Adhesion Mechanisms in Ceramic Thermal Spray Systems

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Thermal Spray Adhesion Background and Objectives

Ceramic thermal spray coating technology has evolved significantly over the past seven decades since its initial development in the 1950s. This surface engineering technique has become increasingly important across various industrial sectors including aerospace, power generation, automotive, and biomedical applications due to its versatility in providing protective and functional coatings. The fundamental principle involves accelerating ceramic particles at high velocities toward a substrate, where they deform, solidify, and build up to form a coating with specific properties.

The evolution of ceramic thermal spray technology has been marked by several key advancements, including the development of plasma spray in the 1960s, high-velocity oxy-fuel (HVOF) spray in the 1980s, and more recently, suspension and solution precursor thermal spray techniques. Each advancement has progressively improved coating quality, adhesion strength, and application versatility, enabling the technology to address increasingly demanding industrial requirements.

Adhesion mechanisms in ceramic thermal spray systems represent a critical aspect of coating performance and reliability. Unlike metallic coatings that can form metallurgical bonds, ceramic coatings primarily rely on mechanical interlocking and limited chemical bonding at the interface. Understanding these mechanisms is essential for optimizing coating performance and durability in harsh operating environments.

The primary technical objective of this research is to comprehensively analyze the fundamental adhesion mechanisms in ceramic thermal spray systems, with particular focus on the interface phenomena that govern coating-substrate bonding. This includes investigating mechanical interlocking, chemical bonding, residual stress effects, and the influence of processing parameters on adhesion strength.

Secondary objectives include identifying innovative approaches to enhance adhesion strength through surface preparation techniques, interlayer design, and post-deposition treatments. Additionally, this research aims to develop predictive models for adhesion behavior based on material properties, processing conditions, and service environments.

The long-term goal is to establish design principles for ceramic thermal spray systems that can achieve optimal adhesion performance for specific applications, thereby extending component lifetimes and enabling new applications in extreme environments. This includes developing standardized testing methodologies for accurately assessing adhesion strength and failure mechanisms in ceramic thermal spray coatings.

By addressing these objectives, this research seeks to bridge the gap between fundamental understanding of ceramic coating adhesion mechanisms and practical industrial implementation, ultimately contributing to the advancement of thermal spray technology and expanding its application potential.

The evolution of ceramic thermal spray technology has been marked by several key advancements, including the development of plasma spray in the 1960s, high-velocity oxy-fuel (HVOF) spray in the 1980s, and more recently, suspension and solution precursor thermal spray techniques. Each advancement has progressively improved coating quality, adhesion strength, and application versatility, enabling the technology to address increasingly demanding industrial requirements.

Adhesion mechanisms in ceramic thermal spray systems represent a critical aspect of coating performance and reliability. Unlike metallic coatings that can form metallurgical bonds, ceramic coatings primarily rely on mechanical interlocking and limited chemical bonding at the interface. Understanding these mechanisms is essential for optimizing coating performance and durability in harsh operating environments.

The primary technical objective of this research is to comprehensively analyze the fundamental adhesion mechanisms in ceramic thermal spray systems, with particular focus on the interface phenomena that govern coating-substrate bonding. This includes investigating mechanical interlocking, chemical bonding, residual stress effects, and the influence of processing parameters on adhesion strength.

Secondary objectives include identifying innovative approaches to enhance adhesion strength through surface preparation techniques, interlayer design, and post-deposition treatments. Additionally, this research aims to develop predictive models for adhesion behavior based on material properties, processing conditions, and service environments.

The long-term goal is to establish design principles for ceramic thermal spray systems that can achieve optimal adhesion performance for specific applications, thereby extending component lifetimes and enabling new applications in extreme environments. This includes developing standardized testing methodologies for accurately assessing adhesion strength and failure mechanisms in ceramic thermal spray coatings.

By addressing these objectives, this research seeks to bridge the gap between fundamental understanding of ceramic coating adhesion mechanisms and practical industrial implementation, ultimately contributing to the advancement of thermal spray technology and expanding its application potential.

Market Analysis for Ceramic Thermal Spray Applications

The global ceramic thermal spray coatings market is experiencing robust growth, valued at approximately $2.3 billion in 2022 and projected to reach $3.5 billion by 2028, representing a compound annual growth rate of 7.2%. This growth is primarily driven by increasing demand across aerospace, automotive, healthcare, and energy sectors where thermal protection, wear resistance, and corrosion prevention are critical requirements.

The aerospace industry remains the largest consumer of ceramic thermal spray applications, accounting for nearly 35% of the market share. This dominance stems from the essential need for thermal barrier coatings on turbine blades and combustion chambers in aircraft engines, where operating temperatures can exceed 1200°C. The automotive sector follows closely, comprising about 25% of market demand, particularly for coating engine components to improve fuel efficiency and reduce emissions.

Healthcare applications represent the fastest-growing segment with a 9.8% annual growth rate, driven by the expanding use of biocompatible ceramic coatings for medical implants. These coatings significantly enhance implant integration with human tissue while providing necessary wear resistance for joint replacements and dental implants.

Geographically, North America and Europe currently dominate the market with combined market share of 58%, attributed to their advanced aerospace and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the most rapid expansion at 8.5% annually, fueled by China's and India's growing industrial sectors and increasing adoption of advanced manufacturing technologies.

Customer requirements are evolving toward more specialized performance characteristics. End-users increasingly demand coatings with multiple functionalities beyond basic thermal protection, including electrical insulation, electromagnetic shielding, and self-healing properties. This trend is creating new market niches and premium pricing opportunities for innovative solutions.

The market faces challenges from alternative technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) in certain applications. However, thermal spray maintains competitive advantages in cost-effectiveness for large components and ability to apply thicker coatings. Environmental regulations regarding particulate emissions and worker safety during thermal spray operations are becoming more stringent, driving investment in cleaner application technologies.

Raw material price volatility, particularly for rare earth elements used in advanced ceramic formulations, represents a significant concern for market stability and profit margins across the industry.

The aerospace industry remains the largest consumer of ceramic thermal spray applications, accounting for nearly 35% of the market share. This dominance stems from the essential need for thermal barrier coatings on turbine blades and combustion chambers in aircraft engines, where operating temperatures can exceed 1200°C. The automotive sector follows closely, comprising about 25% of market demand, particularly for coating engine components to improve fuel efficiency and reduce emissions.

Healthcare applications represent the fastest-growing segment with a 9.8% annual growth rate, driven by the expanding use of biocompatible ceramic coatings for medical implants. These coatings significantly enhance implant integration with human tissue while providing necessary wear resistance for joint replacements and dental implants.

Geographically, North America and Europe currently dominate the market with combined market share of 58%, attributed to their advanced aerospace and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the most rapid expansion at 8.5% annually, fueled by China's and India's growing industrial sectors and increasing adoption of advanced manufacturing technologies.

Customer requirements are evolving toward more specialized performance characteristics. End-users increasingly demand coatings with multiple functionalities beyond basic thermal protection, including electrical insulation, electromagnetic shielding, and self-healing properties. This trend is creating new market niches and premium pricing opportunities for innovative solutions.

The market faces challenges from alternative technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) in certain applications. However, thermal spray maintains competitive advantages in cost-effectiveness for large components and ability to apply thicker coatings. Environmental regulations regarding particulate emissions and worker safety during thermal spray operations are becoming more stringent, driving investment in cleaner application technologies.

Raw material price volatility, particularly for rare earth elements used in advanced ceramic formulations, represents a significant concern for market stability and profit margins across the industry.

Current Adhesion Challenges in Thermal Spray Technology

Despite significant advancements in thermal spray technology, adhesion remains a critical challenge in ceramic coating systems. Current adhesion issues primarily stem from the inherent material property mismatches between ceramic coatings and metallic substrates. The substantial differences in thermal expansion coefficients create significant interfacial stresses during thermal cycling, leading to coating delamination and spallation in service conditions.

Surface preparation techniques present another major challenge area. Conventional grit blasting methods often fail to create optimal surface profiles for ceramic adhesion, particularly on complex geometries or heat-sensitive substrates. The industry struggles to develop standardized surface preparation protocols that consistently produce the ideal combination of roughness parameters and chemical activation across diverse substrate materials.

Residual stress management continues to be problematic in thermal spray systems. The rapid solidification of molten or semi-molten particles generates substantial tensile stresses within ceramic coatings, which counteract adhesion forces at the interface. Current stress relief methods, including post-deposition heat treatments, often prove inadequate or impractical for many industrial applications due to time constraints or the risk of substrate property degradation.

The industry also faces significant challenges in adhesion testing and quality control. Existing test methods such as pull-off testing and scratch testing frequently yield inconsistent results that poorly correlate with actual in-service performance. This testing gap hampers the development of reliable adhesion prediction models and complicates material selection decisions for specific applications.

Environmental factors present additional adhesion challenges, particularly in harsh operating conditions. Moisture ingress at the coating-substrate interface accelerates chemical degradation mechanisms, while thermal cycling exacerbates mechanical stresses. Current coating systems struggle to maintain adhesion integrity when exposed to combinations of thermal shock, corrosive media, and mechanical loading.

Feedstock optimization remains problematic, with particle size distribution, morphology, and chemistry significantly affecting splat formation and subsequent adhesion properties. The industry lacks comprehensive models that can predict optimal feedstock parameters for specific substrate-coating combinations, resulting in extensive empirical testing requirements for new applications.

Process parameter control presents another significant challenge. The complex interactions between spray parameters (velocity, temperature, standoff distance) and resulting adhesion properties are not fully understood, making process optimization highly dependent on operator experience rather than scientific principles. This knowledge gap impedes the development of automated, adaptive control systems that could ensure consistent adhesion quality.

Surface preparation techniques present another major challenge area. Conventional grit blasting methods often fail to create optimal surface profiles for ceramic adhesion, particularly on complex geometries or heat-sensitive substrates. The industry struggles to develop standardized surface preparation protocols that consistently produce the ideal combination of roughness parameters and chemical activation across diverse substrate materials.

Residual stress management continues to be problematic in thermal spray systems. The rapid solidification of molten or semi-molten particles generates substantial tensile stresses within ceramic coatings, which counteract adhesion forces at the interface. Current stress relief methods, including post-deposition heat treatments, often prove inadequate or impractical for many industrial applications due to time constraints or the risk of substrate property degradation.

The industry also faces significant challenges in adhesion testing and quality control. Existing test methods such as pull-off testing and scratch testing frequently yield inconsistent results that poorly correlate with actual in-service performance. This testing gap hampers the development of reliable adhesion prediction models and complicates material selection decisions for specific applications.

Environmental factors present additional adhesion challenges, particularly in harsh operating conditions. Moisture ingress at the coating-substrate interface accelerates chemical degradation mechanisms, while thermal cycling exacerbates mechanical stresses. Current coating systems struggle to maintain adhesion integrity when exposed to combinations of thermal shock, corrosive media, and mechanical loading.

Feedstock optimization remains problematic, with particle size distribution, morphology, and chemistry significantly affecting splat formation and subsequent adhesion properties. The industry lacks comprehensive models that can predict optimal feedstock parameters for specific substrate-coating combinations, resulting in extensive empirical testing requirements for new applications.

Process parameter control presents another significant challenge. The complex interactions between spray parameters (velocity, temperature, standoff distance) and resulting adhesion properties are not fully understood, making process optimization highly dependent on operator experience rather than scientific principles. This knowledge gap impedes the development of automated, adaptive control systems that could ensure consistent adhesion quality.

Contemporary Adhesion Enhancement Techniques

01 Surface preparation techniques for ceramic thermal spray adhesion

Various surface preparation methods can significantly enhance the adhesion of ceramic thermal spray coatings to substrates. These techniques include grit blasting, chemical etching, and mechanical roughening to create optimal surface profiles. Proper surface preparation removes contaminants and increases the surface area for mechanical interlocking between the coating and substrate, resulting in stronger adhesion and more durable ceramic thermal spray systems.- Surface preparation techniques for improved adhesion: Various surface preparation methods can significantly enhance the adhesion of ceramic thermal spray coatings to substrates. These techniques include grit blasting, chemical etching, and plasma treatment to create optimal surface roughness and remove contaminants. Proper surface preparation creates mechanical interlocking opportunities and increases the surface area for bonding, resulting in stronger adhesion between the ceramic coating and the substrate material.

- Bond coat formulations for ceramic thermal spray systems: Specialized bond coat formulations serve as intermediate layers between the substrate and ceramic coating to improve adhesion. These formulations typically contain metal alloys such as MCrAlY (where M represents nickel, cobalt, or a combination) or other metallic compositions that provide both mechanical bonding and chemical compatibility. The bond coat accommodates differences in thermal expansion between the substrate and ceramic layer, preventing delamination during thermal cycling.

- Ceramic composition modifications for enhanced adhesion: Modifying the composition of ceramic materials used in thermal spray systems can significantly improve coating adhesion. Incorporating additives such as transition metals, rare earth elements, or nanoparticles into the ceramic formulation enhances bonding characteristics. These modifications can alter the melting behavior during spraying, improve wettability on the substrate, and create stronger interfacial bonds, resulting in coatings with superior adhesion properties.

- Spray parameter optimization for adhesion enhancement: Optimizing thermal spray process parameters is crucial for achieving maximum coating adhesion. Parameters such as spray distance, particle velocity, substrate temperature, plasma power, and feed rate significantly affect the quality of adhesion. Careful control of these parameters ensures proper melting and flattening of ceramic particles upon impact, creating strong mechanical interlocking with the substrate and reducing residual stresses in the coating.

- Post-treatment methods to improve coating adhesion: Various post-treatment techniques can be applied to ceramic thermal spray coatings to enhance their adhesion properties. These include heat treatment, laser remelting, shot peening, and infiltration with sealants. Post-treatments help reduce porosity, relieve residual stresses, promote diffusion bonding at interfaces, and improve overall coating cohesion. These processes can significantly increase the adhesion strength and durability of ceramic thermal spray coatings in demanding applications.

02 Bond coat compositions for improved ceramic coating adhesion

Specialized bond coat compositions serve as intermediate layers between the substrate and ceramic thermal spray coating to enhance adhesion. These bond coats typically contain metallic alloys, MCrAlY (where M represents nickel, cobalt, or iron), or composite materials that provide thermal expansion compatibility and chemical bonding. The bond coat creates a gradient interface that reduces stress concentration and prevents delamination of the ceramic coating during thermal cycling or mechanical loading.Expand Specific Solutions03 Ceramic coating composition modifications for enhanced adhesion

Modifying the composition of ceramic thermal spray materials can significantly improve their adhesion properties. Incorporating certain additives, adjusting particle size distributions, or using nanostructured ceramics can enhance bonding mechanisms. Some formulations include self-healing components or materials with improved mechanical interlocking capabilities. These compositional modifications result in ceramic coatings with superior adhesion characteristics even under extreme thermal and mechanical conditions.Expand Specific Solutions04 Spray process parameters optimization for adhesion enhancement

Optimizing thermal spray process parameters is crucial for achieving maximum adhesion of ceramic coatings. Parameters such as spray distance, particle velocity, substrate temperature, plasma or flame characteristics, and cooling rates significantly affect the coating microstructure and bonding strength. Advanced control systems that monitor and adjust these parameters in real-time can produce more consistent and strongly adhered ceramic coatings with minimal defects and optimal density.Expand Specific Solutions05 Post-treatment methods to improve ceramic coating adhesion

Various post-treatment techniques can be applied to ceramic thermal spray coatings to enhance their adhesion properties. These include heat treatment processes, laser surface modification, infiltration with sealants, and hot isostatic pressing. Post-treatments can reduce porosity, heal microcracks, relieve residual stresses, and promote diffusion bonding at interfaces. These processes significantly improve the long-term adhesion performance and durability of ceramic thermal spray systems in demanding applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermal Spray

The adhesion mechanisms in ceramic thermal spray systems market is currently in a growth phase, with increasing demand across automotive and aerospace sectors. The market size is expanding due to rising applications in thermal barrier coatings and wear-resistant surfaces. Technologically, the field shows varying maturity levels among key players. Industry leaders like Toyota Motor Corp., Ford Motor Co., and Nissan Motor Co. have established robust R&D capabilities, while specialized companies such as Atmospheric Plasma Solutions and Praxair S.T. Technology offer innovative niche solutions. Academic institutions including Guangdong University of Technology and Northwestern Polytechnical University are advancing fundamental research. The competitive landscape features both large corporations (Siemens AG, RTX Corp.) investing in proprietary technologies and smaller specialized firms developing application-specific adhesion solutions.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair has developed advanced solution precursor plasma spray (SPPS) technology for ceramic thermal barrier coatings with enhanced adhesion mechanisms. Their approach involves atomizing liquid precursors directly into the plasma flame, creating nano-structured coatings with superior strain tolerance and adhesion properties. The company's patented process manipulates the ceramic microstructure to create columnar structures with engineered porosity that significantly improves coating durability under thermal cycling conditions. Their technology incorporates specialized bond coat systems with MCrAlY compositions (where M represents nickel, cobalt, or both) that form controlled thermally grown oxide (TGO) layers, enhancing adhesion through both mechanical interlocking and chemical bonding mechanisms. Praxair has also pioneered surface preparation techniques using proprietary grit blasting parameters that optimize surface roughness profiles specifically for ceramic adhesion.

Strengths: Superior strain tolerance due to engineered microstructures; excellent thermal cycling resistance; reduced thermal conductivity compared to conventional coatings. Weaknesses: Higher processing costs; more complex application equipment requirements; greater sensitivity to processing parameters requiring tighter controls.

Sulzer Markets & Technology AG

Technical Solution: Sulzer has pioneered a multi-layer ceramic coating system utilizing their proprietary HVOF (High Velocity Oxy-Fuel) and APS (Atmospheric Plasma Spray) technologies. Their approach focuses on optimizing the interface between metallic substrates and ceramic top coats through carefully engineered gradient layers. The company's MetcoMax solution incorporates nano-structured bond coats with controlled oxidation behavior that promotes chemical bonding while minimizing residual stress accumulation. Sulzer's process employs precise control of particle temperature and velocity during deposition, resulting in coatings with less than 2% porosity and superior adhesion strength exceeding 70 MPa in standard testing. Their technology also features specialized post-deposition heat treatments that promote diffusion bonding at interfaces while relieving internal stresses. For applications requiring extreme thermal cycling resistance, Sulzer has developed segmented ceramic structures with engineered micro-cracks that accommodate thermal expansion differences without compromising adhesion.

Strengths: Exceptional bond strength; excellent thermal shock resistance; highly customizable for specific application requirements; proven long-term durability in industrial settings. Weaknesses: Higher initial implementation costs; requires specialized equipment and expertise; some solutions have limitations in very high temperature applications above 1300°C.

Critical Patents in Ceramic-Substrate Interface Engineering

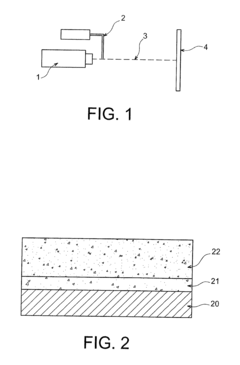

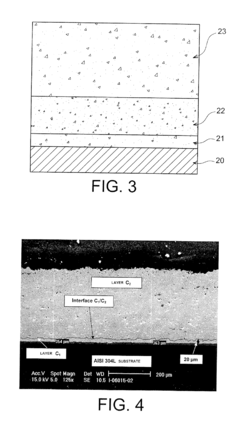

Method for preparing a multilayer coating on a substrate surface by means ofthermal spraying

PatentInactiveUS20130101745A1

Innovation

- A method involving the sequential deposition of a nanostructured or finely structured layer via a liquid route followed by a microstructured layer via a dry route, using thermal spraying, which allows for the creation of thick coatings with enhanced adhesion without requiring surface preparation or activation beyond simple cleaning.

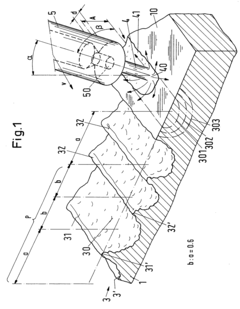

Process for producing a thermally sprayed layer

PatentInactiveEP1304395A1

Innovation

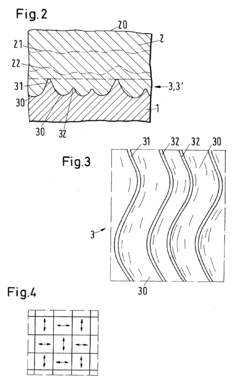

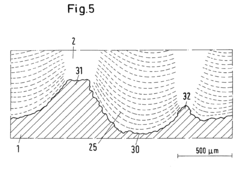

- A method involving surface structuring of the metallic substrate using a high-pressure liquid jet to create a macrotopography with a quasi-fractal microprofile, enhancing adhesion by producing a structured surface with channel-like removal tracks and varying elevations, allowing for thicker ceramic coatings with improved anchoring and tensile strength.

Material Compatibility and Surface Preparation Factors

Material compatibility represents a critical factor in determining the success of ceramic thermal spray coatings. The adhesion strength between the ceramic coating and substrate is fundamentally influenced by the chemical and physical compatibility of these materials. When selecting material combinations, considerations must include thermal expansion coefficients, chemical reactivity, and crystallographic structure compatibility. Materials with significantly different thermal expansion coefficients can develop substantial internal stresses during thermal cycling, leading to premature coating failure through delamination or spallation.

Surface preparation plays an equally vital role in achieving optimal adhesion in ceramic thermal spray systems. The substrate surface characteristics directly impact coating adhesion through mechanical interlocking mechanisms. Standard preparation techniques include grit blasting, chemical etching, and mechanical roughening. Research indicates that controlled surface roughness profiles with Ra values between 3-7 μm typically yield optimal adhesion strength for most ceramic coating applications. However, excessive roughness can create stress concentration points that become failure initiation sites.

Chemical cleanliness of the substrate surface significantly affects bonding quality. Contaminants such as oils, oxides, and moisture can prevent direct contact between coating particles and substrate, resulting in weak interfacial bonding. Advanced cleaning protocols involving ultrasonic cleaning, plasma treatment, and specialized degreasing agents have demonstrated up to 40% improvement in adhesion strength compared to conventional cleaning methods.

Pre-heating of substrates has emerged as another critical factor affecting adhesion. Controlled substrate heating to temperatures between 100-300°C (depending on material combination) reduces thermal shock when molten ceramic particles impact the surface. This practice minimizes residual stress formation and enhances diffusion bonding at the interface. Studies have shown that optimized pre-heating can improve adhesion strength by 25-35% compared to ambient temperature spraying.

The application of bond coats represents a strategic approach to addressing material compatibility challenges. These intermediate layers, typically composed of MCrAlY alloys or similar materials, create a gradual transition zone between dissimilar materials. Bond coats not only improve adhesion through enhanced mechanical interlocking but also provide oxidation resistance and stress accommodation. Recent developments in nanostructured bond coats have demonstrated particularly promising results, with some systems showing up to 60% improvement in coating durability under thermal cycling conditions.

Surface preparation plays an equally vital role in achieving optimal adhesion in ceramic thermal spray systems. The substrate surface characteristics directly impact coating adhesion through mechanical interlocking mechanisms. Standard preparation techniques include grit blasting, chemical etching, and mechanical roughening. Research indicates that controlled surface roughness profiles with Ra values between 3-7 μm typically yield optimal adhesion strength for most ceramic coating applications. However, excessive roughness can create stress concentration points that become failure initiation sites.

Chemical cleanliness of the substrate surface significantly affects bonding quality. Contaminants such as oils, oxides, and moisture can prevent direct contact between coating particles and substrate, resulting in weak interfacial bonding. Advanced cleaning protocols involving ultrasonic cleaning, plasma treatment, and specialized degreasing agents have demonstrated up to 40% improvement in adhesion strength compared to conventional cleaning methods.

Pre-heating of substrates has emerged as another critical factor affecting adhesion. Controlled substrate heating to temperatures between 100-300°C (depending on material combination) reduces thermal shock when molten ceramic particles impact the surface. This practice minimizes residual stress formation and enhances diffusion bonding at the interface. Studies have shown that optimized pre-heating can improve adhesion strength by 25-35% compared to ambient temperature spraying.

The application of bond coats represents a strategic approach to addressing material compatibility challenges. These intermediate layers, typically composed of MCrAlY alloys or similar materials, create a gradual transition zone between dissimilar materials. Bond coats not only improve adhesion through enhanced mechanical interlocking but also provide oxidation resistance and stress accommodation. Recent developments in nanostructured bond coats have demonstrated particularly promising results, with some systems showing up to 60% improvement in coating durability under thermal cycling conditions.

Durability Testing and Performance Standards

Durability testing and performance standards for ceramic thermal spray coatings have evolved significantly to address the complex adhesion mechanisms in these systems. The industry has established rigorous testing protocols that evaluate coating performance under various environmental and mechanical stresses, simulating real-world conditions that these coatings encounter during service.

Accelerated aging tests represent a cornerstone of durability assessment, subjecting coatings to thermal cycling between extreme temperatures (-40°C to 1000°C) to evaluate thermal shock resistance and adhesion stability over time. These tests typically run for 500-1000 cycles, with intermediate adhesion strength measurements to track degradation patterns.

Corrosion resistance testing employs salt spray exposure (ASTM B117) and electrochemical impedance spectroscopy to quantify coating barrier properties. Advanced protocols now incorporate multi-environmental testing chambers that combine humidity, UV exposure, and chemical contaminants to better replicate service conditions in industries such as aerospace and power generation.

Mechanical performance standards have become increasingly sophisticated, moving beyond basic pull-off adhesion tests (ASTM C633) to include scratch testing, impact resistance, and erosion testing. The development of acoustic emission monitoring during these tests has enabled researchers to identify failure initiation points and propagation mechanisms with greater precision.

International standards organizations have established comprehensive frameworks for ceramic thermal spray coating evaluation. ISO 17836 specifies determination methods for coating deposition efficiency, while ISO 14923 addresses surface preparation requirements critical for optimal adhesion. The Thermal Spray Society has published recommended practices that standardize testing methodologies across the industry.

Performance benchmarking has evolved to include application-specific metrics. For aerospace components, erosion resistance at high velocities (ASTM G76) and foreign object damage simulation have become standard requirements. For industrial applications, wear resistance under sliding contact (ASTM G99) and abrasion testing provide critical performance indicators.

Long-term field testing remains essential despite laboratory advances, with instrumented components deployed in actual service environments for periods exceeding five years. These studies have revealed that laboratory tests often underestimate certain degradation mechanisms, particularly those involving synergistic effects between mechanical stresses and environmental factors.

Recent developments include non-destructive evaluation techniques such as infrared thermography and laser shearography that can detect subsurface delamination and adhesion failures without damaging the coating. These methods are increasingly being incorporated into standard inspection protocols for high-value components where coating integrity is critical to system performance.

Accelerated aging tests represent a cornerstone of durability assessment, subjecting coatings to thermal cycling between extreme temperatures (-40°C to 1000°C) to evaluate thermal shock resistance and adhesion stability over time. These tests typically run for 500-1000 cycles, with intermediate adhesion strength measurements to track degradation patterns.

Corrosion resistance testing employs salt spray exposure (ASTM B117) and electrochemical impedance spectroscopy to quantify coating barrier properties. Advanced protocols now incorporate multi-environmental testing chambers that combine humidity, UV exposure, and chemical contaminants to better replicate service conditions in industries such as aerospace and power generation.

Mechanical performance standards have become increasingly sophisticated, moving beyond basic pull-off adhesion tests (ASTM C633) to include scratch testing, impact resistance, and erosion testing. The development of acoustic emission monitoring during these tests has enabled researchers to identify failure initiation points and propagation mechanisms with greater precision.

International standards organizations have established comprehensive frameworks for ceramic thermal spray coating evaluation. ISO 17836 specifies determination methods for coating deposition efficiency, while ISO 14923 addresses surface preparation requirements critical for optimal adhesion. The Thermal Spray Society has published recommended practices that standardize testing methodologies across the industry.

Performance benchmarking has evolved to include application-specific metrics. For aerospace components, erosion resistance at high velocities (ASTM G76) and foreign object damage simulation have become standard requirements. For industrial applications, wear resistance under sliding contact (ASTM G99) and abrasion testing provide critical performance indicators.

Long-term field testing remains essential despite laboratory advances, with instrumented components deployed in actual service environments for periods exceeding five years. These studies have revealed that laboratory tests often underestimate certain degradation mechanisms, particularly those involving synergistic effects between mechanical stresses and environmental factors.

Recent developments include non-destructive evaluation techniques such as infrared thermography and laser shearography that can detect subsurface delamination and adhesion failures without damaging the coating. These methods are increasingly being incorporated into standard inspection protocols for high-value components where coating integrity is critical to system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!