Ceramic Thermal Spray Process Parameters and Coating Quality

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Thermal Spray Technology Evolution and Objectives

Ceramic thermal spray technology has evolved significantly over the past century, transforming from rudimentary flame spray methods to sophisticated plasma and high-velocity systems. The journey began in the early 1900s with Dr. Max Ulrich Schoop's pioneering work on metal spraying, which laid the foundation for thermal spray processes. By the 1950s, plasma spray technology emerged, revolutionizing the capability to deposit ceramic materials with higher melting points, thus expanding application possibilities across industries.

The 1980s marked a significant advancement with the development of High-Velocity Oxy-Fuel (HVOF) and detonation gun techniques, which dramatically improved coating density and adhesion strength. These innovations addressed previous limitations in ceramic coating quality and durability. The 1990s witnessed the integration of computer control systems and automation, enhancing process repeatability and precision in parameter control—critical factors for ceramic coating quality.

Recent decades have seen the emergence of solution precursor and suspension thermal spray methods, enabling the deposition of nanostructured ceramic coatings with superior properties. Additionally, cold spray technology has expanded the material portfolio and reduced thermal degradation issues common in traditional ceramic spraying processes. The integration of in-situ monitoring systems and real-time feedback control represents the current technological frontier, allowing for adaptive process control and quality assurance.

The primary objectives of ceramic thermal spray technology development focus on establishing robust correlations between process parameters and coating quality metrics. This includes understanding the complex relationships between spray distance, powder feed rate, plasma/flame characteristics, and resulting coating microstructure, porosity, and adhesion strength. Researchers aim to develop predictive models that can optimize parameter selection for specific ceramic materials and application requirements.

Another critical objective is enhancing coating reproducibility and reducing sensitivity to minor parameter variations, which has historically been a challenge in ceramic thermal spray processes. The industry seeks to establish standardized parameter sets for common ceramic materials while maintaining flexibility for customization based on specific performance requirements.

Looking forward, the field is moving toward digital twin approaches, where virtual process models run parallel to physical spraying operations, enabling real-time optimization and defect prediction. The ultimate goal remains achieving consistent, high-quality ceramic coatings with predetermined properties while minimizing process variability and maximizing resource efficiency. This requires a comprehensive understanding of the fundamental physics and chemistry governing the interaction between process parameters and coating formation mechanisms.

The 1980s marked a significant advancement with the development of High-Velocity Oxy-Fuel (HVOF) and detonation gun techniques, which dramatically improved coating density and adhesion strength. These innovations addressed previous limitations in ceramic coating quality and durability. The 1990s witnessed the integration of computer control systems and automation, enhancing process repeatability and precision in parameter control—critical factors for ceramic coating quality.

Recent decades have seen the emergence of solution precursor and suspension thermal spray methods, enabling the deposition of nanostructured ceramic coatings with superior properties. Additionally, cold spray technology has expanded the material portfolio and reduced thermal degradation issues common in traditional ceramic spraying processes. The integration of in-situ monitoring systems and real-time feedback control represents the current technological frontier, allowing for adaptive process control and quality assurance.

The primary objectives of ceramic thermal spray technology development focus on establishing robust correlations between process parameters and coating quality metrics. This includes understanding the complex relationships between spray distance, powder feed rate, plasma/flame characteristics, and resulting coating microstructure, porosity, and adhesion strength. Researchers aim to develop predictive models that can optimize parameter selection for specific ceramic materials and application requirements.

Another critical objective is enhancing coating reproducibility and reducing sensitivity to minor parameter variations, which has historically been a challenge in ceramic thermal spray processes. The industry seeks to establish standardized parameter sets for common ceramic materials while maintaining flexibility for customization based on specific performance requirements.

Looking forward, the field is moving toward digital twin approaches, where virtual process models run parallel to physical spraying operations, enabling real-time optimization and defect prediction. The ultimate goal remains achieving consistent, high-quality ceramic coatings with predetermined properties while minimizing process variability and maximizing resource efficiency. This requires a comprehensive understanding of the fundamental physics and chemistry governing the interaction between process parameters and coating formation mechanisms.

Market Analysis for High-Performance Ceramic Coatings

The global market for high-performance ceramic coatings has experienced significant growth over the past decade, driven primarily by increasing demands in aerospace, automotive, and industrial sectors. Current market valuations place the ceramic thermal spray coating segment at approximately 3.8 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 6.7% through 2030.

Aerospace applications represent the largest market share at 32%, where thermal barrier coatings (TBCs) provide critical protection for turbine components operating at extreme temperatures. The automotive sector follows at 24%, with growing adoption in engine components to improve fuel efficiency and reduce emissions. Industrial applications, particularly in power generation and oil & gas, constitute 28% of the market, while emerging applications in medical devices and electronics account for the remaining 16%.

Regional analysis reveals North America and Europe as mature markets with established infrastructure and stringent quality requirements, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 8.9% annually, driven by rapid industrialization and increasing manufacturing capabilities in high-tech sectors.

Customer requirements are increasingly focused on coating performance optimization rather than cost reduction. Key performance metrics demanded by end-users include thermal cycling resistance, erosion resistance, and consistent microstructural properties. Market research indicates that 76% of customers prioritize coating longevity and reliability over initial implementation costs, representing a shift from previous procurement patterns.

Emerging market trends include growing demand for nanostructured ceramic coatings, which offer superior performance characteristics compared to conventional coatings. Additionally, environmental regulations are driving interest in water-based ceramic coating systems and processes with reduced environmental impact. The sustainability factor has become a significant market differentiator, with 62% of industrial customers expressing preference for environmentally compliant coating technologies.

Competition analysis reveals market consolidation among major players, with the top five companies controlling approximately 47% of market share. However, specialized regional providers with expertise in specific application areas continue to maintain strong positions in niche markets. The competitive landscape is characterized by increasing emphasis on process parameter optimization capabilities and quality assurance systems rather than purely on material innovations.

Aerospace applications represent the largest market share at 32%, where thermal barrier coatings (TBCs) provide critical protection for turbine components operating at extreme temperatures. The automotive sector follows at 24%, with growing adoption in engine components to improve fuel efficiency and reduce emissions. Industrial applications, particularly in power generation and oil & gas, constitute 28% of the market, while emerging applications in medical devices and electronics account for the remaining 16%.

Regional analysis reveals North America and Europe as mature markets with established infrastructure and stringent quality requirements, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 8.9% annually, driven by rapid industrialization and increasing manufacturing capabilities in high-tech sectors.

Customer requirements are increasingly focused on coating performance optimization rather than cost reduction. Key performance metrics demanded by end-users include thermal cycling resistance, erosion resistance, and consistent microstructural properties. Market research indicates that 76% of customers prioritize coating longevity and reliability over initial implementation costs, representing a shift from previous procurement patterns.

Emerging market trends include growing demand for nanostructured ceramic coatings, which offer superior performance characteristics compared to conventional coatings. Additionally, environmental regulations are driving interest in water-based ceramic coating systems and processes with reduced environmental impact. The sustainability factor has become a significant market differentiator, with 62% of industrial customers expressing preference for environmentally compliant coating technologies.

Competition analysis reveals market consolidation among major players, with the top five companies controlling approximately 47% of market share. However, specialized regional providers with expertise in specific application areas continue to maintain strong positions in niche markets. The competitive landscape is characterized by increasing emphasis on process parameter optimization capabilities and quality assurance systems rather than purely on material innovations.

Current Challenges in Ceramic Thermal Spray Processes

Despite significant advancements in ceramic thermal spray technology, the industry continues to face several critical challenges that impede optimal coating quality and process efficiency. One of the primary obstacles remains the precise control of process parameters across different spray systems. The complex interrelationships between parameters such as particle velocity, temperature, feed rate, and standoff distance create a multidimensional optimization problem that varies significantly with equipment configuration and target substrate properties.

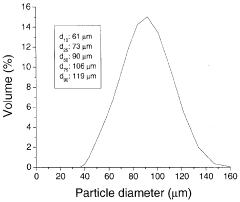

Material inconsistency presents another substantial challenge, as ceramic powders often exhibit batch-to-batch variations in particle size distribution, morphology, and chemical composition. These variations can dramatically affect flowability, melting behavior, and ultimately coating microstructure, making standardization difficult across production runs.

The thermal management of substrates during spraying operations continues to be problematic, particularly for temperature-sensitive components. Inadequate thermal control can lead to residual stress development, coating delamination, and substrate distortion. Current cooling strategies often lack the precision needed for complex geometries or thermally sensitive materials.

In-process monitoring capabilities remain limited despite their critical importance. Real-time assessment of particle parameters and coating formation is technically challenging, resulting in quality control that still relies heavily on post-process inspection rather than preventive control measures. This reactive approach increases production costs and reduces yield rates.

Reproducibility across different equipment sets represents a significant industrial challenge. Process parameters optimized for one thermal spray system often require substantial recalibration when transferred to another system, even of the same model, due to subtle differences in component wear, gas flow dynamics, and power delivery characteristics.

Environmental factors, including ambient temperature, humidity, and air quality, introduce additional variability that current process controls struggle to compensate for effectively. These factors can significantly impact coating quality, particularly for applications requiring high precision and consistency.

The industry also faces challenges in developing comprehensive process models that accurately predict coating properties based on input parameters. Current models often fail to account for the full complexity of plasma-particle interactions, splat formation dynamics, and residual stress development, limiting their practical utility for process optimization.

Automation and robotics integration, while advancing, still present challenges in achieving consistent coating quality on complex geometries. Path planning algorithms and robot kinematics must be precisely calibrated to maintain constant spray angle, velocity, and overlap patterns across irregular surfaces.

Material inconsistency presents another substantial challenge, as ceramic powders often exhibit batch-to-batch variations in particle size distribution, morphology, and chemical composition. These variations can dramatically affect flowability, melting behavior, and ultimately coating microstructure, making standardization difficult across production runs.

The thermal management of substrates during spraying operations continues to be problematic, particularly for temperature-sensitive components. Inadequate thermal control can lead to residual stress development, coating delamination, and substrate distortion. Current cooling strategies often lack the precision needed for complex geometries or thermally sensitive materials.

In-process monitoring capabilities remain limited despite their critical importance. Real-time assessment of particle parameters and coating formation is technically challenging, resulting in quality control that still relies heavily on post-process inspection rather than preventive control measures. This reactive approach increases production costs and reduces yield rates.

Reproducibility across different equipment sets represents a significant industrial challenge. Process parameters optimized for one thermal spray system often require substantial recalibration when transferred to another system, even of the same model, due to subtle differences in component wear, gas flow dynamics, and power delivery characteristics.

Environmental factors, including ambient temperature, humidity, and air quality, introduce additional variability that current process controls struggle to compensate for effectively. These factors can significantly impact coating quality, particularly for applications requiring high precision and consistency.

The industry also faces challenges in developing comprehensive process models that accurately predict coating properties based on input parameters. Current models often fail to account for the full complexity of plasma-particle interactions, splat formation dynamics, and residual stress development, limiting their practical utility for process optimization.

Automation and robotics integration, while advancing, still present challenges in achieving consistent coating quality on complex geometries. Path planning algorithms and robot kinematics must be precisely calibrated to maintain constant spray angle, velocity, and overlap patterns across irregular surfaces.

Process Parameter Optimization Methodologies

01 Composition optimization for thermal spray coatings

The quality of ceramic thermal spray coatings can be significantly improved by optimizing the composition of the coating materials. This includes the use of specific ceramic materials, additives, and binders that enhance adhesion, durability, and thermal resistance. Proper selection of materials based on their thermal expansion coefficients, melting points, and compatibility with the substrate is crucial for achieving high-quality coatings that can withstand extreme thermal and mechanical stresses.- Ceramic coating composition and materials: The composition of ceramic coatings significantly impacts the quality of thermal spray processes. Various ceramic materials such as zirconia, alumina, and titanium oxide can be used to create coatings with specific properties. The selection of appropriate ceramic materials and their proportions in the coating formulation affects characteristics like thermal resistance, durability, and adhesion strength. Additives and binders can be incorporated to enhance specific properties of the ceramic coating.

- Thermal spray process parameters optimization: Optimizing process parameters is crucial for achieving high-quality ceramic thermal spray coatings. Parameters such as spray distance, gun angle, powder feed rate, plasma or flame temperature, and substrate temperature significantly influence coating quality. Proper calibration and control of these parameters help minimize defects like porosity and cracking while improving coating uniformity and adhesion. Advanced process monitoring systems can be employed to maintain consistent parameters throughout the coating application.

- Surface preparation and pre-treatment techniques: Effective surface preparation is essential for high-quality ceramic thermal spray coatings. Techniques include grit blasting, chemical cleaning, and application of bond coats to improve adhesion between the substrate and ceramic coating. The roughness profile and cleanliness of the substrate surface directly impact coating adhesion and overall quality. Pre-heating the substrate can reduce thermal stress and improve coating integration. Proper masking techniques protect areas where coating is not desired.

- Quality inspection and testing methods: Various inspection and testing methods are employed to evaluate ceramic thermal spray coating quality. Non-destructive techniques include ultrasonic testing, thermal imaging, and X-ray analysis to detect defects without damaging the coating. Destructive testing methods such as adhesion tests, microhardness measurements, and cross-sectional analysis provide detailed information about coating properties. Advanced imaging technologies and automated inspection systems help identify inconsistencies in coating thickness, porosity, and microstructure. Quality control standards and specifications guide the evaluation process.

- Post-processing and coating enhancement: Post-processing treatments improve the performance and quality of ceramic thermal spray coatings. Techniques include heat treatment, sealing, and surface finishing to enhance coating properties. Heat treatment reduces residual stresses and improves coating cohesion. Sealing processes fill pores and increase corrosion resistance. Surface finishing methods like grinding and polishing improve surface smoothness and dimensional accuracy. Additional treatments can be applied to enhance specific properties such as wear resistance, thermal insulation, or electrical conductivity.

02 Process parameter control and optimization

Controlling and optimizing process parameters is essential for ensuring high-quality ceramic thermal spray coatings. Key parameters include spray distance, angle, particle velocity, temperature, feed rate, and cooling conditions. Advanced monitoring systems can be used to maintain consistent parameters throughout the coating process. Proper calibration and adjustment of these parameters based on the specific ceramic material and substrate characteristics can significantly improve coating uniformity, density, and adhesion.Expand Specific Solutions03 Surface preparation techniques

Effective surface preparation is critical for achieving high-quality ceramic thermal spray coatings. Techniques include grit blasting, chemical cleaning, and pre-heating of the substrate to remove contaminants and create an optimal surface profile for coating adhesion. The roughness and cleanliness of the substrate surface directly impact the mechanical interlocking between the coating and substrate. Proper surface preparation methods can significantly reduce coating defects such as delamination and poor adhesion.Expand Specific Solutions04 Quality assessment and testing methods

Various testing and assessment methods are employed to evaluate the quality of ceramic thermal spray coatings. These include adhesion testing, microstructural analysis, porosity measurement, hardness testing, and thermal cycling tests. Non-destructive evaluation techniques such as ultrasonic testing, thermal imaging, and X-ray diffraction can be used to detect defects without damaging the coating. Implementing comprehensive quality control protocols throughout the coating process ensures consistent coating performance and reliability.Expand Specific Solutions05 Post-processing treatments

Post-processing treatments can significantly enhance the quality and performance of ceramic thermal spray coatings. These treatments include heat treatment, sealing, laser remelting, and surface finishing operations. Post-processing can reduce porosity, improve homogeneity, enhance adhesion, and increase the coating's resistance to wear and corrosion. The selection of appropriate post-processing methods depends on the specific ceramic material, coating thickness, and intended application of the coated component.Expand Specific Solutions

Critical Patents and Research on Coating Microstructure Control

Thermal spray coating of porous nanostructured ceramic feedstock

PatentActiveCA2648643C

Innovation

- Controlled thermal spray deposition parameters, such as particle size distribution, morphology, temperature, and velocity, are used to produce nanostructured coatings with porous inclusions, which maintain porosity and mechanical stability, reducing thermal diffusivity and elastic modulus, and enhancing abradability and durability.

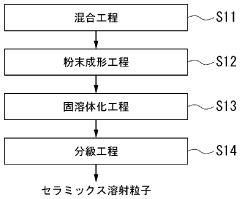

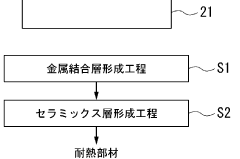

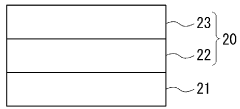

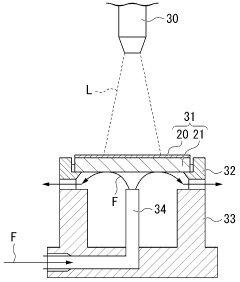

Ceramic thermal spray particles and method for forming thermal barrier coating layer

PatentWO2023248784A1

Innovation

- The method involves forming ceramic spray particles composed of ZrO2 and Yb2O3 with a standard deviation of 2% to 7% by mass, which are then used to create a thermal barrier coating layer with a metal bonding layer, achieving low thermal conductivity and enhanced thermal cycle durability through specific manufacturing processes like plasma spraying.

Quality Control and Testing Standards for Ceramic Coatings

Quality control and testing standards for ceramic coatings have evolved significantly to ensure the reliability and performance of thermally sprayed ceramic layers. The industry has established comprehensive testing protocols that evaluate both physical and mechanical properties of these coatings, ensuring they meet the stringent requirements of various applications.

Non-destructive testing (NDT) methods form the cornerstone of quality assurance for ceramic coatings. Techniques such as ultrasonic testing, eddy current inspection, and thermography allow for the detection of subsurface defects without compromising the integrity of the coating. These methods are particularly valuable for identifying delamination, porosity clusters, and inclusion defects that may compromise coating performance.

Adhesion testing represents a critical quality parameter, typically conducted according to ASTM C633 or ISO 14916 standards. These tests quantify the bond strength between the ceramic coating and substrate, providing essential data on coating durability under operational conditions. The minimum acceptable adhesion values vary by application, ranging from 20 MPa for thermal barrier coatings to over 70 MPa for wear-resistant applications.

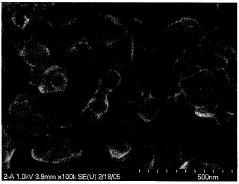

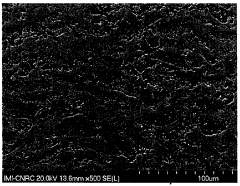

Microstructural analysis through scanning electron microscopy (SEM) and optical microscopy has become standard practice for quality assessment. These techniques enable the evaluation of coating porosity, oxide content, unmelted particles, and interfacial characteristics. The ASTM E2109 standard provides guidelines for the preparation and examination of thermal spray coating cross-sections.

Hardness testing, typically performed using Vickers or Knoop microhardness methods (ASTM E384), serves as an indicator of coating wear resistance and overall quality. For ceramic coatings, hardness values typically range from 800 to 1500 HV, depending on the specific ceramic material and application requirements.

Thermal cycling tests have gained prominence for evaluating coating durability under temperature fluctuations. Standards such as ISO 14923 and ASTM C1171 outline procedures for subjecting coated specimens to repeated heating and cooling cycles, simulating operational conditions and identifying potential failure modes.

Corrosion resistance testing, following ASTM B117 (salt spray) or electrochemical impedance spectroscopy methods, has become increasingly important as ceramic coatings find applications in aggressive environments. These tests evaluate the coating's ability to protect the substrate from chemical attack and environmental degradation.

Statistical process control (SPC) methodologies are now being integrated into quality assurance systems for ceramic thermal spray operations. These approaches, aligned with ISO 9001 quality management principles, enable continuous monitoring of process parameters and early detection of deviations that might affect coating quality.

Non-destructive testing (NDT) methods form the cornerstone of quality assurance for ceramic coatings. Techniques such as ultrasonic testing, eddy current inspection, and thermography allow for the detection of subsurface defects without compromising the integrity of the coating. These methods are particularly valuable for identifying delamination, porosity clusters, and inclusion defects that may compromise coating performance.

Adhesion testing represents a critical quality parameter, typically conducted according to ASTM C633 or ISO 14916 standards. These tests quantify the bond strength between the ceramic coating and substrate, providing essential data on coating durability under operational conditions. The minimum acceptable adhesion values vary by application, ranging from 20 MPa for thermal barrier coatings to over 70 MPa for wear-resistant applications.

Microstructural analysis through scanning electron microscopy (SEM) and optical microscopy has become standard practice for quality assessment. These techniques enable the evaluation of coating porosity, oxide content, unmelted particles, and interfacial characteristics. The ASTM E2109 standard provides guidelines for the preparation and examination of thermal spray coating cross-sections.

Hardness testing, typically performed using Vickers or Knoop microhardness methods (ASTM E384), serves as an indicator of coating wear resistance and overall quality. For ceramic coatings, hardness values typically range from 800 to 1500 HV, depending on the specific ceramic material and application requirements.

Thermal cycling tests have gained prominence for evaluating coating durability under temperature fluctuations. Standards such as ISO 14923 and ASTM C1171 outline procedures for subjecting coated specimens to repeated heating and cooling cycles, simulating operational conditions and identifying potential failure modes.

Corrosion resistance testing, following ASTM B117 (salt spray) or electrochemical impedance spectroscopy methods, has become increasingly important as ceramic coatings find applications in aggressive environments. These tests evaluate the coating's ability to protect the substrate from chemical attack and environmental degradation.

Statistical process control (SPC) methodologies are now being integrated into quality assurance systems for ceramic thermal spray operations. These approaches, aligned with ISO 9001 quality management principles, enable continuous monitoring of process parameters and early detection of deviations that might affect coating quality.

Environmental Impact and Sustainability Considerations

The ceramic thermal spray industry is increasingly facing scrutiny regarding its environmental footprint. Traditional thermal spray processes consume significant energy, with plasma spray systems requiring between 40-120 kW of power and HVOF systems utilizing substantial amounts of combustible gases. This energy consumption directly correlates with greenhouse gas emissions, particularly when fossil fuel-based energy sources are employed. Additionally, the process generates particulate matter and potentially hazardous waste, including heavy metal-containing overspray that requires proper disposal protocols.

Recent advancements have focused on developing more environmentally sustainable thermal spray technologies. Water-stabilized plasma systems have demonstrated up to 30% reduction in energy consumption compared to conventional gas-stabilized systems while maintaining comparable coating quality. Similarly, optimized HVOF systems with improved combustion efficiency have reduced fuel consumption by 15-25% while enhancing deposition efficiency, thereby minimizing material waste.

Material selection represents another critical sustainability consideration. The industry is gradually shifting toward environmentally benign ceramic materials that avoid toxic elements like chromium, lead, and cadmium previously common in certain coating applications. Recycled ceramic feedstock materials have also emerged as viable alternatives, with studies showing that properly processed recycled powders can achieve 85-95% of the performance characteristics of virgin materials in specific applications.

Process parameter optimization plays a dual role in sustainability improvement. Fine-tuning spray distance, powder feed rate, and carrier gas flow not only enhances coating quality but also significantly reduces overspray and material waste. Advanced facilities have reported material utilization improvements from typical rates of 40-60% to over 75% through careful parameter optimization, representing substantial reductions in raw material consumption and waste generation.

Closed-loop systems for powder recovery and recycling have become increasingly sophisticated, with modern systems capable of reclaiming up to 70% of overspray material for reprocessing. These systems incorporate advanced filtration technologies that minimize environmental releases while recovering valuable materials. Similarly, water recycling systems in wet collection booths can reduce freshwater consumption by 80-90% compared to once-through systems.

Life cycle assessment (LCA) studies indicate that despite the energy-intensive nature of thermal spray processes, the extended service life and improved performance of ceramic-coated components often result in net environmental benefits over product lifecycles. Components with optimized ceramic coatings have demonstrated 2-5 times longer service lives in certain applications, significantly reducing resource consumption associated with replacement part manufacturing and maintenance operations.

Recent advancements have focused on developing more environmentally sustainable thermal spray technologies. Water-stabilized plasma systems have demonstrated up to 30% reduction in energy consumption compared to conventional gas-stabilized systems while maintaining comparable coating quality. Similarly, optimized HVOF systems with improved combustion efficiency have reduced fuel consumption by 15-25% while enhancing deposition efficiency, thereby minimizing material waste.

Material selection represents another critical sustainability consideration. The industry is gradually shifting toward environmentally benign ceramic materials that avoid toxic elements like chromium, lead, and cadmium previously common in certain coating applications. Recycled ceramic feedstock materials have also emerged as viable alternatives, with studies showing that properly processed recycled powders can achieve 85-95% of the performance characteristics of virgin materials in specific applications.

Process parameter optimization plays a dual role in sustainability improvement. Fine-tuning spray distance, powder feed rate, and carrier gas flow not only enhances coating quality but also significantly reduces overspray and material waste. Advanced facilities have reported material utilization improvements from typical rates of 40-60% to over 75% through careful parameter optimization, representing substantial reductions in raw material consumption and waste generation.

Closed-loop systems for powder recovery and recycling have become increasingly sophisticated, with modern systems capable of reclaiming up to 70% of overspray material for reprocessing. These systems incorporate advanced filtration technologies that minimize environmental releases while recovering valuable materials. Similarly, water recycling systems in wet collection booths can reduce freshwater consumption by 80-90% compared to once-through systems.

Life cycle assessment (LCA) studies indicate that despite the energy-intensive nature of thermal spray processes, the extended service life and improved performance of ceramic-coated components often result in net environmental benefits over product lifecycles. Components with optimized ceramic coatings have demonstrated 2-5 times longer service lives in certain applications, significantly reducing resource consumption associated with replacement part manufacturing and maintenance operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!