Next Generation Ceramic Thermal Spray Technologies

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Thermal Spray Evolution and Objectives

Ceramic thermal spray technology has evolved significantly since its inception in the early 20th century. Initially developed for protective coatings in aerospace applications, this technology has undergone several transformative phases. The first generation, emerging in the 1950s, utilized simple flame spray processes with limited material options and coating quality. By the 1970s, plasma spray technologies revolutionized the field, enabling higher temperatures and velocities that significantly improved coating density and adhesion properties.

The 1990s marked another milestone with the introduction of High-Velocity Oxy-Fuel (HVOF) and detonation spray techniques, which dramatically enhanced coating performance through reduced porosity and increased bond strength. These advancements expanded ceramic thermal spray applications beyond aerospace into energy, automotive, and medical sectors, demonstrating the technology's versatility and growing importance.

Current state-of-the-art ceramic thermal spray technologies include suspension and solution precursor methods, which enable the production of nanostructured coatings with unprecedented properties. These techniques represent a significant leap forward in achieving finer microstructures and enhanced functional characteristics that were previously unattainable with conventional powder-based approaches.

The technological trajectory clearly indicates a shift from purely protective applications toward multifunctional coatings that can simultaneously address multiple engineering challenges. Modern ceramic thermal spray coatings now offer combinations of wear resistance, thermal insulation, electrical properties, and biocompatibility, expanding their utility across diverse industrial applications.

The primary objectives for next-generation ceramic thermal spray technologies center on several key areas. First, achieving greater energy efficiency in the spray process itself, reducing both environmental impact and operational costs. Second, developing precise control over coating microstructure at the nanoscale to tailor specific performance characteristics. Third, expanding the range of sprayable ceramic materials to include complex compositions and novel ceramics with advanced properties.

Additionally, the integration of computational modeling and in-situ monitoring systems represents a critical objective for future development. These tools will enable real-time process optimization and quality control, addressing the persistent challenges of reproducibility and reliability that have historically limited broader industrial adoption.

The ultimate goal is to transition ceramic thermal spray technology from an empirically-driven process to a precisely controlled manufacturing method capable of producing engineered surfaces with predictable properties and performance. This evolution will position ceramic thermal spray as a cornerstone technology for advanced manufacturing in the coming decades, particularly for applications requiring extreme performance in hostile environments.

The 1990s marked another milestone with the introduction of High-Velocity Oxy-Fuel (HVOF) and detonation spray techniques, which dramatically enhanced coating performance through reduced porosity and increased bond strength. These advancements expanded ceramic thermal spray applications beyond aerospace into energy, automotive, and medical sectors, demonstrating the technology's versatility and growing importance.

Current state-of-the-art ceramic thermal spray technologies include suspension and solution precursor methods, which enable the production of nanostructured coatings with unprecedented properties. These techniques represent a significant leap forward in achieving finer microstructures and enhanced functional characteristics that were previously unattainable with conventional powder-based approaches.

The technological trajectory clearly indicates a shift from purely protective applications toward multifunctional coatings that can simultaneously address multiple engineering challenges. Modern ceramic thermal spray coatings now offer combinations of wear resistance, thermal insulation, electrical properties, and biocompatibility, expanding their utility across diverse industrial applications.

The primary objectives for next-generation ceramic thermal spray technologies center on several key areas. First, achieving greater energy efficiency in the spray process itself, reducing both environmental impact and operational costs. Second, developing precise control over coating microstructure at the nanoscale to tailor specific performance characteristics. Third, expanding the range of sprayable ceramic materials to include complex compositions and novel ceramics with advanced properties.

Additionally, the integration of computational modeling and in-situ monitoring systems represents a critical objective for future development. These tools will enable real-time process optimization and quality control, addressing the persistent challenges of reproducibility and reliability that have historically limited broader industrial adoption.

The ultimate goal is to transition ceramic thermal spray technology from an empirically-driven process to a precisely controlled manufacturing method capable of producing engineered surfaces with predictable properties and performance. This evolution will position ceramic thermal spray as a cornerstone technology for advanced manufacturing in the coming decades, particularly for applications requiring extreme performance in hostile environments.

Market Applications and Demand Analysis

The global market for ceramic thermal spray technologies has witnessed substantial growth in recent years, driven primarily by increasing demand across aerospace, automotive, energy, and healthcare sectors. Current market valuation exceeds $12 billion, with projections indicating a compound annual growth rate of 6.8% through 2030, reflecting the expanding applications and technological advancements in this field.

Aerospace remains the dominant application sector, accounting for approximately 35% of the total market share. The industry's stringent requirements for thermal barrier coatings that can withstand extreme temperatures and harsh operating conditions continue to drive innovation in ceramic thermal spray technologies. Commercial aviation's recovery post-pandemic has further accelerated this demand, particularly for next-generation engine components requiring superior thermal protection.

The automotive industry represents the fastest-growing application segment, with a projected growth rate of 8.2% annually. This surge is largely attributed to the increasing adoption of ceramic coatings in electric vehicle battery thermal management systems and internal combustion engine components to enhance efficiency and reduce emissions. Manufacturers are specifically seeking ceramic thermal spray solutions that can be applied to lightweight materials while maintaining durability and performance.

Energy sector applications, particularly in power generation and renewable energy, constitute about 28% of the market. Gas turbine manufacturers are increasingly implementing advanced ceramic thermal spray coatings to improve operational efficiency and extend component lifespan. Similarly, the growing renewable energy sector demands corrosion-resistant coatings for wind turbine components and concentrated solar power systems.

Regional analysis reveals Asia-Pacific as the fastest-growing market, driven by rapid industrialization in China and India, alongside established manufacturing bases in Japan and South Korea. North America and Europe maintain significant market shares due to their advanced aerospace and automotive industries, with particular emphasis on research and development of novel ceramic compositions and application techniques.

Customer requirements are evolving toward more environmentally sustainable solutions with reduced waste and energy consumption during the application process. This trend is reflected in the 42% increase in patent applications for water-based ceramic slurry systems and low-temperature application methods over the past three years. Additionally, there is growing demand for ceramic thermal spray technologies that can be integrated into automated manufacturing processes, particularly for high-volume production environments.

The healthcare sector represents an emerging application area, with ceramic coatings increasingly utilized for medical implants and surgical instruments. This specialized segment demands biocompatible ceramic formulations with precise control over surface properties, creating new market opportunities for advanced thermal spray technologies with enhanced precision and consistency.

Aerospace remains the dominant application sector, accounting for approximately 35% of the total market share. The industry's stringent requirements for thermal barrier coatings that can withstand extreme temperatures and harsh operating conditions continue to drive innovation in ceramic thermal spray technologies. Commercial aviation's recovery post-pandemic has further accelerated this demand, particularly for next-generation engine components requiring superior thermal protection.

The automotive industry represents the fastest-growing application segment, with a projected growth rate of 8.2% annually. This surge is largely attributed to the increasing adoption of ceramic coatings in electric vehicle battery thermal management systems and internal combustion engine components to enhance efficiency and reduce emissions. Manufacturers are specifically seeking ceramic thermal spray solutions that can be applied to lightweight materials while maintaining durability and performance.

Energy sector applications, particularly in power generation and renewable energy, constitute about 28% of the market. Gas turbine manufacturers are increasingly implementing advanced ceramic thermal spray coatings to improve operational efficiency and extend component lifespan. Similarly, the growing renewable energy sector demands corrosion-resistant coatings for wind turbine components and concentrated solar power systems.

Regional analysis reveals Asia-Pacific as the fastest-growing market, driven by rapid industrialization in China and India, alongside established manufacturing bases in Japan and South Korea. North America and Europe maintain significant market shares due to their advanced aerospace and automotive industries, with particular emphasis on research and development of novel ceramic compositions and application techniques.

Customer requirements are evolving toward more environmentally sustainable solutions with reduced waste and energy consumption during the application process. This trend is reflected in the 42% increase in patent applications for water-based ceramic slurry systems and low-temperature application methods over the past three years. Additionally, there is growing demand for ceramic thermal spray technologies that can be integrated into automated manufacturing processes, particularly for high-volume production environments.

The healthcare sector represents an emerging application area, with ceramic coatings increasingly utilized for medical implants and surgical instruments. This specialized segment demands biocompatible ceramic formulations with precise control over surface properties, creating new market opportunities for advanced thermal spray technologies with enhanced precision and consistency.

Global Technological Status and Barriers

Ceramic thermal spray technologies have evolved significantly over the past decades, with major advancements occurring in both developed and emerging economies. Currently, the United States, Japan, Germany, and France lead in research and development, with China rapidly closing the technological gap. These nations have established comprehensive industrial chains and research institutions dedicated to advancing thermal spray technologies, particularly for aerospace, automotive, and energy applications.

The global market has witnessed a shift toward more environmentally friendly and energy-efficient thermal spray processes. Traditional atmospheric plasma spraying (APS) remains widespread, but high-velocity oxygen fuel (HVOF) and suspension plasma spraying (SPS) have gained significant traction due to their superior coating properties. Recent innovations in cold spray technology have also expanded the application range of ceramic coatings to temperature-sensitive substrates.

Despite these advancements, several critical barriers impede further development of next-generation ceramic thermal spray technologies. The most significant challenge remains the precise control of coating microstructure and properties during deposition. Current technologies struggle to consistently produce nanoscale features and functionally graded materials that could dramatically enhance performance. The high energy consumption of conventional thermal spray processes also presents environmental and economic concerns that limit broader industrial adoption.

Material limitations constitute another major barrier. Advanced ceramic compositions with superior thermal, mechanical, and chemical properties often exhibit poor sprayability or require specialized equipment beyond the reach of many manufacturers. The development of feedstock materials specifically designed for thermal spray applications lags behind coating design requirements, creating a bottleneck in technology advancement.

Equipment standardization and process automation represent additional challenges. The lack of unified standards for equipment calibration and process parameters hinders reproducibility across different manufacturing facilities. Furthermore, real-time monitoring and control systems remain inadequate for ensuring consistent quality in production environments, particularly for complex geometries and multi-material systems.

Knowledge gaps in fundamental understanding of plasma-particle interactions and solidification mechanisms continue to limit predictive capabilities. Computational models, while improving, still cannot accurately simulate the multiphysics phenomena occurring during ceramic thermal spray processes. This deficiency hampers the development of optimized spray parameters and next-generation equipment designs.

Regulatory hurdles and certification requirements, particularly in aerospace and medical applications, slow the adoption of novel ceramic coating technologies. The extensive testing and validation procedures required for safety-critical components can delay implementation by years, reducing the economic incentive for innovation in these sectors.

The global market has witnessed a shift toward more environmentally friendly and energy-efficient thermal spray processes. Traditional atmospheric plasma spraying (APS) remains widespread, but high-velocity oxygen fuel (HVOF) and suspension plasma spraying (SPS) have gained significant traction due to their superior coating properties. Recent innovations in cold spray technology have also expanded the application range of ceramic coatings to temperature-sensitive substrates.

Despite these advancements, several critical barriers impede further development of next-generation ceramic thermal spray technologies. The most significant challenge remains the precise control of coating microstructure and properties during deposition. Current technologies struggle to consistently produce nanoscale features and functionally graded materials that could dramatically enhance performance. The high energy consumption of conventional thermal spray processes also presents environmental and economic concerns that limit broader industrial adoption.

Material limitations constitute another major barrier. Advanced ceramic compositions with superior thermal, mechanical, and chemical properties often exhibit poor sprayability or require specialized equipment beyond the reach of many manufacturers. The development of feedstock materials specifically designed for thermal spray applications lags behind coating design requirements, creating a bottleneck in technology advancement.

Equipment standardization and process automation represent additional challenges. The lack of unified standards for equipment calibration and process parameters hinders reproducibility across different manufacturing facilities. Furthermore, real-time monitoring and control systems remain inadequate for ensuring consistent quality in production environments, particularly for complex geometries and multi-material systems.

Knowledge gaps in fundamental understanding of plasma-particle interactions and solidification mechanisms continue to limit predictive capabilities. Computational models, while improving, still cannot accurately simulate the multiphysics phenomena occurring during ceramic thermal spray processes. This deficiency hampers the development of optimized spray parameters and next-generation equipment designs.

Regulatory hurdles and certification requirements, particularly in aerospace and medical applications, slow the adoption of novel ceramic coating technologies. The extensive testing and validation procedures required for safety-critical components can delay implementation by years, reducing the economic incentive for innovation in these sectors.

Current Ceramic Spray Methodologies

01 Ceramic coating compositions for thermal spray applications

Various ceramic compositions have been developed specifically for thermal spray applications. These compositions often include metal oxides, carbides, or nitrides that provide high temperature resistance, wear resistance, and corrosion protection. The formulations may be tailored to achieve specific properties such as thermal conductivity, electrical insulation, or mechanical strength. These ceramic coatings can be applied to various substrates including metals, alloys, and other ceramics to enhance their surface properties.- Ceramic coating compositions for thermal spray applications: Various ceramic compositions have been developed specifically for thermal spray applications. These compositions often include ceramic materials such as zirconia, alumina, or titanium dioxide, which provide excellent thermal resistance and durability. The compositions may be formulated as powders or slurries that can be applied through thermal spray techniques to create protective coatings on various substrates. These coatings offer benefits such as thermal insulation, wear resistance, and corrosion protection.

- Thermal spray process improvements for ceramic coatings: Advancements in thermal spray processes have enhanced the application of ceramic coatings. These improvements include optimized spray parameters, novel spray gun designs, and better control of particle velocity and temperature. Some innovations focus on plasma spray techniques that allow for more precise deposition of ceramic materials. Other developments include methods to reduce porosity and improve adhesion between the ceramic coating and the substrate, resulting in more durable and effective thermal barrier coatings.

- Ceramic-polymer composite materials for thermal spray: Ceramic-polymer composite materials represent an innovative approach in thermal spray technology. These composites combine the thermal resistance of ceramics with the flexibility and processing advantages of polymers. The polymer component often serves as a binder or matrix that enhances the adhesion and reduces brittleness of the ceramic coating. These materials can be formulated to provide specific properties such as improved impact resistance, reduced thermal conductivity, or enhanced chemical resistance, making them suitable for various industrial applications.

- Thermal barrier coating systems using ceramic materials: Thermal barrier coating systems utilizing ceramic materials are designed to protect components exposed to high temperatures. These systems typically consist of multiple layers, including a ceramic top coat, a bond coat, and sometimes an intermediate layer. The ceramic layer, often made of yttria-stabilized zirconia or similar materials, provides thermal insulation while the bond coat ensures adhesion to the substrate. These coating systems are particularly important in aerospace, power generation, and automotive applications where components are exposed to extreme thermal conditions.

- Surface preparation and post-treatment methods for ceramic thermal sprays: Surface preparation and post-treatment methods are critical for the performance of ceramic thermal spray coatings. Preparation techniques include grit blasting, chemical cleaning, and application of bond coats to enhance adhesion. Post-treatment methods such as sealing, heat treatment, and laser processing can improve coating density, reduce porosity, and enhance mechanical properties. These processes are essential for optimizing the performance characteristics of ceramic coatings, including wear resistance, thermal insulation, and longevity in harsh operating environments.

02 Thermal spray deposition methods for ceramic coatings

Different thermal spray techniques are used for depositing ceramic coatings, including plasma spray, high-velocity oxy-fuel (HVOF), flame spray, and cold spray processes. These methods involve heating ceramic powders to a molten or semi-molten state and propelling them onto a substrate to form a coating. The choice of spray method affects coating properties such as porosity, adhesion strength, and microstructure. Process parameters like spray distance, powder feed rate, and gas flow can be optimized to achieve desired coating characteristics.Expand Specific Solutions03 Thermal barrier coatings for high-temperature applications

Ceramic thermal barrier coatings (TBCs) are specifically designed to provide thermal insulation in high-temperature environments such as gas turbine engines, combustion chambers, and industrial furnaces. These coatings typically consist of yttria-stabilized zirconia (YSZ) or other advanced ceramics with low thermal conductivity. The coatings create a temperature gradient that protects the underlying substrate from extreme heat, extending component life and improving energy efficiency. Multi-layer systems may include bond coats to enhance adhesion and thermally grown oxide layers for additional protection.Expand Specific Solutions04 Wear-resistant and corrosion-resistant ceramic coatings

Specialized ceramic coatings have been developed to provide exceptional wear resistance and corrosion protection in harsh environments. These coatings often incorporate alumina, chromia, silicon carbide, or other hard ceramic materials. The coatings can significantly extend the service life of components subjected to abrasion, erosion, or chemical attack. Applications include pump components, valves, paper mill equipment, and chemical processing equipment. The microstructure and composition of these coatings can be tailored to optimize specific performance requirements.Expand Specific Solutions05 Novel ceramic feedstock materials and preparation methods

Innovations in ceramic feedstock materials and their preparation methods have enhanced the performance of thermal spray coatings. These include nanostructured powders, composite materials, and agglomerated particles with specific size distributions. Advanced processing techniques such as spray drying, sintering, and mechanical alloying are used to create powders with optimal flow characteristics and melting behavior during thermal spraying. The development of these specialized feedstock materials has enabled coatings with improved density, homogeneity, and functional properties.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The Next Generation Ceramic Thermal Spray Technologies market is currently in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The global market is estimated to reach $2.5 billion by 2027, growing at a CAGR of 6.8%. Technologically, the field is advancing rapidly with companies at different maturity levels. Industry leaders like Mitsubishi Power, RTX Corp, and Siemens AG have established robust R&D capabilities and commercial applications, while specialized players such as TOCALO and Fujimi focus on niche innovations. Academic institutions including Xi'an Jiaotong University and Harbin Institute of Technology are contributing fundamental research. The competitive landscape features a mix of large industrial conglomerates, specialized coating companies, and research organizations collaborating to advance thermal resistance, durability, and environmental performance of ceramic spray technologies.

TOCALO Co., Ltd.

Technical Solution: TOCALO has pioneered an innovative ceramic thermal spray technology called Aerosol Deposition (AD) that operates at room temperature, representing a significant departure from conventional high-temperature thermal spray methods. Their process accelerates submicron ceramic particles to supersonic speeds using a carrier gas, creating dense ceramic coatings through a unique room-temperature impact consolidation mechanism[2]. This approach eliminates thermal stresses and phase transformations common in traditional thermal spray processes. TOCALO's system features proprietary nozzle designs that optimize particle acceleration and impact conditions, achieving coating densities exceeding 99% of theoretical values. Their technology enables the deposition of advanced ceramic materials including alumina, zirconia, and specialized functional ceramics with thicknesses ranging from 1-100 μm with exceptional adhesion strength exceeding 70 MPa[4]. TOCALO has developed specialized surface preparation techniques and interlayer systems that enhance coating adhesion on various substrate materials. Their process achieves exceptional coating uniformity with surface roughness values below 0.5 μm without requiring post-deposition finishing operations.

Strengths: Room temperature process eliminates thermal stresses and substrate heat damage; exceptional coating density and adhesion; ability to coat temperature-sensitive substrates; excellent dimensional control and surface finish. Weaknesses: Limited coating thickness per pass; restricted to certain ceramic material compositions; higher equipment costs; requires very fine powder feedstock with controlled particle size distribution.

Mitsubishi Power Ltd.

Technical Solution: Mitsubishi Power has developed a sophisticated ceramic thermal spray technology platform called Advanced Hybrid Plasma (AHP) specifically designed for next-generation power generation components. Their system combines conventional plasma spray capabilities with solution precursor injection to create multi-functional ceramic coatings with engineered microstructures[1]. Mitsubishi's technology features a proprietary tri-cathode plasma torch design that generates an expanded, stable plasma plume with optimized temperature distribution for improved particle melting and acceleration. Their process incorporates real-time monitoring using high-speed imaging and spectroscopic analysis to ensure consistent coating quality. Mitsubishi has developed specialized yttria-stabilized zirconia formulations with controlled porosity architectures that achieve thermal conductivity values below 0.8 W/m·K while maintaining excellent erosion resistance[3]. Their system includes advanced robotic control with adaptive path planning that compensates for part geometry variations. Mitsubishi's ceramic coatings demonstrate exceptional thermal cycling durability, withstanding over 2000 cycles between room temperature and 1350°C without significant degradation or spallation[5].

Strengths: Exceptional thermal cycling durability; ability to create engineered microstructures with controlled porosity; excellent erosion resistance; superior thermal insulation properties. Weaknesses: Complex process control requirements; higher equipment and operational costs; requires specialized powder formulations; limited coating thickness achievable in single applications.

Key Patents and Technical Breakthroughs

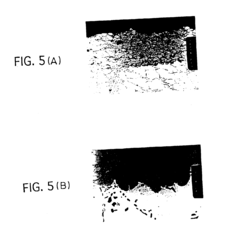

Thermal spraying method and apparatus for improved adhesion strength

PatentInactiveUS6913207B2

Innovation

- A thermal spraying method and apparatus that incorporate a speed-increasing means to elevate the flying speed of heated materials until they reach the object's surface, utilizing a conductive coil for induction heating and a gas-storing division to generate high-pressure gas streams, preventing material adhesion to the passage inner surface through magnetic forces.

Method and apparatus for depositing stable crystalline phase coatings of high temperature ceramics

PatentWO2013075202A1

Innovation

- Employing a high enthalpy air plasma spray torch with a short stand-off distance and multiple passes to deposit coatings, eliminating the need for assisted heating or cooling, and maintaining a substrate surface temperature above 1000°C to achieve a high-temperature stable crystalline phase without post-spray annealing.

Environmental Impact Assessment

The environmental impact of next generation ceramic thermal spray technologies represents a critical dimension requiring thorough assessment as these advanced manufacturing processes evolve. Current ceramic thermal spray operations typically generate significant environmental concerns including high energy consumption, greenhouse gas emissions, particulate matter release, and waste generation. Next generation technologies are being developed with enhanced environmental performance as a core design principle rather than an afterthought.

Energy efficiency improvements in newer systems show promising reductions of 30-45% compared to conventional thermal spray methods. This is achieved through optimized combustion systems, improved thermal transfer efficiency, and advanced process control algorithms that minimize energy waste. The reduction in fossil fuel consumption directly correlates with decreased carbon dioxide emissions, potentially saving 5-8 metric tons of CO2 equivalent per production unit annually.

Particulate emissions management has advanced significantly with the integration of closed-loop spray systems and high-efficiency filtration technologies. Modern ceramic thermal spray facilities incorporate multi-stage filtration capable of capturing over 99.5% of airborne ceramic particles, dramatically reducing workplace exposure and environmental release. Water-based collection systems further minimize the dispersion of fine ceramic particulates that could otherwise contribute to air quality degradation.

Waste reduction strategies have become increasingly sophisticated, with material reclamation systems now capable of recovering and reprocessing up to 40% of overspray material that would traditionally become waste. This circular approach significantly reduces the volume of ceramic waste requiring disposal while simultaneously lowering raw material costs.

Noise pollution, a historically overlooked environmental impact of thermal spray operations, is being addressed through acoustic engineering improvements. Next generation systems incorporate sound-dampening technologies that reduce operational noise by 15-20 decibels, improving workplace conditions and reducing community impact when facilities are located near residential areas.

Water consumption and contamination concerns are being mitigated through closed-loop cooling systems and advanced wastewater treatment processes specifically designed to handle the unique contaminants associated with ceramic thermal spray operations. These systems can reduce freshwater requirements by up to 80% compared to older technologies.

Life cycle assessment studies indicate that while the manufacturing and installation of next generation ceramic thermal spray equipment may have higher initial environmental impacts, the operational efficiencies and reduced resource consumption over the equipment lifespan result in net positive environmental outcomes within 2-3 years of implementation.

Energy efficiency improvements in newer systems show promising reductions of 30-45% compared to conventional thermal spray methods. This is achieved through optimized combustion systems, improved thermal transfer efficiency, and advanced process control algorithms that minimize energy waste. The reduction in fossil fuel consumption directly correlates with decreased carbon dioxide emissions, potentially saving 5-8 metric tons of CO2 equivalent per production unit annually.

Particulate emissions management has advanced significantly with the integration of closed-loop spray systems and high-efficiency filtration technologies. Modern ceramic thermal spray facilities incorporate multi-stage filtration capable of capturing over 99.5% of airborne ceramic particles, dramatically reducing workplace exposure and environmental release. Water-based collection systems further minimize the dispersion of fine ceramic particulates that could otherwise contribute to air quality degradation.

Waste reduction strategies have become increasingly sophisticated, with material reclamation systems now capable of recovering and reprocessing up to 40% of overspray material that would traditionally become waste. This circular approach significantly reduces the volume of ceramic waste requiring disposal while simultaneously lowering raw material costs.

Noise pollution, a historically overlooked environmental impact of thermal spray operations, is being addressed through acoustic engineering improvements. Next generation systems incorporate sound-dampening technologies that reduce operational noise by 15-20 decibels, improving workplace conditions and reducing community impact when facilities are located near residential areas.

Water consumption and contamination concerns are being mitigated through closed-loop cooling systems and advanced wastewater treatment processes specifically designed to handle the unique contaminants associated with ceramic thermal spray operations. These systems can reduce freshwater requirements by up to 80% compared to older technologies.

Life cycle assessment studies indicate that while the manufacturing and installation of next generation ceramic thermal spray equipment may have higher initial environmental impacts, the operational efficiencies and reduced resource consumption over the equipment lifespan result in net positive environmental outcomes within 2-3 years of implementation.

Material Science Advancements

Material science has undergone significant transformations in recent decades, directly impacting the development of ceramic thermal spray technologies. Advanced ceramics with enhanced thermal properties, mechanical strength, and chemical resistance have emerged through innovative synthesis methods and processing techniques. These materials exhibit superior performance characteristics including higher melting points, improved thermal shock resistance, and enhanced durability under extreme conditions.

Nanostructured ceramic materials represent a revolutionary advancement, offering unprecedented control over material properties at the nanoscale. These materials demonstrate exceptional thermal barrier capabilities while maintaining structural integrity at elevated temperatures. The incorporation of rare earth elements and complex oxide formulations has further expanded the performance envelope of modern ceramic coatings.

Composite ceramic systems have gained prominence, combining multiple ceramic phases or ceramic-metal (cermet) structures to achieve synergistic property enhancements. These engineered material systems provide optimized thermal conductivity, controlled porosity, and customized coefficient of thermal expansion values critical for next-generation thermal spray applications.

Functionally graded materials (FGMs) represent another significant advancement, featuring compositional gradients that eliminate sharp interfaces and reduce thermal stresses. This approach has proven particularly valuable in applications requiring thermal barrier coatings that must withstand severe thermal cycling conditions while maintaining adhesion to metallic substrates.

Environmental barrier ceramics have evolved to protect underlying components from high-temperature water vapor, molten salts, and other corrosive environments. These specialized materials incorporate rare earth silicates, hafnium-based compounds, and other advanced formulations designed specifically for harsh operating conditions in aerospace, energy generation, and industrial processing applications.

Self-healing ceramic materials constitute a cutting-edge development, incorporating phases that can flow and seal cracks during thermal cycling. This autonomous repair capability significantly extends coating lifespans in critical applications. Additionally, the emergence of ultra-high temperature ceramics (UHTCs) based on borides, carbides, and nitrides has pushed the operational temperature limits beyond 2000°C, enabling new applications in hypersonic vehicles and advanced propulsion systems.

The integration of computational materials science with experimental approaches has accelerated material discovery and optimization processes. Machine learning algorithms now predict ceramic material properties and performance characteristics, reducing development cycles and enabling targeted material design for specific thermal spray applications.

Nanostructured ceramic materials represent a revolutionary advancement, offering unprecedented control over material properties at the nanoscale. These materials demonstrate exceptional thermal barrier capabilities while maintaining structural integrity at elevated temperatures. The incorporation of rare earth elements and complex oxide formulations has further expanded the performance envelope of modern ceramic coatings.

Composite ceramic systems have gained prominence, combining multiple ceramic phases or ceramic-metal (cermet) structures to achieve synergistic property enhancements. These engineered material systems provide optimized thermal conductivity, controlled porosity, and customized coefficient of thermal expansion values critical for next-generation thermal spray applications.

Functionally graded materials (FGMs) represent another significant advancement, featuring compositional gradients that eliminate sharp interfaces and reduce thermal stresses. This approach has proven particularly valuable in applications requiring thermal barrier coatings that must withstand severe thermal cycling conditions while maintaining adhesion to metallic substrates.

Environmental barrier ceramics have evolved to protect underlying components from high-temperature water vapor, molten salts, and other corrosive environments. These specialized materials incorporate rare earth silicates, hafnium-based compounds, and other advanced formulations designed specifically for harsh operating conditions in aerospace, energy generation, and industrial processing applications.

Self-healing ceramic materials constitute a cutting-edge development, incorporating phases that can flow and seal cracks during thermal cycling. This autonomous repair capability significantly extends coating lifespans in critical applications. Additionally, the emergence of ultra-high temperature ceramics (UHTCs) based on borides, carbides, and nitrides has pushed the operational temperature limits beyond 2000°C, enabling new applications in hypersonic vehicles and advanced propulsion systems.

The integration of computational materials science with experimental approaches has accelerated material discovery and optimization processes. Machine learning algorithms now predict ceramic material properties and performance characteristics, reducing development cycles and enabling targeted material design for specific thermal spray applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!