laboratory successes to industrial production environments. This disconnect frequently results in promising technologies failing to achieve commercial viability despite excellent performance characteristics in controlled settings.

State-of-the-Art Scalable Fabrication Approaches

01 Scalable membrane manufacturing techniques

Various manufacturing techniques have been developed to scale up the production of capture membranes. These include advanced fabrication methods that allow for consistent quality across large production volumes. The techniques focus on maintaining membrane integrity and performance characteristics while increasing production capacity. Innovations in this area address challenges related to material uniformity, thickness control, and structural consistency during mass production.- Scalable membrane manufacturing techniques: Various manufacturing techniques have been developed to scale up the production of capture membranes. These include advanced fabrication methods that allow for consistent quality across large production volumes. The techniques focus on maintaining membrane integrity and performance characteristics while increasing production capacity. Innovations in this area address challenges related to material uniformity, thickness control, and structural consistency during mass production.

- Modular membrane systems for capacity expansion: Modular approaches to membrane system design enable scalability through the addition of standardized units. These systems allow for incremental capacity expansion without redesigning the entire setup. The modular architecture facilitates maintenance, replacement, and upgrades while maintaining operational continuity. This approach is particularly valuable for applications requiring flexible scaling based on changing throughput demands.

- Membrane materials optimized for large-scale applications: Advanced materials have been developed specifically for large-scale membrane applications. These materials offer improved durability, fouling resistance, and capture efficiency when deployed at industrial scales. The formulations address challenges such as mechanical stress, chemical stability, and performance consistency that become more pronounced in scaled-up operations. Material innovations focus on extending membrane lifespan while maintaining capture effectiveness.

- Process optimization for industrial-scale membrane operations: Computational models and process optimization techniques have been developed to enhance the efficiency of large-scale membrane operations. These approaches include flow dynamics analysis, pressure distribution optimization, and operational parameter tuning for maximum throughput. Advanced monitoring and control systems enable real-time adjustments to maintain optimal performance as scale increases. These methodologies help overcome efficiency losses typically associated with scaling up membrane processes.

- Integration of membrane systems with industrial processes: Methods for effectively integrating scalable membrane systems with existing industrial processes have been developed. These integration approaches address challenges related to process compatibility, space constraints, and operational synchronization. The solutions include standardized interfaces, adaptive control systems, and flexible configuration options that facilitate deployment across various industrial settings. This integration focus enables membrane technology to be more readily adopted at commercial scales.

02 Modular membrane systems for capacity expansion

Modular approaches to membrane system design enable scalability through the addition of standardized units. These systems allow for incremental capacity expansion without redesigning the entire setup. The modular architecture facilitates maintenance, replacement, and upgrades while maintaining operational continuity. This approach is particularly valuable for applications where demand may increase over time or where space constraints exist.Expand Specific Solutions03 Materials innovation for high-throughput membranes

Advanced materials are being developed to enhance the throughput and capacity of capture membranes. These materials offer improved selectivity, durability, and flow rates, enabling more efficient capture processes at scale. Innovations include composite structures, functionalized surfaces, and novel polymers that maintain performance under high-volume conditions. These material advances are critical for scaling membrane technologies to industrial applications.Expand Specific Solutions04 Process optimization for large-scale membrane operations

Optimizing operational parameters is essential for scaling membrane capture systems. This includes developing algorithms and control systems that maintain optimal performance across varying conditions and scales. Process innovations focus on flow distribution, pressure management, and fouling prevention in large-scale implementations. These optimizations help maintain efficiency and extend membrane lifetime in industrial-scale applications.Expand Specific Solutions05 Integrated testing and quality control for scaled production

As membrane production scales up, integrated testing and quality control systems become essential. These systems ensure consistent performance across large production volumes through automated inspection, real-time monitoring, and standardized testing protocols. Advanced analytical techniques are employed to verify membrane integrity, capture efficiency, and longevity at scale. This systematic approach to quality management is crucial for reliable performance in commercial applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The capture membrane fabrication landscape is evolving rapidly, with significant advancements in scalability techniques. Currently in the growth phase, this market is expanding as demand increases across biomedical, environmental, and industrial applications. Technical maturity varies significantly among key players: research institutions like CNRS, École Polytechnique, and California Institute of Technology are pioneering fundamental innovations, while commercial entities including LG Chem, Samsung SDI, and Dow Global Technologies are scaling these breakthroughs for industrial applications. Academic-industrial partnerships, particularly involving KAUST and EPFL, are accelerating development of novel nanofabrication methods. The competitive advantage lies in developing cost-effective, high-throughput manufacturing processes that maintain nanoscale precision while enabling mass production of capture membranes with consistent performance characteristics.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered advanced fabrication methods for capture membranes through their FLM (Facilitated Layer Manufacturing) technology. This approach combines traditional phase inversion techniques with proprietary surface modification processes to create highly scalable membrane structures. Their method involves a continuous roll-to-roll manufacturing process that deposits nanoscale functional layers onto porous support substrates, enabling precise control over membrane porosity and surface chemistry. Dow's fabrication technology incorporates automated quality control systems that use real-time optical monitoring to ensure consistent pore size distribution across large membrane areas. Additionally, they've developed environmentally sustainable solvent recovery systems that reduce waste by up to 85% compared to conventional membrane manufacturing processes[1]. Their membranes feature self-healing capabilities through incorporation of dynamic cross-linking agents that respond to mechanical stress, extending operational lifetimes in industrial separation applications.

Strengths: Dow's technology offers exceptional scalability through continuous roll-to-roll processing, enabling production of large membrane areas with consistent quality. Their integrated quality control systems minimize defects and ensure reliability. Weaknesses: The specialized surface modification chemistry requires precise environmental controls during manufacturing, potentially limiting production facilities to those with advanced capabilities. Higher initial capital investment compared to conventional membrane fabrication methods.

Sartorius Stedim Biotech GmbH

Technical Solution: Sartorius has developed an advanced membrane fabrication platform called ICMS (Integrated Continuous Membrane Synthesis) specifically designed to enhance scalability of capture membranes for biopharmaceutical applications. Their approach utilizes a continuous casting process combined with proprietary phase inversion control systems that precisely regulate membrane formation kinetics. This results in highly reproducible pore structures across large membrane areas. The Sartorius method incorporates automated in-line functionalization where reactive chemical groups are introduced to the membrane surface through controlled exposure to activation agents and functional monomers. Their fabrication system features a modular design that allows parallel processing of multiple membrane rolls simultaneously, significantly increasing production throughput. Sartorius has pioneered the implementation of Process Analytical Technology (PAT) throughout their manufacturing line, with multiple sensor systems monitoring critical quality attributes in real-time[5]. Their membranes incorporate specially engineered support structures that enhance mechanical stability while minimizing flow resistance, allowing higher operating pressures without compression. Additionally, they've developed proprietary sterilization protocols compatible with their manufacturing process that ensure bioburden control without compromising membrane performance, critical for biopharmaceutical applications.

Strengths: Sartorius's continuous manufacturing approach achieves exceptional batch-to-batch consistency, crucial for regulated industries like biopharmaceuticals. Their integrated quality systems ensure complete traceability throughout the production process. Weaknesses: The specialized nature of their biopharmaceutical-grade manufacturing requires cleanroom environments and extensive validation, increasing production costs. Their technology is optimized for specific capture applications and may require significant adaptation for other separation challenges.

Breakthrough Patents in Membrane Production Scaling

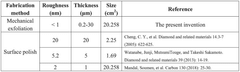

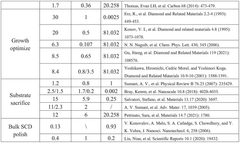

Method for scalable fabrication of ultraflat polycrystalline diamond membranes

PatentWO2025031337A1

Innovation

- A method for scalable fabrication of ultraflat polycrystalline diamond membranes involves growing the membranes on a growth substrate with diamond seeds using chemical vapor deposition, cutting off the substrate, applying a peeling tape, and peeling off the membrane to expose the nucleation surface with reduced roughness.

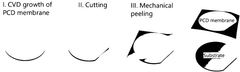

Rapid and facile membrane adsorber fabrication with ultra high binding capacity

PatentPendingUS20250018348A1

Innovation

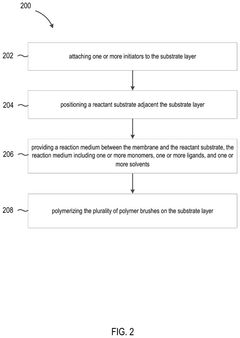

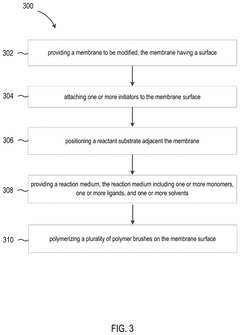

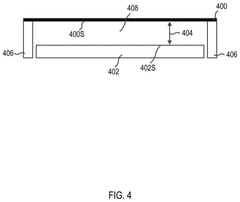

- A method involving the attachment of initiators to a membrane surface, positioning a copper reactant substrate, and polymerizing polymer brushes in a reaction medium at ambient temperature, using specific monomers, ligands, and solvents to create a modified membrane with enhanced separation capabilities.

Material Science Advancements for Membrane Performance

Recent advancements in material science have significantly transformed the landscape of capture membrane technology, offering unprecedented improvements in performance metrics critical for industrial applications. Nanomaterials have emerged as game-changers, with graphene oxide and carbon nanotubes demonstrating exceptional mechanical strength while maintaining high permeability. These materials exhibit remarkable selectivity at the molecular level, enabling precise filtration capabilities that were previously unattainable with conventional polymeric membranes.

Composite materials represent another frontier, combining the advantages of different material classes to overcome inherent limitations. Polymer-ceramic hybrids, for instance, merge the flexibility and processability of polymers with the thermal stability and mechanical robustness of ceramics. This synergistic approach has yielded membranes with enhanced fouling resistance and extended operational lifespans in harsh industrial environments.

Surface modification techniques have evolved substantially, allowing for tailored membrane properties without compromising structural integrity. Plasma treatment, chemical grafting, and layer-by-layer assembly methods enable precise control over surface chemistry, hydrophilicity, and charge distribution. These modifications directly influence membrane performance parameters such as flux, selectivity, and antifouling properties, ultimately contributing to improved efficiency in separation processes.

Stimuli-responsive materials represent a paradigm shift in membrane technology, introducing dynamic functionality that responds to environmental changes. Membranes incorporating temperature-sensitive polymers, pH-responsive groups, or light-activated materials can adjust their permeability and selectivity in real-time, offering unprecedented control over separation processes. This adaptive behavior is particularly valuable for applications requiring variable filtration parameters under fluctuating conditions.

Biomimetic approaches have gained traction, drawing inspiration from natural filtration systems like cell membranes and aquaporins. These bio-inspired designs replicate the exceptional efficiency and selectivity observed in biological systems, while addressing scalability challenges through innovative fabrication techniques. Aquaporin-incorporated membranes, for example, demonstrate water permeability orders of magnitude higher than conventional membranes while maintaining excellent rejection of contaminants.

Self-healing materials address one of the most persistent challenges in membrane technology: performance degradation over time. By incorporating microcapsules containing healing agents or designing intrinsically self-repairing polymer networks, these advanced materials can autonomously restore membrane integrity following damage from mechanical stress or chemical exposure, significantly extending operational lifetimes and reducing replacement frequency.

Composite materials represent another frontier, combining the advantages of different material classes to overcome inherent limitations. Polymer-ceramic hybrids, for instance, merge the flexibility and processability of polymers with the thermal stability and mechanical robustness of ceramics. This synergistic approach has yielded membranes with enhanced fouling resistance and extended operational lifespans in harsh industrial environments.

Surface modification techniques have evolved substantially, allowing for tailored membrane properties without compromising structural integrity. Plasma treatment, chemical grafting, and layer-by-layer assembly methods enable precise control over surface chemistry, hydrophilicity, and charge distribution. These modifications directly influence membrane performance parameters such as flux, selectivity, and antifouling properties, ultimately contributing to improved efficiency in separation processes.

Stimuli-responsive materials represent a paradigm shift in membrane technology, introducing dynamic functionality that responds to environmental changes. Membranes incorporating temperature-sensitive polymers, pH-responsive groups, or light-activated materials can adjust their permeability and selectivity in real-time, offering unprecedented control over separation processes. This adaptive behavior is particularly valuable for applications requiring variable filtration parameters under fluctuating conditions.

Biomimetic approaches have gained traction, drawing inspiration from natural filtration systems like cell membranes and aquaporins. These bio-inspired designs replicate the exceptional efficiency and selectivity observed in biological systems, while addressing scalability challenges through innovative fabrication techniques. Aquaporin-incorporated membranes, for example, demonstrate water permeability orders of magnitude higher than conventional membranes while maintaining excellent rejection of contaminants.

Self-healing materials address one of the most persistent challenges in membrane technology: performance degradation over time. By incorporating microcapsules containing healing agents or designing intrinsically self-repairing polymer networks, these advanced materials can autonomously restore membrane integrity following damage from mechanical stress or chemical exposure, significantly extending operational lifetimes and reducing replacement frequency.

Sustainability Considerations in Large-Scale Production

The scaling of capture membrane production presents significant environmental and resource challenges that must be addressed for sustainable large-scale implementation. Current fabrication methods often rely on energy-intensive processes and environmentally harmful chemicals, creating substantial ecological footprints. As production volumes increase to meet global demands, these impacts are magnified, necessitating a comprehensive sustainability framework for membrane manufacturing.

Material selection represents a critical sustainability factor in membrane fabrication. Traditional petroleum-based polymers are being increasingly supplemented or replaced with bio-based alternatives derived from renewable resources. Recent innovations include cellulose-based membranes and chitosan composites that maintain capture efficiency while reducing environmental impact. These materials not only decrease dependence on fossil fuels but also often exhibit improved biodegradability at end-of-life.

Energy consumption during manufacturing presents another sustainability challenge. Novel approaches such as room-temperature synthesis protocols and solvent-free fabrication methods have demonstrated potential to reduce energy requirements by up to 40% compared to conventional techniques. Additionally, integration of renewable energy sources in production facilities has become increasingly viable, with several membrane manufacturers implementing solar-powered production lines to offset carbon emissions.

Water usage in membrane production represents a paradoxical challenge - technologies designed to purify water often require significant water inputs during manufacturing. Closed-loop water recycling systems have emerged as promising solutions, with advanced filtration and purification stages enabling up to 90% water recovery in some production facilities. These systems significantly reduce freshwater withdrawal while minimizing wastewater discharge.

Chemical management strategies have evolved to address toxicity concerns in large-scale membrane production. Green chemistry principles are being applied to develop less hazardous alternatives to traditional solvents and reagents. For instance, supercritical CO2 processing has demonstrated potential as a replacement for organic solvents in certain membrane fabrication steps, eliminating volatile organic compound emissions while improving worker safety.

Life cycle assessment (LCA) methodologies are increasingly being employed to quantify the environmental impacts of different membrane fabrication approaches. These assessments consider impacts from raw material extraction through manufacturing, use, and disposal phases. Recent LCA studies indicate that innovations in fabrication methods can reduce the carbon footprint of membrane production by 30-60% compared to conventional techniques, providing valuable metrics for sustainability-focused development.

Material selection represents a critical sustainability factor in membrane fabrication. Traditional petroleum-based polymers are being increasingly supplemented or replaced with bio-based alternatives derived from renewable resources. Recent innovations include cellulose-based membranes and chitosan composites that maintain capture efficiency while reducing environmental impact. These materials not only decrease dependence on fossil fuels but also often exhibit improved biodegradability at end-of-life.

Energy consumption during manufacturing presents another sustainability challenge. Novel approaches such as room-temperature synthesis protocols and solvent-free fabrication methods have demonstrated potential to reduce energy requirements by up to 40% compared to conventional techniques. Additionally, integration of renewable energy sources in production facilities has become increasingly viable, with several membrane manufacturers implementing solar-powered production lines to offset carbon emissions.

Water usage in membrane production represents a paradoxical challenge - technologies designed to purify water often require significant water inputs during manufacturing. Closed-loop water recycling systems have emerged as promising solutions, with advanced filtration and purification stages enabling up to 90% water recovery in some production facilities. These systems significantly reduce freshwater withdrawal while minimizing wastewater discharge.

Chemical management strategies have evolved to address toxicity concerns in large-scale membrane production. Green chemistry principles are being applied to develop less hazardous alternatives to traditional solvents and reagents. For instance, supercritical CO2 processing has demonstrated potential as a replacement for organic solvents in certain membrane fabrication steps, eliminating volatile organic compound emissions while improving worker safety.

Life cycle assessment (LCA) methodologies are increasingly being employed to quantify the environmental impacts of different membrane fabrication approaches. These assessments consider impacts from raw material extraction through manufacturing, use, and disposal phases. Recent LCA studies indicate that innovations in fabrication methods can reduce the carbon footprint of membrane production by 30-60% compared to conventional techniques, providing valuable metrics for sustainability-focused development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!