High Temperature Oxidation Resistance of Ceramic Coatings

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Coating Oxidation Background and Objectives

Ceramic coatings have emerged as a critical solution for protecting materials operating in extreme high-temperature environments. The evolution of these protective systems traces back to the mid-20th century, with significant advancements occurring during the aerospace revolution of the 1960s and 1970s. Initially developed for turbine engine components, ceramic coatings have progressively expanded into various industrial applications including power generation, automotive, chemical processing, and advanced manufacturing sectors.

The technological trajectory of ceramic coatings has been characterized by continuous innovation in material composition, deposition techniques, and microstructural design. Early systems primarily utilized alumina and zirconia-based ceramics, while contemporary solutions incorporate complex multi-component formulations with engineered nano and microstructures. This evolution reflects the growing understanding of oxidation mechanisms and the increasing demands for performance in more severe operating conditions.

Current research trends indicate a shift toward multi-functional ceramic coating systems that simultaneously address oxidation resistance, thermal insulation, mechanical durability, and chemical stability. The integration of rare earth elements, transition metal oxides, and advanced composite structures represents the cutting edge of development in this field. Additionally, there is increasing focus on environmentally sustainable coating technologies that reduce reliance on scarce or hazardous materials.

The primary technical objective of high-temperature oxidation resistance research is to develop ceramic coating systems capable of maintaining structural integrity and protective functionality at temperatures exceeding 1200°C for extended durations. This includes preventing oxygen diffusion to substrate materials, minimizing phase transformations during thermal cycling, and ensuring adhesion under thermal and mechanical stresses.

Secondary objectives encompass enhancing coating lifespan prediction models, developing accelerated testing methodologies that accurately simulate real-world conditions, and establishing standardized performance metrics for comparative evaluation. There is also significant interest in reducing manufacturing complexity and cost to enable broader industrial adoption of advanced ceramic coating technologies.

The long-term vision for ceramic coating development includes self-healing capabilities, in-situ health monitoring functionality, and adaptive performance characteristics that respond to changing environmental conditions. These aspirational goals drive fundamental research into novel material systems, processing techniques, and characterization methodologies that will shape the next generation of high-temperature oxidation resistant coatings.

The technological trajectory of ceramic coatings has been characterized by continuous innovation in material composition, deposition techniques, and microstructural design. Early systems primarily utilized alumina and zirconia-based ceramics, while contemporary solutions incorporate complex multi-component formulations with engineered nano and microstructures. This evolution reflects the growing understanding of oxidation mechanisms and the increasing demands for performance in more severe operating conditions.

Current research trends indicate a shift toward multi-functional ceramic coating systems that simultaneously address oxidation resistance, thermal insulation, mechanical durability, and chemical stability. The integration of rare earth elements, transition metal oxides, and advanced composite structures represents the cutting edge of development in this field. Additionally, there is increasing focus on environmentally sustainable coating technologies that reduce reliance on scarce or hazardous materials.

The primary technical objective of high-temperature oxidation resistance research is to develop ceramic coating systems capable of maintaining structural integrity and protective functionality at temperatures exceeding 1200°C for extended durations. This includes preventing oxygen diffusion to substrate materials, minimizing phase transformations during thermal cycling, and ensuring adhesion under thermal and mechanical stresses.

Secondary objectives encompass enhancing coating lifespan prediction models, developing accelerated testing methodologies that accurately simulate real-world conditions, and establishing standardized performance metrics for comparative evaluation. There is also significant interest in reducing manufacturing complexity and cost to enable broader industrial adoption of advanced ceramic coating technologies.

The long-term vision for ceramic coating development includes self-healing capabilities, in-situ health monitoring functionality, and adaptive performance characteristics that respond to changing environmental conditions. These aspirational goals drive fundamental research into novel material systems, processing techniques, and characterization methodologies that will shape the next generation of high-temperature oxidation resistant coatings.

Market Analysis for High-Temperature Resistant Coatings

The global market for high-temperature resistant coatings, particularly ceramic coatings, has been experiencing robust growth driven by increasing demands across multiple industrial sectors. The aerospace industry represents the largest market segment, where these coatings are essential for protecting engine components operating under extreme thermal conditions. Current market estimates value this segment at several billion dollars with a compound annual growth rate exceeding 5%.

The energy sector follows closely as the second-largest consumer of high-temperature resistant ceramic coatings. Power generation facilities, especially those utilizing gas turbines, require these specialized coatings to enhance equipment durability and operational efficiency. This market segment has shown consistent growth patterns as global energy demands continue to rise and aging infrastructure requires upgrading.

Automotive applications constitute another significant market, particularly with the evolution of high-performance engines and exhaust systems. The trend toward more efficient combustion processes operating at higher temperatures has intensified the need for advanced ceramic coating solutions. This segment is projected to grow substantially as emission regulations become more stringent worldwide.

Industrial manufacturing represents a diverse application area encompassing metallurgy, glass production, and chemical processing. These industries operate equipment under severe thermal conditions that necessitate superior oxidation resistance. The market in this sector demonstrates steady growth as manufacturing processes advance toward higher temperature operations to improve productivity.

Regional analysis reveals that North America and Europe currently dominate the high-temperature resistant coatings market due to their established aerospace and automotive industries. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization in China and India, alongside expanding manufacturing capabilities.

Customer requirements are evolving toward coatings that not only provide oxidation resistance but also offer additional functionalities such as wear resistance, corrosion protection, and thermal insulation. This multi-functionality trend is reshaping product development strategies across the industry.

Price sensitivity varies significantly by application sector. While aerospace and specialized industrial applications prioritize performance over cost, mass-market applications like automotive components remain highly price-sensitive. This dichotomy creates distinct market segments with different growth dynamics and competitive landscapes.

The market structure features a combination of large multinational corporations with diverse coating portfolios and specialized niche players focusing on specific high-performance applications. Recent years have witnessed increased consolidation through mergers and acquisitions as companies seek to expand their technological capabilities and geographic reach.

The energy sector follows closely as the second-largest consumer of high-temperature resistant ceramic coatings. Power generation facilities, especially those utilizing gas turbines, require these specialized coatings to enhance equipment durability and operational efficiency. This market segment has shown consistent growth patterns as global energy demands continue to rise and aging infrastructure requires upgrading.

Automotive applications constitute another significant market, particularly with the evolution of high-performance engines and exhaust systems. The trend toward more efficient combustion processes operating at higher temperatures has intensified the need for advanced ceramic coating solutions. This segment is projected to grow substantially as emission regulations become more stringent worldwide.

Industrial manufacturing represents a diverse application area encompassing metallurgy, glass production, and chemical processing. These industries operate equipment under severe thermal conditions that necessitate superior oxidation resistance. The market in this sector demonstrates steady growth as manufacturing processes advance toward higher temperature operations to improve productivity.

Regional analysis reveals that North America and Europe currently dominate the high-temperature resistant coatings market due to their established aerospace and automotive industries. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization in China and India, alongside expanding manufacturing capabilities.

Customer requirements are evolving toward coatings that not only provide oxidation resistance but also offer additional functionalities such as wear resistance, corrosion protection, and thermal insulation. This multi-functionality trend is reshaping product development strategies across the industry.

Price sensitivity varies significantly by application sector. While aerospace and specialized industrial applications prioritize performance over cost, mass-market applications like automotive components remain highly price-sensitive. This dichotomy creates distinct market segments with different growth dynamics and competitive landscapes.

The market structure features a combination of large multinational corporations with diverse coating portfolios and specialized niche players focusing on specific high-performance applications. Recent years have witnessed increased consolidation through mergers and acquisitions as companies seek to expand their technological capabilities and geographic reach.

Current Challenges in Ceramic Coating Oxidation Resistance

Despite significant advancements in ceramic coating technologies, several critical challenges persist in achieving optimal high-temperature oxidation resistance. The fundamental issue lies in the inherent trade-off between thermal protection and mechanical stability, particularly at temperatures exceeding 1200°C where most industrial applications operate. Current ceramic coating systems struggle to maintain structural integrity during thermal cycling, leading to premature failure through spallation and delamination.

Microstructural stability represents another significant challenge, as prolonged exposure to high temperatures induces phase transformations and grain growth that compromise protective properties. For instance, yttria-stabilized zirconia (YSZ) coatings, widely used in turbine applications, undergo destabilization above 1200°C, resulting in volume changes that create pathways for oxygen penetration.

Interface degradation between the ceramic coating and metallic substrate presents a persistent problem. The coefficient of thermal expansion mismatch generates substantial stresses during thermal cycling, while interdiffusion of elements across the interface leads to the formation of detrimental reaction products. These phenomena accelerate coating failure and reduce service life dramatically in aggressive environments.

Porosity control remains elusive in current manufacturing processes. While some porosity is beneficial for strain tolerance, excessive or interconnected porosity creates direct pathways for oxygen transport to the substrate. Conversely, overly dense coatings lack the necessary strain tolerance to withstand thermal cycling without cracking.

The development of effective oxygen barrier layers within multilayer coating systems continues to challenge researchers. Current diffusion barrier concepts show promising results in laboratory settings but frequently underperform in real-world applications where complex stress states and chemical environments coexist.

Manufacturing consistency presents a significant industrial challenge, with current deposition techniques (plasma spraying, EB-PVD, etc.) exhibiting considerable variability in microstructure and composition. This inconsistency translates directly to unpredictable performance and reliability issues in critical applications.

Self-healing capabilities, while theoretically promising, remain largely underdeveloped in ceramic coating systems. The ability to autonomously repair microcracks and damage during service would dramatically extend coating lifetimes, but current approaches lack the necessary reaction kinetics at operating temperatures.

Finally, accurate lifetime prediction models for ceramic coatings remain inadequate. Current models fail to incorporate the complex interplay between mechanical stresses, chemical degradation, and microstructural evolution, limiting the ability to design optimized coating systems for specific applications and operating conditions.

Microstructural stability represents another significant challenge, as prolonged exposure to high temperatures induces phase transformations and grain growth that compromise protective properties. For instance, yttria-stabilized zirconia (YSZ) coatings, widely used in turbine applications, undergo destabilization above 1200°C, resulting in volume changes that create pathways for oxygen penetration.

Interface degradation between the ceramic coating and metallic substrate presents a persistent problem. The coefficient of thermal expansion mismatch generates substantial stresses during thermal cycling, while interdiffusion of elements across the interface leads to the formation of detrimental reaction products. These phenomena accelerate coating failure and reduce service life dramatically in aggressive environments.

Porosity control remains elusive in current manufacturing processes. While some porosity is beneficial for strain tolerance, excessive or interconnected porosity creates direct pathways for oxygen transport to the substrate. Conversely, overly dense coatings lack the necessary strain tolerance to withstand thermal cycling without cracking.

The development of effective oxygen barrier layers within multilayer coating systems continues to challenge researchers. Current diffusion barrier concepts show promising results in laboratory settings but frequently underperform in real-world applications where complex stress states and chemical environments coexist.

Manufacturing consistency presents a significant industrial challenge, with current deposition techniques (plasma spraying, EB-PVD, etc.) exhibiting considerable variability in microstructure and composition. This inconsistency translates directly to unpredictable performance and reliability issues in critical applications.

Self-healing capabilities, while theoretically promising, remain largely underdeveloped in ceramic coating systems. The ability to autonomously repair microcracks and damage during service would dramatically extend coating lifetimes, but current approaches lack the necessary reaction kinetics at operating temperatures.

Finally, accurate lifetime prediction models for ceramic coatings remain inadequate. Current models fail to incorporate the complex interplay between mechanical stresses, chemical degradation, and microstructural evolution, limiting the ability to design optimized coating systems for specific applications and operating conditions.

Current Solutions for High-Temperature Oxidation Protection

01 Composition of ceramic coatings for oxidation resistance

Ceramic coatings can be formulated with specific compositions to enhance oxidation resistance. These compositions typically include metal oxides, nitrides, or carbides that form protective layers when exposed to high temperatures. The incorporation of elements such as aluminum, silicon, zirconium, and yttrium can significantly improve the oxidation resistance properties of ceramic coatings by forming stable oxide scales that prevent further oxidation of the underlying substrate.- Composition of ceramic coatings for oxidation resistance: Ceramic coatings with specific compositions can significantly enhance oxidation resistance of various substrates. These compositions typically include metal oxides, nitrides, or carbides that form protective barriers against oxygen penetration. The formulations may incorporate elements such as aluminum, silicon, zirconium, and rare earth metals that contribute to the formation of stable, adherent oxide scales. These specialized ceramic compositions can withstand high temperatures while maintaining structural integrity and preventing substrate degradation.

- Multi-layer ceramic coating systems: Multi-layer ceramic coating systems provide enhanced oxidation protection through complementary functional layers. These systems typically consist of a bond coat that adheres to the substrate, an intermediate layer that accommodates thermal expansion differences, and a top ceramic layer that provides thermal and oxidation resistance. The layered structure helps prevent crack propagation and enhances overall durability. Each layer can be optimized for specific properties, creating a comprehensive protection system that outperforms single-layer coatings in harsh oxidizing environments.

- Advanced deposition techniques for ceramic coatings: Various deposition techniques can be employed to create high-performance ceramic coatings with superior oxidation resistance. These include physical vapor deposition, chemical vapor deposition, plasma spraying, and sol-gel processes. Each method offers distinct advantages in terms of coating density, adhesion, thickness control, and microstructure. Advanced techniques allow for precise manipulation of coating properties, enabling customization for specific operating conditions and substrate materials. The deposition parameters significantly influence the coating's ability to resist oxidation at elevated temperatures.

- Self-healing ceramic coating mechanisms: Self-healing ceramic coatings incorporate reactive components that can repair damage caused by oxidation or mechanical stress. These innovative coatings contain materials that react with oxygen to form protective compounds that fill cracks or damaged areas. The self-healing mechanism may involve phase transformations, viscous flow of glass phases, or chemical reactions triggered by exposure to oxidizing environments. This autonomous repair capability significantly extends the service life of coated components in high-temperature applications by maintaining the integrity of the protective barrier even after damage occurs.

- Nanostructured ceramic coatings for enhanced oxidation resistance: Nanostructured ceramic coatings offer superior oxidation resistance due to their unique microstructural features. These coatings incorporate nanoscale particles, grains, or layers that create numerous interfaces, which act as barriers to oxygen diffusion. The nano-scale features also enhance mechanical properties such as hardness and toughness while maintaining excellent thermal stability. Additionally, the high surface area of nanostructured materials promotes the formation of protective oxide scales. These advanced coatings can be tailored to specific applications by controlling the size, distribution, and composition of the nanostructured elements.

02 Multi-layer ceramic coating systems

Multi-layer ceramic coating systems provide enhanced oxidation resistance through the strategic layering of different ceramic materials. These systems typically consist of a bond coat, a thermally grown oxide layer, and a top ceramic layer. Each layer serves a specific function in protecting the substrate from oxidation. The bond coat provides adhesion and oxidation resistance, the thermally grown oxide layer acts as a diffusion barrier, and the top ceramic layer provides thermal insulation and additional oxidation protection.Expand Specific Solutions03 Thermal barrier ceramic coatings

Thermal barrier ceramic coatings are specifically designed to provide both thermal insulation and oxidation resistance for components operating in high-temperature environments. These coatings typically consist of yttria-stabilized zirconia or other ceramic materials with low thermal conductivity. By reducing the temperature of the underlying substrate and forming a protective oxide layer, these coatings significantly enhance oxidation resistance while maintaining thermal protection properties.Expand Specific Solutions04 Surface modification techniques for ceramic coatings

Various surface modification techniques can be employed to enhance the oxidation resistance of ceramic coatings. These techniques include plasma spraying, physical vapor deposition, chemical vapor deposition, and sol-gel processes. Each method offers unique advantages in terms of coating density, adhesion, and microstructure, which directly impact the oxidation resistance properties. Post-deposition treatments such as laser glazing or heat treatment can further improve the oxidation resistance by sealing pores and creating more uniform protective layers.Expand Specific Solutions05 Self-healing ceramic coating systems

Self-healing ceramic coating systems represent an advanced approach to oxidation resistance. These coatings contain reactive elements or compounds that can fill cracks or voids that develop during service, thereby maintaining the protective barrier against oxidation. The self-healing mechanism is typically triggered by the oxidation process itself, where the reactive components form oxides that expand and seal the damaged areas. This technology significantly extends the service life of components exposed to oxidizing environments at high temperatures.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The high temperature oxidation resistance ceramic coatings market is currently in a growth phase, driven by increasing demand in aerospace, power generation, and industrial applications. The global market size is estimated to exceed $2 billion, with a projected CAGR of 6-8% through 2028. Technologically, the field shows varying maturity levels across different applications. Leading players include Saint-Gobain Ceramics & Plastics and Schott AG, who have established comprehensive product portfolios, while research institutions like Northwestern Polytechnical University and Institute of Metal Research CAS are advancing fundamental innovations. Siemens AG, Kyocera, and CoorsTek are leveraging their materials expertise to develop specialized solutions, while companies like Oerlikon Surface Solutions focus on application-specific coating technologies. The competitive landscape features both established industrial giants and specialized research-driven organizations collaborating to address high-temperature environmental challenges.

Saint-Gobain Ceramics & Plastics, Inc.

Technical Solution: Saint-Gobain has developed advanced ceramic coating systems with multi-layered structures specifically designed for high temperature oxidation resistance. Their technology incorporates yttria-stabilized zirconia (YSZ) top coats combined with specialized bond coats containing aluminum-rich MCrAlY (where M represents nickel, cobalt, or iron). The company has pioneered the integration of rare earth elements like lanthanum and cerium into their ceramic formulations, which significantly improves oxygen diffusion resistance at temperatures exceeding 1200°C. Their plasma spray deposition technique creates controlled porosity (15-25%) that accommodates thermal expansion while maintaining coating integrity. Recent innovations include self-healing ceramic matrices that can repair microcracks through viscous flow mechanisms when exposed to high temperatures, extending component lifetimes by up to 40% compared to conventional coatings.

Strengths: Superior thermal cycling resistance due to engineered porosity; excellent adhesion properties through optimized bond coat formulations; industry-leading oxidation protection at extreme temperatures (>1200°C). Weaknesses: Higher manufacturing costs compared to conventional coatings; requires specialized application equipment; thickness limitations in complex geometries.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed innovative ceramic coating systems based on silicon carbide (SiC) and silicon nitride (Si3N4) matrices with tailored additives for enhanced oxidation resistance. Their research has yielded breakthrough composite coatings incorporating rare earth silicates that form protective scales at temperatures up to 1600°C. IMR's proprietary chemical vapor deposition (CVD) process creates ultra-dense coatings with controlled nanostructures that significantly reduce oxygen permeability. Their multi-layer approach includes transition layers with gradually changing composition to minimize thermal expansion mismatch stress. Recent publications demonstrate their success with novel MAX phase ceramics (Ti3SiC2 and Ti2AlC) that combine metallic and ceramic properties, providing self-healing capabilities through the formation of protective Al2O3 scales when exposed to high-temperature oxidizing environments. Testing has shown these coatings maintain structural integrity after 1000+ hours at 1400°C with weight gains below 0.5 mg/cm².

Strengths: Exceptional high-temperature stability; sophisticated microstructural control through advanced deposition techniques; self-healing capabilities that extend service life. Weaknesses: Complex manufacturing processes limit industrial scalability; high material costs for rare earth components; requires specialized characterization equipment for quality control.

Key Innovations in Ceramic Coating Composition and Structure

High temperature oxidation resistant glassy coating

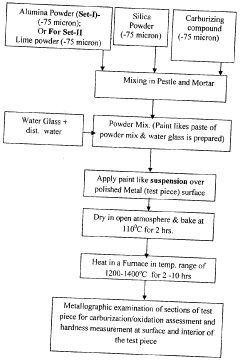

PatentInactiveIN153DEL2010A

Innovation

- A single-layer high temperature oxidation resistant glassy coating comprising Alumina or Lime, Silica, and a carburizing compound in powder form, which can be applied as a paste and liquefies at treatment temperature to protect metallic surfaces from oxidation without altering the substrate chemistry, and peels off upon cooling due to thermal contraction differences.

Environmental Impact and Sustainability Considerations

The environmental impact of ceramic coating technologies extends far beyond their primary function of providing high temperature oxidation resistance. These coatings significantly reduce the environmental footprint of high-temperature industrial processes by extending component lifespans and improving energy efficiency. When ceramic-coated parts operate at elevated temperatures, they maintain structural integrity longer, directly reducing the consumption of raw materials and energy required for replacement manufacturing.

From a life cycle assessment perspective, ceramic coatings demonstrate considerable sustainability advantages. The production phase of ceramic coatings typically consumes less energy compared to the manufacturing of entire replacement components. Although certain coating processes involve energy-intensive thermal spray operations, the net environmental benefit remains positive when considering the extended service life of coated components.

The reduction in harmful emissions represents another critical environmental benefit. High-temperature oxidation resistant ceramic coatings enable more efficient combustion processes in power generation and aerospace applications, resulting in decreased carbon dioxide, nitrogen oxides, and sulfur oxide emissions. This contribution to cleaner industrial operations aligns with global climate change mitigation efforts and increasingly stringent environmental regulations.

Material selection for ceramic coatings presents both challenges and opportunities for sustainability. Traditional coating systems may incorporate rare earth elements or toxic heavy metals that pose environmental concerns during mining, processing, and disposal. The industry is responding with research into alternative compositions that maintain performance while utilizing more abundant, less environmentally problematic materials. Bio-inspired ceramic formulations and naturally derived precursors represent promising directions in this evolution toward greener coating technologies.

End-of-life considerations for ceramic coated components are gaining attention as circular economy principles become more prominent in industrial design. While ceramic coatings can complicate recycling processes due to material separation challenges, emerging technologies for coating removal and material recovery are advancing. Some newer coating systems are being designed with recyclability as a key performance criterion, facilitating more sustainable material flows throughout the product lifecycle.

Water consumption during coating manufacturing processes presents another environmental consideration. Traditional wet chemical methods can require significant water resources and generate contaminated wastewater streams. Newer dry coating technologies and closed-loop water systems are being developed to address these concerns, reducing both water consumption and pollution risks associated with ceramic coating production.

From a life cycle assessment perspective, ceramic coatings demonstrate considerable sustainability advantages. The production phase of ceramic coatings typically consumes less energy compared to the manufacturing of entire replacement components. Although certain coating processes involve energy-intensive thermal spray operations, the net environmental benefit remains positive when considering the extended service life of coated components.

The reduction in harmful emissions represents another critical environmental benefit. High-temperature oxidation resistant ceramic coatings enable more efficient combustion processes in power generation and aerospace applications, resulting in decreased carbon dioxide, nitrogen oxides, and sulfur oxide emissions. This contribution to cleaner industrial operations aligns with global climate change mitigation efforts and increasingly stringent environmental regulations.

Material selection for ceramic coatings presents both challenges and opportunities for sustainability. Traditional coating systems may incorporate rare earth elements or toxic heavy metals that pose environmental concerns during mining, processing, and disposal. The industry is responding with research into alternative compositions that maintain performance while utilizing more abundant, less environmentally problematic materials. Bio-inspired ceramic formulations and naturally derived precursors represent promising directions in this evolution toward greener coating technologies.

End-of-life considerations for ceramic coated components are gaining attention as circular economy principles become more prominent in industrial design. While ceramic coatings can complicate recycling processes due to material separation challenges, emerging technologies for coating removal and material recovery are advancing. Some newer coating systems are being designed with recyclability as a key performance criterion, facilitating more sustainable material flows throughout the product lifecycle.

Water consumption during coating manufacturing processes presents another environmental consideration. Traditional wet chemical methods can require significant water resources and generate contaminated wastewater streams. Newer dry coating technologies and closed-loop water systems are being developed to address these concerns, reducing both water consumption and pollution risks associated with ceramic coating production.

Testing Standards and Performance Evaluation Methods

The evaluation of ceramic coatings for high temperature oxidation resistance requires standardized testing methods to ensure reliable and comparable results across different research institutions and industries. Currently, several international standards govern these evaluations, with ASTM G54 and ISO 21608 being the most widely adopted for high-temperature oxidation testing of ceramic coatings. These standards specify precise testing conditions, including temperature ranges, exposure times, and atmospheric compositions.

Cyclic oxidation testing represents a critical evaluation method that simulates real-world operating conditions by subjecting coated specimens to repeated heating and cooling cycles. The ASTM C1371 standard outlines procedures for these tests, typically involving exposure to temperatures between 800°C and 1600°C for predetermined intervals, followed by rapid cooling. This method effectively assesses coating durability under thermal shock conditions that frequently occur in industrial applications.

Isothermal oxidation testing, governed by ISO 26146, provides complementary data by maintaining specimens at constant elevated temperatures for extended periods. This approach allows researchers to evaluate long-term oxidation behavior and coating degradation mechanisms. The standard specifies holding times ranging from 100 to 10,000 hours depending on the intended application environment.

Microstructural evaluation techniques form another essential component of performance assessment. Cross-sectional analysis using scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) enables quantification of oxide layer growth, coating degradation, and elemental diffusion across interfaces. The ASTM E1920 standard provides guidelines for preparing and analyzing such specimens.

Weight change measurement represents a fundamental quantitative method for oxidation resistance evaluation. According to ISO 21608, specimens are precisely weighed before and after exposure to high-temperature environments, with results typically expressed as weight change per unit surface area (mg/cm²). Positive values indicate oxide formation, while negative values suggest material loss through spallation or volatilization.

Adhesion strength testing, standardized under ASTM C633, evaluates the mechanical integrity of ceramic coatings after oxidation exposure. This test measures the force required to separate the coating from the substrate, providing critical data on coating durability under service conditions. Industry standards typically require minimum adhesion strengths of 20-30 MPa for high-temperature applications.

Thermal shock resistance evaluation, outlined in ASTM C1525, subjects coated specimens to rapid temperature changes to assess coating integrity. This test is particularly relevant for applications involving frequent startup and shutdown cycles, such as gas turbine components and industrial furnace elements.

Cyclic oxidation testing represents a critical evaluation method that simulates real-world operating conditions by subjecting coated specimens to repeated heating and cooling cycles. The ASTM C1371 standard outlines procedures for these tests, typically involving exposure to temperatures between 800°C and 1600°C for predetermined intervals, followed by rapid cooling. This method effectively assesses coating durability under thermal shock conditions that frequently occur in industrial applications.

Isothermal oxidation testing, governed by ISO 26146, provides complementary data by maintaining specimens at constant elevated temperatures for extended periods. This approach allows researchers to evaluate long-term oxidation behavior and coating degradation mechanisms. The standard specifies holding times ranging from 100 to 10,000 hours depending on the intended application environment.

Microstructural evaluation techniques form another essential component of performance assessment. Cross-sectional analysis using scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) enables quantification of oxide layer growth, coating degradation, and elemental diffusion across interfaces. The ASTM E1920 standard provides guidelines for preparing and analyzing such specimens.

Weight change measurement represents a fundamental quantitative method for oxidation resistance evaluation. According to ISO 21608, specimens are precisely weighed before and after exposure to high-temperature environments, with results typically expressed as weight change per unit surface area (mg/cm²). Positive values indicate oxide formation, while negative values suggest material loss through spallation or volatilization.

Adhesion strength testing, standardized under ASTM C633, evaluates the mechanical integrity of ceramic coatings after oxidation exposure. This test measures the force required to separate the coating from the substrate, providing critical data on coating durability under service conditions. Industry standards typically require minimum adhesion strengths of 20-30 MPa for high-temperature applications.

Thermal shock resistance evaluation, outlined in ASTM C1525, subjects coated specimens to rapid temperature changes to assess coating integrity. This test is particularly relevant for applications involving frequent startup and shutdown cycles, such as gas turbine components and industrial furnace elements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!