Advances in Yttria Stabilized Zirconia Thermal Sprays

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

YSZ Thermal Spray Technology Background and Objectives

Yttria Stabilized Zirconia (YSZ) thermal spray technology has evolved significantly since its inception in the mid-20th century. Initially developed for aerospace applications, YSZ coatings have become critical components in various high-temperature environments due to their exceptional thermal barrier properties. The evolution of this technology has been driven by the increasing demand for materials capable of withstanding extreme thermal conditions while maintaining structural integrity.

The fundamental principle behind YSZ thermal sprays involves the stabilization of zirconia's crystal structure through the addition of yttria, typically in concentrations ranging from 7-8 wt%. This stabilization prevents detrimental phase transformations that would otherwise occur during thermal cycling, ensuring coating longevity and performance reliability. Early applications primarily focused on turbine engine components, but the technology has since expanded to numerous industrial sectors.

Technological advancements in spray techniques have marked distinct evolutionary phases. The 1970s saw the development of atmospheric plasma spraying (APS), which remained the industry standard for decades. The 1990s brought significant improvements with the introduction of electron beam physical vapor deposition (EB-PVD), offering superior strain tolerance and surface finish. Recent innovations include suspension and solution precursor plasma spraying, enabling the creation of nanostructured coatings with enhanced performance characteristics.

The current technological trajectory aims to address several critical objectives. Primary among these is the enhancement of coating durability under increasingly extreme operating conditions, with modern gas turbines pushing temperature boundaries beyond 1300°C. Researchers are focusing on improving thermal cycling resistance, reducing thermal conductivity, and enhancing erosion resistance while maintaining coating adherence to substrates.

Another significant objective involves the development of advanced manufacturing processes that offer greater precision, reproducibility, and cost-effectiveness. This includes the integration of computational modeling for spray parameter optimization and the implementation of in-situ monitoring systems to ensure coating quality during deposition.

Environmental considerations have also emerged as important drivers in YSZ technology development. Current research aims to reduce energy consumption during the coating process and minimize waste production, aligning with global sustainability initiatives. Additionally, there is growing interest in developing YSZ coatings for renewable energy applications, such as solid oxide fuel cells and concentrated solar power systems.

The convergence of materials science, advanced manufacturing, and computational modeling is expected to propel YSZ thermal spray technology toward new frontiers, enabling applications previously considered unfeasible due to thermal limitations.

The fundamental principle behind YSZ thermal sprays involves the stabilization of zirconia's crystal structure through the addition of yttria, typically in concentrations ranging from 7-8 wt%. This stabilization prevents detrimental phase transformations that would otherwise occur during thermal cycling, ensuring coating longevity and performance reliability. Early applications primarily focused on turbine engine components, but the technology has since expanded to numerous industrial sectors.

Technological advancements in spray techniques have marked distinct evolutionary phases. The 1970s saw the development of atmospheric plasma spraying (APS), which remained the industry standard for decades. The 1990s brought significant improvements with the introduction of electron beam physical vapor deposition (EB-PVD), offering superior strain tolerance and surface finish. Recent innovations include suspension and solution precursor plasma spraying, enabling the creation of nanostructured coatings with enhanced performance characteristics.

The current technological trajectory aims to address several critical objectives. Primary among these is the enhancement of coating durability under increasingly extreme operating conditions, with modern gas turbines pushing temperature boundaries beyond 1300°C. Researchers are focusing on improving thermal cycling resistance, reducing thermal conductivity, and enhancing erosion resistance while maintaining coating adherence to substrates.

Another significant objective involves the development of advanced manufacturing processes that offer greater precision, reproducibility, and cost-effectiveness. This includes the integration of computational modeling for spray parameter optimization and the implementation of in-situ monitoring systems to ensure coating quality during deposition.

Environmental considerations have also emerged as important drivers in YSZ technology development. Current research aims to reduce energy consumption during the coating process and minimize waste production, aligning with global sustainability initiatives. Additionally, there is growing interest in developing YSZ coatings for renewable energy applications, such as solid oxide fuel cells and concentrated solar power systems.

The convergence of materials science, advanced manufacturing, and computational modeling is expected to propel YSZ thermal spray technology toward new frontiers, enabling applications previously considered unfeasible due to thermal limitations.

Market Demand Analysis for Advanced Thermal Barrier Coatings

The global market for advanced thermal barrier coatings (TBCs) has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, power generation, and automotive industries. Yttria Stabilized Zirconia (YSZ) thermal sprays represent a critical segment within this market, valued at approximately $2.3 billion in 2022 with projections to reach $3.5 billion by 2028, reflecting a compound annual growth rate of 7.2%.

Aerospace applications constitute the largest market segment for YSZ thermal sprays, accounting for nearly 45% of total demand. This is attributed to the critical need for high-temperature protection in aircraft engines, where operating temperatures continue to increase to improve fuel efficiency and performance. Commercial aviation's recovery post-pandemic has further accelerated this demand, with major manufacturers like Boeing and Airbus increasing production rates.

The power generation sector represents the second-largest market for YSZ thermal barrier coatings, driven by the global transition toward more efficient gas turbines and combined cycle power plants. These applications require coatings capable of withstanding temperatures exceeding 1200°C while providing thermal insulation and oxidation resistance. Market analysis indicates a 9.3% growth rate in this sector, outpacing the overall market average.

Automotive applications, particularly in high-performance and racing vehicles, are emerging as a rapidly growing segment with 11.5% annual growth. The push toward more efficient internal combustion engines and the development of new propulsion technologies have created new opportunities for thermal barrier coatings in exhaust systems, cylinder heads, and pistons.

Regionally, North America and Europe currently dominate the market with a combined share of 58%, though Asia-Pacific is experiencing the fastest growth at 10.2% annually. China and India are particularly noteworthy markets due to their expanding aerospace industries and significant investments in power generation infrastructure.

Customer requirements are evolving toward coatings with longer service life, reduced maintenance requirements, and enhanced performance under extreme conditions. This has created a premium segment within the market, where advanced YSZ formulations with improved phase stability and reduced thermal conductivity command price premiums of 30-40% over standard coatings.

The market is also witnessing increased demand for environmentally friendly coating processes with reduced waste and energy consumption. This trend aligns with broader sustainability initiatives across industries and represents a significant opportunity for innovation in YSZ thermal spray technologies and application methods.

Aerospace applications constitute the largest market segment for YSZ thermal sprays, accounting for nearly 45% of total demand. This is attributed to the critical need for high-temperature protection in aircraft engines, where operating temperatures continue to increase to improve fuel efficiency and performance. Commercial aviation's recovery post-pandemic has further accelerated this demand, with major manufacturers like Boeing and Airbus increasing production rates.

The power generation sector represents the second-largest market for YSZ thermal barrier coatings, driven by the global transition toward more efficient gas turbines and combined cycle power plants. These applications require coatings capable of withstanding temperatures exceeding 1200°C while providing thermal insulation and oxidation resistance. Market analysis indicates a 9.3% growth rate in this sector, outpacing the overall market average.

Automotive applications, particularly in high-performance and racing vehicles, are emerging as a rapidly growing segment with 11.5% annual growth. The push toward more efficient internal combustion engines and the development of new propulsion technologies have created new opportunities for thermal barrier coatings in exhaust systems, cylinder heads, and pistons.

Regionally, North America and Europe currently dominate the market with a combined share of 58%, though Asia-Pacific is experiencing the fastest growth at 10.2% annually. China and India are particularly noteworthy markets due to their expanding aerospace industries and significant investments in power generation infrastructure.

Customer requirements are evolving toward coatings with longer service life, reduced maintenance requirements, and enhanced performance under extreme conditions. This has created a premium segment within the market, where advanced YSZ formulations with improved phase stability and reduced thermal conductivity command price premiums of 30-40% over standard coatings.

The market is also witnessing increased demand for environmentally friendly coating processes with reduced waste and energy consumption. This trend aligns with broader sustainability initiatives across industries and represents a significant opportunity for innovation in YSZ thermal spray technologies and application methods.

Current State and Challenges in YSZ Thermal Spray Technology

Yttria Stabilized Zirconia (YSZ) thermal spray technology has reached a significant level of maturity in global industrial applications, particularly in thermal barrier coatings (TBCs) for aerospace, power generation, and automotive sectors. Current state-of-the-art processes include atmospheric plasma spraying (APS), high-velocity oxy-fuel (HVOF), and suspension plasma spraying (SPS), each offering distinct advantages in coating microstructure and performance characteristics.

Despite widespread adoption, YSZ thermal spray technology faces several critical challenges. Coating durability remains a primary concern, with thermal cycling fatigue and hot corrosion resistance limiting component lifespans in extreme environments. Current YSZ coatings typically achieve 1000-2000 thermal cycles before failure, which falls short of next-generation engine requirements that demand 3000+ cycles.

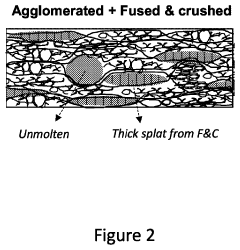

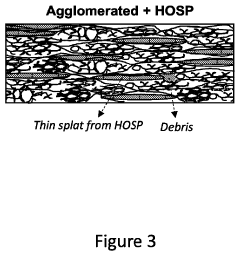

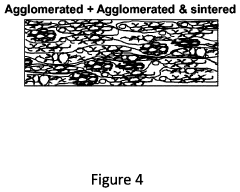

Microstructural control presents another significant challenge. The relationship between spray parameters and resultant coating microstructure remains incompletely understood, leading to inconsistencies in porosity distribution, splat boundaries, and crack networks. These microstructural features directly impact thermal conductivity and strain tolerance, which are crucial performance metrics for TBCs.

Process repeatability and quality control continue to challenge manufacturers. Variations in feedstock materials, equipment wear, and environmental conditions contribute to batch-to-batch inconsistencies. Current in-situ monitoring technologies lack the resolution and response time needed for real-time process adjustments, resulting in post-production quality issues and increased rejection rates.

Energy efficiency concerns are becoming increasingly prominent. Conventional thermal spray processes exhibit thermal efficiencies of only 30-50%, with significant energy losses occurring through radiation, convection, and unused thermal energy in exhaust gases. This inefficiency translates to higher operational costs and environmental impact.

Geographically, YSZ thermal spray technology development shows distinct regional characteristics. North America and Europe lead in fundamental research and high-end applications, while Asia, particularly China and India, demonstrates rapid growth in manufacturing capacity and application breadth. Japan maintains specialized expertise in ultra-thin and precisely controlled coatings for electronics applications.

Emerging alternative materials pose competitive challenges to traditional YSZ. Gadolinium zirconate, lanthanum zirconate, and other rare-earth pyrochlores demonstrate superior high-temperature phase stability and lower thermal conductivity, though they typically exhibit lower fracture toughness than YSZ. These materials are gradually gaining market share in specialized high-temperature applications.

Despite widespread adoption, YSZ thermal spray technology faces several critical challenges. Coating durability remains a primary concern, with thermal cycling fatigue and hot corrosion resistance limiting component lifespans in extreme environments. Current YSZ coatings typically achieve 1000-2000 thermal cycles before failure, which falls short of next-generation engine requirements that demand 3000+ cycles.

Microstructural control presents another significant challenge. The relationship between spray parameters and resultant coating microstructure remains incompletely understood, leading to inconsistencies in porosity distribution, splat boundaries, and crack networks. These microstructural features directly impact thermal conductivity and strain tolerance, which are crucial performance metrics for TBCs.

Process repeatability and quality control continue to challenge manufacturers. Variations in feedstock materials, equipment wear, and environmental conditions contribute to batch-to-batch inconsistencies. Current in-situ monitoring technologies lack the resolution and response time needed for real-time process adjustments, resulting in post-production quality issues and increased rejection rates.

Energy efficiency concerns are becoming increasingly prominent. Conventional thermal spray processes exhibit thermal efficiencies of only 30-50%, with significant energy losses occurring through radiation, convection, and unused thermal energy in exhaust gases. This inefficiency translates to higher operational costs and environmental impact.

Geographically, YSZ thermal spray technology development shows distinct regional characteristics. North America and Europe lead in fundamental research and high-end applications, while Asia, particularly China and India, demonstrates rapid growth in manufacturing capacity and application breadth. Japan maintains specialized expertise in ultra-thin and precisely controlled coatings for electronics applications.

Emerging alternative materials pose competitive challenges to traditional YSZ. Gadolinium zirconate, lanthanum zirconate, and other rare-earth pyrochlores demonstrate superior high-temperature phase stability and lower thermal conductivity, though they typically exhibit lower fracture toughness than YSZ. These materials are gradually gaining market share in specialized high-temperature applications.

Current YSZ Thermal Spray Application Solutions

01 Composition and properties of YSZ thermal spray coatings

Yttria Stabilized Zirconia (YSZ) thermal spray coatings are composed of zirconia (ZrO2) stabilized with yttria (Y2O3) in specific proportions to achieve desired crystal structure and properties. These coatings typically contain 7-8% yttria to stabilize the tetragonal phase of zirconia, providing excellent thermal insulation properties, high temperature stability, and resistance to thermal shock. The microstructure and porosity of these coatings can be controlled during the thermal spray process to optimize performance for specific applications.- Composition and properties of YSZ thermal spray coatings: Yttria Stabilized Zirconia (YSZ) thermal spray coatings are composed of zirconia (ZrO2) stabilized with yttria (Y2O3) in specific proportions to achieve desired crystal structure and properties. These coatings typically contain 7-8 wt% yttria to stabilize the tetragonal phase of zirconia, providing excellent thermal shock resistance and low thermal conductivity. The microstructure and porosity of these coatings can be controlled through spray parameters to optimize thermal barrier performance for high-temperature applications.

- Thermal spray deposition techniques for YSZ coatings: Various thermal spray techniques are employed for depositing Yttria Stabilized Zirconia coatings, including atmospheric plasma spraying (APS), high-velocity oxy-fuel (HVOF), suspension plasma spraying, and solution precursor plasma spraying. Each technique offers different advantages in terms of coating density, adhesion strength, and microstructure. Process parameters such as spray distance, powder feed rate, plasma power, and substrate temperature significantly influence the final coating properties and performance in thermal barrier applications.

- YSZ thermal spray applications in turbine engines: Yttria Stabilized Zirconia thermal spray coatings are widely used in gas turbine engines as thermal barrier coatings (TBCs) to protect metal components from high operating temperatures. These coatings are applied to combustion chambers, turbine blades, vanes, and other hot section components to increase engine efficiency and component lifespan. The coatings provide thermal insulation that allows higher operating temperatures while reducing the thermal load on the underlying metal substrate, resulting in improved engine performance and fuel efficiency.

- Bond coat systems for YSZ thermal spray coatings: Effective application of YSZ thermal spray coatings often requires specialized bond coat systems to ensure proper adhesion and performance. MCrAlY (where M represents Ni, Co, or a combination) bond coats are commonly used between the substrate and the YSZ top coat to improve adhesion and provide oxidation resistance. These bond coat systems form a thermally grown oxide layer that enhances coating durability and thermal cycling performance. Advanced multilayer systems may incorporate gradient compositions or additional ceramic layers to minimize thermal expansion mismatch and improve overall coating system longevity.

- Novel developments in YSZ thermal spray technology: Recent innovations in YSZ thermal spray technology include nanostructured coatings, functionally graded materials, and composite systems with enhanced properties. These developments focus on improving coating durability, reducing thermal conductivity, and enhancing erosion resistance. Advanced processing techniques such as solution precursor plasma spraying enable the creation of unique microstructures with superior performance characteristics. Additionally, doping YSZ with rare earth elements or incorporating secondary phases can further enhance coating properties for extreme environment applications.

02 Thermal spray deposition techniques for YSZ coatings

Various thermal spray techniques are employed for depositing Yttria Stabilized Zirconia coatings, including atmospheric plasma spraying (APS), high-velocity oxy-fuel (HVOF), suspension plasma spraying, and solution precursor plasma spraying. Each technique offers different advantages in terms of coating density, adhesion strength, and microstructure control. Process parameters such as spray distance, powder feed rate, plasma power, and substrate temperature significantly influence the final coating properties and performance.Expand Specific Solutions03 Applications of YSZ thermal spray coatings in thermal barrier systems

Yttria Stabilized Zirconia thermal spray coatings are widely used as thermal barrier coatings (TBCs) in high-temperature applications, particularly in gas turbine engines for aerospace and power generation. These coatings provide thermal insulation to protect underlying metal components from extreme temperatures, extending component life and enabling higher operating temperatures for improved efficiency. The coatings are typically applied as part of a multi-layer system that includes a bond coat to improve adhesion and oxidation resistance.Expand Specific Solutions04 Advanced modifications and enhancements to YSZ thermal spray coatings

Recent advancements in YSZ thermal spray coatings include doping with additional elements, creating nanostructured or graded compositions, and developing hybrid coating systems. These modifications aim to enhance properties such as erosion resistance, thermal cycling durability, and high-temperature stability. Techniques such as co-spraying, layered architectures, and post-deposition treatments are employed to tailor coating performance for specific operating conditions and to address limitations of conventional YSZ coatings.Expand Specific Solutions05 Manufacturing processes and quality control for YSZ thermal spray coatings

Manufacturing processes for YSZ thermal spray coatings involve careful powder preparation, substrate surface preparation, controlled spray parameters, and post-coating treatments. Quality control measures include microstructural analysis, porosity measurement, adhesion testing, thermal conductivity evaluation, and thermal cycling tests. Advanced characterization techniques such as scanning electron microscopy, X-ray diffraction, and thermal imaging are employed to ensure coating consistency and performance. Process monitoring systems help maintain coating quality during production.Expand Specific Solutions

Key Industry Players in YSZ Thermal Spray Market

The Yttria Stabilized Zirconia (YSZ) thermal spray market is currently in a growth phase, with increasing applications across aerospace, energy, and medical sectors. The global market size is estimated to exceed $2 billion, driven by demand for thermal barrier coatings and wear-resistant surfaces. Leading players include Praxair Technology (Linde), Oerlikon Metco, and Saint-Gobain Ceramics, who have established strong technological capabilities through decades of R&D. Asian manufacturers like Tosoh Corp and Daiichi Kigenso are rapidly gaining market share with cost-competitive offerings. The technology has reached commercial maturity for standard applications, but innovation continues in nano-structured coatings and advanced deposition techniques, with companies like Mitsubishi Heavy Industries and United Technologies investing in next-generation solutions for extreme environments.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair S.T. Technology has developed advanced HVOF (High Velocity Oxy-Fuel) thermal spray processes specifically optimized for Yttria Stabilized Zirconia (YSZ) coatings. Their proprietary technology utilizes nano-structured YSZ feedstock materials with precisely controlled particle size distribution (20-45 μm) to achieve superior coating density exceeding 98%. The company's DuraSource™ YSZ coatings incorporate a gradient structure with varying yttria content (from 4-8 mol%) throughout the coating thickness, creating a thermal expansion coefficient gradient that significantly reduces interfacial stresses during thermal cycling. Their process employs computer-controlled spray parameters with real-time monitoring systems that adjust gas flow rates, powder feed rates, and gun trajectories to maintain consistent coating quality across complex geometries. Recent innovations include the development of suspension-based YSZ thermal spray techniques that enable ultra-thin coatings (50-200 μm) with columnar microstructures that enhance strain tolerance.

Strengths: Superior coating density and adhesion strength compared to conventional plasma spray methods; excellent thermal cycling resistance due to engineered microstructure; precise thickness control even on complex geometries. Weaknesses: Higher initial equipment investment costs; more complex process control requirements; limited coating thickness in single-pass applications requiring multiple layers for thicker coatings.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has pioneered the MetcoClad™ system specifically for YSZ thermal spray applications, featuring a proprietary powder injection methodology that achieves uniform particle heating and acceleration. Their technology utilizes a segmented nozzle design that creates controlled turbulence zones, resulting in more homogeneous YSZ coatings with porosity levels below 2%. The company's advanced YSZ formulations incorporate rare earth oxide dopants (Ce, La, Gd) at 0.5-2 wt% concentrations to enhance phase stability at elevated temperatures up to 1400°C. Their process employs a dual-cooling approach during deposition, with primary and secondary cooling jets that control substrate temperature within ±15°C, minimizing residual stresses in the coating. Oerlikon has also developed specialized post-treatment processes including controlled atmosphere heat treatment and laser surface modification that enhance the erosion resistance of YSZ coatings by up to 40% compared to conventional thermal spray coatings. Their latest innovation involves functionally graded YSZ coatings with tailored porosity gradients that optimize both thermal insulation and mechanical durability.

Strengths: Exceptional coating uniformity and reproducibility; superior erosion resistance; excellent high-temperature phase stability; versatile application across multiple industries. Weaknesses: Higher material costs due to specialized powder formulations; more complex equipment setup and maintenance requirements; limited flexibility for on-site applications due to equipment size and complexity.

Critical Patents and Technical Literature in YSZ Thermal Sprays

Composite thermal spray powder of oxides and non-oxides

PatentPendingUS20240059904A1

Innovation

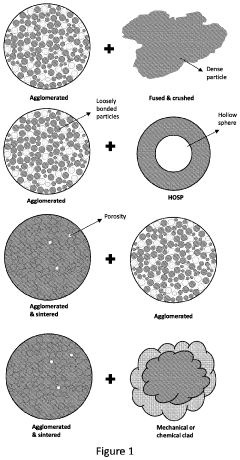

- The use of multiple powder fractions with dissimilar particle sizes and morphologies, produced through various manufacturing methods, is combined to create coatings with improved abradability, erosion resistance, and reduced sintering, incorporating high entropy oxides and rare-earth elements to enhance thermal insulation and durability.

Environmental Impact and Sustainability Considerations

The environmental impact of Yttria Stabilized Zirconia (YSZ) thermal spray technologies has become increasingly important as industries face stricter regulations and sustainability requirements. Traditional thermal spray processes consume significant energy and often generate hazardous waste, making environmental considerations critical for future development and implementation.

Energy consumption represents one of the primary environmental concerns in YSZ thermal spray applications. Conventional plasma spray processes operate at extremely high temperatures (15,000-20,000°C), requiring substantial electrical power. Recent advancements have focused on optimizing spray parameters and equipment design to reduce energy requirements by 15-30% while maintaining coating quality. Solution precursor and suspension thermal spray techniques have demonstrated particular promise, operating at lower overall energy inputs compared to traditional powder-based methods.

Waste generation during YSZ thermal spray operations presents another significant environmental challenge. The process typically yields overspray material that cannot be recaptured, with utilization efficiencies often below 70%. Innovative containment systems and powder recovery technologies have emerged, enabling the collection and reprocessing of up to 40% of overspray materials that would otherwise become waste. These systems not only reduce environmental impact but also offer economic benefits through material conservation.

Atmospheric emissions from thermal spray operations include fine particulate matter, metal oxides, and in some cases, volatile organic compounds. Modern filtration systems have evolved to capture over 99% of particulates, though the management of ultrafine particles remains challenging. Closed-loop spray booths represent the current best practice, significantly reducing workplace exposure and environmental release of potentially harmful substances.

Water usage in cooling systems and post-processing stages has been addressed through the development of closed-cycle cooling technologies and dry finishing methods. These innovations have reduced water consumption by up to 60% compared to conventional systems used a decade ago. Additionally, water treatment technologies specifically designed for thermal spray operations have improved the quality of discharged water.

Life cycle assessment studies indicate that despite the environmental impacts of YSZ thermal spray manufacturing, the technology delivers net environmental benefits through extended component lifespans and improved energy efficiency in applications such as gas turbines. Recent research suggests that YSZ coatings in turbine applications can reduce fuel consumption by 1-3%, translating to significant carbon emission reductions over the operational lifetime of components.

Future sustainability improvements will likely focus on developing lower-temperature spray processes, increasing material utilization efficiency, and exploring bio-based binder alternatives for certain applications. The integration of renewable energy sources to power thermal spray operations also represents a promising avenue for reducing the carbon footprint of YSZ coating production.

Energy consumption represents one of the primary environmental concerns in YSZ thermal spray applications. Conventional plasma spray processes operate at extremely high temperatures (15,000-20,000°C), requiring substantial electrical power. Recent advancements have focused on optimizing spray parameters and equipment design to reduce energy requirements by 15-30% while maintaining coating quality. Solution precursor and suspension thermal spray techniques have demonstrated particular promise, operating at lower overall energy inputs compared to traditional powder-based methods.

Waste generation during YSZ thermal spray operations presents another significant environmental challenge. The process typically yields overspray material that cannot be recaptured, with utilization efficiencies often below 70%. Innovative containment systems and powder recovery technologies have emerged, enabling the collection and reprocessing of up to 40% of overspray materials that would otherwise become waste. These systems not only reduce environmental impact but also offer economic benefits through material conservation.

Atmospheric emissions from thermal spray operations include fine particulate matter, metal oxides, and in some cases, volatile organic compounds. Modern filtration systems have evolved to capture over 99% of particulates, though the management of ultrafine particles remains challenging. Closed-loop spray booths represent the current best practice, significantly reducing workplace exposure and environmental release of potentially harmful substances.

Water usage in cooling systems and post-processing stages has been addressed through the development of closed-cycle cooling technologies and dry finishing methods. These innovations have reduced water consumption by up to 60% compared to conventional systems used a decade ago. Additionally, water treatment technologies specifically designed for thermal spray operations have improved the quality of discharged water.

Life cycle assessment studies indicate that despite the environmental impacts of YSZ thermal spray manufacturing, the technology delivers net environmental benefits through extended component lifespans and improved energy efficiency in applications such as gas turbines. Recent research suggests that YSZ coatings in turbine applications can reduce fuel consumption by 1-3%, translating to significant carbon emission reductions over the operational lifetime of components.

Future sustainability improvements will likely focus on developing lower-temperature spray processes, increasing material utilization efficiency, and exploring bio-based binder alternatives for certain applications. The integration of renewable energy sources to power thermal spray operations also represents a promising avenue for reducing the carbon footprint of YSZ coating production.

Performance Testing and Quality Control Standards

Performance testing and quality control standards for Yttria Stabilized Zirconia (YSZ) thermal spray coatings have evolved significantly to ensure consistent reliability in high-temperature applications. The industry has established comprehensive testing protocols that evaluate both mechanical and thermal properties of these specialized coatings.

Adhesion strength testing represents a critical quality control measure, typically performed through methods such as ASTM C633 pull-off testing or scratch testing. These standardized procedures quantify the bonding effectiveness between the YSZ coating and substrate material, with minimum adhesion strength requirements typically ranging from 20-30 MPa for turbine applications.

Thermal cycling resistance testing has become increasingly sophisticated, subjecting coatings to rapid temperature fluctuations between ambient and operating temperatures (often exceeding 1200°C). Modern testing regimes now incorporate thousands of cycles to simulate real-world service conditions, with failure analysis conducted through advanced imaging techniques including scanning electron microscopy and X-ray diffraction.

Porosity measurement standards have been refined to ensure optimal thermal insulation properties while maintaining structural integrity. Mercury intrusion porosimetry and image analysis techniques now provide quantitative assessments of pore size distribution and volume percentage, with target porosity ranges typically between 10-15% for thermal barrier applications.

Thermal conductivity testing has standardized around laser flash analysis and hot disk methods, allowing precise measurement of a coating's insulation effectiveness. Quality YSZ coatings must demonstrate thermal conductivity values below 1.0-1.5 W/m·K at elevated temperatures to meet industry specifications.

Erosion resistance testing protocols simulate particulate impact conditions using standardized equipment that accelerates abrasive media at controlled velocities against coated specimens. Weight loss measurements and surface profilometry provide quantitative erosion resistance metrics, with acceptance criteria based on application-specific requirements.

Non-destructive evaluation techniques have advanced significantly, with ultrasonic testing, thermography, and eddy current methods now routinely employed for in-process and post-application quality control. These methods enable detection of delamination, cracking, and thickness variations without compromising coating integrity.

Statistical process control methodologies have been integrated into production environments, establishing control limits for critical parameters such as particle velocity, temperature, and feed rate during thermal spray operations. This approach has substantially improved batch-to-batch consistency and reduced defect rates in high-volume manufacturing settings.

Adhesion strength testing represents a critical quality control measure, typically performed through methods such as ASTM C633 pull-off testing or scratch testing. These standardized procedures quantify the bonding effectiveness between the YSZ coating and substrate material, with minimum adhesion strength requirements typically ranging from 20-30 MPa for turbine applications.

Thermal cycling resistance testing has become increasingly sophisticated, subjecting coatings to rapid temperature fluctuations between ambient and operating temperatures (often exceeding 1200°C). Modern testing regimes now incorporate thousands of cycles to simulate real-world service conditions, with failure analysis conducted through advanced imaging techniques including scanning electron microscopy and X-ray diffraction.

Porosity measurement standards have been refined to ensure optimal thermal insulation properties while maintaining structural integrity. Mercury intrusion porosimetry and image analysis techniques now provide quantitative assessments of pore size distribution and volume percentage, with target porosity ranges typically between 10-15% for thermal barrier applications.

Thermal conductivity testing has standardized around laser flash analysis and hot disk methods, allowing precise measurement of a coating's insulation effectiveness. Quality YSZ coatings must demonstrate thermal conductivity values below 1.0-1.5 W/m·K at elevated temperatures to meet industry specifications.

Erosion resistance testing protocols simulate particulate impact conditions using standardized equipment that accelerates abrasive media at controlled velocities against coated specimens. Weight loss measurements and surface profilometry provide quantitative erosion resistance metrics, with acceptance criteria based on application-specific requirements.

Non-destructive evaluation techniques have advanced significantly, with ultrasonic testing, thermography, and eddy current methods now routinely employed for in-process and post-application quality control. These methods enable detection of delamination, cracking, and thickness variations without compromising coating integrity.

Statistical process control methodologies have been integrated into production environments, establishing control limits for critical parameters such as particle velocity, temperature, and feed rate during thermal spray operations. This approach has substantially improved batch-to-batch consistency and reduced defect rates in high-volume manufacturing settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!