Plasma Torch Innovations for Ceramic Coating Applications

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Torch Technology Evolution and Objectives

Plasma torch technology has evolved significantly since its inception in the mid-20th century. Initially developed for metallurgical applications, plasma torches have undergone substantial transformations in design, efficiency, and application scope. The fundamental principle involves creating a high-temperature plasma arc through gas ionization, which generates temperatures exceeding 10,000°C. This extreme thermal environment enables precise material processing capabilities that conventional heating methods cannot achieve.

The evolution trajectory of plasma torch technology for ceramic coating applications can be traced through several distinct phases. The 1960s marked the introduction of basic direct current (DC) plasma spray systems, primarily utilized for rudimentary coating processes. The 1970s and 1980s witnessed significant advancements in power supply stability and torch design, enabling more controlled deposition parameters and improved coating quality. By the 1990s, the integration of computer control systems revolutionized the precision and reproducibility of plasma spray operations.

The early 2000s brought forth innovations in feedstock delivery systems and plasma gas compositions, expanding the range of processable ceramic materials. Recent developments have focused on enhancing energy efficiency, reducing environmental impact, and improving coating microstructure control through advanced plasma diagnostics and modeling techniques. The introduction of suspension and solution precursor plasma spray methods has enabled the deposition of nanostructured coatings with superior properties.

Current technological objectives in plasma torch development for ceramic coating applications center around several key areas. Enhancing energy efficiency remains paramount, with research focused on reducing power consumption while maintaining optimal plasma characteristics. Improving process stability and reproducibility through advanced control systems and real-time monitoring represents another critical objective. The development of novel torch designs capable of processing a wider range of ceramic materials with precise microstructural control continues to drive innovation in this field.

Additionally, there is growing emphasis on environmental sustainability, with objectives aimed at reducing emissions and waste generation during plasma spray operations. The integration of plasma torch technology with additive manufacturing principles is emerging as a promising direction, enabling the fabrication of complex ceramic components with tailored properties. Research is also targeting the development of portable and flexible plasma torch systems for on-site coating applications in various industrial sectors.

The overarching technological goal remains the creation of more versatile, efficient, and precise plasma torch systems capable of producing ceramic coatings with enhanced performance characteristics, longer service life, and reduced production costs. These advancements are expected to expand the application scope of plasma-sprayed ceramic coatings across aerospace, energy, biomedical, and automotive industries.

The evolution trajectory of plasma torch technology for ceramic coating applications can be traced through several distinct phases. The 1960s marked the introduction of basic direct current (DC) plasma spray systems, primarily utilized for rudimentary coating processes. The 1970s and 1980s witnessed significant advancements in power supply stability and torch design, enabling more controlled deposition parameters and improved coating quality. By the 1990s, the integration of computer control systems revolutionized the precision and reproducibility of plasma spray operations.

The early 2000s brought forth innovations in feedstock delivery systems and plasma gas compositions, expanding the range of processable ceramic materials. Recent developments have focused on enhancing energy efficiency, reducing environmental impact, and improving coating microstructure control through advanced plasma diagnostics and modeling techniques. The introduction of suspension and solution precursor plasma spray methods has enabled the deposition of nanostructured coatings with superior properties.

Current technological objectives in plasma torch development for ceramic coating applications center around several key areas. Enhancing energy efficiency remains paramount, with research focused on reducing power consumption while maintaining optimal plasma characteristics. Improving process stability and reproducibility through advanced control systems and real-time monitoring represents another critical objective. The development of novel torch designs capable of processing a wider range of ceramic materials with precise microstructural control continues to drive innovation in this field.

Additionally, there is growing emphasis on environmental sustainability, with objectives aimed at reducing emissions and waste generation during plasma spray operations. The integration of plasma torch technology with additive manufacturing principles is emerging as a promising direction, enabling the fabrication of complex ceramic components with tailored properties. Research is also targeting the development of portable and flexible plasma torch systems for on-site coating applications in various industrial sectors.

The overarching technological goal remains the creation of more versatile, efficient, and precise plasma torch systems capable of producing ceramic coatings with enhanced performance characteristics, longer service life, and reduced production costs. These advancements are expected to expand the application scope of plasma-sprayed ceramic coatings across aerospace, energy, biomedical, and automotive industries.

Market Analysis for Advanced Ceramic Coating Solutions

The global market for advanced ceramic coatings has experienced substantial growth in recent years, driven by increasing demand across multiple industries including aerospace, automotive, medical, and industrial manufacturing. The market size for thermal spray coatings, which includes plasma-sprayed ceramic coatings, was valued at approximately 10.1 billion USD in 2022 and is projected to reach 15.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.6%.

Aerospace and defense sectors currently dominate the ceramic coating market, accounting for nearly 35% of the total market share. This dominance stems from the critical need for thermal barrier coatings that can withstand extreme operating conditions in aircraft engines and turbine components. The automotive industry follows closely, with growing adoption of ceramic coatings for engine components, exhaust systems, and increasingly for decorative and protective exterior applications.

Regional analysis reveals that North America and Europe collectively hold approximately 60% of the market share, primarily due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.2% annually, driven by rapid industrialization in China and India, along with significant aerospace and automotive sector expansion.

Customer demand patterns show a clear shift toward coatings that offer multiple functionalities beyond traditional thermal protection. End-users increasingly seek solutions that combine thermal resistance with properties such as wear resistance, corrosion protection, and electrical insulation. This multi-functionality trend has created new market segments and opportunities for plasma torch innovation.

The competitive landscape features both established players and emerging specialists. Major corporations like Oerlikon Metco, Praxair Surface Technologies, and H.C. Starck dominate with comprehensive coating solution portfolios, while specialized firms like Plasma-Tec and APS Materials have carved out niches through technological innovation in specific application areas.

Market challenges include the high initial investment costs for plasma spray equipment, which can range from 500,000 to 2 million USD depending on configuration and capabilities. Additionally, stringent environmental regulations regarding emissions and waste management are reshaping market dynamics, with sustainable coating solutions gaining premium positioning.

Future market growth will likely be driven by emerging applications in renewable energy infrastructure, particularly in concentrated solar power systems and wind turbines, where advanced ceramic coatings can significantly enhance component durability and efficiency. The medical implant sector also presents substantial growth potential, with plasma-sprayed hydroxyapatite coatings for orthopedic implants expected to grow at 8.5% annually through 2030.

Aerospace and defense sectors currently dominate the ceramic coating market, accounting for nearly 35% of the total market share. This dominance stems from the critical need for thermal barrier coatings that can withstand extreme operating conditions in aircraft engines and turbine components. The automotive industry follows closely, with growing adoption of ceramic coatings for engine components, exhaust systems, and increasingly for decorative and protective exterior applications.

Regional analysis reveals that North America and Europe collectively hold approximately 60% of the market share, primarily due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.2% annually, driven by rapid industrialization in China and India, along with significant aerospace and automotive sector expansion.

Customer demand patterns show a clear shift toward coatings that offer multiple functionalities beyond traditional thermal protection. End-users increasingly seek solutions that combine thermal resistance with properties such as wear resistance, corrosion protection, and electrical insulation. This multi-functionality trend has created new market segments and opportunities for plasma torch innovation.

The competitive landscape features both established players and emerging specialists. Major corporations like Oerlikon Metco, Praxair Surface Technologies, and H.C. Starck dominate with comprehensive coating solution portfolios, while specialized firms like Plasma-Tec and APS Materials have carved out niches through technological innovation in specific application areas.

Market challenges include the high initial investment costs for plasma spray equipment, which can range from 500,000 to 2 million USD depending on configuration and capabilities. Additionally, stringent environmental regulations regarding emissions and waste management are reshaping market dynamics, with sustainable coating solutions gaining premium positioning.

Future market growth will likely be driven by emerging applications in renewable energy infrastructure, particularly in concentrated solar power systems and wind turbines, where advanced ceramic coatings can significantly enhance component durability and efficiency. The medical implant sector also presents substantial growth potential, with plasma-sprayed hydroxyapatite coatings for orthopedic implants expected to grow at 8.5% annually through 2030.

Current Plasma Torch Limitations and Technical Barriers

Despite significant advancements in plasma torch technology for ceramic coating applications, several critical limitations and technical barriers continue to impede optimal performance and broader industrial adoption. Current plasma spray systems face substantial challenges in thermal efficiency, with energy losses reaching up to 60% in conventional designs. This inefficiency stems primarily from inadequate heat transfer mechanisms and suboptimal electrode configurations, resulting in excessive power consumption and increased operational costs.

Temperature control precision represents another significant barrier, as conventional plasma torches exhibit temperature fluctuations of ±300°C during operation. These variations directly impact coating quality, creating inconsistencies in microstructure, porosity levels, and adhesion strength. The inability to maintain stable plasma conditions throughout the coating process remains a fundamental challenge for high-precision applications.

Electrode degradation presents a persistent technical limitation, with current tungsten-based electrodes typically requiring replacement after 80-100 operational hours. This degradation not only increases maintenance downtime but also introduces variability in plasma characteristics as electrodes wear, compromising coating reproducibility across production batches.

Gas dynamics within plasma torches pose additional challenges, particularly in achieving uniform particle heating and acceleration. Current designs struggle with turbulent flow patterns that create uneven temperature distributions within the plasma plume. This non-uniformity results in inconsistent melting of ceramic feedstock particles, leading to coating defects and reduced performance properties.

Scaling limitations represent a significant barrier for large-area applications, as conventional plasma torches are restricted to coating widths of 10-15mm per pass. This constraint necessitates multiple overlapping passes for larger components, introducing potential weaknesses at pass interfaces and extending processing times considerably.

Feedstock compatibility issues further limit versatility, with current plasma systems optimized for specific particle size distributions and material compositions. Many advanced ceramic formulations require specialized handling that exceeds the capabilities of standard torch designs, particularly for nanoscale powders that tend to agglomerate or decompose under conventional plasma conditions.

Environmental and safety concerns also present technical barriers, as traditional plasma systems generate significant noise (often exceeding 100 dB), electromagnetic interference, and ultraviolet radiation. These factors necessitate extensive shielding and protective measures, increasing system complexity and installation requirements while limiting integration possibilities in sensitive manufacturing environments.

Temperature control precision represents another significant barrier, as conventional plasma torches exhibit temperature fluctuations of ±300°C during operation. These variations directly impact coating quality, creating inconsistencies in microstructure, porosity levels, and adhesion strength. The inability to maintain stable plasma conditions throughout the coating process remains a fundamental challenge for high-precision applications.

Electrode degradation presents a persistent technical limitation, with current tungsten-based electrodes typically requiring replacement after 80-100 operational hours. This degradation not only increases maintenance downtime but also introduces variability in plasma characteristics as electrodes wear, compromising coating reproducibility across production batches.

Gas dynamics within plasma torches pose additional challenges, particularly in achieving uniform particle heating and acceleration. Current designs struggle with turbulent flow patterns that create uneven temperature distributions within the plasma plume. This non-uniformity results in inconsistent melting of ceramic feedstock particles, leading to coating defects and reduced performance properties.

Scaling limitations represent a significant barrier for large-area applications, as conventional plasma torches are restricted to coating widths of 10-15mm per pass. This constraint necessitates multiple overlapping passes for larger components, introducing potential weaknesses at pass interfaces and extending processing times considerably.

Feedstock compatibility issues further limit versatility, with current plasma systems optimized for specific particle size distributions and material compositions. Many advanced ceramic formulations require specialized handling that exceeds the capabilities of standard torch designs, particularly for nanoscale powders that tend to agglomerate or decompose under conventional plasma conditions.

Environmental and safety concerns also present technical barriers, as traditional plasma systems generate significant noise (often exceeding 100 dB), electromagnetic interference, and ultraviolet radiation. These factors necessitate extensive shielding and protective measures, increasing system complexity and installation requirements while limiting integration possibilities in sensitive manufacturing environments.

State-of-the-Art Plasma Torch Designs for Ceramics

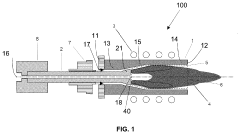

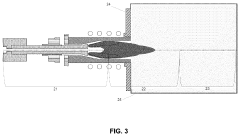

01 Plasma torch design and structure

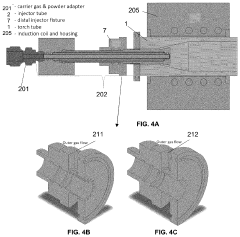

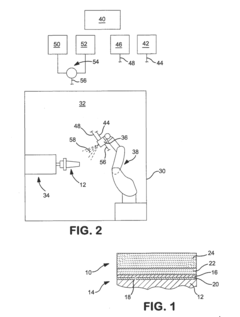

Plasma torches are designed with specific structural elements to enhance performance and durability. These designs include specialized electrode configurations, cooling systems, and nozzle geometries that affect plasma formation and stability. Advanced structural designs can improve arc stability, increase operational lifespan, and enhance cutting or welding capabilities across various industrial applications.- Plasma torch design and structure: Plasma torches are designed with specific structural elements to optimize performance and durability. These designs include specialized electrode configurations, cooling systems, and nozzle geometries that enhance plasma formation and control. The structural innovations focus on improving arc stability, extending component lifespan, and ensuring efficient energy transfer within the torch system.

- Cooling systems for plasma torches: Effective cooling mechanisms are crucial for plasma torch operation to prevent overheating and extend component life. These systems typically employ water or gas cooling channels strategically positioned around critical components such as electrodes and nozzles. Advanced cooling designs incorporate thermal management techniques that balance heat distribution and optimize energy efficiency while maintaining operational stability during high-temperature plasma generation.

- Plasma torch applications in material processing: Plasma torches are widely used in various material processing applications including cutting, welding, surface treatment, and waste processing. The high-temperature plasma enables precise cutting of conductive materials, efficient welding of difficult-to-join metals, and effective surface modification treatments. In waste management, plasma technology facilitates the breakdown of hazardous materials through thermal decomposition while minimizing environmental impact.

- Power supply and control systems: Sophisticated power supply and control systems are essential for optimal plasma torch operation. These systems regulate current, voltage, and gas flow parameters to maintain stable plasma conditions. Advanced control mechanisms incorporate feedback loops that monitor operational parameters in real-time, allowing for automatic adjustments to optimize performance. Digital control interfaces enable precise manipulation of plasma characteristics for specific applications while enhancing safety and reliability.

- Innovations in electrode and consumable components: Ongoing innovations in electrode materials and consumable components aim to extend service life and improve plasma torch performance. These advancements include novel electrode compositions that resist erosion, specialized cathode designs that enhance electron emission, and improved nozzle configurations that optimize gas flow dynamics. Material science developments have led to components capable of withstanding extreme thermal cycling while maintaining consistent plasma characteristics throughout their operational lifetime.

02 Plasma torch cooling systems

Effective cooling systems are critical for plasma torch operation to prevent overheating and extend component life. These systems typically use water or gas cooling methods to manage the extreme temperatures generated during plasma formation. Advanced cooling technologies include segmented water channels, vortex cooling mechanisms, and thermal barrier coatings that protect critical components while maintaining operational efficiency.Expand Specific Solutions03 Plasma torch control systems

Control systems for plasma torches regulate various operational parameters including power input, gas flow rates, and arc characteristics. These systems often incorporate sensors for real-time monitoring and feedback loops to maintain optimal cutting or welding conditions. Advanced control technologies may include digital interfaces, automated parameter adjustment based on material properties, and integration with robotic systems for precision manufacturing applications.Expand Specific Solutions04 Plasma torch applications in waste treatment

Plasma torches are increasingly used in waste treatment and disposal applications. The high-temperature plasma can effectively break down hazardous materials, convert waste to energy, and reduce environmental pollutants. These systems can process municipal solid waste, medical waste, and industrial byproducts, converting them into syngas or vitrified slag while minimizing harmful emissions and maximizing resource recovery.Expand Specific Solutions05 Plasma torch electrode improvements

Electrode design and materials significantly impact plasma torch performance and longevity. Advanced electrode technologies include specialized alloys, composite materials, and novel geometries that resist erosion under extreme operating conditions. Recent innovations focus on extending electrode life through improved thermal management, optimized current distribution, and materials that can withstand high-temperature oxidation and thermal cycling.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The plasma torch technology for ceramic coating applications is currently in a growth phase, with an expanding market driven by increasing demand in aerospace, automotive, and industrial sectors. The global market size is estimated to reach $2-3 billion by 2025, growing at a CAGR of approximately 6-8%. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established industrial equipment manufacturers like Hypertherm Associates and ESAB Group, alongside research-focused organizations such as the National Research Council of Canada and Centre National de la Recherche Scientifique. Academic institutions like Xi'an Jiaotong University and Virginia Tech are advancing fundamental research, while specialized companies like Fourth State Medicine and Oerlikon Metco are developing niche applications. Asian manufacturers, particularly from China and Japan (NIPPON STEEL, POSCO Holdings), are increasingly challenging traditional Western market dominance.

Hypertherm Associates, Inc.

Technical Solution: Hypertherm has developed advanced plasma torch systems specifically optimized for ceramic coating applications. Their XPR300 plasma system incorporates proprietary Vented Water Injection (VWI) technology that provides superior cut quality and consistency when working with ceramic materials. The system features X-Definition class plasma cutting technology that delivers exceptional angularity and edge quality necessary for precision ceramic coating preparation. Hypertherm's Cool Nozzle technology maintains optimal temperature during extended operations, critical for consistent ceramic deposition. Their Smart Pierce technology intelligently controls the pierce process to prevent material damage when working with delicate ceramic substrates. Additionally, Hypertherm has pioneered True Hole technology that enables precise hole cutting in ceramic materials with minimal taper, essential for complex coating applications.

Strengths: Industry-leading precision and cut quality; comprehensive digital control systems allowing for automated parameter optimization; robust design for industrial environments. Weaknesses: Higher initial investment compared to conventional systems; requires specialized training for operators; consumable parts need regular replacement in high-volume production environments.

FRONIUS INTERNATIONAL GMBH

Technical Solution: Fronius has developed the TransPlas ceramic coating system that incorporates their innovative digital resonance technology for superior plasma arc stability. Their system utilizes a microprocessor-controlled inverter power source that provides precise control over arc characteristics, essential for consistent ceramic deposition. The TransPlas features Fronius' PulsePlasma technology that alternates between high and low current phases at frequencies up to 1000Hz, allowing for controlled heat input and reduced thermal stress on ceramic materials. Their SprayTrack vision system provides real-time monitoring and adjustment of spray parameters based on actual coating formation, ensuring consistent quality. Fronius has also pioneered the CeramicJet injection system that optimizes the trajectory and velocity of ceramic powder particles entering the plasma stream, significantly improving deposition efficiency. The system incorporates advanced gas mixing technology that allows for precise control of plasma chemistry, critical for specific ceramic compositions.

Strengths: Exceptional arc stability and control; advanced digital monitoring systems; energy-efficient design reducing operational costs; modular construction allowing for easy upgrades. Weaknesses: Higher initial cost compared to basic systems; requires specialized technical support; more complex setup procedures for new coating formulations.

Key Patents and Breakthroughs in Plasma Spray Technology

A radio frequency inductively coupled plasma (RF-ICP) torch

PatentActiveUS20230345611A1

Innovation

- The RF-ICP torch features a tubular component with a conical portion and an injector tube that delivers plasma gas and sample particles, utilizing a load coil to energize the plasma gas, achieving higher temperatures and reduced gas consumption through optimized geometry and gas flow paths.

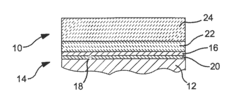

Ceramic coating deposition

PatentInactiveUS20180251881A1

Innovation

- A ceramic coating process involving the introduction of a suspension with fine ceramic particulate and a liquid carrier into a plasma torch, where co-spraying or mixing of dissimilar ceramic materials like YSZ and GdZ or Gd2Zr2O7 is performed to form multi-material layers with enhanced toughness, reacting beneficially with calcium-magnesium alumino-silicates, and agglomerating into splats for improved substrate coating.

Energy Efficiency and Sustainability Considerations

The plasma torch industry is increasingly focusing on energy efficiency and sustainability as key drivers for innovation in ceramic coating applications. Traditional plasma spray systems are known for their high energy consumption, with electrical efficiency typically ranging from 40-60%. Recent advancements have pushed these figures to 65-70% through improved electrode designs and optimized gas flow dynamics, resulting in significant energy savings for industrial operations.

Material utilization represents another critical sustainability aspect. Conventional plasma spray processes often achieve only 50-65% deposition efficiency, with substantial material wastage. Next-generation plasma torch systems incorporate powder recycling mechanisms and precise powder injection techniques that can increase deposition efficiency to 75-85%, dramatically reducing waste and raw material consumption.

Environmental impact considerations have led to the development of water-stabilized plasma torches that reduce harmful emissions compared to gas-stabilized alternatives. These systems demonstrate 30-40% lower NOx emissions while maintaining comparable coating quality. Additionally, closed-loop cooling systems have been implemented to reduce water consumption by up to 80% compared to traditional open-loop configurations.

Life cycle assessment studies indicate that modern plasma torch systems for ceramic coating applications can reduce the overall carbon footprint by 25-35% compared to systems from a decade ago. This improvement stems from both direct energy consumption reductions and extended equipment lifespans through advanced component designs that resist erosion and thermal fatigue.

The integration of digital monitoring and control systems has further enhanced sustainability by enabling real-time process optimization. Smart plasma systems can automatically adjust power levels and gas flows based on coating requirements, reducing energy consumption by an additional 10-15% while maintaining consistent coating quality. These systems also provide predictive maintenance capabilities that minimize downtime and extend equipment service life.

Renewable energy compatibility represents an emerging trend in plasma torch design. New power supply architectures can accommodate fluctuating inputs from renewable sources while maintaining stable plasma conditions. This development enables manufacturing facilities to utilize on-site renewable energy generation for plasma coating operations, further reducing environmental impact and operational costs.

Material utilization represents another critical sustainability aspect. Conventional plasma spray processes often achieve only 50-65% deposition efficiency, with substantial material wastage. Next-generation plasma torch systems incorporate powder recycling mechanisms and precise powder injection techniques that can increase deposition efficiency to 75-85%, dramatically reducing waste and raw material consumption.

Environmental impact considerations have led to the development of water-stabilized plasma torches that reduce harmful emissions compared to gas-stabilized alternatives. These systems demonstrate 30-40% lower NOx emissions while maintaining comparable coating quality. Additionally, closed-loop cooling systems have been implemented to reduce water consumption by up to 80% compared to traditional open-loop configurations.

Life cycle assessment studies indicate that modern plasma torch systems for ceramic coating applications can reduce the overall carbon footprint by 25-35% compared to systems from a decade ago. This improvement stems from both direct energy consumption reductions and extended equipment lifespans through advanced component designs that resist erosion and thermal fatigue.

The integration of digital monitoring and control systems has further enhanced sustainability by enabling real-time process optimization. Smart plasma systems can automatically adjust power levels and gas flows based on coating requirements, reducing energy consumption by an additional 10-15% while maintaining consistent coating quality. These systems also provide predictive maintenance capabilities that minimize downtime and extend equipment service life.

Renewable energy compatibility represents an emerging trend in plasma torch design. New power supply architectures can accommodate fluctuating inputs from renewable sources while maintaining stable plasma conditions. This development enables manufacturing facilities to utilize on-site renewable energy generation for plasma coating operations, further reducing environmental impact and operational costs.

Material Science Advancements for Ceramic Coatings

Recent advancements in material science have significantly transformed the landscape of ceramic coating applications, particularly when coupled with plasma torch technology. The evolution of ceramic materials has been characterized by the development of novel compositions with enhanced thermal resistance, mechanical durability, and chemical stability. Traditional ceramic materials such as alumina and zirconia have been supplemented by complex ceramic composites incorporating rare earth elements and transition metals, resulting in coatings with superior performance characteristics.

Nanostructured ceramic materials represent a breakthrough in this field, offering unprecedented control over coating microstructure. These materials exhibit grain sizes below 100 nanometers, enabling exceptional hardness-to-toughness ratios that were previously unattainable with conventional ceramics. The incorporation of nanoparticles into ceramic matrices has demonstrated up to 30% improvement in wear resistance and thermal shock tolerance compared to their microstructured counterparts.

Functionally graded materials (FGMs) have emerged as another significant innovation, allowing for gradual transitions in composition and properties throughout the coating thickness. This approach effectively addresses the challenge of thermal expansion mismatch between substrate and coating, reducing delamination risks by up to 40% in high-temperature cycling applications. FGMs enable tailored property profiles that optimize performance across varying operational conditions.

Self-healing ceramic compositions represent the cutting edge of material science in this domain. These advanced materials incorporate microcapsules or vascular networks containing healing agents that are released upon crack formation. Studies have shown that such systems can recover up to 80% of original mechanical strength after damage events, substantially extending coating service life in harsh environments.

Computational materials science has accelerated development through predictive modeling of ceramic behavior under plasma deposition conditions. Machine learning algorithms now enable the optimization of material compositions based on desired property profiles, reducing experimental iterations by approximately 60%. These digital tools facilitate rapid prototyping of novel ceramic formulations specifically designed for plasma torch application methods.

Environmentally sustainable ceramic materials are gaining prominence, with research focused on reducing rare earth content and eliminating toxic components. Bio-inspired ceramic structures mimicking natural hierarchical arrangements have demonstrated exceptional toughness while utilizing more abundant elements. These developments align with global sustainability initiatives while maintaining or enhancing the performance characteristics essential for advanced coating applications.

Nanostructured ceramic materials represent a breakthrough in this field, offering unprecedented control over coating microstructure. These materials exhibit grain sizes below 100 nanometers, enabling exceptional hardness-to-toughness ratios that were previously unattainable with conventional ceramics. The incorporation of nanoparticles into ceramic matrices has demonstrated up to 30% improvement in wear resistance and thermal shock tolerance compared to their microstructured counterparts.

Functionally graded materials (FGMs) have emerged as another significant innovation, allowing for gradual transitions in composition and properties throughout the coating thickness. This approach effectively addresses the challenge of thermal expansion mismatch between substrate and coating, reducing delamination risks by up to 40% in high-temperature cycling applications. FGMs enable tailored property profiles that optimize performance across varying operational conditions.

Self-healing ceramic compositions represent the cutting edge of material science in this domain. These advanced materials incorporate microcapsules or vascular networks containing healing agents that are released upon crack formation. Studies have shown that such systems can recover up to 80% of original mechanical strength after damage events, substantially extending coating service life in harsh environments.

Computational materials science has accelerated development through predictive modeling of ceramic behavior under plasma deposition conditions. Machine learning algorithms now enable the optimization of material compositions based on desired property profiles, reducing experimental iterations by approximately 60%. These digital tools facilitate rapid prototyping of novel ceramic formulations specifically designed for plasma torch application methods.

Environmentally sustainable ceramic materials are gaining prominence, with research focused on reducing rare earth content and eliminating toxic components. Bio-inspired ceramic structures mimicking natural hierarchical arrangements have demonstrated exceptional toughness while utilizing more abundant elements. These developments align with global sustainability initiatives while maintaining or enhancing the performance characteristics essential for advanced coating applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!