Coating Thickness Effects on Thermal Barrier Performance

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coating Evolution and Objectives

Thermal barrier coatings (TBCs) have evolved significantly since their inception in the 1950s, initially developed for aerospace applications to protect metal components from extreme temperatures. The early iterations consisted of simple ceramic layers with minimal thickness control, providing basic thermal protection but lacking durability under cyclic thermal conditions. By the 1970s, advancements in materials science led to the development of yttria-stabilized zirconia (YSZ) coatings, which became the industry standard due to their superior thermal insulation properties and structural stability at high temperatures.

The evolution of TBC technology has been driven by the continuous demand for higher operating temperatures in gas turbines, jet engines, and other high-temperature applications. This push for increased efficiency has necessitated a deeper understanding of how coating thickness affects thermal barrier performance. Research has demonstrated that while thicker coatings generally provide better thermal insulation, they also introduce challenges related to adhesion, thermal stress management, and overall component weight.

The 1990s marked a significant turning point with the introduction of electron beam physical vapor deposition (EB-PVD) and air plasma spray (APS) techniques, enabling precise control over coating microstructure and thickness. These advancements allowed engineers to create columnar structures that enhanced strain tolerance while maintaining thermal protection. Concurrently, multi-layer coating systems emerged, incorporating bond coats and thermally grown oxide (TGO) layers that improved adhesion and oxidation resistance.

Recent developments have focused on nanostructured coatings and compositional gradients that optimize the balance between thermal insulation and mechanical properties. The relationship between coating thickness and thermal cycling behavior has become a central research focus, as thicker coatings may provide better insulation but often exhibit reduced durability under thermal cycling conditions due to increased internal stresses.

The primary objectives in thermal barrier coating research now center on establishing optimal thickness parameters that maximize both thermal protection and coating lifespan. This includes developing predictive models that can accurately simulate the thermal-mechanical behavior of coatings with varying thicknesses under different operating conditions. Additionally, researchers aim to create adaptive coating systems that can maintain performance across a wider range of temperatures and environmental conditions.

Future research directions include the development of self-healing coating mechanisms, integration of sensors for real-time performance monitoring, and exploration of novel materials that can withstand even more extreme temperatures while maintaining controlled thickness profiles. The ultimate goal remains creating coating systems that provide maximum thermal protection with minimal thickness, thereby optimizing component performance, efficiency, and lifespan in high-temperature applications.

The evolution of TBC technology has been driven by the continuous demand for higher operating temperatures in gas turbines, jet engines, and other high-temperature applications. This push for increased efficiency has necessitated a deeper understanding of how coating thickness affects thermal barrier performance. Research has demonstrated that while thicker coatings generally provide better thermal insulation, they also introduce challenges related to adhesion, thermal stress management, and overall component weight.

The 1990s marked a significant turning point with the introduction of electron beam physical vapor deposition (EB-PVD) and air plasma spray (APS) techniques, enabling precise control over coating microstructure and thickness. These advancements allowed engineers to create columnar structures that enhanced strain tolerance while maintaining thermal protection. Concurrently, multi-layer coating systems emerged, incorporating bond coats and thermally grown oxide (TGO) layers that improved adhesion and oxidation resistance.

Recent developments have focused on nanostructured coatings and compositional gradients that optimize the balance between thermal insulation and mechanical properties. The relationship between coating thickness and thermal cycling behavior has become a central research focus, as thicker coatings may provide better insulation but often exhibit reduced durability under thermal cycling conditions due to increased internal stresses.

The primary objectives in thermal barrier coating research now center on establishing optimal thickness parameters that maximize both thermal protection and coating lifespan. This includes developing predictive models that can accurately simulate the thermal-mechanical behavior of coatings with varying thicknesses under different operating conditions. Additionally, researchers aim to create adaptive coating systems that can maintain performance across a wider range of temperatures and environmental conditions.

Future research directions include the development of self-healing coating mechanisms, integration of sensors for real-time performance monitoring, and exploration of novel materials that can withstand even more extreme temperatures while maintaining controlled thickness profiles. The ultimate goal remains creating coating systems that provide maximum thermal protection with minimal thickness, thereby optimizing component performance, efficiency, and lifespan in high-temperature applications.

Market Analysis for High-Performance Thermal Barrier Systems

The global market for high-performance thermal barrier systems has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, automotive, and industrial applications. The thermal barrier coating (TBC) market was valued at approximately $17 billion in 2022 and is projected to reach $24 billion by 2028, representing a compound annual growth rate of 5.9%. This growth trajectory is largely attributed to the expanding aerospace industry and the rising need for fuel-efficient engines.

Aerospace remains the dominant sector, accounting for nearly 40% of the total market share. The commercial aviation segment, in particular, has shown robust demand for advanced thermal barrier systems that can withstand extreme operating temperatures while maintaining structural integrity. Military aerospace applications follow closely, with specialized requirements for stealth capabilities and enhanced durability under combat conditions.

The automotive industry represents the second-largest market segment, with a growing emphasis on improving engine efficiency and reducing emissions. High-performance thermal barriers are increasingly being incorporated into exhaust systems, cylinder linings, and turbochargers. This trend is particularly evident in premium and performance vehicle segments, where thermal management directly impacts engine output and longevity.

Industrial applications, including power generation, oil and gas, and manufacturing, collectively constitute approximately 25% of the market. These sectors primarily utilize thermal barrier coatings to extend equipment lifespan and improve operational efficiency under high-temperature conditions. The power generation industry, specifically gas turbines, has emerged as a significant growth driver due to the global transition toward cleaner energy sources.

Regional analysis reveals that North America and Europe currently lead the market, accounting for 35% and 30% of global demand respectively. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid industrialization in China and India, along with expanding aerospace manufacturing capabilities.

Customer requirements are increasingly focused on coating thickness optimization, with end-users seeking solutions that balance thermal protection with weight considerations. Market research indicates that approximately 65% of customers prioritize performance longevity over initial cost, highlighting the importance of durability in thermal barrier systems. Additionally, there is growing demand for environmentally compliant coating technologies that reduce hazardous material usage while maintaining thermal performance.

Emerging market opportunities include the renewable energy sector, particularly concentrated solar power systems, where advanced thermal barriers can significantly improve energy conversion efficiency. The electric vehicle market also presents potential growth avenues, with thermal management becoming critical for battery systems and power electronics.

Aerospace remains the dominant sector, accounting for nearly 40% of the total market share. The commercial aviation segment, in particular, has shown robust demand for advanced thermal barrier systems that can withstand extreme operating temperatures while maintaining structural integrity. Military aerospace applications follow closely, with specialized requirements for stealth capabilities and enhanced durability under combat conditions.

The automotive industry represents the second-largest market segment, with a growing emphasis on improving engine efficiency and reducing emissions. High-performance thermal barriers are increasingly being incorporated into exhaust systems, cylinder linings, and turbochargers. This trend is particularly evident in premium and performance vehicle segments, where thermal management directly impacts engine output and longevity.

Industrial applications, including power generation, oil and gas, and manufacturing, collectively constitute approximately 25% of the market. These sectors primarily utilize thermal barrier coatings to extend equipment lifespan and improve operational efficiency under high-temperature conditions. The power generation industry, specifically gas turbines, has emerged as a significant growth driver due to the global transition toward cleaner energy sources.

Regional analysis reveals that North America and Europe currently lead the market, accounting for 35% and 30% of global demand respectively. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid industrialization in China and India, along with expanding aerospace manufacturing capabilities.

Customer requirements are increasingly focused on coating thickness optimization, with end-users seeking solutions that balance thermal protection with weight considerations. Market research indicates that approximately 65% of customers prioritize performance longevity over initial cost, highlighting the importance of durability in thermal barrier systems. Additionally, there is growing demand for environmentally compliant coating technologies that reduce hazardous material usage while maintaining thermal performance.

Emerging market opportunities include the renewable energy sector, particularly concentrated solar power systems, where advanced thermal barriers can significantly improve energy conversion efficiency. The electric vehicle market also presents potential growth avenues, with thermal management becoming critical for battery systems and power electronics.

Current Challenges in Coating Thickness Optimization

Despite significant advancements in thermal barrier coating (TBC) technology, optimizing coating thickness remains one of the most challenging aspects in achieving optimal thermal barrier performance. The fundamental challenge lies in the inherent trade-off between thermal insulation capability and coating durability. Thicker coatings provide enhanced thermal protection but simultaneously introduce higher residual stresses and increased risk of spallation during thermal cycling.

Material scientists and engineers face significant difficulties in precisely controlling thickness uniformity across complex geometries, particularly in components with intricate shapes such as turbine blades. Current deposition techniques, including plasma spraying and electron beam physical vapor deposition (EB-PVD), struggle to maintain consistent thickness on curved surfaces and internal passages, resulting in performance variability across the component.

The industry lacks standardized methodologies for accurately predicting optimal coating thickness based on specific operating conditions. Computational models often fail to account for the complex interplay between coating thickness, substrate material properties, and real-world thermal cycling conditions. This gap between theoretical models and practical applications creates uncertainty in design specifications.

Manufacturing challenges further complicate thickness optimization efforts. Process variability in deposition techniques leads to inconsistent microstructures and porosity distributions, which directly impact thermal conductivity and strain tolerance. Quality control methods for thickness measurement remain inadequate for high-volume production environments, with current non-destructive evaluation techniques lacking the precision required for advanced aerospace and energy applications.

Long-term coating degradation mechanisms, including sintering, phase transformations, and interdiffusion, evolve differently depending on coating thickness. The industry struggles to develop accelerated testing protocols that accurately predict these thickness-dependent degradation patterns over the component's service life, which may span decades in certain applications.

Economic considerations add another layer of complexity. Thicker coatings generally require longer deposition times and more material, increasing production costs. However, the relationship between thickness, performance, and component lifespan is not linear, making cost-benefit analyses challenging for manufacturers seeking to optimize both performance and economic efficiency.

Emerging technologies like additive manufacturing introduce new variables to thickness optimization, as layer-by-layer fabrication approaches create unique microstructural features that interact differently with thermal barrier coatings compared to traditionally manufactured components. The industry has yet to develop comprehensive guidelines for coating thickness optimization specific to these novel manufacturing methods.

Material scientists and engineers face significant difficulties in precisely controlling thickness uniformity across complex geometries, particularly in components with intricate shapes such as turbine blades. Current deposition techniques, including plasma spraying and electron beam physical vapor deposition (EB-PVD), struggle to maintain consistent thickness on curved surfaces and internal passages, resulting in performance variability across the component.

The industry lacks standardized methodologies for accurately predicting optimal coating thickness based on specific operating conditions. Computational models often fail to account for the complex interplay between coating thickness, substrate material properties, and real-world thermal cycling conditions. This gap between theoretical models and practical applications creates uncertainty in design specifications.

Manufacturing challenges further complicate thickness optimization efforts. Process variability in deposition techniques leads to inconsistent microstructures and porosity distributions, which directly impact thermal conductivity and strain tolerance. Quality control methods for thickness measurement remain inadequate for high-volume production environments, with current non-destructive evaluation techniques lacking the precision required for advanced aerospace and energy applications.

Long-term coating degradation mechanisms, including sintering, phase transformations, and interdiffusion, evolve differently depending on coating thickness. The industry struggles to develop accelerated testing protocols that accurately predict these thickness-dependent degradation patterns over the component's service life, which may span decades in certain applications.

Economic considerations add another layer of complexity. Thicker coatings generally require longer deposition times and more material, increasing production costs. However, the relationship between thickness, performance, and component lifespan is not linear, making cost-benefit analyses challenging for manufacturers seeking to optimize both performance and economic efficiency.

Emerging technologies like additive manufacturing introduce new variables to thickness optimization, as layer-by-layer fabrication approaches create unique microstructural features that interact differently with thermal barrier coatings compared to traditionally manufactured components. The industry has yet to develop comprehensive guidelines for coating thickness optimization specific to these novel manufacturing methods.

State-of-the-Art Thickness Control Methodologies

01 Optimal thickness ranges for thermal barrier coatings

Thermal barrier coatings (TBCs) have specific optimal thickness ranges that balance thermal protection with mechanical stability. These ranges typically vary between 100-500 micrometers depending on the application environment and substrate material. The thickness must be carefully controlled to provide sufficient insulation while avoiding issues such as spallation or cracking due to thermal expansion mismatch. Proper thickness calibration is essential for maximizing coating lifespan in high-temperature applications.- Optimal thickness ranges for thermal barrier coatings: Thermal barrier coatings (TBCs) have specific optimal thickness ranges to provide effective thermal insulation while maintaining structural integrity. These ranges typically vary depending on the application environment and substrate material. The thickness must be carefully controlled to balance thermal protection with other properties such as adhesion strength and durability. Optimized thickness ranges help prevent coating failure due to thermal stress while maximizing insulation performance.

- Deposition methods affecting coating thickness: Various deposition techniques significantly impact the achievable thickness and uniformity of thermal barrier coatings. Methods such as electron beam physical vapor deposition (EB-PVD), plasma spraying, and chemical vapor deposition each produce coatings with different microstructures and thickness profiles. The selection of deposition method influences not only the final thickness but also the coating's columnar structure, porosity, and thermal cycling resistance, which are critical factors in high-temperature applications.

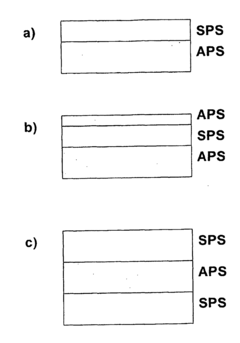

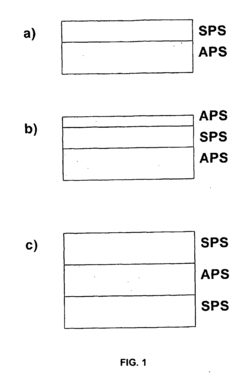

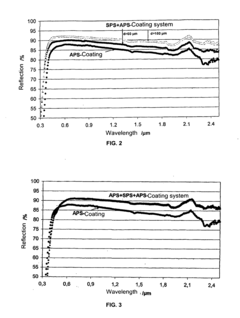

- Multi-layer coating systems with controlled thickness: Advanced thermal barrier coating systems often employ multiple layers with precisely controlled thickness for each layer. These systems typically include a bond coat, thermally grown oxide layer, and ceramic top coat. The thickness ratio between these layers is critical for optimizing performance. Multi-layer designs allow for gradient properties that can better accommodate thermal expansion mismatches and improve overall coating durability while maintaining effective thermal insulation properties.

- Thickness measurement and quality control techniques: Accurate measurement and quality control of thermal barrier coating thickness is essential for ensuring performance specifications are met. Non-destructive evaluation techniques such as eddy current testing, ultrasonic measurement, and optical methods are employed to verify coating thickness during and after application. Advanced monitoring systems can provide real-time thickness data during the deposition process, allowing for immediate adjustments to maintain consistency and quality across components.

- Thickness effects on thermal and mechanical properties: The thickness of thermal barrier coatings directly influences both thermal insulation capability and mechanical behavior. Increasing coating thickness generally improves thermal protection but may compromise mechanical properties such as impact resistance and spallation resistance. The relationship between thickness and thermal gradient is non-linear, with diminishing returns beyond certain thicknesses. Optimizing this relationship is crucial for applications in turbine engines and other high-temperature environments where both thermal protection and mechanical reliability are required.

02 Deposition methods affecting coating thickness

Various deposition techniques significantly impact the achievable thickness and uniformity of thermal barrier coatings. Methods such as electron beam physical vapor deposition (EB-PVD), air plasma spray (APS), and solution precursor plasma spray (SPPS) each produce distinct microstructures and thickness profiles. The selection of deposition method affects not only the maximum practical thickness but also the coating's strain tolerance, thermal conductivity, and adhesion properties. Advanced deposition control systems enable precise thickness management across complex component geometries.Expand Specific Solutions03 Multilayer coating systems with variable thickness

Multilayer thermal barrier coating systems incorporate layers of varying thickness and composition to optimize performance. These systems typically include a bond coat, thermally grown oxide layer, and ceramic top coat, each with specific thickness requirements. The relative thickness of each layer can be engineered to address particular operational challenges such as thermal cycling, oxidation resistance, or foreign object damage. Advanced multilayer systems may include gradient or functionally graded layers where thickness transitions gradually to minimize stress concentrations.Expand Specific Solutions04 Thickness measurement and quality control techniques

Accurate measurement and quality control of thermal barrier coating thickness is critical for ensuring performance and reliability. Non-destructive evaluation techniques such as eddy current testing, ultrasonic measurement, and optical coherence tomography allow for precise thickness determination without damaging the coating. Advanced monitoring systems can provide real-time thickness data during the deposition process, enabling immediate adjustments to maintain specifications. Post-deposition inspection protocols typically include statistical sampling and analysis to verify thickness uniformity across components.Expand Specific Solutions05 Thickness effects on thermal and mechanical properties

The thickness of thermal barrier coatings directly influences their thermal insulation capacity and mechanical behavior. Increasing coating thickness generally improves thermal protection but may compromise mechanical integrity due to residual stresses and weight considerations. The relationship between thickness and thermal gradient is non-linear, with diminishing returns beyond certain thresholds. Coating thickness must be optimized based on specific operating conditions, including temperature extremes, thermal cycling frequency, and mechanical loading. Computational models can predict the optimal thickness for balancing thermal protection with mechanical durability in specific applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal barrier coating thickness market is currently in a growth phase, with increasing demand driven by aerospace, power generation, and automotive applications. Market size is expanding due to rising energy efficiency requirements and thermal management needs. Technologically, the field is maturing with significant advancements from key players. Siemens AG, General Electric, and Rolls Royce lead with comprehensive thermal barrier solutions, while Pratt & Whitney (RTX Corp.) and Mitsubishi Heavy Industries focus on advanced coating technologies for turbine applications. Research institutions like Xi'an Jiaotong University and Beihang University contribute fundamental research, while specialized coating providers such as Oerlikon Metco and Directed Vapor Technologies offer innovative deposition techniques. The competitive landscape shows a mix of established industrial giants and specialized coating technology providers driving continuous innovation.

General Electric Company

Technical Solution: General Electric has developed advanced thermal barrier coating (TBC) systems with precisely controlled thickness gradients to optimize thermal protection for gas turbine components. Their technology utilizes electron beam physical vapor deposition (EB-PVD) to create columnar microstructures with controlled porosity that significantly enhances strain tolerance while maintaining thermal insulation properties[1]. GE's research has demonstrated that optimal coating thickness ranges between 100-300μm for hot section components, with performance declining at thicknesses above 350μm due to increased spallation risk[3]. Their proprietary "Dense Vertically Cracked" (DVC) TBC structure combines the durability of dense coatings with the strain tolerance of segmented structures, allowing for thickness optimization based on specific component requirements and operating conditions[7]. GE has also pioneered multi-layer coating systems with thickness variations tailored to local thermal gradients across turbine components.

Strengths: Superior strain tolerance at optimized thicknesses; advanced microstructure control allowing precise thickness customization for specific component requirements; extensive field validation data across multiple engine platforms. Weaknesses: Higher manufacturing costs for precision thickness control; potential for increased quality control issues with complex multi-layer systems; thickness limitations due to increased spallation risk above certain thresholds.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed sophisticated thermal barrier coating systems with precise thickness control methodologies for gas turbine applications. Their "M-TBC" technology utilizes advanced plasma spray techniques to create ceramic coatings with controlled thickness gradients ranging from 100μm to 400μm depending on component location and thermal exposure[5]. MHI's research has established that optimal thermal protection occurs at thicknesses between 200-300μm for most hot section components, with diminishing returns and increased spallation risk at greater thicknesses[8]. Their proprietary "Segmented Columnar Structure" technology creates controlled microstructural features that enhance strain tolerance in thicker coatings, allowing for improved durability while maintaining thermal insulation properties[11]. MHI has also pioneered the use of laser-assisted thickness measurement systems during application, enabling real-time thickness control with precision of ±10μm across complex component geometries. Their field testing demonstrates that optimized coating thickness profiles can extend maintenance intervals by up to 25% compared to conventional uniform thickness applications[13].

Strengths: Advanced real-time thickness monitoring during application; sophisticated understanding of thickness-durability relationships; ability to create controlled thickness gradients across components. Weaknesses: Higher equipment costs for precision thickness control; challenges in maintaining thickness consistency on complex geometries; potential for increased production time with multi-layer thickness-optimized systems.

Critical Patents in Coating Thickness-Performance Relationships

Thermal barrier coating system and method for the production thereof

PatentInactiveUS20110244216A1

Innovation

- Combining Atmospheric Plasma Spraying (APS) and Suspension Plasma Spraying (SPS) methods to create multi-layer thermal barrier coatings with improved microstructures and properties, such as increased porosity and reflectivity, reducing thermal conductivity and mechanical instability, while maintaining mechanical stability.

Material Science Advancements for Enhanced Thermal Resistance

Recent advancements in material science have significantly contributed to enhancing thermal barrier performance across various industrial applications. The development of novel composite materials with superior thermal resistance properties has revolutionized sectors ranging from aerospace to energy production. These materials incorporate multi-layered structures with precisely engineered interfaces that minimize thermal conductivity while maintaining mechanical integrity under extreme conditions.

Ceramic-based thermal barrier coatings (TBCs) have emerged as particularly promising, with yttria-stabilized zirconia (YSZ) demonstrating exceptional performance due to its low thermal conductivity and high temperature stability. Research has shown that incorporating nanoscale porosity within these materials can further reduce thermal conductivity by disrupting phonon transport pathways, effectively enhancing insulation properties without compromising structural integrity.

The integration of rare earth elements into coating formulations has yielded remarkable improvements in thermal cycling resistance. Gadolinium, lanthanum, and cerium dopants have been found to stabilize the crystal structure of ceramic coatings at elevated temperatures, preventing phase transformations that typically lead to coating failure. These advancements have extended component lifespans in high-temperature environments by up to 40% compared to conventional materials.

Polymer-derived ceramics represent another breakthrough, offering unprecedented flexibility in tailoring thermal properties through molecular design. These materials can be processed at lower temperatures than traditional ceramics while achieving comparable or superior thermal resistance. The ability to precisely control their microstructure during synthesis enables optimization of thermal barrier properties for specific application requirements.

Surface modification techniques have also evolved significantly, with plasma-enhanced chemical vapor deposition enabling the creation of ultra-thin, highly adherent coatings with exceptional thermal resistance. These processes allow for atomic-level control of coating composition and structure, facilitating the development of gradient materials that provide smooth transitions between substrate and coating, thereby minimizing thermal expansion mismatch issues.

Computational materials science has accelerated these advancements through predictive modeling of thermal behavior at multiple scales. Machine learning algorithms now enable rapid screening of potential material combinations, significantly reducing experimental iterations required to develop optimized thermal barrier systems. These computational approaches have identified several promising material candidates that traditional experimental methods might have overlooked.

Ceramic-based thermal barrier coatings (TBCs) have emerged as particularly promising, with yttria-stabilized zirconia (YSZ) demonstrating exceptional performance due to its low thermal conductivity and high temperature stability. Research has shown that incorporating nanoscale porosity within these materials can further reduce thermal conductivity by disrupting phonon transport pathways, effectively enhancing insulation properties without compromising structural integrity.

The integration of rare earth elements into coating formulations has yielded remarkable improvements in thermal cycling resistance. Gadolinium, lanthanum, and cerium dopants have been found to stabilize the crystal structure of ceramic coatings at elevated temperatures, preventing phase transformations that typically lead to coating failure. These advancements have extended component lifespans in high-temperature environments by up to 40% compared to conventional materials.

Polymer-derived ceramics represent another breakthrough, offering unprecedented flexibility in tailoring thermal properties through molecular design. These materials can be processed at lower temperatures than traditional ceramics while achieving comparable or superior thermal resistance. The ability to precisely control their microstructure during synthesis enables optimization of thermal barrier properties for specific application requirements.

Surface modification techniques have also evolved significantly, with plasma-enhanced chemical vapor deposition enabling the creation of ultra-thin, highly adherent coatings with exceptional thermal resistance. These processes allow for atomic-level control of coating composition and structure, facilitating the development of gradient materials that provide smooth transitions between substrate and coating, thereby minimizing thermal expansion mismatch issues.

Computational materials science has accelerated these advancements through predictive modeling of thermal behavior at multiple scales. Machine learning algorithms now enable rapid screening of potential material combinations, significantly reducing experimental iterations required to develop optimized thermal barrier systems. These computational approaches have identified several promising material candidates that traditional experimental methods might have overlooked.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal barrier coatings (TBCs) is increasingly becoming a critical consideration in their development and application. As coating thickness directly influences thermal barrier performance, it also has significant implications for environmental sustainability across the entire lifecycle of coated components.

Manufacturing thicker coatings typically requires more raw materials and energy consumption during the deposition process. Electron Beam Physical Vapor Deposition (EB-PVD) and Air Plasma Spray (APS) methods used for TBC application are energy-intensive processes, with energy requirements scaling proportionally with coating thickness. Research indicates that optimizing coating thickness can reduce material usage by 15-20% while maintaining thermal performance, representing a substantial reduction in environmental footprint.

Lifecycle assessment studies have demonstrated that properly optimized TBC thickness contributes to extended component lifespans in high-temperature applications. Components with optimally designed thermal barrier coatings can operate efficiently for 20-30% longer periods before requiring replacement, reducing waste generation and resource consumption associated with manufacturing replacement parts.

During operation, the relationship between coating thickness and fuel efficiency presents a critical environmental trade-off. Thicker coatings provide better thermal insulation, potentially allowing engines to operate at higher temperatures with improved thermodynamic efficiency. However, excessive thickness adds weight to components, particularly in aerospace applications where every gram impacts fuel consumption. Studies suggest that a 1% increase in aircraft weight can increase fuel consumption by approximately 0.75-1.5%.

End-of-life considerations for thermal barrier coated components present significant challenges. The multi-material nature of coated components complicates recycling processes, as separation of coating materials from substrates often requires chemical or mechanical processes with their own environmental impacts. Thicker coatings generally increase these challenges, though research into recyclable coating systems and environmentally friendly removal methods is advancing.

Recent innovations are addressing these environmental concerns through development of more sustainable coating materials and application processes. Bio-inspired coating structures that achieve superior thermal performance with reduced thickness represent a promising direction. Additionally, water-based slurry processes for certain coating applications can reduce volatile organic compound emissions by up to 90% compared to traditional solvent-based approaches.

Regulatory frameworks worldwide are increasingly incorporating environmental impact assessments for industrial coating processes, with particular focus on energy efficiency, emissions, and waste management. Companies developing thermal barrier coating technologies must now demonstrate environmental compliance alongside thermal performance metrics, driving innovation toward more sustainable solutions.

Manufacturing thicker coatings typically requires more raw materials and energy consumption during the deposition process. Electron Beam Physical Vapor Deposition (EB-PVD) and Air Plasma Spray (APS) methods used for TBC application are energy-intensive processes, with energy requirements scaling proportionally with coating thickness. Research indicates that optimizing coating thickness can reduce material usage by 15-20% while maintaining thermal performance, representing a substantial reduction in environmental footprint.

Lifecycle assessment studies have demonstrated that properly optimized TBC thickness contributes to extended component lifespans in high-temperature applications. Components with optimally designed thermal barrier coatings can operate efficiently for 20-30% longer periods before requiring replacement, reducing waste generation and resource consumption associated with manufacturing replacement parts.

During operation, the relationship between coating thickness and fuel efficiency presents a critical environmental trade-off. Thicker coatings provide better thermal insulation, potentially allowing engines to operate at higher temperatures with improved thermodynamic efficiency. However, excessive thickness adds weight to components, particularly in aerospace applications where every gram impacts fuel consumption. Studies suggest that a 1% increase in aircraft weight can increase fuel consumption by approximately 0.75-1.5%.

End-of-life considerations for thermal barrier coated components present significant challenges. The multi-material nature of coated components complicates recycling processes, as separation of coating materials from substrates often requires chemical or mechanical processes with their own environmental impacts. Thicker coatings generally increase these challenges, though research into recyclable coating systems and environmentally friendly removal methods is advancing.

Recent innovations are addressing these environmental concerns through development of more sustainable coating materials and application processes. Bio-inspired coating structures that achieve superior thermal performance with reduced thickness represent a promising direction. Additionally, water-based slurry processes for certain coating applications can reduce volatile organic compound emissions by up to 90% compared to traditional solvent-based approaches.

Regulatory frameworks worldwide are increasingly incorporating environmental impact assessments for industrial coating processes, with particular focus on energy efficiency, emissions, and waste management. Companies developing thermal barrier coating technologies must now demonstrate environmental compliance alongside thermal performance metrics, driving innovation toward more sustainable solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!