Microstructural Control in Ceramic Thermal Spray Coatings

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Thermal Spray Coating Evolution and Objectives

Ceramic thermal spray coatings have evolved significantly over the past seven decades, transforming from rudimentary surface treatments to sophisticated engineered microstructures with tailored properties. The journey began in the 1950s with simple flame spray processes, primarily focused on wear resistance applications. By the 1970s, plasma spray technology emerged, enabling higher temperatures and velocities that expanded coating capabilities and applications across industries.

The 1980s and 1990s witnessed critical advancements in understanding the relationship between process parameters and microstructural features. Researchers established correlations between spray conditions, particle behavior in-flight, and the resulting coating architecture. This period marked the transition from empirical approaches to more scientific methodologies in coating development.

The early 2000s brought significant breakthroughs with the introduction of suspension and solution precursor thermal spray techniques, allowing for the deposition of sub-micron and nanoscale features within coatings. These innovations opened new possibilities for controlling porosity, crack networks, and interfacial characteristics at unprecedented scales.

Current technological trajectories focus on precise microstructural control to achieve multifunctional performance. The field has progressed from merely depositing material to engineering specific microstructural elements—such as columnar structures, controlled porosity gradients, and tailored interfaces—that directly influence thermal, mechanical, and chemical properties of the coating system.

The primary objective in ceramic thermal spray coating development today is achieving deterministic microstructural control across multiple length scales. This involves the ability to design and reliably produce specific microstructural features that optimize performance for targeted applications, particularly in extreme environments such as gas turbines, aerospace components, and energy systems.

Secondary objectives include enhancing coating durability through stress management strategies, improving thermal cycling resistance, and developing self-healing capabilities within ceramic microstructures. These aims address the persistent challenges of ceramic brittleness and thermal shock sensitivity that have historically limited broader application.

From a manufacturing perspective, key objectives include process repeatability, quality control standardization, and computational modeling capabilities that can predict microstructural outcomes based on process parameters. The industry is moving toward digital twin approaches that combine real-time monitoring with predictive algorithms to ensure consistent microstructural control.

Looking forward, the field aims to develop adaptive coating systems with gradient or layered architectures that can respond to environmental conditions. This represents the evolution from static protective barriers to dynamic material systems with enhanced functionality and longevity in increasingly demanding operational environments.

The 1980s and 1990s witnessed critical advancements in understanding the relationship between process parameters and microstructural features. Researchers established correlations between spray conditions, particle behavior in-flight, and the resulting coating architecture. This period marked the transition from empirical approaches to more scientific methodologies in coating development.

The early 2000s brought significant breakthroughs with the introduction of suspension and solution precursor thermal spray techniques, allowing for the deposition of sub-micron and nanoscale features within coatings. These innovations opened new possibilities for controlling porosity, crack networks, and interfacial characteristics at unprecedented scales.

Current technological trajectories focus on precise microstructural control to achieve multifunctional performance. The field has progressed from merely depositing material to engineering specific microstructural elements—such as columnar structures, controlled porosity gradients, and tailored interfaces—that directly influence thermal, mechanical, and chemical properties of the coating system.

The primary objective in ceramic thermal spray coating development today is achieving deterministic microstructural control across multiple length scales. This involves the ability to design and reliably produce specific microstructural features that optimize performance for targeted applications, particularly in extreme environments such as gas turbines, aerospace components, and energy systems.

Secondary objectives include enhancing coating durability through stress management strategies, improving thermal cycling resistance, and developing self-healing capabilities within ceramic microstructures. These aims address the persistent challenges of ceramic brittleness and thermal shock sensitivity that have historically limited broader application.

From a manufacturing perspective, key objectives include process repeatability, quality control standardization, and computational modeling capabilities that can predict microstructural outcomes based on process parameters. The industry is moving toward digital twin approaches that combine real-time monitoring with predictive algorithms to ensure consistent microstructural control.

Looking forward, the field aims to develop adaptive coating systems with gradient or layered architectures that can respond to environmental conditions. This represents the evolution from static protective barriers to dynamic material systems with enhanced functionality and longevity in increasingly demanding operational environments.

Market Applications and Industry Demand Analysis

The ceramic thermal spray coatings market has witnessed substantial growth in recent years, driven primarily by increasing demand across aerospace, automotive, energy, and healthcare sectors. The global thermal spray coatings market was valued at approximately 10.1 billion USD in 2021, with ceramic coatings representing a significant segment growing at nearly 6.8% CAGR. This growth trajectory is expected to continue as industries seek advanced surface engineering solutions to enhance component performance and longevity.

In the aerospace industry, ceramic thermal spray coatings have become indispensable for protecting turbine blades, combustion chambers, and other high-temperature components. The need for microstructurally controlled coatings has intensified as manufacturers push for higher operating temperatures to improve fuel efficiency and reduce emissions. Boeing and Airbus have both increased their utilization of advanced ceramic coatings in their latest generation aircraft engines, highlighting the critical market demand.

The power generation sector represents another significant market, with gas turbines requiring thermal barrier coatings that can withstand extreme thermal cycling and corrosive environments. The transition toward renewable energy has not diminished this demand, as concentrated solar power systems and biomass facilities also require high-performance ceramic coatings with precisely controlled microstructures.

Healthcare applications have emerged as a rapidly growing segment, particularly in medical implants where biocompatible ceramic coatings with controlled porosity and surface roughness are essential for osseointegration. The global orthopedic implants market, valued at 46.5 billion USD, increasingly relies on advanced ceramic coating technologies to improve implant performance and patient outcomes.

Regional analysis reveals that North America and Europe currently dominate the market for high-end ceramic thermal spray coatings, though Asia-Pacific is experiencing the fastest growth rate due to rapid industrialization in China and India. These emerging markets are primarily driven by automotive and industrial applications, while established markets focus more on aerospace and medical applications requiring more sophisticated microstructural control.

Industry surveys indicate that end-users are increasingly demanding coatings with tailored microstructures that can be customized for specific operating conditions. This has shifted the competitive landscape toward companies that can offer precision-engineered coating solutions rather than standard products. The ability to control porosity, crack networks, interface characteristics, and grain boundaries has become a key differentiator in the market.

In the aerospace industry, ceramic thermal spray coatings have become indispensable for protecting turbine blades, combustion chambers, and other high-temperature components. The need for microstructurally controlled coatings has intensified as manufacturers push for higher operating temperatures to improve fuel efficiency and reduce emissions. Boeing and Airbus have both increased their utilization of advanced ceramic coatings in their latest generation aircraft engines, highlighting the critical market demand.

The power generation sector represents another significant market, with gas turbines requiring thermal barrier coatings that can withstand extreme thermal cycling and corrosive environments. The transition toward renewable energy has not diminished this demand, as concentrated solar power systems and biomass facilities also require high-performance ceramic coatings with precisely controlled microstructures.

Healthcare applications have emerged as a rapidly growing segment, particularly in medical implants where biocompatible ceramic coatings with controlled porosity and surface roughness are essential for osseointegration. The global orthopedic implants market, valued at 46.5 billion USD, increasingly relies on advanced ceramic coating technologies to improve implant performance and patient outcomes.

Regional analysis reveals that North America and Europe currently dominate the market for high-end ceramic thermal spray coatings, though Asia-Pacific is experiencing the fastest growth rate due to rapid industrialization in China and India. These emerging markets are primarily driven by automotive and industrial applications, while established markets focus more on aerospace and medical applications requiring more sophisticated microstructural control.

Industry surveys indicate that end-users are increasingly demanding coatings with tailored microstructures that can be customized for specific operating conditions. This has shifted the competitive landscape toward companies that can offer precision-engineered coating solutions rather than standard products. The ability to control porosity, crack networks, interface characteristics, and grain boundaries has become a key differentiator in the market.

Current Microstructural Control Challenges

Despite significant advancements in ceramic thermal spray coating technologies, several critical microstructural control challenges persist that limit optimal performance and reliability. The inherent complexity of the thermal spray process creates substantial variability in coating microstructure, with parameters such as particle size distribution, injection velocity, flame temperature, and substrate conditions all contributing to inconsistencies. This multi-parameter dependency makes precise control and reproducibility particularly difficult to achieve at industrial scales.

Porosity management remains one of the most significant challenges, as current technologies struggle to achieve the ideal balance between necessary strain tolerance and detrimental permeability. Conventional thermal spray methods typically produce coatings with 10-20% porosity, often with interconnected networks that can accelerate degradation through oxygen penetration and subsequent oxidation of bond coats in high-temperature applications.

Interfacial adhesion between the ceramic coating and metallic substrate presents another persistent challenge. The substantial difference in thermal expansion coefficients between ceramics and metals creates significant stress concentrations during thermal cycling, leading to delamination and spallation failures. Current bonding mechanisms rely heavily on mechanical interlocking rather than chemical bonding, limiting the ultimate adhesion strength achievable.

Residual stress development during deposition and cooling remains inadequately controlled in existing processes. These stresses can reach critical levels that initiate microcracking networks throughout the coating, compromising mechanical integrity before the component even enters service. The industry lacks reliable in-situ monitoring techniques to measure and respond to stress development during the deposition process.

Phase stability control presents another significant challenge, particularly for zirconia-based thermal barrier coatings. The transformation between tetragonal and monoclinic phases during thermal cycling can induce volume changes of approximately 3-5%, creating additional internal stresses that accelerate coating degradation. Current stabilization approaches using yttria or other rare earth oxides provide only partial solutions to this challenge.

Grain boundary engineering, which has proven effective in bulk ceramics, remains largely unexplored in thermal spray coatings due to the rapid solidification inherent in the process. The inability to precisely control grain boundary character distribution limits opportunities to enhance creep resistance and fracture toughness through microstructural design.

Finally, the industry faces significant challenges in developing standardized characterization methodologies that can effectively correlate microstructural features with performance metrics. This gap hampers the development of predictive models that could accelerate innovation and quality control in manufacturing environments.

Porosity management remains one of the most significant challenges, as current technologies struggle to achieve the ideal balance between necessary strain tolerance and detrimental permeability. Conventional thermal spray methods typically produce coatings with 10-20% porosity, often with interconnected networks that can accelerate degradation through oxygen penetration and subsequent oxidation of bond coats in high-temperature applications.

Interfacial adhesion between the ceramic coating and metallic substrate presents another persistent challenge. The substantial difference in thermal expansion coefficients between ceramics and metals creates significant stress concentrations during thermal cycling, leading to delamination and spallation failures. Current bonding mechanisms rely heavily on mechanical interlocking rather than chemical bonding, limiting the ultimate adhesion strength achievable.

Residual stress development during deposition and cooling remains inadequately controlled in existing processes. These stresses can reach critical levels that initiate microcracking networks throughout the coating, compromising mechanical integrity before the component even enters service. The industry lacks reliable in-situ monitoring techniques to measure and respond to stress development during the deposition process.

Phase stability control presents another significant challenge, particularly for zirconia-based thermal barrier coatings. The transformation between tetragonal and monoclinic phases during thermal cycling can induce volume changes of approximately 3-5%, creating additional internal stresses that accelerate coating degradation. Current stabilization approaches using yttria or other rare earth oxides provide only partial solutions to this challenge.

Grain boundary engineering, which has proven effective in bulk ceramics, remains largely unexplored in thermal spray coatings due to the rapid solidification inherent in the process. The inability to precisely control grain boundary character distribution limits opportunities to enhance creep resistance and fracture toughness through microstructural design.

Finally, the industry faces significant challenges in developing standardized characterization methodologies that can effectively correlate microstructural features with performance metrics. This gap hampers the development of predictive models that could accelerate innovation and quality control in manufacturing environments.

State-of-the-Art Microstructural Control Methods

01 Microstructure control in ceramic thermal spray coatings

The microstructure of ceramic thermal spray coatings can be controlled through various processing parameters such as spray distance, particle velocity, and temperature. These factors influence the formation of splats, porosity, and grain boundaries within the coating. Controlling these parameters allows for tailored microstructural features that enhance coating performance, including improved thermal resistance, mechanical strength, and durability.- Microstructure control in ceramic thermal spray coatings: The microstructure of ceramic thermal spray coatings can be controlled through various processing parameters such as spray distance, particle velocity, and temperature. By optimizing these parameters, it is possible to achieve desired microstructural features like porosity, crack density, and grain size. This control is essential for tailoring the coating properties to specific applications, including thermal barrier coatings for high-temperature environments.

- Porosity and defect management in ceramic coatings: Porosity and defects in ceramic thermal spray coatings significantly influence their performance characteristics. Techniques to manage and control porosity levels include adjusting spray parameters, using specific powder morphologies, and post-deposition treatments. Controlled porosity can enhance thermal insulation properties while reducing thermal conductivity, which is particularly beneficial for thermal barrier applications. Managing defects such as microcracks and inter-splat boundaries is crucial for coating durability and performance.

- Layered and composite ceramic coating structures: Multilayered and composite ceramic thermal spray coatings offer enhanced performance through the combination of different materials or graded compositions. These structures can provide improved thermal cycling resistance, better adhesion to substrates, and reduced residual stresses. The interfaces between layers play a critical role in determining overall coating performance, with controlled microstructure at these boundaries being essential for preventing delamination and failure during service.

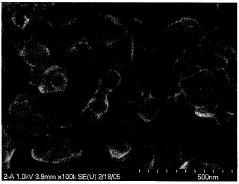

- Nanostructured ceramic thermal spray coatings: Nanostructured ceramic thermal spray coatings exhibit unique microstructural features that can lead to superior properties compared to conventional coatings. These coatings typically contain nanoscale grains, particles, or phases that enhance mechanical properties, thermal shock resistance, and durability. The preservation of nanostructures during the high-temperature spray process requires specialized techniques such as agglomerated nanopowders or suspension/solution precursor feedstocks. The resulting microstructure often shows improved cohesion and reduced defect propagation.

- Phase composition and transformation in ceramic coatings: The phase composition and transformation behavior in ceramic thermal spray coatings significantly impact their performance and durability. During the thermal spray process, rapid solidification can lead to metastable phases, amorphous regions, or non-equilibrium microstructures. Post-deposition heat treatments or service at elevated temperatures can induce phase transformations that affect coating properties. Understanding and controlling these phase-related microstructural features is essential for developing coatings with stable performance under operating conditions.

02 Porosity and defect management in ceramic coatings

Managing porosity and defects in ceramic thermal spray coatings is crucial for optimizing performance. Techniques include using specific powder morphologies, adjusting spray parameters, and post-deposition treatments. Controlled porosity can enhance thermal insulation properties while minimizing detrimental defects like cracks and delamination. The microstructural arrangement of pores and their distribution significantly impacts coating functionality in high-temperature applications.Expand Specific Solutions03 Multi-layer ceramic coating architectures

Multi-layer ceramic thermal spray coating systems feature engineered microstructures with distinct layers serving different functions. These architectures typically include bond coats, functional ceramic layers, and sometimes top sealant layers. The interfaces between layers and their respective microstructures are designed to accommodate thermal expansion mismatches, enhance adhesion, and provide specific performance characteristics such as thermal barrier properties or wear resistance.Expand Specific Solutions04 Nano-structured ceramic thermal spray coatings

Nano-structured ceramic thermal spray coatings incorporate nanoscale features within their microstructure to enhance performance properties. These coatings can be produced using nano-sized feedstock materials or through processing techniques that generate nano-features during deposition. The resulting microstructures exhibit improved cohesion, higher hardness, better wear resistance, and enhanced thermal properties compared to conventional coatings due to the increased grain boundary area and refined microstructural features.Expand Specific Solutions05 Phase composition and stability in ceramic coatings

The phase composition and stability of ceramic thermal spray coatings significantly influence their microstructural characteristics and long-term performance. During the thermal spray process, rapid solidification can result in metastable phases, amorphous regions, or crystalline structures different from equilibrium conditions. Post-deposition heat treatments can be employed to control phase transformations, relieve residual stresses, and stabilize the microstructure for enhanced durability in high-temperature or corrosive environments.Expand Specific Solutions

Leading Companies and Research Institutions

The ceramic thermal spray coatings market is currently in a growth phase, with increasing demand driven by aerospace, power generation, and automotive applications. The global market size is estimated to reach $2.5 billion by 2025, growing at a CAGR of 6.8%. Technologically, the field is maturing with significant innovations in microstructural control. Leading players include Praxair S.T. Technology (Linde) and Oerlikon Metco, who dominate with advanced coating solutions, while research institutions like National Research Council of Canada and University of Maryland contribute fundamental breakthroughs. Industrial giants such as Siemens AG, Rolls-Royce, and Mitsubishi Hitachi Power Systems are integrating these technologies into high-performance applications, focusing on thermal efficiency and durability improvements for extreme operating environments.

Praxair S.T. Technology, Inc.

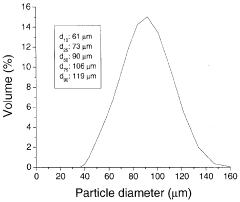

Technical Solution: Praxair S.T. Technology has developed the HVOF (High Velocity Oxy-Fuel) and APS (Atmospheric Plasma Spray) processes specifically optimized for ceramic thermal spray coatings with controlled microstructure. Their proprietary DVC (Dense Vertically Cracked) coating architecture creates predetermined crack networks that enhance strain tolerance while maintaining thermal insulation properties. The company utilizes specialized powder feedstock with controlled particle size distribution and morphology to achieve consistent coating microstructures. Their technology incorporates precise manipulation of spray parameters including standoff distance, gun traverse speed, and substrate temperature to control splat formation and layering patterns. Praxair has pioneered the development of nanostructured and bimodal ceramic powders that, when thermally sprayed, create coatings with refined microstructures featuring controlled porosity networks and grain boundaries[2][4]. Their process includes post-spray heat treatments to stabilize phases and relieve residual stresses, further enhancing coating durability and performance under thermal cycling conditions.

Strengths: Extensive experience in powder development specifically engineered for thermal spray applications; ability to create strain-tolerant microstructures; established manufacturing processes for consistent quality; wide range of ceramic compositions available. Weaknesses: Traditional thermal spray methods may have limitations in achieving certain advanced microstructures compared to newer solution-based approaches; higher material costs for specialized powders; some processes require significant energy consumption.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed advanced Solution Precursor Plasma Spray (SPPS) technology for ceramic thermal spray coatings with precise microstructural control. Their approach involves atomizing liquid precursors directly into plasma flames, enabling the formation of nanoscale features and columnar structures within the coating. This technology allows for the creation of strain-tolerant thermal barrier coatings (TBCs) with enhanced durability and thermal cycling resistance. The company has pioneered the use of suspension and solution precursor feedstocks to achieve unique microstructures not possible with conventional powder-based methods. Their patented process controls splat formation and stacking patterns by manipulating plasma parameters, particle velocity, and substrate temperature, resulting in coatings with tailored porosity networks and crack distributions that enhance thermal insulation properties while maintaining mechanical integrity[1][3]. Oerlikon's approach also incorporates in-situ diagnostic tools to monitor coating growth and adjust parameters in real-time, ensuring consistent microstructural development throughout the coating process.

Strengths: Superior control over nano and microstructural features; ability to create strain-tolerant columnar structures; enhanced thermal cycling performance; reduced thermal conductivity compared to conventional APS coatings. Weaknesses: Higher process complexity requiring precise control of multiple parameters; potentially higher production costs; more sensitive to processing conditions; may require specialized equipment not compatible with all existing thermal spray infrastructure.

Key Patents and Scientific Breakthroughs

Method for microstructure control of ceramic thermal spray coating

PatentInactiveEP1752553A3

Innovation

- A method and apparatus for forming segmented ceramic coatings that control thermal gradients and crack formation by preheating the substrate surface before deposition, promoting vertical microcracking to enhance strain tolerance and durability, involving the use of heat sources and monitoring temperature to manage thermal cycling and crack propagation.

Thermal spray coating of porous nanostructured ceramic feedstock

PatentActiveCA2648643C

Innovation

- Controlled thermal spray deposition parameters, such as particle size distribution, morphology, temperature, and velocity, are used to produce nanostructured coatings with porous inclusions, which maintain porosity and mechanical stability, reducing thermal diffusivity and elastic modulus, and enhancing abradability and durability.

Material Characterization Techniques

Effective characterization of microstructure is fundamental to understanding and controlling ceramic thermal spray coatings. X-ray diffraction (XRD) remains a cornerstone technique, providing critical information about phase composition, crystallinity, and residual stress within the coating layers. Modern XRD equipment with high-resolution capabilities can detect minor phases and quantify amorphous content, which is particularly important as rapid solidification during thermal spraying often produces metastable or amorphous structures.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) offers detailed morphological and elemental analysis at the microscale. The ability to observe splat formation, inter-splat boundaries, and porosity distribution provides direct feedback on spray parameters and their influence on coating microstructure. Advanced SEM techniques such as electron backscatter diffraction (EBSD) further enable crystallographic orientation mapping, revealing texture development that affects mechanical and thermal properties.

Transmission electron microscopy (TEM) extends characterization to the nanoscale, critical for examining fine-grained structures and interfaces in advanced ceramic coatings. TEM analysis can reveal grain boundary characteristics, dislocation structures, and nanoprecipitates that significantly influence coating performance. Recent developments in in-situ TEM allow for real-time observation of microstructural evolution under thermal or mechanical loading conditions.

Non-destructive evaluation techniques have gained prominence for quality control and service life assessment. Ultrasonic testing provides information on coating thickness and adhesion, while infrared thermography can detect subsurface defects and thermal property variations. These techniques are particularly valuable for monitoring coatings in industrial applications without compromising structural integrity.

Advanced 3D characterization methods, including focused ion beam-scanning electron microscopy (FIB-SEM) tomography and X-ray computed tomography (CT), have revolutionized microstructural analysis by providing volumetric information about pore networks, crack propagation paths, and phase distribution. These techniques overcome the limitations of traditional 2D analyses and enable more accurate correlation between processing parameters and resulting microstructures.

Mechanical property mapping through nanoindentation and microhardness testing complements microstructural characterization by linking observed structures to performance metrics. Spatially resolved hardness and elastic modulus measurements can identify property gradients and local variations that affect coating durability and thermal barrier efficiency.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) offers detailed morphological and elemental analysis at the microscale. The ability to observe splat formation, inter-splat boundaries, and porosity distribution provides direct feedback on spray parameters and their influence on coating microstructure. Advanced SEM techniques such as electron backscatter diffraction (EBSD) further enable crystallographic orientation mapping, revealing texture development that affects mechanical and thermal properties.

Transmission electron microscopy (TEM) extends characterization to the nanoscale, critical for examining fine-grained structures and interfaces in advanced ceramic coatings. TEM analysis can reveal grain boundary characteristics, dislocation structures, and nanoprecipitates that significantly influence coating performance. Recent developments in in-situ TEM allow for real-time observation of microstructural evolution under thermal or mechanical loading conditions.

Non-destructive evaluation techniques have gained prominence for quality control and service life assessment. Ultrasonic testing provides information on coating thickness and adhesion, while infrared thermography can detect subsurface defects and thermal property variations. These techniques are particularly valuable for monitoring coatings in industrial applications without compromising structural integrity.

Advanced 3D characterization methods, including focused ion beam-scanning electron microscopy (FIB-SEM) tomography and X-ray computed tomography (CT), have revolutionized microstructural analysis by providing volumetric information about pore networks, crack propagation paths, and phase distribution. These techniques overcome the limitations of traditional 2D analyses and enable more accurate correlation between processing parameters and resulting microstructures.

Mechanical property mapping through nanoindentation and microhardness testing complements microstructural characterization by linking observed structures to performance metrics. Spatially resolved hardness and elastic modulus measurements can identify property gradients and local variations that affect coating durability and thermal barrier efficiency.

Sustainability and Environmental Impact

The sustainability aspects of ceramic thermal spray coatings have gained significant attention as industries increasingly prioritize environmental responsibility. Traditional thermal spray processes often involve high energy consumption, with temperatures reaching several thousand degrees Celsius during application. This energy-intensive nature contributes substantially to the carbon footprint of coating operations, particularly when fossil fuels are used as energy sources. Recent advancements in microstructural control techniques have demonstrated potential for reducing energy requirements by optimizing particle size distribution and spray parameters, resulting in more efficient material deposition and reduced process duration.

Material efficiency represents another critical sustainability dimension. Conventional thermal spray methods typically achieve deposition efficiencies of 40-70%, meaning significant material wastage. By implementing precise microstructural control strategies, researchers have achieved improvements of up to 15% in deposition efficiency, directly reducing raw material consumption and associated environmental impacts. Additionally, the development of nanostructured feedstock materials has enabled thinner coatings with equivalent performance characteristics, further conserving resources.

The environmental impact of ceramic coating production extends to the entire lifecycle. Mining and processing of ceramic raw materials often involve significant land disturbance and energy consumption. Microstructural engineering approaches that incorporate recycled materials or industrial byproducts as feedstock components have demonstrated promising results, with some formulations achieving up to 30% incorporation of recycled content without compromising coating integrity. These circular economy approaches significantly reduce the demand for virgin materials.

Toxicity concerns also merit consideration in ceramic thermal spray applications. Certain traditional coating processes release potentially harmful particulates and volatile compounds. Advanced microstructural control techniques have enabled the development of water-based slurry systems and powder formulations that minimize hazardous emissions during application. Furthermore, improved coating durability through microstructural optimization extends service life, reducing the frequency of reapplication and associated environmental impacts.

Looking forward, the integration of life cycle assessment (LCA) methodologies into coating development processes represents a promising approach for comprehensive sustainability evaluation. Early studies indicate that microstructurally optimized ceramic coatings can reduce overall environmental impact by 20-40% compared to conventional alternatives when considering the entire product lifecycle. This holistic perspective is essential for guiding future research priorities and industrial implementation strategies in ceramic thermal spray technology.

Material efficiency represents another critical sustainability dimension. Conventional thermal spray methods typically achieve deposition efficiencies of 40-70%, meaning significant material wastage. By implementing precise microstructural control strategies, researchers have achieved improvements of up to 15% in deposition efficiency, directly reducing raw material consumption and associated environmental impacts. Additionally, the development of nanostructured feedstock materials has enabled thinner coatings with equivalent performance characteristics, further conserving resources.

The environmental impact of ceramic coating production extends to the entire lifecycle. Mining and processing of ceramic raw materials often involve significant land disturbance and energy consumption. Microstructural engineering approaches that incorporate recycled materials or industrial byproducts as feedstock components have demonstrated promising results, with some formulations achieving up to 30% incorporation of recycled content without compromising coating integrity. These circular economy approaches significantly reduce the demand for virgin materials.

Toxicity concerns also merit consideration in ceramic thermal spray applications. Certain traditional coating processes release potentially harmful particulates and volatile compounds. Advanced microstructural control techniques have enabled the development of water-based slurry systems and powder formulations that minimize hazardous emissions during application. Furthermore, improved coating durability through microstructural optimization extends service life, reducing the frequency of reapplication and associated environmental impacts.

Looking forward, the integration of life cycle assessment (LCA) methodologies into coating development processes represents a promising approach for comprehensive sustainability evaluation. Early studies indicate that microstructurally optimized ceramic coatings can reduce overall environmental impact by 20-40% compared to conventional alternatives when considering the entire product lifecycle. This holistic perspective is essential for guiding future research priorities and industrial implementation strategies in ceramic thermal spray technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!