Nanostructured Ceramic Thermal Barrier Coatings

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanostructured Ceramic TBC Evolution and Objectives

Thermal Barrier Coatings (TBCs) have evolved significantly since their inception in the 1950s, initially developed for aerospace applications to protect engine components from extreme temperatures. The evolution of nanostructured ceramic TBCs represents a critical advancement in this field, offering superior thermal insulation properties and enhanced durability compared to conventional coatings. This technological progression has been driven by the increasing demands of modern gas turbine engines, which operate at ever-higher temperatures to improve efficiency and reduce emissions.

The development of nanostructured ceramic TBCs can be traced through several key phases. Early TBCs utilized simple ceramic compositions with limited temperature capabilities. The 1980s saw the introduction of yttria-stabilized zirconia (YSZ) as the standard material, which remained dominant for decades. The paradigm shift toward nanostructured ceramics began in the early 2000s, when researchers recognized that manipulating the material structure at the nanoscale could dramatically enhance performance characteristics.

Nanostructured ceramic TBCs incorporate features such as nanopores, nanolayers, or nanoparticles that significantly reduce thermal conductivity while maintaining mechanical integrity. These structures create numerous interfaces that scatter phonons, the primary carriers of heat in ceramic materials. Additionally, the nanoscale features can enhance strain tolerance, improving resistance to thermal cycling and mechanical stresses that typically lead to coating failure.

The primary objective of current research in nanostructured ceramic TBCs is to develop coatings capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity for extended operational periods. This represents a significant challenge as conventional YSZ-based systems typically begin to degrade at temperatures above 1200°C due to phase transformations and sintering effects.

Secondary objectives include reducing coating thickness without sacrificing thermal protection, enhancing erosion resistance, and developing manufacturing processes suitable for industrial-scale production. Researchers are also focusing on creating multi-functional coatings that provide not only thermal protection but also resistance to environmental degradation from contaminants such as calcium-magnesium-alumino-silicates (CMAS) and volcanic ash.

The long-term vision for nanostructured ceramic TBCs extends beyond traditional aerospace applications to include automotive engines, power generation turbines, and even hypersonic vehicles. These diverse applications present unique challenges that drive continued innovation in coating composition, structure, and deposition techniques. As operational temperatures continue to increase in pursuit of greater efficiency, the development of advanced nanostructured ceramic TBCs remains a critical enabling technology for next-generation high-temperature systems.

The development of nanostructured ceramic TBCs can be traced through several key phases. Early TBCs utilized simple ceramic compositions with limited temperature capabilities. The 1980s saw the introduction of yttria-stabilized zirconia (YSZ) as the standard material, which remained dominant for decades. The paradigm shift toward nanostructured ceramics began in the early 2000s, when researchers recognized that manipulating the material structure at the nanoscale could dramatically enhance performance characteristics.

Nanostructured ceramic TBCs incorporate features such as nanopores, nanolayers, or nanoparticles that significantly reduce thermal conductivity while maintaining mechanical integrity. These structures create numerous interfaces that scatter phonons, the primary carriers of heat in ceramic materials. Additionally, the nanoscale features can enhance strain tolerance, improving resistance to thermal cycling and mechanical stresses that typically lead to coating failure.

The primary objective of current research in nanostructured ceramic TBCs is to develop coatings capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity for extended operational periods. This represents a significant challenge as conventional YSZ-based systems typically begin to degrade at temperatures above 1200°C due to phase transformations and sintering effects.

Secondary objectives include reducing coating thickness without sacrificing thermal protection, enhancing erosion resistance, and developing manufacturing processes suitable for industrial-scale production. Researchers are also focusing on creating multi-functional coatings that provide not only thermal protection but also resistance to environmental degradation from contaminants such as calcium-magnesium-alumino-silicates (CMAS) and volcanic ash.

The long-term vision for nanostructured ceramic TBCs extends beyond traditional aerospace applications to include automotive engines, power generation turbines, and even hypersonic vehicles. These diverse applications present unique challenges that drive continued innovation in coating composition, structure, and deposition techniques. As operational temperatures continue to increase in pursuit of greater efficiency, the development of advanced nanostructured ceramic TBCs remains a critical enabling technology for next-generation high-temperature systems.

Market Analysis for Advanced Thermal Protection Systems

The global market for advanced thermal protection systems, particularly nanostructured ceramic thermal barrier coatings (TBCs), has experienced significant growth driven by increasing demands across aerospace, power generation, and automotive industries. Current market valuations indicate that the thermal barrier coatings segment reached approximately 11 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030.

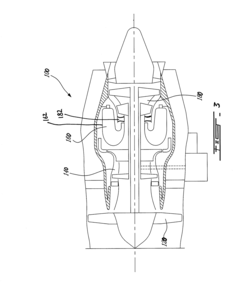

Aerospace applications represent the largest market share, accounting for nearly 40% of the total TBC market. This dominance stems from the critical need for high-performance materials capable of withstanding extreme temperatures in aircraft engines and hypersonic vehicles. The commercial aviation sector's recovery post-pandemic has further accelerated demand for advanced TBCs that can improve fuel efficiency and extend component lifespans.

Power generation follows as the second-largest application segment, driven by increasing global energy demands and the push for more efficient gas turbines. Enhanced thermal efficiency through advanced ceramic coatings directly translates to reduced fuel consumption and lower emissions, aligning with stringent environmental regulations worldwide.

Regional analysis reveals North America and Europe as market leaders, collectively holding over 60% of the global market share. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at approximately 8.5% annually, fueled by expanding aerospace industries and substantial investments in power infrastructure.

Customer requirements are evolving toward coatings with enhanced durability, reduced thermal conductivity, and improved resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration. This shift has created new market opportunities for nanostructured ceramic TBCs that offer superior performance compared to conventional yttria-stabilized zirconia (YSZ) coatings.

Market barriers include high manufacturing costs, complex application processes, and technical challenges in achieving consistent quality at scale. The specialized equipment and expertise required for advanced deposition techniques like electron beam physical vapor deposition (EB-PVD) limit market entry for smaller players.

Future market growth will be significantly influenced by technological advancements in multilayer coating systems, novel ceramic compositions, and improved manufacturing processes. The development of self-healing TBCs represents an emerging segment with substantial growth potential, addressing the critical issue of coating longevity in extreme environments.

Industry consolidation continues as major players like General Electric, Praxair Surface Technologies, and Oerlikon Metco expand their technological capabilities through strategic acquisitions and research partnerships with academic institutions, securing their competitive positions in this high-value market.

Aerospace applications represent the largest market share, accounting for nearly 40% of the total TBC market. This dominance stems from the critical need for high-performance materials capable of withstanding extreme temperatures in aircraft engines and hypersonic vehicles. The commercial aviation sector's recovery post-pandemic has further accelerated demand for advanced TBCs that can improve fuel efficiency and extend component lifespans.

Power generation follows as the second-largest application segment, driven by increasing global energy demands and the push for more efficient gas turbines. Enhanced thermal efficiency through advanced ceramic coatings directly translates to reduced fuel consumption and lower emissions, aligning with stringent environmental regulations worldwide.

Regional analysis reveals North America and Europe as market leaders, collectively holding over 60% of the global market share. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at approximately 8.5% annually, fueled by expanding aerospace industries and substantial investments in power infrastructure.

Customer requirements are evolving toward coatings with enhanced durability, reduced thermal conductivity, and improved resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration. This shift has created new market opportunities for nanostructured ceramic TBCs that offer superior performance compared to conventional yttria-stabilized zirconia (YSZ) coatings.

Market barriers include high manufacturing costs, complex application processes, and technical challenges in achieving consistent quality at scale. The specialized equipment and expertise required for advanced deposition techniques like electron beam physical vapor deposition (EB-PVD) limit market entry for smaller players.

Future market growth will be significantly influenced by technological advancements in multilayer coating systems, novel ceramic compositions, and improved manufacturing processes. The development of self-healing TBCs represents an emerging segment with substantial growth potential, addressing the critical issue of coating longevity in extreme environments.

Industry consolidation continues as major players like General Electric, Praxair Surface Technologies, and Oerlikon Metco expand their technological capabilities through strategic acquisitions and research partnerships with academic institutions, securing their competitive positions in this high-value market.

Global Status and Technical Barriers in Nanostructured Ceramics

Nanostructured ceramic thermal barrier coatings (TBCs) have emerged as a critical technology in high-temperature applications, particularly in aerospace, power generation, and automotive industries. Globally, research on these advanced materials has accelerated significantly over the past decade, with major developments occurring in North America, Europe, and East Asia. The United States maintains leadership through substantial investments from both government agencies like NASA and DARPA, and private corporations such as General Electric and Pratt & Whitney, focusing on next-generation turbine engine applications.

European research, particularly in Germany, France, and the UK, has concentrated on fundamental science aspects of nanostructured ceramics, with organizations like the German Aerospace Center (DLR) and Imperial College London pioneering novel synthesis methods. Japan has established expertise in ultra-fine ceramic powders and precise microstructural control, while China has rapidly expanded its research capacity, becoming the largest publisher of academic papers in this field since 2018.

Despite global progress, significant technical barriers persist in nanostructured ceramic TBCs. The primary challenge remains the trade-off between thermal insulation performance and mechanical durability. Conventional yttria-stabilized zirconia (YSZ) coatings with nanoscale features often exhibit enhanced thermal resistance but suffer from accelerated sintering at elevated temperatures, compromising their long-term stability.

Another major obstacle is the scalable manufacturing of nanostructured ceramics with consistent properties. Current deposition techniques, including electron beam physical vapor deposition (EB-PVD) and solution precursor plasma spray (SPPS), struggle to maintain nanoscale features uniformly across large components. The high cost and complexity of these processes have limited widespread industrial adoption.

Interface stability between the ceramic top coat and metallic bond coat represents another significant challenge. The formation of thermally grown oxide (TGO) layers at this interface can lead to premature spallation failure, particularly problematic for nanostructured systems due to their higher interfacial area and reactivity.

Thermal cycling resistance remains inadequate for many advanced applications, with current nanostructured TBCs typically achieving 300-500 cycles before failure—significantly below the 1000+ cycles required for next-generation turbine engines. This limitation stems from coefficient of thermal expansion mismatches and phase stability issues at extreme temperatures.

Environmental degradation, particularly from calcium-magnesium-alumino-silicate (CMAS) infiltration and volcanic ash exposure, presents an emerging challenge as operating temperatures increase. Nanostructured ceramics often show greater susceptibility to these contaminants due to their higher surface area and porosity characteristics.

European research, particularly in Germany, France, and the UK, has concentrated on fundamental science aspects of nanostructured ceramics, with organizations like the German Aerospace Center (DLR) and Imperial College London pioneering novel synthesis methods. Japan has established expertise in ultra-fine ceramic powders and precise microstructural control, while China has rapidly expanded its research capacity, becoming the largest publisher of academic papers in this field since 2018.

Despite global progress, significant technical barriers persist in nanostructured ceramic TBCs. The primary challenge remains the trade-off between thermal insulation performance and mechanical durability. Conventional yttria-stabilized zirconia (YSZ) coatings with nanoscale features often exhibit enhanced thermal resistance but suffer from accelerated sintering at elevated temperatures, compromising their long-term stability.

Another major obstacle is the scalable manufacturing of nanostructured ceramics with consistent properties. Current deposition techniques, including electron beam physical vapor deposition (EB-PVD) and solution precursor plasma spray (SPPS), struggle to maintain nanoscale features uniformly across large components. The high cost and complexity of these processes have limited widespread industrial adoption.

Interface stability between the ceramic top coat and metallic bond coat represents another significant challenge. The formation of thermally grown oxide (TGO) layers at this interface can lead to premature spallation failure, particularly problematic for nanostructured systems due to their higher interfacial area and reactivity.

Thermal cycling resistance remains inadequate for many advanced applications, with current nanostructured TBCs typically achieving 300-500 cycles before failure—significantly below the 1000+ cycles required for next-generation turbine engines. This limitation stems from coefficient of thermal expansion mismatches and phase stability issues at extreme temperatures.

Environmental degradation, particularly from calcium-magnesium-alumino-silicate (CMAS) infiltration and volcanic ash exposure, presents an emerging challenge as operating temperatures increase. Nanostructured ceramics often show greater susceptibility to these contaminants due to their higher surface area and porosity characteristics.

Current Nanostructured TBC Design Approaches

01 Composition of nanostructured ceramic thermal barrier coatings

Nanostructured ceramic thermal barrier coatings typically consist of materials such as yttria-stabilized zirconia (YSZ), rare earth oxides, and other ceramic compounds. These materials are engineered at the nanoscale to enhance thermal insulation properties. The nanostructured composition provides improved thermal resistance, durability, and longevity compared to conventional coatings. The specific composition can be tailored to meet the requirements of different high-temperature applications.- Composition and structure of nanostructured ceramic thermal barrier coatings: Nanostructured ceramic thermal barrier coatings typically consist of materials such as yttria-stabilized zirconia (YSZ) and other ceramic oxides with nanoscale features. These coatings have a unique microstructure with nano-sized grains, pores, or layered structures that enhance thermal insulation properties. The nanostructured design creates numerous interfaces that scatter phonons and reduce thermal conductivity, making them more effective at protecting underlying components from high temperatures in turbine engines and other high-temperature applications.

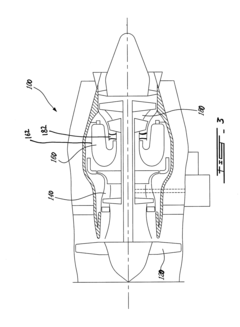

- Deposition methods for nanostructured ceramic thermal barrier coatings: Various deposition techniques are employed to create nanostructured ceramic thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), solution precursor plasma spray, and chemical vapor deposition. These methods can be optimized to control the nanoscale features of the coating, such as columnar structures, porosity, and grain size. Advanced deposition techniques allow for precise control over coating thickness, adhesion, and microstructure, which directly influence the thermal and mechanical properties of the coating system.

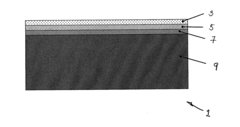

- Multi-layered and functionally graded nanostructured thermal barrier coatings: Multi-layered and functionally graded nanostructured thermal barrier coatings consist of different ceramic materials arranged in layers or with gradual compositional changes throughout the coating thickness. These designs combine the beneficial properties of different materials to enhance overall performance. The layered or graded structure can provide improved thermal cycling resistance, better adhesion to the substrate, and optimized thermal insulation. Such coatings often include a bond coat layer, a thermally grown oxide layer, and the ceramic top coat with carefully engineered interfaces between layers.

- Enhanced durability and thermal cycling resistance: Nanostructured ceramic thermal barrier coatings exhibit enhanced durability and resistance to thermal cycling compared to conventional coatings. The nanoscale features help accommodate thermal expansion mismatch stresses between the coating and substrate, reducing the likelihood of spallation and cracking during thermal cycling. Strain-tolerant microstructures, such as columnar or feathery structures, allow the coating to expand and contract without developing damaging stresses. Additionally, nanostructured coatings often demonstrate improved erosion resistance and better performance under thermal shock conditions.

- Novel ceramic compositions and additives for improved performance: Research has led to the development of novel ceramic compositions and additives that enhance the performance of nanostructured thermal barrier coatings. These include rare earth zirconates, hafnates, pyrochlores, and perovskites that offer lower thermal conductivity and better phase stability at elevated temperatures compared to traditional YSZ. Dopants and additives are incorporated to modify sintering behavior, improve mechanical properties, and enhance resistance to environmental degradation from contaminants like calcium-magnesium-alumino-silicates (CMAS). These advanced compositions extend the operating temperature range and service life of thermal barrier coating systems.

02 Deposition methods for nanostructured ceramic coatings

Various deposition techniques are employed to create nanostructured ceramic thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), solution precursor plasma spray, and chemical vapor deposition. These methods control the microstructure and porosity of the coating, which directly affects its thermal insulation properties. Advanced deposition techniques can create columnar structures, layered architectures, or graded compositions that optimize thermal performance while maintaining mechanical integrity.Expand Specific Solutions03 Multilayer and functionally graded coating systems

Multilayer and functionally graded coating systems incorporate different layers with varying compositions and structures to optimize thermal protection. These systems typically include a bond coat, a thermally grown oxide layer, and a ceramic top coat. The gradual transition between layers helps reduce thermal expansion mismatch stress and improves coating adhesion. By engineering the interfaces between layers, these systems can provide enhanced thermal cycling resistance and longer service life in extreme temperature environments.Expand Specific Solutions04 Porosity control and microstructure engineering

Controlling porosity and engineering the microstructure of ceramic thermal barrier coatings at the nanoscale is crucial for optimizing thermal insulation performance. Techniques include introducing controlled nano-porosity, creating segmentation cracks, and developing specific crystalline structures. These features reduce thermal conductivity by increasing phonon scattering pathways. Advanced microstructure engineering can create coatings with strain tolerance, erosion resistance, and thermal stability at elevated temperatures.Expand Specific Solutions05 Novel additives and dopants for enhanced performance

Incorporating novel additives and dopants into ceramic thermal barrier coatings can significantly enhance their performance characteristics. Rare earth elements, transition metals, and other specialized compounds are used to modify the coating properties. These additives can lower thermal conductivity, improve phase stability, enhance sintering resistance, and increase mechanical strength. Research focuses on developing new dopant combinations that can extend coating lifetime under extreme thermal cycling and harsh environmental conditions.Expand Specific Solutions

Industry Leaders in Nanostructured Ceramic Coatings

The nanostructured ceramic thermal barrier coatings market is in a growth phase, driven by increasing demand in aerospace and energy sectors. With an estimated market size of $2-3 billion and projected CAGR of 6-8%, this technology is gaining traction for its superior thermal protection capabilities. Technical maturity varies across players, with aerospace giants like RTX Corp., Honeywell, and Pratt & Whitney demonstrating advanced capabilities through established product lines. Research institutions including Rice University, Cornell University, and Beihang University are pushing boundaries in nanomaterial development. Energy sector leaders Siemens Energy and Bosch are integrating these coatings into turbine systems. Chinese institutions and companies are rapidly advancing their technical capabilities, particularly in industrial applications, creating a competitive landscape that spans North America, Europe, and Asia.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced nanostructured ceramic thermal barrier coatings (TBCs) utilizing a proprietary sol-gel synthesis approach combined with air plasma spray (APS) deposition techniques. Their technology incorporates zirconia nanoparticles (30-50 nm) doped with multiple rare earth elements including yttria, gadolinia, and erbia to create phase-stable coatings with enhanced thermal cycling performance. Honeywell's multi-component ceramic systems demonstrate thermal conductivity reductions of up to 35% compared to conventional YSZ coatings while maintaining excellent mechanical properties. A key innovation in their approach is the development of functionally graded coatings with nanostructured interlayers that mitigate thermal expansion mismatch stresses between the ceramic top coat and metallic bond coat. Their coatings feature engineered nanoscale porosity that effectively scatters phonons across a wide temperature range, maintaining low thermal conductivity even after extended high-temperature exposure. Recent developments include self-diagnosing TBCs with embedded luminescent nanoparticles that enable non-destructive evaluation of coating degradation during service.

Strengths: Excellent thermal cycling durability; reduced thermal conductivity maintained over extended service periods; compatibility with existing APS infrastructure; effective stress management through graded structures. Weaknesses: Higher raw material costs due to rare earth element additions; potential for sintering at very high temperatures (>1300°C); more complex quality control requirements compared to conventional coatings.

RTX Corp.

Technical Solution: RTX Corp. (formerly United Technologies) has developed advanced nanostructured ceramic thermal barrier coatings (TBCs) primarily for aerospace applications. Their technology focuses on yttria-stabilized zirconia (YSZ) with engineered nanoscale features that significantly enhance coating durability and thermal performance. RTX's approach incorporates a multi-layered coating system with nanostructured ceramic topcoats that can withstand temperatures exceeding 1200°C while providing superior strain tolerance. Their proprietary electron beam physical vapor deposition (EB-PVD) process creates columnar microstructures with nanoscale porosity that effectively reduces thermal conductivity by up to 40% compared to conventional coatings. RTX has also pioneered the integration of rare earth elements into their ceramic matrix to enhance phase stability and extend coating lifespans in extreme thermal cycling environments. Recent developments include self-healing nanostructured ceramics that can repair microcracks during operation, significantly extending component life in gas turbine engines.

Strengths: Superior thermal cycling resistance and strain tolerance due to engineered columnar microstructure; excellent high-temperature stability; reduced thermal conductivity; proven performance in aerospace applications. Weaknesses: Higher manufacturing costs compared to conventional plasma spray methods; complex deposition process requiring specialized equipment; potential challenges in coating complex geometries.

Key Patents and Research in Ceramic Nanostructuring

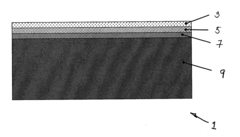

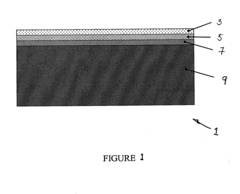

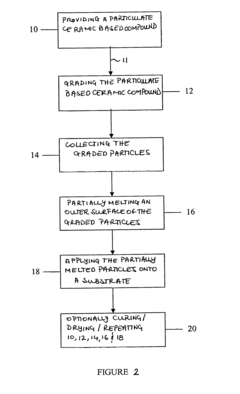

Thermal barrier coating with lower thermal conductivity

PatentInactiveUS20100227146A1

Innovation

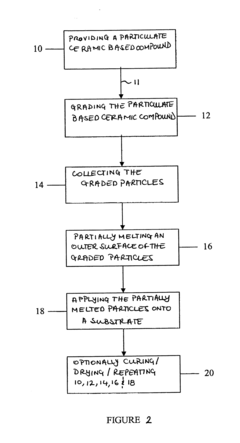

- A nano-structured thermal barrier coating comprising ceramic compounds like lanthanum, cerium, and gadolinium oxides with porosity up to 50% by volume and nano-structured inclusions, applied through a process involving particulate grading and partial melting to enhance thermal resistance.

Thermal Barrier Coating with Lower Thermal Conductivity

PatentInactiveUS20160333455A1

Innovation

- A nano-structured thermal barrier coating comprising a ceramic-based compound of gadolinia and zirconia with a porosity of up to 50% by volume, applied using a process that involves grading particulate ceramic compounds to produce nanosized particles, partially melting their surfaces, and depositing them onto a substrate, often used in gas turbine engine components.

Environmental Impact and Sustainability Factors

The environmental impact of nanostructured ceramic thermal barrier coatings (TBCs) represents a critical consideration in their development and application. These advanced materials, while primarily designed for thermal protection in high-temperature environments, carry significant sustainability implications throughout their lifecycle. The manufacturing processes for nanostructured ceramic TBCs typically involve energy-intensive methods such as plasma spraying, electron beam physical vapor deposition, and sol-gel techniques, which contribute to considerable carbon emissions and resource consumption.

When examining raw material extraction, the environmental footprint becomes evident. Many ceramic components require mining of rare earth elements and other minerals, which can lead to habitat destruction, soil erosion, and water contamination. The processing of these materials often involves hazardous chemicals and generates waste streams that require careful management to prevent environmental contamination.

During the operational phase, nanostructured ceramic TBCs deliver substantial environmental benefits by improving energy efficiency in turbines, engines, and industrial equipment. By enabling higher operating temperatures and providing superior thermal insulation, these coatings can reduce fuel consumption by 1-3% in aerospace applications and up to 5% in power generation systems. This translates to significant reductions in greenhouse gas emissions over the operational lifetime of coated components.

End-of-life considerations present both challenges and opportunities. The complex composition of nanostructured TBCs can complicate recycling efforts, as separation of the nanomaterials from substrates often requires specialized processes. However, research into recovery methods for valuable components, particularly rare earth elements, is advancing. Circular economy approaches are being developed to reprocess coating materials for secondary applications, reducing the need for virgin material extraction.

Health and safety concerns also factor into the sustainability equation. Nanoparticles used in these coatings may pose occupational exposure risks during manufacturing and maintenance operations. Stringent controls and protective measures are necessary to mitigate potential respiratory and dermal hazards associated with nanoparticle handling.

Regulatory frameworks worldwide are evolving to address these environmental considerations. The European Union's REACH regulations, the United States EPA's nanomaterial reporting rules, and similar initiatives in Asia are establishing guidelines for responsible development and application of nanotechnology in coatings. Industry compliance with these regulations is driving innovation toward greener manufacturing processes and safer material formulations.

Future research directions are increasingly focused on developing environmentally benign alternatives to traditional coating components and processes. Bio-inspired ceramics, water-based application methods, and non-toxic stabilizers represent promising avenues for reducing the environmental impact while maintaining or enhancing coating performance.

When examining raw material extraction, the environmental footprint becomes evident. Many ceramic components require mining of rare earth elements and other minerals, which can lead to habitat destruction, soil erosion, and water contamination. The processing of these materials often involves hazardous chemicals and generates waste streams that require careful management to prevent environmental contamination.

During the operational phase, nanostructured ceramic TBCs deliver substantial environmental benefits by improving energy efficiency in turbines, engines, and industrial equipment. By enabling higher operating temperatures and providing superior thermal insulation, these coatings can reduce fuel consumption by 1-3% in aerospace applications and up to 5% in power generation systems. This translates to significant reductions in greenhouse gas emissions over the operational lifetime of coated components.

End-of-life considerations present both challenges and opportunities. The complex composition of nanostructured TBCs can complicate recycling efforts, as separation of the nanomaterials from substrates often requires specialized processes. However, research into recovery methods for valuable components, particularly rare earth elements, is advancing. Circular economy approaches are being developed to reprocess coating materials for secondary applications, reducing the need for virgin material extraction.

Health and safety concerns also factor into the sustainability equation. Nanoparticles used in these coatings may pose occupational exposure risks during manufacturing and maintenance operations. Stringent controls and protective measures are necessary to mitigate potential respiratory and dermal hazards associated with nanoparticle handling.

Regulatory frameworks worldwide are evolving to address these environmental considerations. The European Union's REACH regulations, the United States EPA's nanomaterial reporting rules, and similar initiatives in Asia are establishing guidelines for responsible development and application of nanotechnology in coatings. Industry compliance with these regulations is driving innovation toward greener manufacturing processes and safer material formulations.

Future research directions are increasingly focused on developing environmentally benign alternatives to traditional coating components and processes. Bio-inspired ceramics, water-based application methods, and non-toxic stabilizers represent promising avenues for reducing the environmental impact while maintaining or enhancing coating performance.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for nanostructured ceramic thermal barrier coatings (TBCs) presents significant challenges that directly impact their commercial viability. Current production methods, including electron beam physical vapor deposition (EB-PVD) and air plasma spraying (APS), face substantial limitations when scaled to industrial volumes. EB-PVD, while producing superior columnar microstructures with excellent strain tolerance, requires sophisticated vacuum equipment and has relatively low deposition rates, resulting in production bottlenecks for large components.

Cost analysis reveals that material expenses constitute approximately 15-25% of total production costs, while equipment investment and energy consumption represent 40-50% and 20-30% respectively. The specialized zirconia powders with controlled nano-additives command premium prices of $200-500 per kilogram, significantly higher than conventional ceramic materials. Furthermore, the precision equipment required for consistent nanostructure formation typically demands capital investments exceeding $2-5 million per production line.

Recent innovations in solution precursor plasma spraying (SPPS) and suspension plasma spraying (SPS) show promise for more cost-effective manufacturing. These techniques can reduce production costs by 30-40% compared to traditional EB-PVD while maintaining comparable thermal performance. However, they still struggle with reproducibility issues when implemented at industrial scales, particularly for components with complex geometries.

Energy consumption remains a critical cost factor, with typical production facilities requiring 150-300 kWh per square meter of coating. Implementation of energy recovery systems and process optimization has demonstrated potential to reduce this consumption by 20-25%, though such systems require additional upfront investment of $500,000-1,000,000 per facility.

Labor costs vary significantly by region, ranging from 5-15% of total production expenses. The specialized nature of nanostructured TBC application requires highly trained technicians, commanding hourly rates 30-50% above standard manufacturing positions. This specialized workforce requirement creates additional scaling challenges in regions with limited technical expertise.

Economic modeling indicates that current nanostructured TBC production becomes cost-competitive with conventional coatings only at annual production volumes exceeding 10,000 components. Below this threshold, the premium for nanostructured coatings ranges from 60-120% over conventional alternatives. This cost differential presents a significant barrier to adoption in price-sensitive market segments, despite the superior performance characteristics.

Cost analysis reveals that material expenses constitute approximately 15-25% of total production costs, while equipment investment and energy consumption represent 40-50% and 20-30% respectively. The specialized zirconia powders with controlled nano-additives command premium prices of $200-500 per kilogram, significantly higher than conventional ceramic materials. Furthermore, the precision equipment required for consistent nanostructure formation typically demands capital investments exceeding $2-5 million per production line.

Recent innovations in solution precursor plasma spraying (SPPS) and suspension plasma spraying (SPS) show promise for more cost-effective manufacturing. These techniques can reduce production costs by 30-40% compared to traditional EB-PVD while maintaining comparable thermal performance. However, they still struggle with reproducibility issues when implemented at industrial scales, particularly for components with complex geometries.

Energy consumption remains a critical cost factor, with typical production facilities requiring 150-300 kWh per square meter of coating. Implementation of energy recovery systems and process optimization has demonstrated potential to reduce this consumption by 20-25%, though such systems require additional upfront investment of $500,000-1,000,000 per facility.

Labor costs vary significantly by region, ranging from 5-15% of total production expenses. The specialized nature of nanostructured TBC application requires highly trained technicians, commanding hourly rates 30-50% above standard manufacturing positions. This specialized workforce requirement creates additional scaling challenges in regions with limited technical expertise.

Economic modeling indicates that current nanostructured TBC production becomes cost-competitive with conventional coatings only at annual production volumes exceeding 10,000 components. Below this threshold, the premium for nanostructured coatings ranges from 60-120% over conventional alternatives. This cost differential presents a significant barrier to adoption in price-sensitive market segments, despite the superior performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!