Ceramic Thermal Spray Techniques APS HVOF and SPS Comparison

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Thermal Spray Evolution and Objectives

Thermal spray coating technology has evolved significantly over the past century, transforming from rudimentary flame spray methods to sophisticated high-velocity and plasma-based techniques. The journey began in the early 1900s with Dr. Max Ulrich Schoop's pioneering work on metal spraying, which laid the foundation for modern thermal spray processes. By mid-century, plasma spray technologies emerged, revolutionizing the industry's capabilities for applying ceramic coatings with enhanced properties.

The evolution of ceramic thermal spray techniques has been driven by increasing demands for superior coating performance in extreme environments. Atmospheric Plasma Spray (APS), developed in the 1960s, represented a significant advancement by enabling the deposition of ceramics with melting points exceeding 3000°C. High Velocity Oxy-Fuel (HVOF) technology, which gained prominence in the 1980s, addressed limitations in coating density and adhesion strength by dramatically increasing particle velocities.

Suspension Plasma Spray (SPS), the most recent major innovation emerging in the early 2000s, has pushed boundaries further by enabling the processing of sub-micron and nano-sized particles, resulting in finer microstructures and enhanced coating properties. This technological progression reflects the industry's continuous pursuit of improved coating quality, efficiency, and application versatility.

Current research objectives in ceramic thermal spray technology focus on several key areas. First, enhancing coating performance characteristics such as wear resistance, thermal insulation, and corrosion protection remains paramount. Second, improving process efficiency and reducing environmental impact through lower energy consumption and waste generation has become increasingly important in response to sustainability concerns.

Another critical objective is expanding the range of applicable materials and substrates, particularly for advanced ceramics with complex compositions. Researchers are also working to develop more precise control over coating microstructure and properties through parameter optimization and in-process monitoring systems. The integration of computational modeling with experimental approaches is accelerating this development by enabling more efficient process parameter optimization.

The ultimate goal of current ceramic thermal spray research is to establish comprehensive understanding of the relationships between process parameters, resulting microstructures, and coating performance across APS, HVOF, and SPS techniques. This knowledge will enable more targeted application-specific coating solutions and facilitate the transition of these technologies into new industrial sectors beyond their traditional aerospace and power generation applications.

The evolution of ceramic thermal spray techniques has been driven by increasing demands for superior coating performance in extreme environments. Atmospheric Plasma Spray (APS), developed in the 1960s, represented a significant advancement by enabling the deposition of ceramics with melting points exceeding 3000°C. High Velocity Oxy-Fuel (HVOF) technology, which gained prominence in the 1980s, addressed limitations in coating density and adhesion strength by dramatically increasing particle velocities.

Suspension Plasma Spray (SPS), the most recent major innovation emerging in the early 2000s, has pushed boundaries further by enabling the processing of sub-micron and nano-sized particles, resulting in finer microstructures and enhanced coating properties. This technological progression reflects the industry's continuous pursuit of improved coating quality, efficiency, and application versatility.

Current research objectives in ceramic thermal spray technology focus on several key areas. First, enhancing coating performance characteristics such as wear resistance, thermal insulation, and corrosion protection remains paramount. Second, improving process efficiency and reducing environmental impact through lower energy consumption and waste generation has become increasingly important in response to sustainability concerns.

Another critical objective is expanding the range of applicable materials and substrates, particularly for advanced ceramics with complex compositions. Researchers are also working to develop more precise control over coating microstructure and properties through parameter optimization and in-process monitoring systems. The integration of computational modeling with experimental approaches is accelerating this development by enabling more efficient process parameter optimization.

The ultimate goal of current ceramic thermal spray research is to establish comprehensive understanding of the relationships between process parameters, resulting microstructures, and coating performance across APS, HVOF, and SPS techniques. This knowledge will enable more targeted application-specific coating solutions and facilitate the transition of these technologies into new industrial sectors beyond their traditional aerospace and power generation applications.

Market Applications and Industry Demand Analysis

The ceramic thermal spray coatings market has experienced significant growth in recent years, driven by increasing demand across multiple industrial sectors. The global thermal spray coatings market was valued at approximately 10.1 billion USD in 2020 and is projected to reach 15.7 billion USD by 2026, with ceramic coatings representing a substantial segment of this market.

Aerospace and aviation industries remain the primary consumers of advanced ceramic thermal spray technologies, particularly APS (Atmospheric Plasma Spray), HVOF (High-Velocity Oxygen Fuel), and SPS (Suspension Plasma Spray). These sectors demand high-performance coatings for turbine blades, combustion chambers, and other critical components operating under extreme thermal conditions. The need for improved fuel efficiency and extended component lifespan continues to drive innovation in this space.

The power generation industry represents another significant market, with thermal barrier coatings becoming essential for gas turbines and other heat-intensive equipment. As global energy demand rises and efficiency standards become more stringent, the adoption of advanced ceramic coatings has accelerated. The transition toward renewable energy sources has also created new applications for specialized ceramic coatings in solar thermal systems and biomass facilities.

Automotive manufacturing has emerged as a rapidly growing application area, particularly for HVOF coatings. The push toward lightweight materials and improved engine efficiency has increased demand for wear-resistant and thermally insulating coatings. Electric vehicle production has further expanded market opportunities, with thermal management becoming a critical factor in battery performance and longevity.

Medical device manufacturing represents a specialized but high-value market segment, particularly for SPS technology. The biocompatibility and precise control offered by SPS coatings make them ideal for orthopedic implants and dental applications. This sector is expected to show the highest compound annual growth rate among all application areas over the next decade.

Regional analysis reveals that North America and Europe currently dominate the market for advanced ceramic thermal spray technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region, particularly China and India, is showing the fastest growth rate as manufacturing capabilities expand and industrial standards evolve. The increasing focus on environmental regulations worldwide has also boosted demand for ceramic coatings as alternatives to traditional chrome plating and other environmentally problematic surface treatments.

Aerospace and aviation industries remain the primary consumers of advanced ceramic thermal spray technologies, particularly APS (Atmospheric Plasma Spray), HVOF (High-Velocity Oxygen Fuel), and SPS (Suspension Plasma Spray). These sectors demand high-performance coatings for turbine blades, combustion chambers, and other critical components operating under extreme thermal conditions. The need for improved fuel efficiency and extended component lifespan continues to drive innovation in this space.

The power generation industry represents another significant market, with thermal barrier coatings becoming essential for gas turbines and other heat-intensive equipment. As global energy demand rises and efficiency standards become more stringent, the adoption of advanced ceramic coatings has accelerated. The transition toward renewable energy sources has also created new applications for specialized ceramic coatings in solar thermal systems and biomass facilities.

Automotive manufacturing has emerged as a rapidly growing application area, particularly for HVOF coatings. The push toward lightweight materials and improved engine efficiency has increased demand for wear-resistant and thermally insulating coatings. Electric vehicle production has further expanded market opportunities, with thermal management becoming a critical factor in battery performance and longevity.

Medical device manufacturing represents a specialized but high-value market segment, particularly for SPS technology. The biocompatibility and precise control offered by SPS coatings make them ideal for orthopedic implants and dental applications. This sector is expected to show the highest compound annual growth rate among all application areas over the next decade.

Regional analysis reveals that North America and Europe currently dominate the market for advanced ceramic thermal spray technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region, particularly China and India, is showing the fastest growth rate as manufacturing capabilities expand and industrial standards evolve. The increasing focus on environmental regulations worldwide has also boosted demand for ceramic coatings as alternatives to traditional chrome plating and other environmentally problematic surface treatments.

Current Capabilities and Technical Limitations

The current state of ceramic thermal spray technologies reveals distinct capabilities and limitations across APS (Atmospheric Plasma Spray), HVOF (High Velocity Oxy-Fuel), and SPS (Suspension Plasma Spray) methods. Each technique demonstrates unique performance characteristics that determine their suitability for specific industrial applications.

APS technology offers excellent versatility in coating various ceramic materials with thicknesses ranging from 50μm to several millimeters. It achieves deposition rates of 1-10 kg/h with moderate particle velocities (100-300 m/s) and high temperatures (10,000-15,000°C). However, APS coatings typically exhibit 10-15% porosity and moderate adhesion strength (20-70 MPa), limiting their performance in extreme mechanical environments.

HVOF demonstrates superior capabilities in producing dense coatings with porosity below 2% and exceptional bond strength (>80 MPa). Operating at lower temperatures (2,500-3,000°C) but higher velocities (400-800 m/s), HVOF excels in applications requiring wear and corrosion resistance. Its primary limitation lies in processing high-melting-point ceramics, as the lower flame temperature may not fully melt certain ceramic materials, restricting its application range.

SPS represents the newest advancement, capable of producing nanostructured coatings with refined microstructures and controlled porosity (5-10%). It processes submicron and nano-sized particles effectively, achieving coating thicknesses from 10-200μm with exceptional uniformity. However, SPS faces significant challenges in industrial scaling, with lower deposition rates (0.1-1 kg/h) and higher operational costs compared to conventional methods.

Cross-cutting limitations affect all three technologies. Process control remains challenging, with coating quality highly dependent on numerous parameters that require precise monitoring and adjustment. Substrate material compatibility issues persist, particularly with temperature-sensitive materials that may deform under thermal spray conditions. Equipment costs present another barrier, with specialized systems requiring investments of $200,000-$1,000,000, plus substantial maintenance expenses.

Reproducibility challenges exist across all techniques, with batch-to-batch variations affecting coating consistency. This becomes particularly problematic in industries requiring stringent quality control, such as aerospace and medical applications. Energy efficiency also remains suboptimal, with significant energy losses during operation contributing to higher operational costs and environmental impact.

Recent advancements have begun addressing these limitations through automated parameter control systems, hybrid spray techniques, and improved feedstock materials. However, substantial technical hurdles remain before these technologies can achieve their full potential across broader industrial applications.

APS technology offers excellent versatility in coating various ceramic materials with thicknesses ranging from 50μm to several millimeters. It achieves deposition rates of 1-10 kg/h with moderate particle velocities (100-300 m/s) and high temperatures (10,000-15,000°C). However, APS coatings typically exhibit 10-15% porosity and moderate adhesion strength (20-70 MPa), limiting their performance in extreme mechanical environments.

HVOF demonstrates superior capabilities in producing dense coatings with porosity below 2% and exceptional bond strength (>80 MPa). Operating at lower temperatures (2,500-3,000°C) but higher velocities (400-800 m/s), HVOF excels in applications requiring wear and corrosion resistance. Its primary limitation lies in processing high-melting-point ceramics, as the lower flame temperature may not fully melt certain ceramic materials, restricting its application range.

SPS represents the newest advancement, capable of producing nanostructured coatings with refined microstructures and controlled porosity (5-10%). It processes submicron and nano-sized particles effectively, achieving coating thicknesses from 10-200μm with exceptional uniformity. However, SPS faces significant challenges in industrial scaling, with lower deposition rates (0.1-1 kg/h) and higher operational costs compared to conventional methods.

Cross-cutting limitations affect all three technologies. Process control remains challenging, with coating quality highly dependent on numerous parameters that require precise monitoring and adjustment. Substrate material compatibility issues persist, particularly with temperature-sensitive materials that may deform under thermal spray conditions. Equipment costs present another barrier, with specialized systems requiring investments of $200,000-$1,000,000, plus substantial maintenance expenses.

Reproducibility challenges exist across all techniques, with batch-to-batch variations affecting coating consistency. This becomes particularly problematic in industries requiring stringent quality control, such as aerospace and medical applications. Energy efficiency also remains suboptimal, with significant energy losses during operation contributing to higher operational costs and environmental impact.

Recent advancements have begun addressing these limitations through automated parameter control systems, hybrid spray techniques, and improved feedstock materials. However, substantial technical hurdles remain before these technologies can achieve their full potential across broader industrial applications.

Comparative Analysis of APS, HVOF, and SPS Techniques

01 Atmospheric Plasma Spray (APS) Techniques

Atmospheric Plasma Spray (APS) is a thermal spray technique used for applying ceramic coatings. In this process, ceramic powder is injected into a high-temperature plasma jet, where it melts and is propelled toward a substrate. The molten particles flatten upon impact and solidify to form a coating. APS is particularly effective for creating thermal barrier coatings with good adhesion and controlled porosity, making it suitable for applications requiring thermal insulation and wear resistance.- Atmospheric Plasma Spray (APS) Techniques: Atmospheric Plasma Spray is a thermal spray technique used for applying ceramic coatings at atmospheric pressure. The process involves injecting ceramic powder into a high-temperature plasma jet, which melts the particles and propels them toward the substrate. APS is widely used for thermal barrier coatings, wear-resistant surfaces, and electrical insulation applications. The technique allows for relatively thick coatings with good adhesion properties and can be applied to various substrate materials.

- High Velocity Oxy-Fuel (HVOF) Spray Technology: HVOF is a thermal spray process that uses a combination of oxygen and fuel to create a high-velocity gas stream that accelerates ceramic particles toward the substrate. This technique produces dense coatings with low porosity and excellent bond strength due to the high kinetic energy of the particles. HVOF ceramic coatings exhibit superior wear resistance, corrosion protection, and thermal properties compared to conventional spray methods. The process is particularly suitable for applying carbide and oxide ceramic materials where mechanical properties are critical.

- Suspension Plasma Spray (SPS) Methods: Suspension Plasma Spray is an advanced thermal spray technique that uses liquid suspensions containing fine ceramic particles instead of dry powder. This method allows for the deposition of nanostructured or finely structured ceramic coatings with unique properties. SPS produces coatings with enhanced thermal insulation, improved strain tolerance, and better surface finish compared to conventional thermal spray methods. The technique enables the creation of thin, columnar microstructures that are beneficial for thermal barrier applications in high-temperature environments.

- Ceramic Coating Composition and Microstructure Control: The composition and microstructure of ceramic thermal spray coatings can be controlled through various processing parameters and material selections. By adjusting spray parameters, feedstock characteristics, and post-treatment processes, specific coating properties can be achieved. Techniques include layered structures, composite materials, and gradient compositions to optimize performance for specific applications. Control of porosity, crack networks, and phase distribution in ceramic coatings is essential for achieving desired thermal, mechanical, and chemical properties in harsh operating environments.

- Novel Applications and Advancements in Ceramic Thermal Spray: Recent advancements in ceramic thermal spray technologies have expanded their applications across various industries. Innovations include specialized coatings for extreme environments, biocompatible ceramic surfaces for medical implants, and functional ceramic layers for energy applications. New developments focus on improving coating durability, reducing process costs, and enhancing environmental sustainability. Hybrid approaches combining different thermal spray techniques or integrating with other coating methods are emerging to create multifunctional ceramic surfaces with superior performance characteristics.

02 High Velocity Oxy-Fuel (HVOF) Spray Technology

High Velocity Oxy-Fuel (HVOF) spray is a thermal spray process where fuel and oxygen combust to produce a high-velocity gas stream that accelerates ceramic particles toward a substrate. The high kinetic energy of the particles results in dense, well-bonded coatings with low porosity and high hardness. HVOF ceramic coatings exhibit excellent wear resistance, corrosion protection, and thermal properties, making them ideal for components in harsh environments such as turbine parts, valves, and industrial equipment.Expand Specific Solutions03 Suspension Plasma Spray (SPS) Methods

Suspension Plasma Spray (SPS) is an advanced thermal spray technique that uses liquid suspensions containing fine ceramic particles instead of dry powders. This method allows for the deposition of nanostructured or finely structured ceramic coatings with enhanced properties. The suspension is injected into a plasma jet where the liquid carrier evaporates, and the ceramic particles melt before impacting the substrate. SPS coatings typically feature improved thermal insulation, better strain tolerance, and unique microstructures compared to conventional spray methods.Expand Specific Solutions04 Ceramic Coating Compositions and Materials

Various ceramic materials can be applied using thermal spray techniques to achieve specific properties. Common materials include zirconia, alumina, titania, and their composites, often stabilized with additives like yttria. The composition of the ceramic material significantly influences the coating's performance characteristics such as thermal conductivity, wear resistance, and durability. Advanced ceramic formulations may incorporate rare earth elements or specialized dopants to enhance specific properties like thermal shock resistance or electrical insulation capabilities.Expand Specific Solutions05 Process Parameters and Optimization

The performance of ceramic thermal spray coatings is highly dependent on process parameters such as spray distance, gas flow rates, powder feed rate, and substrate temperature. Optimizing these parameters is crucial for achieving desired coating properties including adhesion strength, porosity, thickness uniformity, and microstructure. Advanced monitoring and control systems can be employed to maintain consistent coating quality. Pre-treatment of substrates and post-spray heat treatments are also important factors that influence the final coating performance and durability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Ceramic thermal spray techniques (APS, HVOF, SPS) are currently in a growth phase, with the global thermal spray coatings market expanding at approximately 6-7% CAGR. The market size is estimated at $10-12 billion, driven by increasing demand in aerospace, automotive, and industrial applications. Technologically, these methods show varying maturity levels: APS (Atmospheric Plasma Spray) is well-established with widespread industrial adoption by companies like Oerlikon Metco, Siemens, and Praxair; HVOF (High-Velocity Oxy-Fuel) has reached commercial maturity with RTX, Safran, and MTU Aero Engines leading implementation; while SPS (Solution Plasma Spray) remains in early commercialization stages with INFRAMAT and research institutions like Forschungszentrum Jülich pioneering development. The competitive landscape features established industrial players alongside specialized coating technology providers and research institutions advancing next-generation applications.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair Surface Technologies (now part of Linde plc) has developed extensive ceramic thermal spray capabilities comparing APS, HVOF, and SPS technologies across multiple industrial applications. Their APS systems utilize SG-100 and F4 plasma guns operating at power levels of 30-80 kW, producing ceramic coatings with controlled microstructures featuring porosity levels of 5-15% depending on application requirements. Their HVOF technology employs JP-5000 and DJ-2600 systems with kerosene or hydrogen fuel, achieving particle velocities of 600-800 m/s while maintaining temperatures suitable for partially melting ceramic materials without significant decomposition, resulting in dense coatings with porosity below 2% and bond strength values exceeding 70 MPa. Praxair's SPS development has focused on creating fine-structured ceramic coatings using suspensions with solid content of 20-35 wt% and particle sizes of 0.5-5 μm, enabling the creation of coatings with unique microstructures featuring either high density or controlled columnar structures depending on process parameters. Their comparative analysis demonstrates that while APS offers the most versatile and cost-effective solution for standard ceramic applications, HVOF provides superior wear and corrosion resistance for demanding environments, and SPS enables specialized microstructures for thermal management and catalytic applications.

Strengths: Comprehensive materials portfolio with proprietary powder and suspension formulations optimized for each spray technology. Their global service network provides technical support and application development capabilities across diverse industries. Weaknesses: Following merger with Linde, some technology development initiatives were reorganized, potentially affecting innovation continuity. Their SPS technology remains at a higher cost point compared to conventional thermal spray methods, limiting widespread industrial adoption.

Sulzer-Metco

Technical Solution: Sulzer-Metco (now part of Oerlikon following acquisition) pioneered comparative research between APS, HVOF, and SPS ceramic coating technologies. Their APS systems operate with dual-cathode plasma guns generating stable plasma jets with power levels of 80-120 kW, achieving deposition rates of 150-200 g/min for ceramic materials. Their HVOF technology utilizes a proprietary Diamond Jet system with hydrogen or natural gas fuel, producing particle velocities of 600-800 m/s while maintaining temperatures suitable for partially melting ceramic materials without decomposition. Their SPS development focused on fine-structured coatings using suspensions with solid content of 25-40 wt%, enabling the creation of segmented coatings with columnar structures having thermal conductivity values 30-40% lower than conventional APS coatings. Their comparative studies demonstrated that while APS produces coatings with 10-15% porosity suitable for thermal barriers, HVOF ceramic coatings exhibit superior erosion resistance (3-5x better than APS) but limited thickness capability (typically <500 μm), and SPS offers superior strain tolerance with controlled vertical crack networks.

Strengths: Extensive historical expertise in thermal spray technology development with comprehensive material-process relationship understanding. Their systems feature advanced diagnostic capabilities for real-time process monitoring and quality control. Weaknesses: Following acquisition by Oerlikon, some technology development initiatives were consolidated, potentially reducing independent innovation paths. Their HVOF ceramic solutions remain limited in maximum achievable thickness compared to APS alternatives.

Critical Patents and Scientific Breakthroughs

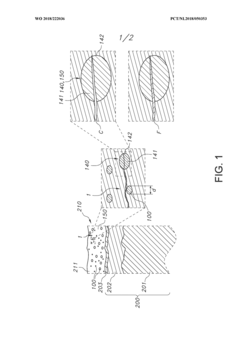

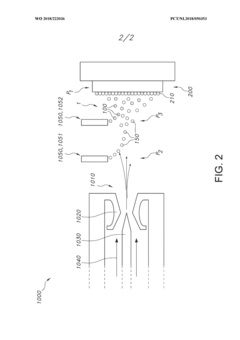

Self-healing particles for high temperature ceramics

PatentWO2018222036A1

Innovation

- A particulate material comprising molybdenum silicide (MoSi2) with alloyed aluminum and boron, forming a core-shell structure, where the molybdenum silicide core and alumina shell provide self-healing properties by forming silica to fill cracks, thereby enhancing the durability of high-temperature ceramic coatings.

Material-Process Compatibility Assessment

The compatibility between ceramic materials and thermal spray processes is a critical factor determining coating quality and performance. For atmospheric plasma spray (APS), materials with high melting points such as alumina (Al2O3), zirconia (ZrO2), and yttria-stabilized zirconia (YSZ) demonstrate excellent compatibility due to the process's high temperature capability (10,000-15,000°C). These materials achieve optimal melting states during spraying, resulting in well-formed splats and cohesive coatings with porosity typically ranging from 5-15%.

High-velocity oxy-fuel (HVOF) spray exhibits superior compatibility with cermet materials like chromium carbide (Cr3C2) and tungsten carbide (WC) with metallic binders. The moderate temperature (2,500-3,000°C) combined with supersonic particle velocities (>800 m/s) creates dense coatings with minimal decomposition of carbide phases. However, pure ceramics with very high melting points often achieve only partial melting in HVOF, leading to increased porosity and reduced inter-splat bonding.

Suspension plasma spray (SPS) demonstrates exceptional compatibility with nano-structured ceramics and complex oxide compositions. The ability to process sub-micron and nano-sized particles enables the creation of finely structured coatings with columnar morphologies or dense structures depending on spray parameters. Materials like gadolinium zirconate (Gd2Zr2O7), lanthanum zirconate (La2Zr2O7), and hydroxyapatite show excellent compatibility with SPS.

Material feedstock preparation requirements vary significantly between processes. APS utilizes conventional powder sizes (10-100 μm), while SPS requires stable suspensions with optimized solid loading (typically 20-30 wt%) and appropriate dispersants to prevent agglomeration. HVOF demands flowable powders with controlled size distributions (typically 5-45 μm) to achieve consistent feeding and optimal in-flight particle behavior.

Process-specific limitations include thermal decomposition of temperature-sensitive ceramics in APS, incomplete melting of high-temperature ceramics in HVOF, and challenges in suspension stability and feeding consistency for SPS. Material-process compatibility must also consider thermal expansion coefficient matching between substrate and coating materials to minimize residual stress development during cooling.

The selection of optimal spray technique for specific ceramic materials should be guided by comprehensive compatibility assessment, considering not only melting behavior but also phase stability, oxidation resistance, and final microstructural requirements for the intended application environment.

High-velocity oxy-fuel (HVOF) spray exhibits superior compatibility with cermet materials like chromium carbide (Cr3C2) and tungsten carbide (WC) with metallic binders. The moderate temperature (2,500-3,000°C) combined with supersonic particle velocities (>800 m/s) creates dense coatings with minimal decomposition of carbide phases. However, pure ceramics with very high melting points often achieve only partial melting in HVOF, leading to increased porosity and reduced inter-splat bonding.

Suspension plasma spray (SPS) demonstrates exceptional compatibility with nano-structured ceramics and complex oxide compositions. The ability to process sub-micron and nano-sized particles enables the creation of finely structured coatings with columnar morphologies or dense structures depending on spray parameters. Materials like gadolinium zirconate (Gd2Zr2O7), lanthanum zirconate (La2Zr2O7), and hydroxyapatite show excellent compatibility with SPS.

Material feedstock preparation requirements vary significantly between processes. APS utilizes conventional powder sizes (10-100 μm), while SPS requires stable suspensions with optimized solid loading (typically 20-30 wt%) and appropriate dispersants to prevent agglomeration. HVOF demands flowable powders with controlled size distributions (typically 5-45 μm) to achieve consistent feeding and optimal in-flight particle behavior.

Process-specific limitations include thermal decomposition of temperature-sensitive ceramics in APS, incomplete melting of high-temperature ceramics in HVOF, and challenges in suspension stability and feeding consistency for SPS. Material-process compatibility must also consider thermal expansion coefficient matching between substrate and coating materials to minimize residual stress development during cooling.

The selection of optimal spray technique for specific ceramic materials should be guided by comprehensive compatibility assessment, considering not only melting behavior but also phase stability, oxidation resistance, and final microstructural requirements for the intended application environment.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal spray coating processes has become increasingly important as industries strive for more sustainable manufacturing practices. When comparing APS (Atmospheric Plasma Spray), HVOF (High Velocity Oxy-Fuel), and SPS (Suspension Plasma Spray) techniques, several environmental factors must be considered to make informed decisions about their implementation.

Energy consumption varies significantly among these techniques. APS typically requires high power inputs (40-80 kW) to generate the plasma jet, resulting in substantial energy consumption. HVOF, while operating at lower electrical power, utilizes combustible gases that contribute to its overall energy footprint. SPS generally demonstrates improved energy efficiency compared to conventional APS due to its ability to process finer particles with optimized parameters, potentially reducing the total energy required per coated area.

Emissions and air quality impacts differ across these technologies. APS produces nitrogen oxides (NOx) due to high-temperature plasma interaction with atmospheric air. HVOF combustion processes generate carbon dioxide (CO2) and carbon monoxide (CO), contributing to greenhouse gas emissions. Both techniques may release metal and ceramic particulates that require filtration systems. SPS typically produces fewer particulate emissions due to its use of liquid feedstock rather than dry powder, reducing airborne contamination risks.

Material utilization efficiency represents another critical environmental consideration. Traditional APS may have deposition efficiencies of 40-60%, meaning significant material waste. HVOF generally achieves higher deposition efficiencies (60-70%), reducing material waste. SPS can achieve comparable or better material utilization than conventional methods when properly optimized, particularly for nanomaterial applications.

Water consumption and waste generation also vary. SPS requires water or organic solvents for suspension preparation, creating potential liquid waste streams that require treatment. APS and HVOF typically use less water directly in the process but may require water for cooling systems.

Recent sustainability advancements include closed-loop water recycling systems for SPS processes, improved filtration technologies for all three methods, and energy recovery systems that capture and repurpose waste heat. Some manufacturers have implemented renewable energy sources to power these energy-intensive processes, further reducing their carbon footprint.

Life cycle assessment studies indicate that despite higher initial environmental impacts during manufacturing, thermal spray coatings often provide net environmental benefits through extended component lifespans, reduced maintenance requirements, and improved operational efficiencies in the coated parts' applications.

Energy consumption varies significantly among these techniques. APS typically requires high power inputs (40-80 kW) to generate the plasma jet, resulting in substantial energy consumption. HVOF, while operating at lower electrical power, utilizes combustible gases that contribute to its overall energy footprint. SPS generally demonstrates improved energy efficiency compared to conventional APS due to its ability to process finer particles with optimized parameters, potentially reducing the total energy required per coated area.

Emissions and air quality impacts differ across these technologies. APS produces nitrogen oxides (NOx) due to high-temperature plasma interaction with atmospheric air. HVOF combustion processes generate carbon dioxide (CO2) and carbon monoxide (CO), contributing to greenhouse gas emissions. Both techniques may release metal and ceramic particulates that require filtration systems. SPS typically produces fewer particulate emissions due to its use of liquid feedstock rather than dry powder, reducing airborne contamination risks.

Material utilization efficiency represents another critical environmental consideration. Traditional APS may have deposition efficiencies of 40-60%, meaning significant material waste. HVOF generally achieves higher deposition efficiencies (60-70%), reducing material waste. SPS can achieve comparable or better material utilization than conventional methods when properly optimized, particularly for nanomaterial applications.

Water consumption and waste generation also vary. SPS requires water or organic solvents for suspension preparation, creating potential liquid waste streams that require treatment. APS and HVOF typically use less water directly in the process but may require water for cooling systems.

Recent sustainability advancements include closed-loop water recycling systems for SPS processes, improved filtration technologies for all three methods, and energy recovery systems that capture and repurpose waste heat. Some manufacturers have implemented renewable energy sources to power these energy-intensive processes, further reducing their carbon footprint.

Life cycle assessment studies indicate that despite higher initial environmental impacts during manufacturing, thermal spray coatings often provide net environmental benefits through extended component lifespans, reduced maintenance requirements, and improved operational efficiencies in the coated parts' applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!