Transverse insertion mechanism for automatic single-paper die-cutting machine

A die-cutting machine, sheet-fed technology, applied in the direction of sending objects, thin material handling, transportation and packaging, etc., to achieve the effect of improving stability, rigidity and beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

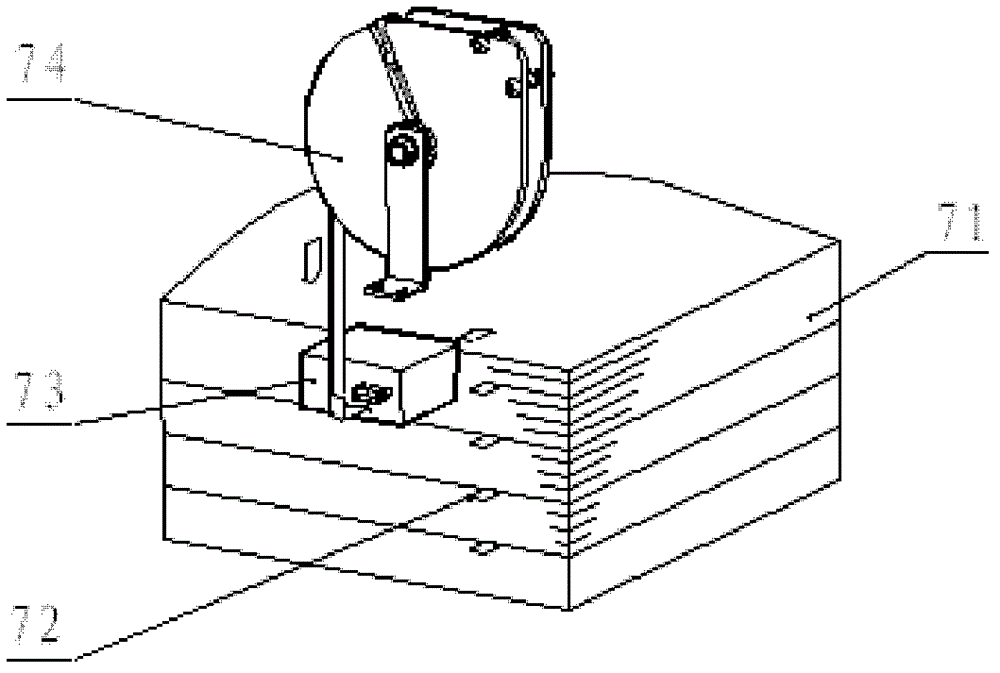

[0018] see Figure 4 to Figure 6 , the horizontal interleaving mechanism 4 for the sheet-fed automatic die-cutting machine of the present invention includes an interleaved paper pile 41 installed outside the finished product part 2 side of the automatic die-cutting machine and a whole sheet stacked in the interleaved paper pile 41. Insert paper 42 also includes a fixed mount 45, a cylinder 43, a synchronous belt 410, a one-way guide rod 46, a two-way guide rod 47, some suction head connecting rods 44 and some groups of suction heads 49, wherein:

[0019] Fixed mount 45 is installed on the frame of automatic die-cutting machine and is positioned at the top of paper stack 41, and the cross section of this fixed mount 45 is concave shape,

[0020] The cylinder 43 is installed on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com