Advances in Plasma Sprayed Ceramic Coatings for Thermal Protection

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Sprayed Ceramic Coatings Evolution and Objectives

Plasma sprayed ceramic coatings have evolved significantly over the past several decades, transforming from rudimentary thermal barriers to sophisticated multi-functional protection systems. The technology originated in the 1950s with simple alumina coatings, primarily developed for aerospace applications where thermal protection was critical for components exposed to extreme temperatures. By the 1970s, yttria-stabilized zirconia (YSZ) emerged as the industry standard material due to its exceptional thermal insulation properties and phase stability at high temperatures.

The evolution of plasma spraying techniques has been equally important in this technological progression. Early atmospheric plasma spray (APS) systems offered limited control over coating microstructure and properties. The introduction of vacuum plasma spraying (VPS) in the 1980s represented a significant advancement, allowing for denser coatings with reduced oxidation and improved adhesion. More recently, suspension and solution precursor plasma spray techniques have enabled the deposition of nanostructured coatings with enhanced performance characteristics.

Material science breakthroughs have continuously expanded the capabilities of ceramic thermal barrier coatings. The development of rare-earth zirconates in the early 2000s provided alternatives to traditional YSZ with improved phase stability and reduced thermal conductivity. Layered and functionally graded coating architectures have further enhanced performance by optimizing thermal, mechanical, and chemical properties throughout the coating thickness.

The primary objective of current research in plasma sprayed ceramic coatings is to develop next-generation thermal protection systems capable of withstanding increasingly extreme operating environments. This includes temperatures exceeding 1400°C for extended periods, resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration, and improved strain tolerance to prevent spallation during thermal cycling. Additionally, there is growing interest in multifunctional coatings that combine thermal protection with self-healing capabilities, environmental barrier properties, and integrated sensing functionalities.

Another critical objective is the enhancement of coating durability and reliability. This involves developing improved bond coat systems, optimizing coating architectures to mitigate stress concentrations, and implementing advanced manufacturing controls to ensure consistent quality. Computational modeling and simulation have become essential tools in this pursuit, enabling researchers to predict coating behavior under complex operating conditions and optimize designs before physical testing.

The integration of plasma sprayed ceramic coatings with additive manufacturing technologies represents an emerging frontier in this field. Researchers aim to develop hybrid manufacturing approaches that combine the high deposition rates of plasma spraying with the geometric freedom of additive processes, potentially enabling the creation of components with integrated thermal protection features rather than applied coatings.

The evolution of plasma spraying techniques has been equally important in this technological progression. Early atmospheric plasma spray (APS) systems offered limited control over coating microstructure and properties. The introduction of vacuum plasma spraying (VPS) in the 1980s represented a significant advancement, allowing for denser coatings with reduced oxidation and improved adhesion. More recently, suspension and solution precursor plasma spray techniques have enabled the deposition of nanostructured coatings with enhanced performance characteristics.

Material science breakthroughs have continuously expanded the capabilities of ceramic thermal barrier coatings. The development of rare-earth zirconates in the early 2000s provided alternatives to traditional YSZ with improved phase stability and reduced thermal conductivity. Layered and functionally graded coating architectures have further enhanced performance by optimizing thermal, mechanical, and chemical properties throughout the coating thickness.

The primary objective of current research in plasma sprayed ceramic coatings is to develop next-generation thermal protection systems capable of withstanding increasingly extreme operating environments. This includes temperatures exceeding 1400°C for extended periods, resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration, and improved strain tolerance to prevent spallation during thermal cycling. Additionally, there is growing interest in multifunctional coatings that combine thermal protection with self-healing capabilities, environmental barrier properties, and integrated sensing functionalities.

Another critical objective is the enhancement of coating durability and reliability. This involves developing improved bond coat systems, optimizing coating architectures to mitigate stress concentrations, and implementing advanced manufacturing controls to ensure consistent quality. Computational modeling and simulation have become essential tools in this pursuit, enabling researchers to predict coating behavior under complex operating conditions and optimize designs before physical testing.

The integration of plasma sprayed ceramic coatings with additive manufacturing technologies represents an emerging frontier in this field. Researchers aim to develop hybrid manufacturing approaches that combine the high deposition rates of plasma spraying with the geometric freedom of additive processes, potentially enabling the creation of components with integrated thermal protection features rather than applied coatings.

Market Demand Analysis for Thermal Protection Systems

The global market for thermal protection systems (TPS) has been experiencing robust growth, driven primarily by increasing applications in aerospace, defense, and industrial sectors. The demand for advanced plasma sprayed ceramic coatings has seen a compound annual growth rate exceeding 6% over the past five years, with the market value projected to reach several billion dollars by 2028.

Aerospace and defense sectors remain the dominant consumers of thermal protection systems, accounting for approximately two-thirds of the total market share. This dominance stems from the critical need for materials capable of withstanding extreme temperatures during atmospheric re-entry of spacecraft and hypersonic flight conditions. Commercial space companies have emerged as significant new customers, with their increased launch frequencies creating substantial demand for reliable thermal protection solutions.

The automotive industry represents a growing market segment, particularly with the rise of high-performance vehicles and racing applications where thermal management is crucial for engine efficiency and safety. Additionally, industrial applications in power generation, particularly in gas turbines and nuclear facilities, constitute a steady demand source for advanced ceramic coating technologies.

Geographically, North America leads the market consumption of thermal protection systems, followed by Europe and Asia-Pacific. However, the fastest growth rates are being observed in emerging economies, particularly in China and India, where rapid industrialization and expanding aerospace programs are driving increased adoption of advanced thermal protection technologies.

Customer requirements are evolving toward more sophisticated performance metrics. End-users increasingly demand thermal barrier coatings with enhanced durability, reduced weight, improved thermal cycling resistance, and longer service life. The ability to withstand temperatures exceeding 1600°C while maintaining structural integrity has become a standard requirement for next-generation aerospace applications.

Cost considerations remain a significant factor influencing market dynamics. Despite the superior performance of advanced ceramic coatings, their relatively high production costs compared to conventional materials present a market constraint. This has created a distinct market segment for cost-effective thermal protection solutions that balance performance with economic viability.

Environmental regulations and sustainability concerns are reshaping market demands, with growing preference for coating technologies that minimize hazardous materials and reduce environmental impact during both manufacturing and end-of-life disposal. This trend is particularly pronounced in European markets where regulatory frameworks are more stringent.

Aerospace and defense sectors remain the dominant consumers of thermal protection systems, accounting for approximately two-thirds of the total market share. This dominance stems from the critical need for materials capable of withstanding extreme temperatures during atmospheric re-entry of spacecraft and hypersonic flight conditions. Commercial space companies have emerged as significant new customers, with their increased launch frequencies creating substantial demand for reliable thermal protection solutions.

The automotive industry represents a growing market segment, particularly with the rise of high-performance vehicles and racing applications where thermal management is crucial for engine efficiency and safety. Additionally, industrial applications in power generation, particularly in gas turbines and nuclear facilities, constitute a steady demand source for advanced ceramic coating technologies.

Geographically, North America leads the market consumption of thermal protection systems, followed by Europe and Asia-Pacific. However, the fastest growth rates are being observed in emerging economies, particularly in China and India, where rapid industrialization and expanding aerospace programs are driving increased adoption of advanced thermal protection technologies.

Customer requirements are evolving toward more sophisticated performance metrics. End-users increasingly demand thermal barrier coatings with enhanced durability, reduced weight, improved thermal cycling resistance, and longer service life. The ability to withstand temperatures exceeding 1600°C while maintaining structural integrity has become a standard requirement for next-generation aerospace applications.

Cost considerations remain a significant factor influencing market dynamics. Despite the superior performance of advanced ceramic coatings, their relatively high production costs compared to conventional materials present a market constraint. This has created a distinct market segment for cost-effective thermal protection solutions that balance performance with economic viability.

Environmental regulations and sustainability concerns are reshaping market demands, with growing preference for coating technologies that minimize hazardous materials and reduce environmental impact during both manufacturing and end-of-life disposal. This trend is particularly pronounced in European markets where regulatory frameworks are more stringent.

Current State and Challenges in Plasma Spray Technology

Plasma spray technology has evolved significantly over the past decades, establishing itself as a cornerstone method for applying thermal barrier coatings (TBCs) in high-temperature applications. Currently, the global market for plasma sprayed ceramic coatings is dominated by atmospheric plasma spraying (APS) and vacuum plasma spraying (VPS) techniques. These methods have reached industrial maturity with standardized processes implemented across aerospace, power generation, and automotive sectors.

The state-of-the-art plasma spray systems operate at temperatures exceeding 10,000°C, allowing for the deposition of ceramics with high melting points such as yttria-stabilized zirconia (YSZ), which remains the industry standard material for thermal protection applications. Recent advancements include the development of suspension and solution precursor plasma spray techniques, which enable the creation of nanostructured coatings with enhanced thermal cycling resistance and lower thermal conductivity compared to conventional methods.

Despite these achievements, significant technical challenges persist in plasma spray technology. Coating reproducibility remains problematic due to the inherent complexity of plasma physics and particle-plasma interactions. Variations in feedstock properties, plasma fluctuations, and environmental conditions can lead to inconsistent coating microstructures, affecting thermal protection performance and service life predictability.

Another critical challenge is the limited fundamental understanding of the relationship between processing parameters and resultant coating properties. The multiphysics nature of plasma spraying—involving fluid dynamics, heat transfer, phase transformations, and mechanical interactions—creates a parameter space too complex for purely empirical optimization approaches.

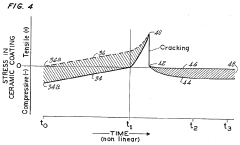

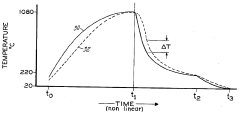

Durability under extreme thermal cycling conditions continues to be a significant hurdle, particularly for applications in next-generation hypersonic vehicles and advanced gas turbines. Current ceramic coatings often suffer from thermal stress-induced cracking and spallation after repeated thermal cycles, limiting their operational lifespan.

Energy efficiency represents another challenge, as conventional plasma spray systems convert only 40-60% of input power into useful thermal energy for particle melting. The remainder is lost through various mechanisms including radiation, convection, and cooling systems.

Geographically, plasma spray technology development is concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and increasingly China leading research efforts. This distribution reflects both historical industrial capabilities and current investment patterns in advanced manufacturing technologies.

Environmental and health concerns associated with the process, including hazardous dust emissions and high energy consumption, are driving research toward more sustainable approaches. Regulatory pressures in developed economies are accelerating the need for cleaner production methods and safer workplace practices in plasma spray operations.

The state-of-the-art plasma spray systems operate at temperatures exceeding 10,000°C, allowing for the deposition of ceramics with high melting points such as yttria-stabilized zirconia (YSZ), which remains the industry standard material for thermal protection applications. Recent advancements include the development of suspension and solution precursor plasma spray techniques, which enable the creation of nanostructured coatings with enhanced thermal cycling resistance and lower thermal conductivity compared to conventional methods.

Despite these achievements, significant technical challenges persist in plasma spray technology. Coating reproducibility remains problematic due to the inherent complexity of plasma physics and particle-plasma interactions. Variations in feedstock properties, plasma fluctuations, and environmental conditions can lead to inconsistent coating microstructures, affecting thermal protection performance and service life predictability.

Another critical challenge is the limited fundamental understanding of the relationship between processing parameters and resultant coating properties. The multiphysics nature of plasma spraying—involving fluid dynamics, heat transfer, phase transformations, and mechanical interactions—creates a parameter space too complex for purely empirical optimization approaches.

Durability under extreme thermal cycling conditions continues to be a significant hurdle, particularly for applications in next-generation hypersonic vehicles and advanced gas turbines. Current ceramic coatings often suffer from thermal stress-induced cracking and spallation after repeated thermal cycles, limiting their operational lifespan.

Energy efficiency represents another challenge, as conventional plasma spray systems convert only 40-60% of input power into useful thermal energy for particle melting. The remainder is lost through various mechanisms including radiation, convection, and cooling systems.

Geographically, plasma spray technology development is concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and increasingly China leading research efforts. This distribution reflects both historical industrial capabilities and current investment patterns in advanced manufacturing technologies.

Environmental and health concerns associated with the process, including hazardous dust emissions and high energy consumption, are driving research toward more sustainable approaches. Regulatory pressures in developed economies are accelerating the need for cleaner production methods and safer workplace practices in plasma spray operations.

Current Technical Solutions for Thermal Barrier Coatings

01 Composition of thermal barrier ceramic coatings

Ceramic coatings for thermal protection can be composed of various materials such as zirconia, alumina, and rare earth oxides. These compositions are specifically designed to withstand high temperatures and provide effective thermal insulation. The microstructure and porosity of these ceramic materials play crucial roles in determining their thermal conductivity and overall protective performance. Advanced ceramic compositions may include stabilizers to prevent phase transformations at elevated temperatures.- Composition of thermal barrier ceramic coatings: Thermal barrier ceramic coatings can be composed of various materials to provide effective thermal protection. These materials include zirconia-based ceramics, alumina, and rare earth oxides that offer high temperature resistance and low thermal conductivity. The specific composition can be tailored to meet the requirements of different applications, such as aerospace components or industrial equipment operating in high-temperature environments.

- Plasma spray deposition techniques: Various plasma spray deposition techniques are used to apply ceramic coatings for thermal protection. These include atmospheric plasma spraying, vacuum plasma spraying, and suspension plasma spraying. The process parameters, such as plasma power, spray distance, and powder feed rate, can be optimized to achieve desired coating properties including thickness, porosity, and adhesion strength, which directly influence the thermal protection performance.

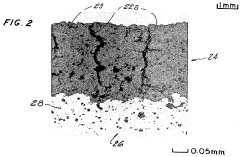

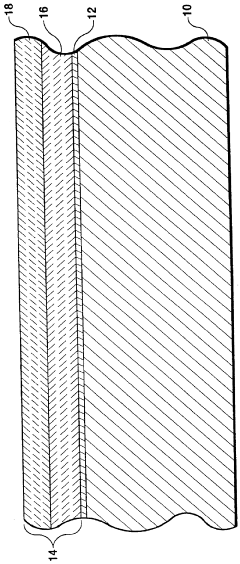

- Multilayer coating systems for enhanced thermal protection: Multilayer ceramic coating systems can provide enhanced thermal protection compared to single-layer coatings. These systems typically consist of a bond coat, a thermally grown oxide layer, and a ceramic top coat. The bond coat improves adhesion to the substrate, while the ceramic top coat provides thermal insulation. The multilayer structure can be designed to accommodate thermal expansion mismatch and improve durability under thermal cycling conditions.

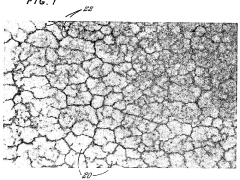

- Microstructure control for optimized thermal performance: The microstructure of plasma-sprayed ceramic coatings significantly affects their thermal protection capabilities. Features such as porosity, crack networks, and splat boundaries can be controlled during the plasma spray process to optimize thermal insulation properties. Engineered microstructures with controlled porosity distribution and crack patterns can reduce thermal conductivity while maintaining mechanical integrity, leading to improved thermal barrier performance.

- Advanced ceramic materials for extreme temperature applications: Advanced ceramic materials have been developed for thermal protection in extreme temperature environments. These include rare-earth zirconates, hafnates, and pyrochlore structures that offer superior phase stability and lower thermal conductivity compared to conventional materials. Nanostructured ceramics and ceramic composites with engineered interfaces can provide enhanced thermal shock resistance and longer service life in demanding applications such as rocket engines, gas turbines, and hypersonic vehicles.

02 Plasma spray deposition techniques

Various plasma spray techniques are employed for depositing ceramic thermal barrier coatings, including atmospheric plasma spraying (APS), vacuum plasma spraying (VPS), and suspension plasma spraying (SPS). These methods control the microstructure, porosity, and adhesion of the coating to the substrate. Process parameters such as plasma power, spray distance, powder feed rate, and carrier gas flow significantly influence the quality and performance of the resulting coating.Expand Specific Solutions03 Multi-layer coating systems for enhanced thermal protection

Multi-layer ceramic coating systems provide superior thermal protection compared to single-layer coatings. These systems typically consist of a bond coat, a thermally grown oxide layer, and a ceramic top coat. Each layer serves a specific function: the bond coat improves adhesion, the oxide layer provides oxidation resistance, and the ceramic top coat provides thermal insulation. The combination of different materials with complementary properties enhances the overall thermal protection and durability of the coating system.Expand Specific Solutions04 Thermal cycling resistance and durability enhancements

Improving the thermal cycling resistance of ceramic coatings is crucial for applications involving frequent temperature fluctuations. This can be achieved through the incorporation of stress-relieving microstructures, segmentation cracks, and strain-tolerant designs. Advanced coating architectures with columnar structures or engineered porosity distribution help accommodate thermal expansion mismatches between the coating and substrate, thereby enhancing durability and extending service life under severe thermal conditions.Expand Specific Solutions05 Novel additives and nanostructured coatings

Incorporating novel additives and nanostructured materials into ceramic coatings can significantly enhance thermal protection properties. Rare earth elements, transition metal oxides, and ceramic nanoparticles can be added to modify thermal conductivity, phase stability, and sintering resistance. Nanostructured coatings with controlled grain boundaries and interfaces offer improved thermal insulation and mechanical properties compared to conventional microstructured coatings, making them particularly suitable for extreme temperature applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The plasma sprayed ceramic coatings for thermal protection market is currently in a growth phase, characterized by increasing demand across aerospace, power generation, and industrial sectors. The global market size is estimated to exceed $2 billion, with projected annual growth of 6-8%. Technologically, the field shows varying maturity levels with established players like Oerlikon Metco, Praxair Technology (Linde), and Applied Materials leading commercial applications, while research institutions such as Xi'an Jiaotong University and Beijing University of Technology drive innovation in advanced compositions. Companies including Siemens AG, RTX Corp., and Mitsubishi Heavy Industries are integrating these coatings into high-performance systems, while specialized firms like Treibacher Industrie AG focus on material development. The competitive landscape features both diversified industrial conglomerates and specialized coating technology providers competing through performance enhancement and cost reduction strategies.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed the TAFA Plazjet high-energy plasma spray system specifically designed for thermal barrier ceramic coatings. This system operates at power levels up to 200 kW, significantly higher than conventional systems (typically 40-80 kW), enabling faster deposition rates and improved coating density control[1]. Their proprietary ceramic powder formulations feature hollow-sphere morphologies that create predetermined porosity structures when deposited, enhancing thermal insulation properties. Praxair's advanced ceramic coatings incorporate gadolinia, yttria, and ceria as stabilizers for zirconia, providing superior phase stability at elevated temperatures exceeding 1200°C[2]. The company has pioneered the development of functionally graded ceramic coatings where composition and microstructure gradually change throughout the coating thickness, minimizing thermal expansion mismatch stresses and improving durability during thermal cycling. Their plasma spray process utilizes specialized nozzle geometries and controlled atmosphere chambers that minimize oxide formation during deposition, resulting in coatings with superior adhesion strength exceeding 30 MPa and thermal conductivity values as low as 0.8-1.2 W/m·K[3].

Strengths: High-energy plasma systems enable faster deposition rates and better economics for thick coatings; specialized powder morphologies create optimized microstructures for thermal insulation; extensive experience in aerospace and power generation applications provides proven reliability. Weaknesses: Higher gas consumption compared to competing technologies; more complex equipment requiring specialized maintenance; some proprietary powder formulations may have higher material costs than standard compositions.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed advanced thermal spray solutions for ceramic coatings with their SinplexPro™ plasma spray technology. This system utilizes a cascading arc design that creates a more stable plasma jet with higher enthalpy, resulting in superior coating quality and consistency[1]. Their ceramic coating solutions incorporate yttria-stabilized zirconia (YSZ) with optimized porosity structures that enhance thermal insulation while maintaining mechanical integrity. The company has pioneered the development of suspension and solution precursor plasma spray techniques (SPPS) that enable the deposition of nano-structured ceramic coatings with enhanced strain tolerance and thermal cycling resistance[2]. Their thermal barrier coating systems typically consist of multiple layers including bond coats with MCrAlY compositions that improve adhesion and oxidation resistance. Oerlikon's advanced process control systems maintain precise parameters during deposition, ensuring reproducible coating microstructures with controlled porosity levels between 10-20% that optimize thermal protection performance[3].

Strengths: Superior plasma stability through cascading arc technology resulting in more consistent coating quality; advanced process monitoring capabilities allowing real-time adjustments; ability to produce both conventional and nanostructured ceramic coatings. Weaknesses: Higher initial equipment investment compared to conventional systems; more complex operation requiring specialized technical expertise; some processes may have lower deposition rates affecting production efficiency.

Key Innovations in Plasma Sprayed Ceramic Materials

Quench-cracked ceramic thermal barrier coatings

PatentInactiveUS4457948A

Innovation

- A process involving plasma spraying a ceramic coating onto a metal substrate, followed by heating and quenching in a high heat transfer medium to induce microcracking, creating a columnar segmented structure that enhances thermal fatigue resistance and adherence.

Plasma sprayed ceramic thermal barrier coating for NIa1-based intermetallic alloys

PatentInactiveUS5302465A

Innovation

- A two-layer zirconia-yttria ceramic thermal barrier coating system is applied directly to the NiAl-based substrate, where the first layer is low-pressure plasma sprayed onto a preoxidized surface to form a thin Al2O3 scale, followed by a thicker layer applied using atmospheric pressure plasma spraying, eliminating the need for a metallic bond coat and ensuring strong adherence.

Environmental Impact and Sustainability Considerations

The environmental impact of plasma sprayed ceramic coatings for thermal protection systems extends beyond their primary protective function. Traditional coating processes often involve significant energy consumption and greenhouse gas emissions. Plasma spraying, while energy-intensive, has shown improvements in efficiency compared to alternative thermal barrier coating methods, with recent advancements reducing energy requirements by approximately 15-20% through optimized spray parameters and equipment design.

Material selection plays a crucial role in the sustainability profile of these coatings. Conventional ceramic materials like yttria-stabilized zirconia (YSZ) require high-temperature processing, contributing to their environmental footprint. Research trends indicate a shift toward more environmentally benign alternatives, including natural mineral-derived ceramics and recycled ceramic precursors, which can reduce the carbon footprint by up to 30% compared to virgin materials.

Waste generation during plasma spraying processes presents another environmental challenge. Overspray material typically accounts for 20-40% of the total material input, representing significant resource inefficiency. Advanced reclamation systems have been developed to capture and reprocess overspray particles, achieving recovery rates of up to 60% in optimized systems, substantially reducing waste streams and raw material requirements.

Lifecycle assessment studies reveal that the environmental benefits of ceramic thermal protection coatings often outweigh their production impacts. By extending component lifespans and improving thermal efficiency in high-temperature applications, these coatings contribute to reduced fuel consumption and emissions in aerospace, power generation, and industrial systems. Quantitative analyses suggest that advanced ceramic coatings can enable energy savings of 3-7% in turbine applications over their operational lifetime.

Water consumption represents another important sustainability consideration. Traditional wet processing methods can require significant water resources, while newer semi-dry and dry plasma spraying techniques have demonstrated water usage reductions of up to 80%. These approaches not only conserve water but also eliminate the need for wastewater treatment associated with conventional processes.

Regulatory frameworks increasingly influence development directions in this field. The European Union's REACH regulations and similar global initiatives have accelerated research into non-toxic alternatives to certain coating additives and processing chemicals. This regulatory pressure has catalyzed innovation in environmentally compatible stabilizers and sintering aids that maintain performance while reducing ecological impact.

Looking forward, circular economy principles are being integrated into coating development strategies. Research into coating removal and substrate recovery technologies enables material reclamation at end-of-life, creating closed-loop material cycles that significantly reduce the overall environmental footprint of thermal protection systems across their complete lifecycle.

Material selection plays a crucial role in the sustainability profile of these coatings. Conventional ceramic materials like yttria-stabilized zirconia (YSZ) require high-temperature processing, contributing to their environmental footprint. Research trends indicate a shift toward more environmentally benign alternatives, including natural mineral-derived ceramics and recycled ceramic precursors, which can reduce the carbon footprint by up to 30% compared to virgin materials.

Waste generation during plasma spraying processes presents another environmental challenge. Overspray material typically accounts for 20-40% of the total material input, representing significant resource inefficiency. Advanced reclamation systems have been developed to capture and reprocess overspray particles, achieving recovery rates of up to 60% in optimized systems, substantially reducing waste streams and raw material requirements.

Lifecycle assessment studies reveal that the environmental benefits of ceramic thermal protection coatings often outweigh their production impacts. By extending component lifespans and improving thermal efficiency in high-temperature applications, these coatings contribute to reduced fuel consumption and emissions in aerospace, power generation, and industrial systems. Quantitative analyses suggest that advanced ceramic coatings can enable energy savings of 3-7% in turbine applications over their operational lifetime.

Water consumption represents another important sustainability consideration. Traditional wet processing methods can require significant water resources, while newer semi-dry and dry plasma spraying techniques have demonstrated water usage reductions of up to 80%. These approaches not only conserve water but also eliminate the need for wastewater treatment associated with conventional processes.

Regulatory frameworks increasingly influence development directions in this field. The European Union's REACH regulations and similar global initiatives have accelerated research into non-toxic alternatives to certain coating additives and processing chemicals. This regulatory pressure has catalyzed innovation in environmentally compatible stabilizers and sintering aids that maintain performance while reducing ecological impact.

Looking forward, circular economy principles are being integrated into coating development strategies. Research into coating removal and substrate recovery technologies enables material reclamation at end-of-life, creating closed-loop material cycles that significantly reduce the overall environmental footprint of thermal protection systems across their complete lifecycle.

Performance Testing and Quality Assurance Methodologies

Performance testing and quality assurance methodologies for plasma sprayed ceramic coatings have evolved significantly to meet the demanding requirements of thermal protection systems. These methodologies encompass a comprehensive suite of standardized tests designed to evaluate coating performance under extreme conditions that simulate real-world applications.

Thermal cycling tests represent a critical evaluation method, subjecting coatings to rapid temperature fluctuations between cryogenic and elevated temperatures. These tests typically involve hundreds or thousands of cycles to assess coating durability and adhesion strength over time. Modern thermal cycling chambers can achieve heating rates exceeding 100°C per minute and cooling rates that closely mimic reentry conditions for aerospace applications.

Erosion resistance testing has become increasingly sophisticated, utilizing particle impingement at various angles and velocities to simulate different operational environments. Advanced testing equipment can accelerate particles to speeds exceeding 300 m/s, allowing for accelerated wear testing that correlates with years of service conditions. Quantitative measurements of mass loss and surface profile changes provide valuable data for coating optimization.

Thermal conductivity measurements have benefited from advancements in laser flash analysis and steady-state heat flow methods. These techniques can now characterize thermal properties across temperature ranges from -196°C to over 1600°C with precision better than ±5%. Such measurements are essential for validating the insulating capabilities of ceramic coatings in thermal protection systems.

Non-destructive evaluation techniques have revolutionized quality assurance processes. Infrared thermography, ultrasonic inspection, and X-ray computed tomography now enable detection of subsurface defects as small as 10-50 μm without damaging the coating. These methods have been integrated into production lines for real-time quality monitoring, significantly reducing rejection rates and improving consistency.

Statistical process control methodologies have been implemented to monitor critical coating parameters such as thickness uniformity, porosity distribution, and phase composition. Advanced image analysis algorithms can automatically process micrographs to quantify microstructural features with high reproducibility. These data-driven approaches enable manufacturers to establish robust correlations between processing parameters and coating performance.

Accelerated aging tests have been developed to predict long-term performance under various environmental conditions. Exposure to simulated atmospheric reentry conditions, salt spray, humidity cycling, and atomic oxygen can compress years of service life into weeks of testing. The resulting degradation mechanisms are carefully analyzed using advanced characterization techniques to develop predictive models for coating lifetime.

Thermal cycling tests represent a critical evaluation method, subjecting coatings to rapid temperature fluctuations between cryogenic and elevated temperatures. These tests typically involve hundreds or thousands of cycles to assess coating durability and adhesion strength over time. Modern thermal cycling chambers can achieve heating rates exceeding 100°C per minute and cooling rates that closely mimic reentry conditions for aerospace applications.

Erosion resistance testing has become increasingly sophisticated, utilizing particle impingement at various angles and velocities to simulate different operational environments. Advanced testing equipment can accelerate particles to speeds exceeding 300 m/s, allowing for accelerated wear testing that correlates with years of service conditions. Quantitative measurements of mass loss and surface profile changes provide valuable data for coating optimization.

Thermal conductivity measurements have benefited from advancements in laser flash analysis and steady-state heat flow methods. These techniques can now characterize thermal properties across temperature ranges from -196°C to over 1600°C with precision better than ±5%. Such measurements are essential for validating the insulating capabilities of ceramic coatings in thermal protection systems.

Non-destructive evaluation techniques have revolutionized quality assurance processes. Infrared thermography, ultrasonic inspection, and X-ray computed tomography now enable detection of subsurface defects as small as 10-50 μm without damaging the coating. These methods have been integrated into production lines for real-time quality monitoring, significantly reducing rejection rates and improving consistency.

Statistical process control methodologies have been implemented to monitor critical coating parameters such as thickness uniformity, porosity distribution, and phase composition. Advanced image analysis algorithms can automatically process micrographs to quantify microstructural features with high reproducibility. These data-driven approaches enable manufacturers to establish robust correlations between processing parameters and coating performance.

Accelerated aging tests have been developed to predict long-term performance under various environmental conditions. Exposure to simulated atmospheric reentry conditions, salt spray, humidity cycling, and atomic oxygen can compress years of service life into weeks of testing. The resulting degradation mechanisms are carefully analyzed using advanced characterization techniques to develop predictive models for coating lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!