Tyre for vehicles

A technology for tires and vehicles, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as damaging handling performance and weakening tread structure, and achieve good performance and excellent handling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

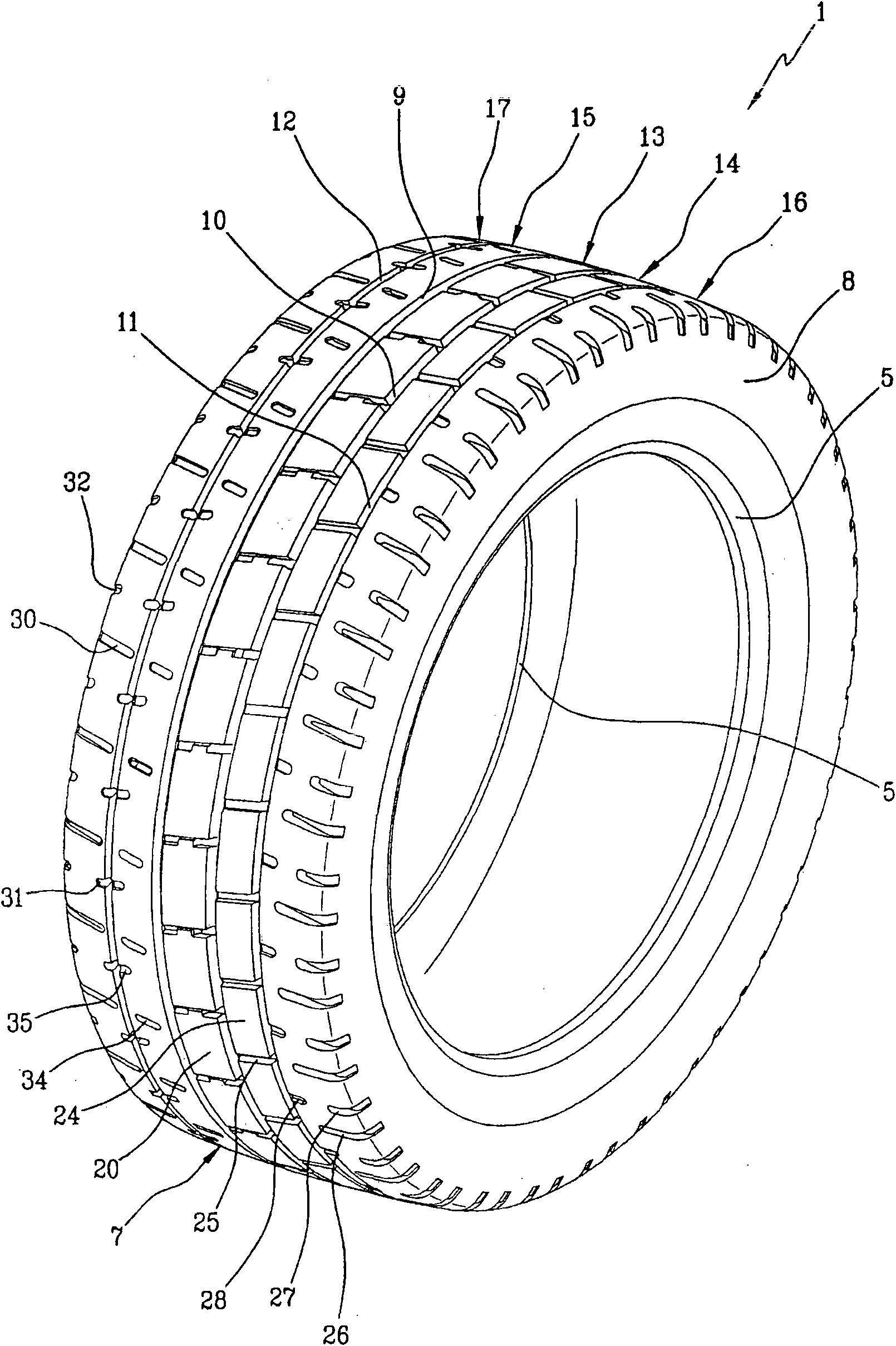

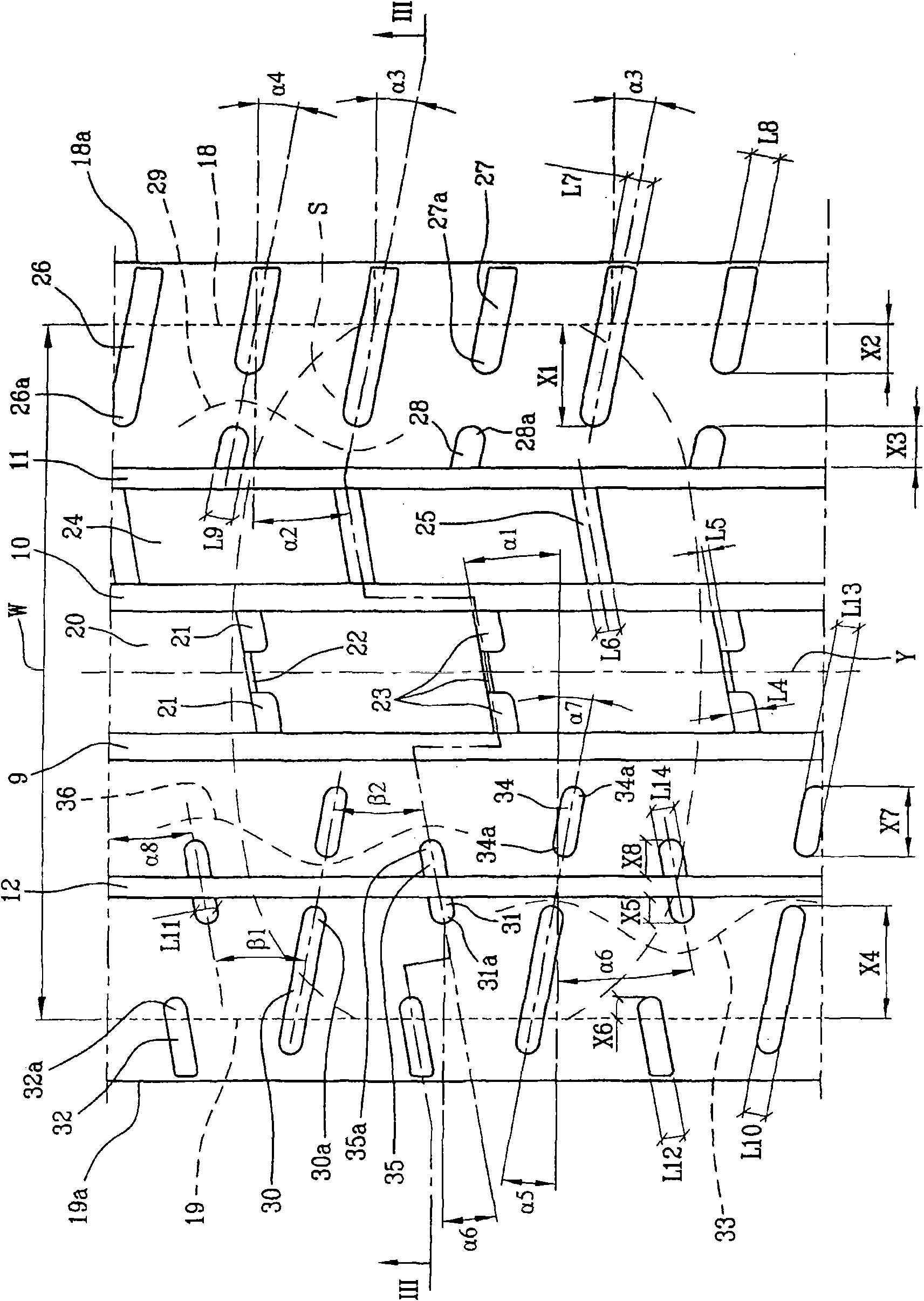

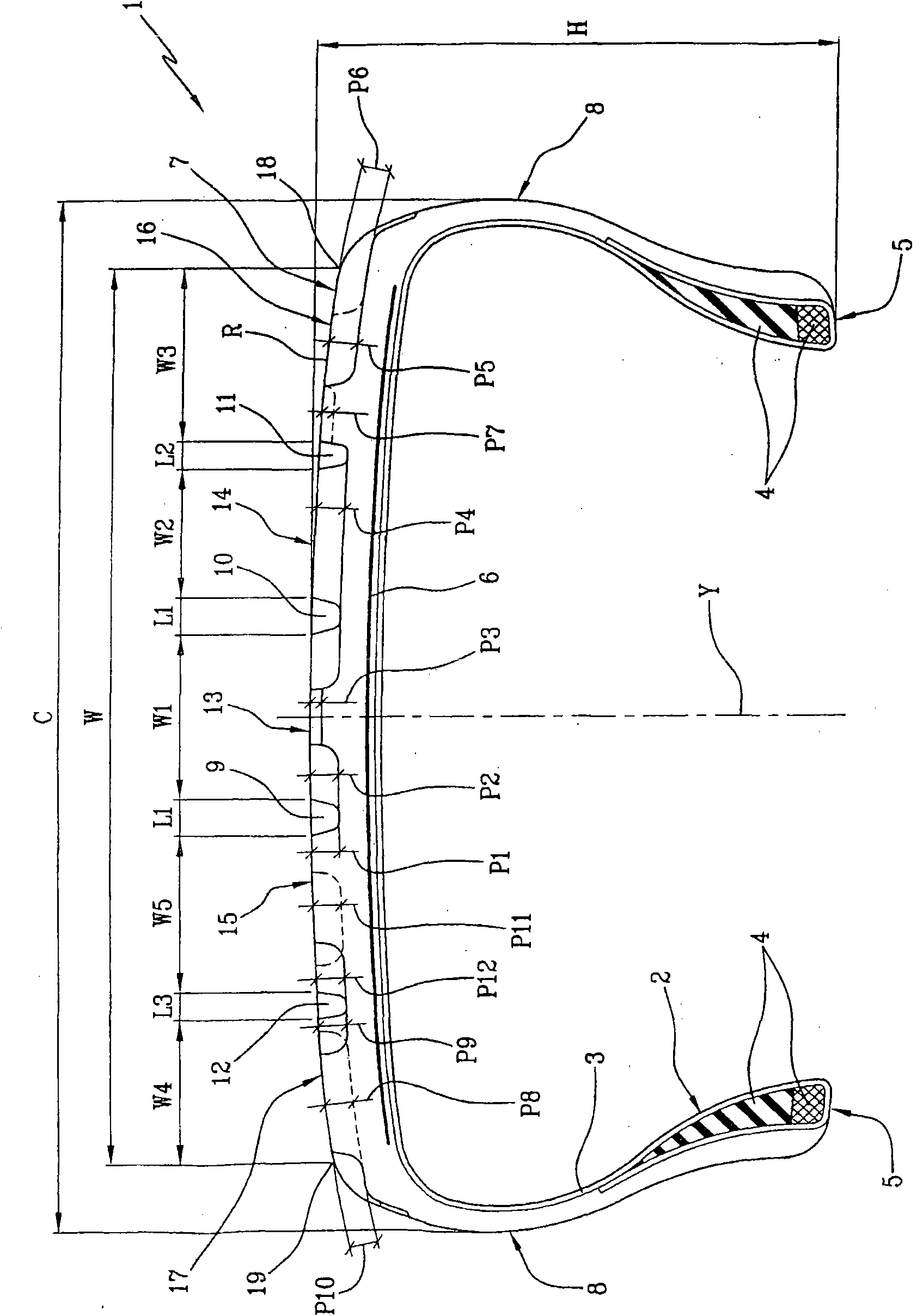

[0089] Referring to the above-mentioned figures, the device according to the invention for tires of vehicles is generally designated by the numeral 1 .

[0090] The tire 1 mainly comprises a carcass structure 2 having at least one carcass ply 3 joined to the carcass ply 3 by two annular anchoring structures 4 integrated into what are now called "beads" 5 In this area, the tire 1 is usually joined to the corresponding mounting rim at the bead 5 .

[0091] The belt structure 6 is attached and wound on one or more carcass plies 3 along the circumferential direction, and the tread strip 7 is laminated on the belt structure 6 along the circumferential direction.

[0092] Sidewalls 8 are attached to two opposite side portions of the carcass ply 3 , both sidewalls extending from the corresponding bead 5 to the corresponding sidewall of the tread strip 7 .

[0093] The tire 1 is specially designed for high performance and ultra high performance vehicles, it is also suitable for sport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com