Thermal Conductivity Optimization in Ceramic Coatings

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Coating Thermal Properties Evolution

The evolution of thermal properties in ceramic coatings represents a fascinating journey through materials science and engineering. Initially developed primarily for their chemical resistance and hardness, ceramic coatings have undergone significant transformation in thermal property optimization over the past five decades. The earliest applications focused on simple thermal barriers with limited conductivity control, primarily using aluminum oxide and zirconia-based materials.

During the 1980s, the introduction of plasma-sprayed yttria-stabilized zirconia (YSZ) marked a pivotal advancement, establishing the foundation for modern thermal barrier coatings (TBCs) with controlled thermal conductivity. This period saw thermal conductivity values decrease from approximately 2.0-2.5 W/m·K to 1.0-1.5 W/m·K, enabling new applications in aerospace and power generation.

The 1990s witnessed the emergence of structured ceramic coatings with engineered porosity and layered architectures. Researchers discovered that deliberately introducing specific pore structures could reduce thermal conductivity by up to 50% compared to conventional dense coatings. This era also saw the development of the first computational models for predicting thermal behavior in complex ceramic microstructures.

By the early 2000s, nanostructured ceramic coatings began to dominate research efforts. The incorporation of nanoscale features and interfaces created unprecedented phonon scattering effects, pushing thermal conductivity values below 0.8 W/m·K while maintaining mechanical integrity. Rare earth zirconates and hafnates emerged as promising alternatives to traditional YSZ, offering superior phase stability at extreme temperatures.

The past decade has seen remarkable innovation in functionally graded ceramic coatings that feature continuously varying composition and microstructure. These advanced systems can achieve thermal conductivity gradients that optimize heat flow management across different operating conditions. Additionally, the incorporation of MAX phases and MXenes has opened new possibilities for coatings with tunable thermal properties.

Most recently, machine learning approaches have accelerated the discovery of novel ceramic compositions with unprecedented thermal performance. These computational methods have identified counterintuitive material combinations that experimental approaches might have overlooked, leading to ceramic coatings with thermal conductivities approaching the theoretical minimum limits for solid materials.

The evolution continues with current research focusing on self-healing ceramic coatings that can maintain optimal thermal properties throughout their service life, even after exposure to thermal cycling and mechanical damage. This represents a significant shift from static thermal property optimization to dynamic, responsive thermal management systems.

During the 1980s, the introduction of plasma-sprayed yttria-stabilized zirconia (YSZ) marked a pivotal advancement, establishing the foundation for modern thermal barrier coatings (TBCs) with controlled thermal conductivity. This period saw thermal conductivity values decrease from approximately 2.0-2.5 W/m·K to 1.0-1.5 W/m·K, enabling new applications in aerospace and power generation.

The 1990s witnessed the emergence of structured ceramic coatings with engineered porosity and layered architectures. Researchers discovered that deliberately introducing specific pore structures could reduce thermal conductivity by up to 50% compared to conventional dense coatings. This era also saw the development of the first computational models for predicting thermal behavior in complex ceramic microstructures.

By the early 2000s, nanostructured ceramic coatings began to dominate research efforts. The incorporation of nanoscale features and interfaces created unprecedented phonon scattering effects, pushing thermal conductivity values below 0.8 W/m·K while maintaining mechanical integrity. Rare earth zirconates and hafnates emerged as promising alternatives to traditional YSZ, offering superior phase stability at extreme temperatures.

The past decade has seen remarkable innovation in functionally graded ceramic coatings that feature continuously varying composition and microstructure. These advanced systems can achieve thermal conductivity gradients that optimize heat flow management across different operating conditions. Additionally, the incorporation of MAX phases and MXenes has opened new possibilities for coatings with tunable thermal properties.

Most recently, machine learning approaches have accelerated the discovery of novel ceramic compositions with unprecedented thermal performance. These computational methods have identified counterintuitive material combinations that experimental approaches might have overlooked, leading to ceramic coatings with thermal conductivities approaching the theoretical minimum limits for solid materials.

The evolution continues with current research focusing on self-healing ceramic coatings that can maintain optimal thermal properties throughout their service life, even after exposure to thermal cycling and mechanical damage. This represents a significant shift from static thermal property optimization to dynamic, responsive thermal management systems.

Market Applications for Thermally Optimized Ceramics

The aerospace industry represents one of the most significant markets for thermally optimized ceramic coatings, with applications in jet engines, rocket nozzles, and thermal protection systems for spacecraft. These environments demand materials that can withstand extreme temperatures while maintaining structural integrity. The global aerospace thermal management market is projected to reach $9.4 billion by 2026, with ceramic thermal barrier coatings constituting a substantial segment of this growth.

Power generation, particularly gas turbines, forms another crucial application area. Advanced ceramic coatings with optimized thermal conductivity enable higher operating temperatures in turbine engines, directly translating to improved efficiency and reduced emissions. The energy sector's transition toward cleaner technologies has accelerated demand for these materials, with the gas turbine market expected to grow at 4.8% annually through 2028.

The automotive industry has increasingly adopted thermally optimized ceramics for exhaust systems, cylinder linings, and brake components. These applications leverage ceramics' ability to manage heat while reducing vehicle weight. With the electric vehicle revolution, new applications are emerging in battery thermal management systems where precise control of heat dissipation is critical for safety and performance.

Electronics cooling represents a rapidly expanding market as device miniaturization continues to increase power densities. Thermally conductive ceramic substrates and packages help manage heat in high-performance computing, power electronics, and LED lighting. This segment is experiencing particularly strong growth in Asia-Pacific markets, driven by the semiconductor and consumer electronics industries.

Industrial manufacturing processes that involve extreme temperatures—such as metal casting, glass production, and cement manufacturing—benefit significantly from thermally optimized ceramic linings and components. These materials extend equipment life and improve energy efficiency, with the global industrial thermal management market valued at approximately $3.7 billion.

The medical device industry has found specialized applications for thermally optimized ceramics in surgical tools, implantable devices, and diagnostic equipment. These materials' biocompatibility combined with their thermal properties makes them ideal for applications requiring precise thermal control in biological environments.

Defense applications include thermal protection for missile systems, radar components, and armor systems where thermal shock resistance is critical. This sector's demand for advanced ceramics is driven by the need for materials that perform reliably under extreme conditions while meeting increasingly stringent performance requirements.

Power generation, particularly gas turbines, forms another crucial application area. Advanced ceramic coatings with optimized thermal conductivity enable higher operating temperatures in turbine engines, directly translating to improved efficiency and reduced emissions. The energy sector's transition toward cleaner technologies has accelerated demand for these materials, with the gas turbine market expected to grow at 4.8% annually through 2028.

The automotive industry has increasingly adopted thermally optimized ceramics for exhaust systems, cylinder linings, and brake components. These applications leverage ceramics' ability to manage heat while reducing vehicle weight. With the electric vehicle revolution, new applications are emerging in battery thermal management systems where precise control of heat dissipation is critical for safety and performance.

Electronics cooling represents a rapidly expanding market as device miniaturization continues to increase power densities. Thermally conductive ceramic substrates and packages help manage heat in high-performance computing, power electronics, and LED lighting. This segment is experiencing particularly strong growth in Asia-Pacific markets, driven by the semiconductor and consumer electronics industries.

Industrial manufacturing processes that involve extreme temperatures—such as metal casting, glass production, and cement manufacturing—benefit significantly from thermally optimized ceramic linings and components. These materials extend equipment life and improve energy efficiency, with the global industrial thermal management market valued at approximately $3.7 billion.

The medical device industry has found specialized applications for thermally optimized ceramics in surgical tools, implantable devices, and diagnostic equipment. These materials' biocompatibility combined with their thermal properties makes them ideal for applications requiring precise thermal control in biological environments.

Defense applications include thermal protection for missile systems, radar components, and armor systems where thermal shock resistance is critical. This sector's demand for advanced ceramics is driven by the need for materials that perform reliably under extreme conditions while meeting increasingly stringent performance requirements.

Current Limitations in Ceramic Thermal Conductivity

Despite significant advancements in ceramic coating technologies, several critical limitations persist in achieving optimal thermal conductivity performance. Current ceramic thermal barrier coatings (TBCs) typically exhibit thermal conductivity values ranging from 1-2 W/m·K, which remains insufficient for extreme high-temperature applications exceeding 1400°C. This limitation primarily stems from the inherent microstructural characteristics of conventional ceramic materials.

Porosity control represents a major challenge in ceramic coating development. While porosity effectively reduces thermal conductivity, excessive porosity compromises mechanical integrity and erosion resistance. Current manufacturing processes struggle to achieve the ideal balance between thermal insulation properties and structural stability, particularly in applications subject to thermal cycling and mechanical stress.

Phase stability at elevated temperatures presents another significant limitation. Many ceramic compositions undergo phase transformations when exposed to extreme thermal conditions, resulting in volume changes that induce internal stresses and potential coating failure. For instance, yttria-stabilized zirconia (YSZ), the industry standard, experiences phase destabilization above 1200°C, limiting its application in next-generation turbine engines and hypersonic vehicles.

Interface thermal resistance management remains problematic in multilayer ceramic coating systems. Current bonding techniques create imperfect interfaces that contribute to thermal barrier degradation over time. The coefficient of thermal expansion mismatch between ceramic layers and metallic substrates generates interfacial stresses during thermal cycling, leading to delamination and spallation failures that compromise thermal conductivity performance.

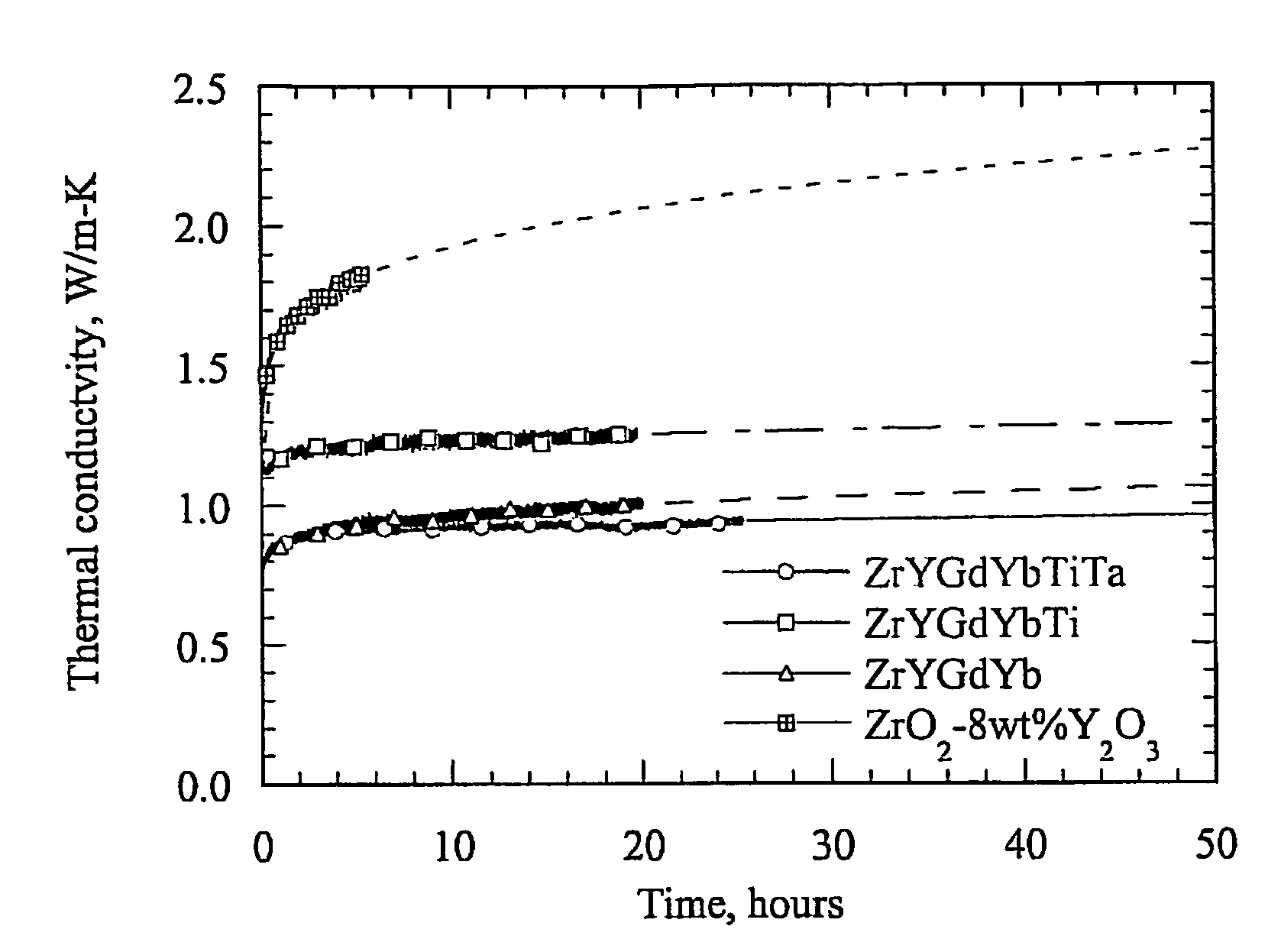

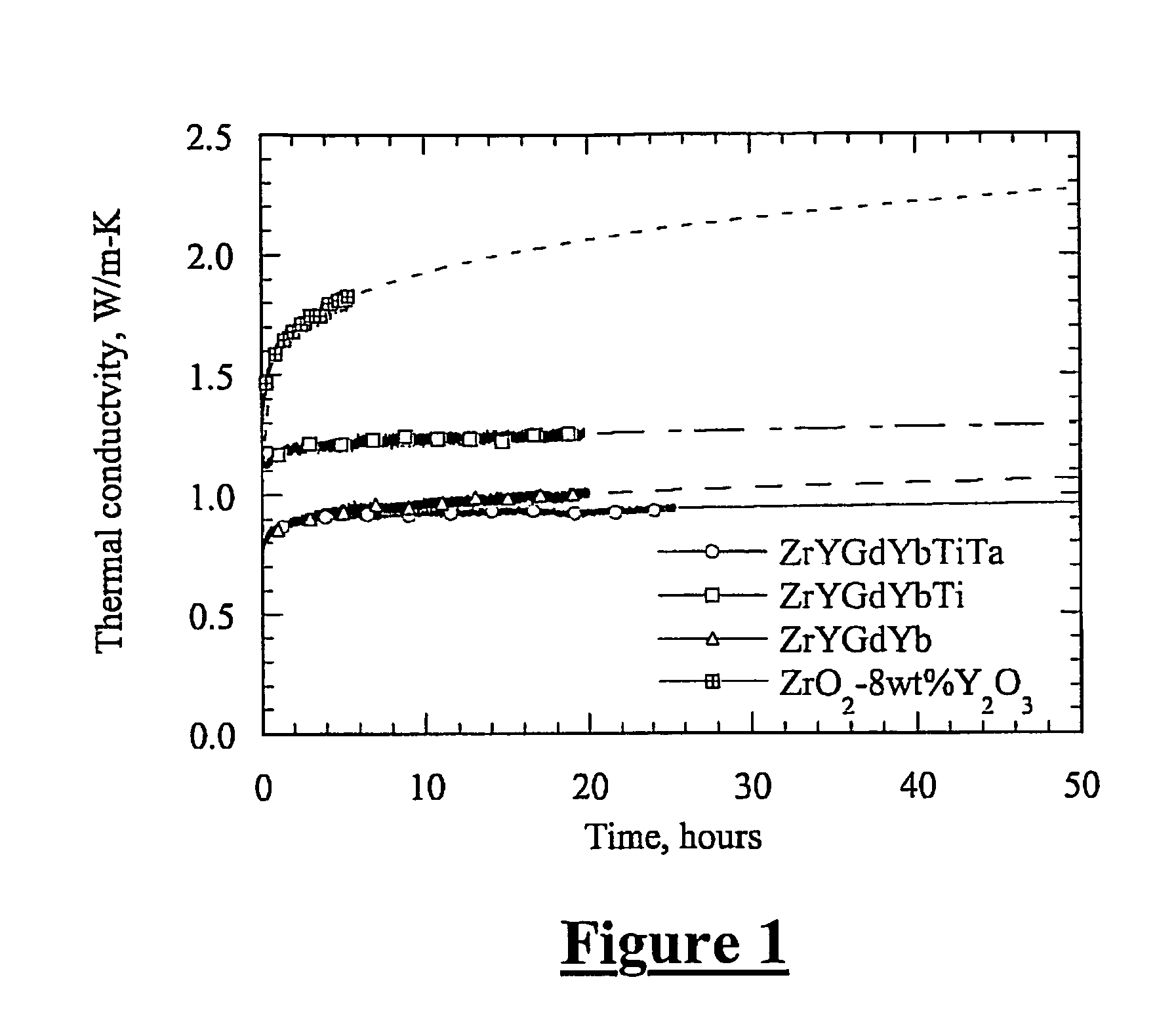

Sintering effects at high temperatures constitute another limitation. Extended exposure to elevated temperatures causes densification of the ceramic microstructure, gradually eliminating the beneficial porous network that provides thermal insulation. This sintering effect increases thermal conductivity over time, reducing the coating's effectiveness and operational lifespan.

Manufacturing consistency presents ongoing challenges. Current deposition methods, including plasma spraying and electron beam physical vapor deposition (EB-PVD), struggle to produce uniform microstructures across complex geometries. This inconsistency results in variable thermal conductivity properties within the same component, creating localized hotspots and thermal management issues.

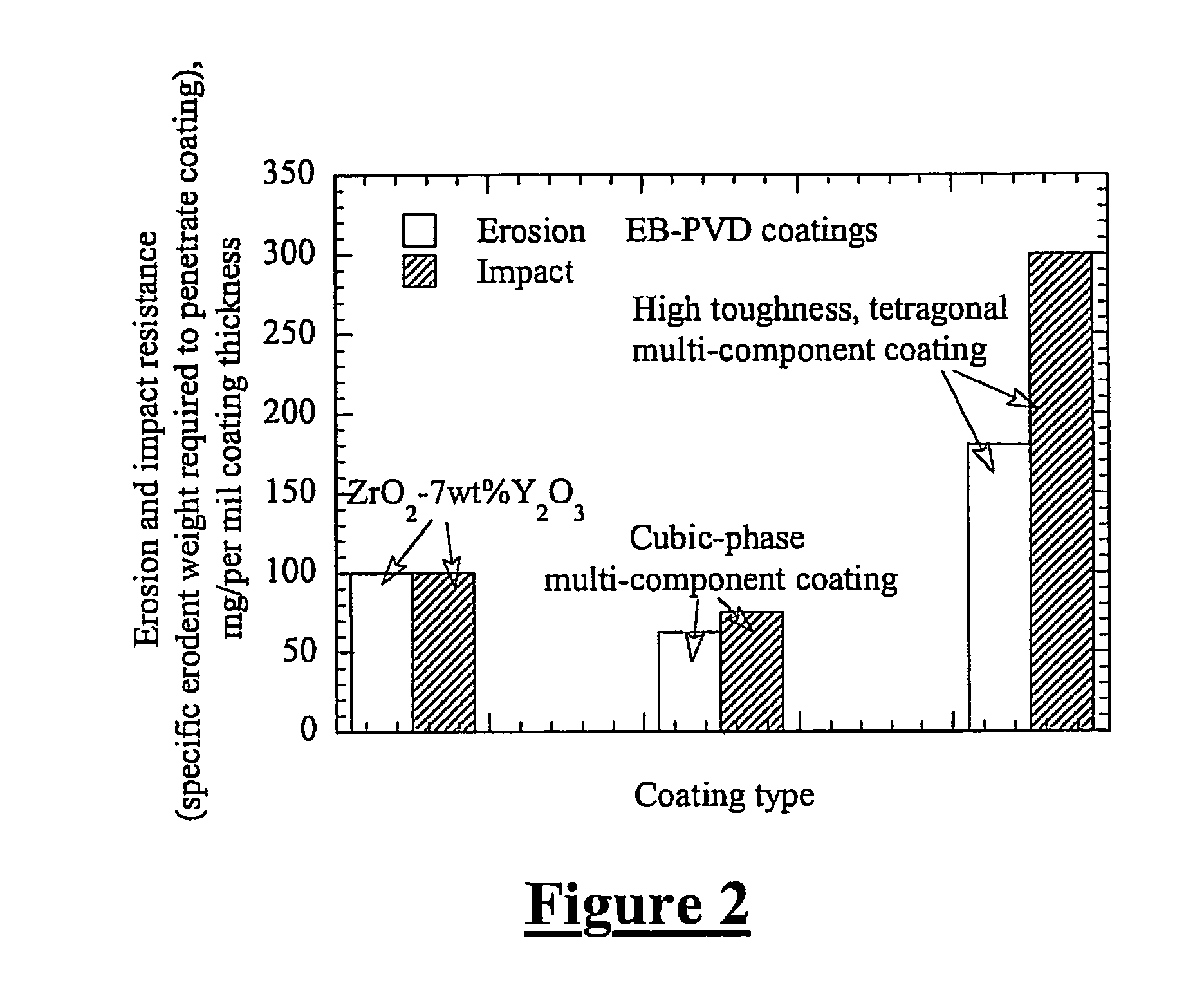

Additionally, the trade-off between thermal conductivity and other essential properties remains unresolved. Enhancing thermal insulation often comes at the expense of erosion resistance, mechanical strength, or chemical stability. Current ceramic formulations have not successfully overcome this fundamental materials science challenge, limiting their application in demanding operational environments.

Porosity control represents a major challenge in ceramic coating development. While porosity effectively reduces thermal conductivity, excessive porosity compromises mechanical integrity and erosion resistance. Current manufacturing processes struggle to achieve the ideal balance between thermal insulation properties and structural stability, particularly in applications subject to thermal cycling and mechanical stress.

Phase stability at elevated temperatures presents another significant limitation. Many ceramic compositions undergo phase transformations when exposed to extreme thermal conditions, resulting in volume changes that induce internal stresses and potential coating failure. For instance, yttria-stabilized zirconia (YSZ), the industry standard, experiences phase destabilization above 1200°C, limiting its application in next-generation turbine engines and hypersonic vehicles.

Interface thermal resistance management remains problematic in multilayer ceramic coating systems. Current bonding techniques create imperfect interfaces that contribute to thermal barrier degradation over time. The coefficient of thermal expansion mismatch between ceramic layers and metallic substrates generates interfacial stresses during thermal cycling, leading to delamination and spallation failures that compromise thermal conductivity performance.

Sintering effects at high temperatures constitute another limitation. Extended exposure to elevated temperatures causes densification of the ceramic microstructure, gradually eliminating the beneficial porous network that provides thermal insulation. This sintering effect increases thermal conductivity over time, reducing the coating's effectiveness and operational lifespan.

Manufacturing consistency presents ongoing challenges. Current deposition methods, including plasma spraying and electron beam physical vapor deposition (EB-PVD), struggle to produce uniform microstructures across complex geometries. This inconsistency results in variable thermal conductivity properties within the same component, creating localized hotspots and thermal management issues.

Additionally, the trade-off between thermal conductivity and other essential properties remains unresolved. Enhancing thermal insulation often comes at the expense of erosion resistance, mechanical strength, or chemical stability. Current ceramic formulations have not successfully overcome this fundamental materials science challenge, limiting their application in demanding operational environments.

State-of-the-Art Thermal Optimization Techniques

01 Ceramic coating compositions for thermal conductivity enhancement

Specific ceramic coating compositions can be formulated to enhance thermal conductivity properties. These compositions typically include materials such as aluminum oxide, zirconium oxide, or silicon carbide, which have inherently high thermal conductivity. The addition of certain dopants or the control of particle size distribution within these compositions can further optimize thermal transfer properties while maintaining structural integrity of the coating.- Ceramic coating compositions for thermal conductivity enhancement: Specific ceramic coating compositions can be formulated to enhance thermal conductivity properties. These compositions typically include materials such as aluminum oxide, zirconium oxide, or silicon carbide, which possess inherently high thermal conductivity characteristics. By carefully selecting and combining these ceramic materials in appropriate ratios, coatings can be developed that efficiently transfer heat while maintaining other desirable properties such as wear resistance and chemical stability.

- Multilayer ceramic coating systems for thermal management: Multilayer ceramic coating systems can be designed to optimize thermal conductivity while providing additional functional benefits. These systems typically consist of different ceramic layers with complementary properties - for example, a high thermal conductivity base layer combined with a thermal barrier top layer. The strategic arrangement of these layers allows for controlled heat transfer, making such systems particularly valuable in applications requiring precise thermal management such as gas turbine components or electronic substrates.

- Ceramic matrix composites with enhanced thermal properties: Ceramic matrix composites incorporate reinforcing elements within a ceramic matrix to enhance thermal conductivity. These composites typically combine ceramic materials with additives such as carbon nanotubes, graphene, or metallic particles that create thermal conduction pathways. The resulting materials exhibit significantly improved heat transfer capabilities while maintaining the characteristic high-temperature stability of ceramics, making them suitable for extreme thermal environments in aerospace, automotive, and industrial applications.

- Processing techniques for controlling thermal conductivity in ceramic coatings: Various processing techniques can be employed to control and enhance the thermal conductivity of ceramic coatings. Methods such as plasma spraying, chemical vapor deposition, sol-gel processing, and sintering can significantly influence the microstructure, porosity, and grain boundaries of ceramic coatings. By optimizing these processing parameters, manufacturers can create coatings with tailored thermal conductivity properties, ranging from highly conductive to thermally insulating, depending on the specific application requirements.

- Novel ceramic coating materials for specialized thermal applications: Novel ceramic materials and compositions are being developed specifically for applications requiring specialized thermal conductivity properties. These include rare-earth doped ceramics, perovskite structures, and advanced ceramic-metal (cermet) composites. Such materials can be engineered to exhibit unique thermal behaviors, including anisotropic thermal conductivity, temperature-dependent conductivity, or enhanced stability under thermal cycling. These innovations enable ceramic coatings to meet the demanding thermal management requirements of emerging technologies in electronics, energy generation, and aerospace sectors.

02 Multilayer ceramic coating systems for thermal management

Multilayer ceramic coating systems can be designed with varying compositions in each layer to create thermal conductivity gradients. These systems typically feature a high thermal conductivity layer adjacent to the substrate for efficient heat transfer, combined with outer layers that may prioritize other properties such as wear resistance or environmental protection. The interfaces between layers can be engineered to minimize thermal resistance while maintaining strong adhesion.Expand Specific Solutions03 Ceramic coatings with embedded conductive materials

Incorporating thermally conductive materials such as metal particles, carbon nanotubes, or graphene into ceramic matrices can significantly enhance the thermal conductivity of ceramic coatings. These composite structures create conductive pathways through the typically insulating ceramic material. The distribution, orientation, and interface characteristics of these embedded materials are critical factors in determining the overall thermal performance of the coating system.Expand Specific Solutions04 Processing techniques for optimizing thermal conductivity

Various processing techniques can be employed to optimize the thermal conductivity of ceramic coatings. These include controlled sintering processes, plasma spraying with specific parameters, sol-gel methods, and specialized heat treatments. These techniques can reduce porosity, control grain boundary formation, and enhance crystallinity, all of which contribute to improved thermal conductivity properties while maintaining other essential coating characteristics.Expand Specific Solutions05 Thermal barrier ceramic coatings with controlled conductivity

Ceramic coatings can be engineered to provide specific thermal barrier properties with precisely controlled thermal conductivity. These coatings are particularly important in high-temperature applications such as gas turbines, where heat management is critical. By manipulating the microstructure, porosity, and composition of the ceramic material, coatings can be designed to provide optimal thermal protection while allowing for controlled heat dissipation where needed.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal conductivity optimization in ceramic coatings market is currently in a growth phase, with an estimated global market size of $3-4 billion and projected annual growth of 6-8%. The technology is approaching maturity in traditional applications but remains developmental for advanced applications. Key players include established industrial giants like United Technologies Corp. (RTX), Sumitomo Electric Industries, and NGK Insulators, who focus on high-performance ceramic solutions for aerospace and energy sectors. Research institutions such as Japan Fine Ceramics Center and NASA are driving innovation, while specialized companies like Kyocera and SCHOTT AG are commercializing advanced thermal barrier coatings. The competitive landscape is characterized by increasing collaboration between materials science companies and end-users to develop application-specific solutions with optimized thermal properties.

Japan Fine Ceramics Center

Technical Solution: The Japan Fine Ceramics Center (JFCC) has developed innovative approaches to thermal conductivity optimization in ceramic coatings through their advanced materials research. Their technology focuses on layered ceramic structures with controlled nanoscale interfaces that create phonon scattering boundaries, significantly reducing thermal conductivity. JFCC has pioneered the use of rare earth zirconates (particularly lanthanum zirconate) with pyrochlore crystal structures that inherently exhibit lower thermal conductivity than conventional YSZ. Their research has demonstrated thermal conductivity reductions of up to 35-40% compared to standard ceramic coatings. JFCC's approach includes the development of composite ceramic systems that combine different materials with complementary properties to achieve optimal thermal performance. Their innovative processing techniques include solution precursor plasma spray and aerosol deposition methods that enable precise control of microstructure and porosity. Recent advancements include the incorporation of hexagonal boron nitride nanoplatelets within ceramic matrices, creating highly anisotropic thermal properties that can be engineered to direct heat flow in specific directions, particularly valuable for components with complex geometries and thermal management requirements.

Strengths: Cutting-edge research capabilities; excellent control of nanoscale structures; ability to create highly customized thermal properties for specific applications. Weaknesses: Some technologies remain at research scale rather than full commercial implementation; potential challenges in scaling production to industrial volumes; higher costs associated with specialized materials and processing techniques.

RTX Corp.

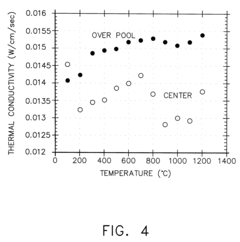

Technical Solution: RTX Corporation (formerly United Technologies) has developed advanced thermal barrier coating (TBC) systems for aerospace applications that optimize thermal conductivity in ceramic coatings. Their proprietary electron beam physical vapor deposition (EB-PVD) technique creates columnar microstructures in yttria-stabilized zirconia (YSZ) coatings that significantly reduce thermal conductivity while maintaining strain tolerance. RTX has pioneered the incorporation of rare earth oxides and complex defect clustering to create phonon scattering centers within the ceramic matrix, achieving thermal conductivity reductions of up to 40% compared to conventional YSZ coatings. Their multi-layer approach combines dense erosion-resistant outer layers with porous inner layers to optimize both thermal insulation and mechanical durability. Recent innovations include nano-structured coatings with thermal conductivity values below 1 W/m·K at elevated temperatures, enabling turbine components to operate at temperatures 150-200°C higher than previous generation materials.

Strengths: Superior high-temperature performance in extreme aerospace environments; excellent strain tolerance from columnar microstructure; proven long-term durability in commercial aircraft engines. Weaknesses: Higher manufacturing costs compared to conventional plasma spray methods; complex processing requirements; limited application outside aerospace due to specialized equipment needs.

Breakthrough Patents in Ceramic Thermal Management

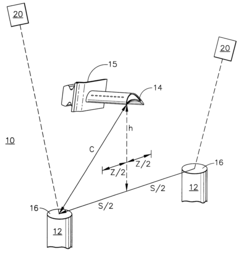

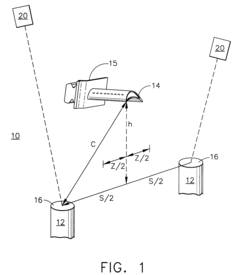

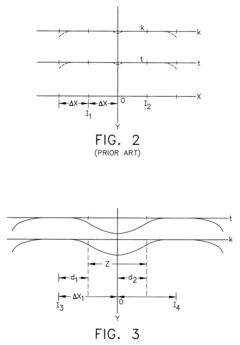

Physical properties of thermal barrier coatings using electron beam-physical vapor deposition

PatentInactiveUS6620465B2

Innovation

- Adjusting the position of the workpiece relative to the ceramic ingot sources during electron beam physical vapor deposition to alter the thermal conductivity of the coating, allowing for reduced thickness and density while maintaining temperature gradient capabilities, by positioning the workpiece at a preselected distance from the ingot sources to achieve at least a 10% reduction in thermal conductivity.

Low conductivity and high toughness tetragonal phase structured ceramic thermal barrier coatings

PatentInactiveUS7700508B1

Innovation

- A multi-component thermal barrier coating composition with a base oxide of zirconia or hafnia, paired rare earth oxides, and transition metal oxides like titanium and tantalum, which forms a tetragonal phase structure with reduced thermal conductivity and enhanced toughness, stability, and erosion resistance.

Environmental Impact of Advanced Ceramic Materials

The environmental implications of ceramic coatings with optimized thermal conductivity extend far beyond their immediate technical applications. Advanced ceramic materials used in thermal barrier coatings significantly reduce energy consumption in various industrial processes, particularly in high-temperature environments such as gas turbines and aerospace applications. By effectively managing heat transfer, these optimized coatings can decrease fuel consumption by 5-8% in turbine engines, directly translating to reduced carbon emissions.

Manufacturing processes for advanced ceramic coatings have evolved to become more environmentally sustainable. Traditional ceramic production methods often required extreme temperatures exceeding 1500°C, consuming substantial energy and generating considerable carbon footprints. Modern techniques such as solution precursor plasma spray and cold spray deposition have reduced energy requirements by approximately 30-40%, while simultaneously decreasing harmful emissions.

The lifecycle assessment of ceramic coatings reveals notable environmental benefits. These materials typically extend component lifespans by 2-3 times compared to conventional alternatives, reducing resource consumption and waste generation. Additionally, many advanced ceramic formulations utilize abundant natural materials like alumina and zirconia, minimizing dependency on rare or environmentally problematic elements.

Waste management considerations have become increasingly important in ceramic coating development. Recent innovations have focused on creating recyclable ceramic composites and implementing closed-loop manufacturing systems. Some manufacturers have achieved up to 25% reuse of ceramic material waste, significantly reducing landfill contributions.

Water usage represents another critical environmental factor. Traditional ceramic processing often required substantial water volumes for mixing and cooling. Contemporary thermal conductivity optimization techniques have integrated water conservation measures, with some facilities reporting 40-60% reductions in water consumption through recirculation systems and dry processing methods.

The end-of-life environmental impact of thermally optimized ceramic coatings presents both challenges and opportunities. While ceramic materials are generally chemically stable and non-toxic, their durability can complicate recycling efforts. Emerging technologies focusing on mechanical separation and chemical dissolution show promise for recovering valuable components from spent ceramic coatings, potentially creating new material streams for circular economy applications.

Manufacturing processes for advanced ceramic coatings have evolved to become more environmentally sustainable. Traditional ceramic production methods often required extreme temperatures exceeding 1500°C, consuming substantial energy and generating considerable carbon footprints. Modern techniques such as solution precursor plasma spray and cold spray deposition have reduced energy requirements by approximately 30-40%, while simultaneously decreasing harmful emissions.

The lifecycle assessment of ceramic coatings reveals notable environmental benefits. These materials typically extend component lifespans by 2-3 times compared to conventional alternatives, reducing resource consumption and waste generation. Additionally, many advanced ceramic formulations utilize abundant natural materials like alumina and zirconia, minimizing dependency on rare or environmentally problematic elements.

Waste management considerations have become increasingly important in ceramic coating development. Recent innovations have focused on creating recyclable ceramic composites and implementing closed-loop manufacturing systems. Some manufacturers have achieved up to 25% reuse of ceramic material waste, significantly reducing landfill contributions.

Water usage represents another critical environmental factor. Traditional ceramic processing often required substantial water volumes for mixing and cooling. Contemporary thermal conductivity optimization techniques have integrated water conservation measures, with some facilities reporting 40-60% reductions in water consumption through recirculation systems and dry processing methods.

The end-of-life environmental impact of thermally optimized ceramic coatings presents both challenges and opportunities. While ceramic materials are generally chemically stable and non-toxic, their durability can complicate recycling efforts. Emerging technologies focusing on mechanical separation and chemical dissolution show promise for recovering valuable components from spent ceramic coatings, potentially creating new material streams for circular economy applications.

Cost-Benefit Analysis of Thermal Optimization Methods

The economic viability of thermal conductivity optimization in ceramic coatings requires rigorous cost-benefit analysis to justify implementation decisions. Initial investment costs for advanced thermal optimization methods typically range from $50,000 to $500,000, depending on the scale of operation and sophistication of the technology employed. These costs encompass equipment acquisition, facility modifications, specialized personnel training, and potential production downtime during implementation.

When evaluating return on investment, manufacturers must consider both direct and indirect benefits. Direct benefits include reduced energy consumption (typically 15-30% improvement), extended component lifespan (25-40% increase in high-temperature applications), and decreased maintenance frequency (maintenance intervals often extended by 30-50%). These translate to quantifiable cost savings that accumulate over the operational lifetime of the coated components.

Indirect benefits, though harder to quantify, include improved product performance, enhanced market competitiveness, and potential access to premium market segments. Environmental compliance benefits also factor significantly into the equation, as optimized thermal coatings can reduce carbon emissions by 10-25% in certain applications, potentially qualifying for carbon credits or avoiding penalties in regulated markets.

Payback periods vary considerably across industries. In power generation, investments typically reach break-even within 2-3 years, while aerospace applications may see returns within 12-18 months due to the high value of performance improvements and fuel efficiency gains. Consumer applications generally show longer payback periods of 3-5 years but offer more stable long-term returns.

Risk assessment must account for technology obsolescence, market shifts, and regulatory changes. Sensitivity analysis reveals that energy price volatility significantly impacts ROI calculations, with a 20% increase in energy costs potentially reducing payback periods by 15-30%. Conversely, implementation delays can erode projected benefits by 5-10% annually due to missed opportunity costs.

Comparative analysis between different optimization methods shows that multi-layer ceramic systems offer the best long-term value despite higher initial costs, while doped single-layer systems provide more modest improvements but with significantly lower implementation barriers. Nano-engineered coatings present the highest initial investment but potentially the greatest long-term returns, particularly in high-value applications where performance improvements command premium pricing.

When evaluating return on investment, manufacturers must consider both direct and indirect benefits. Direct benefits include reduced energy consumption (typically 15-30% improvement), extended component lifespan (25-40% increase in high-temperature applications), and decreased maintenance frequency (maintenance intervals often extended by 30-50%). These translate to quantifiable cost savings that accumulate over the operational lifetime of the coated components.

Indirect benefits, though harder to quantify, include improved product performance, enhanced market competitiveness, and potential access to premium market segments. Environmental compliance benefits also factor significantly into the equation, as optimized thermal coatings can reduce carbon emissions by 10-25% in certain applications, potentially qualifying for carbon credits or avoiding penalties in regulated markets.

Payback periods vary considerably across industries. In power generation, investments typically reach break-even within 2-3 years, while aerospace applications may see returns within 12-18 months due to the high value of performance improvements and fuel efficiency gains. Consumer applications generally show longer payback periods of 3-5 years but offer more stable long-term returns.

Risk assessment must account for technology obsolescence, market shifts, and regulatory changes. Sensitivity analysis reveals that energy price volatility significantly impacts ROI calculations, with a 20% increase in energy costs potentially reducing payback periods by 15-30%. Conversely, implementation delays can erode projected benefits by 5-10% annually due to missed opportunity costs.

Comparative analysis between different optimization methods shows that multi-layer ceramic systems offer the best long-term value despite higher initial costs, while doped single-layer systems provide more modest improvements but with significantly lower implementation barriers. Nano-engineered coatings present the highest initial investment but potentially the greatest long-term returns, particularly in high-value applications where performance improvements command premium pricing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!