Ceramic Coatings for Aerospace and Turbine Applications

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Ceramic Coating Evolution and Objectives

Ceramic coatings for aerospace and turbine applications have evolved significantly over the past seven decades, transforming from rudimentary thermal barriers to sophisticated multi-functional protective systems. The development journey began in the 1950s with simple alumina-based coatings primarily designed for oxidation resistance. By the 1970s, the introduction of yttria-stabilized zirconia (YSZ) marked a pivotal advancement, establishing what would become the industry standard for thermal barrier coatings (TBCs) in high-temperature environments.

The 1980s and 1990s witnessed substantial refinements in coating deposition techniques, with plasma spraying and electron beam physical vapor deposition (EB-PVD) emerging as dominant methodologies. These processes enabled precise microstructural control, significantly enhancing coating durability and performance. The early 2000s brought increased focus on environmental barrier coatings (EBCs) to protect silicon-based ceramic matrix composites from water vapor attack in combustion environments.

Current technological trajectories indicate a shift toward multi-layered, multi-functional coating systems that simultaneously address thermal protection, oxidation resistance, erosion mitigation, and CMAS (calcium-magnesium-alumino-silicate) infiltration prevention. Advanced rare-earth zirconates and hafnates are being explored as next-generation materials with superior phase stability and reduced thermal conductivity compared to conventional YSZ.

The primary objectives of contemporary ceramic coating research center on extending component lifespans in increasingly extreme operating conditions. Modern aerospace engines and industrial gas turbines are pushing toward higher operating temperatures to improve efficiency and reduce emissions, creating unprecedented demands on material systems. Specifically, research aims to develop coatings capable of withstanding temperatures exceeding 1400°C while maintaining structural integrity under severe thermal cycling.

Additional technical goals include reducing coating thickness without compromising protective functions, enhancing strain tolerance to accommodate thermal expansion mismatches, and improving manufacturing reproducibility for complex geometries. There is also significant interest in developing self-healing coating capabilities and non-destructive evaluation techniques for in-service monitoring of coating degradation.

The evolution of these technologies is increasingly driven by computational modeling and simulation tools that enable rapid iteration and testing of novel material compositions and architectures before physical prototyping. This approach, combined with advanced characterization techniques, is accelerating the pace of innovation in this critical field, with the ultimate goal of enabling more efficient, durable, and environmentally friendly propulsion and power generation systems.

The 1980s and 1990s witnessed substantial refinements in coating deposition techniques, with plasma spraying and electron beam physical vapor deposition (EB-PVD) emerging as dominant methodologies. These processes enabled precise microstructural control, significantly enhancing coating durability and performance. The early 2000s brought increased focus on environmental barrier coatings (EBCs) to protect silicon-based ceramic matrix composites from water vapor attack in combustion environments.

Current technological trajectories indicate a shift toward multi-layered, multi-functional coating systems that simultaneously address thermal protection, oxidation resistance, erosion mitigation, and CMAS (calcium-magnesium-alumino-silicate) infiltration prevention. Advanced rare-earth zirconates and hafnates are being explored as next-generation materials with superior phase stability and reduced thermal conductivity compared to conventional YSZ.

The primary objectives of contemporary ceramic coating research center on extending component lifespans in increasingly extreme operating conditions. Modern aerospace engines and industrial gas turbines are pushing toward higher operating temperatures to improve efficiency and reduce emissions, creating unprecedented demands on material systems. Specifically, research aims to develop coatings capable of withstanding temperatures exceeding 1400°C while maintaining structural integrity under severe thermal cycling.

Additional technical goals include reducing coating thickness without compromising protective functions, enhancing strain tolerance to accommodate thermal expansion mismatches, and improving manufacturing reproducibility for complex geometries. There is also significant interest in developing self-healing coating capabilities and non-destructive evaluation techniques for in-service monitoring of coating degradation.

The evolution of these technologies is increasingly driven by computational modeling and simulation tools that enable rapid iteration and testing of novel material compositions and architectures before physical prototyping. This approach, combined with advanced characterization techniques, is accelerating the pace of innovation in this critical field, with the ultimate goal of enabling more efficient, durable, and environmentally friendly propulsion and power generation systems.

Market Analysis for High-Performance Thermal Barrier Coatings

The global market for high-performance thermal barrier coatings (TBCs) is experiencing robust growth, primarily driven by increasing demands in aerospace and power generation sectors. The market value reached approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% through 2028, potentially reaching $1.8 billion by the end of the forecast period.

Aerospace applications currently dominate the market share, accounting for nearly 45% of the total demand. This is attributed to the critical need for materials that can withstand extreme temperatures in aircraft engines, where efficiency improvements directly correlate with operating temperatures. Commercial aviation's recovery post-pandemic and increased defense spending worldwide have further accelerated this demand.

The power generation sector represents the second-largest market segment at 30%, with particular emphasis on gas turbines for electricity production. As global energy demands rise and efficiency standards become more stringent, the implementation of advanced ceramic coatings has become essential for extending turbine life and improving performance metrics.

Regional analysis reveals North America and Europe as market leaders, collectively holding approximately 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 8.5% annually, driven by expanding aerospace manufacturing capabilities and substantial investments in energy infrastructure.

Customer requirements are increasingly focused on multi-functional coatings that offer not only thermal protection but also resistance to environmental degradation, particularly from calcium-magnesium-alumino-silicate (CMAS) infiltration and volcanic ash exposure. This trend has created a premium segment within the market, growing at 9.2% annually.

Cost considerations remain significant market factors, with coating application processes representing up to 40% of the total component manufacturing cost in some high-performance applications. This has created market opportunities for companies developing more cost-effective deposition technologies while maintaining performance standards.

The competitive landscape features both established materials science corporations and specialized coating technology providers. Recent market consolidation through mergers and acquisitions suggests that integrated solution providers are gaining competitive advantage by offering comprehensive coating systems rather than standalone products.

Market forecasts indicate particular growth potential in ceramic matrix composite (CMC) compatible coatings, with this sub-segment expected to grow at twice the rate of traditional coating systems. Additionally, the emerging market for hypersonic vehicle applications represents a high-value niche expected to reach $120 million by 2026.

Aerospace applications currently dominate the market share, accounting for nearly 45% of the total demand. This is attributed to the critical need for materials that can withstand extreme temperatures in aircraft engines, where efficiency improvements directly correlate with operating temperatures. Commercial aviation's recovery post-pandemic and increased defense spending worldwide have further accelerated this demand.

The power generation sector represents the second-largest market segment at 30%, with particular emphasis on gas turbines for electricity production. As global energy demands rise and efficiency standards become more stringent, the implementation of advanced ceramic coatings has become essential for extending turbine life and improving performance metrics.

Regional analysis reveals North America and Europe as market leaders, collectively holding approximately 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 8.5% annually, driven by expanding aerospace manufacturing capabilities and substantial investments in energy infrastructure.

Customer requirements are increasingly focused on multi-functional coatings that offer not only thermal protection but also resistance to environmental degradation, particularly from calcium-magnesium-alumino-silicate (CMAS) infiltration and volcanic ash exposure. This trend has created a premium segment within the market, growing at 9.2% annually.

Cost considerations remain significant market factors, with coating application processes representing up to 40% of the total component manufacturing cost in some high-performance applications. This has created market opportunities for companies developing more cost-effective deposition technologies while maintaining performance standards.

The competitive landscape features both established materials science corporations and specialized coating technology providers. Recent market consolidation through mergers and acquisitions suggests that integrated solution providers are gaining competitive advantage by offering comprehensive coating systems rather than standalone products.

Market forecasts indicate particular growth potential in ceramic matrix composite (CMC) compatible coatings, with this sub-segment expected to grow at twice the rate of traditional coating systems. Additionally, the emerging market for hypersonic vehicle applications represents a high-value niche expected to reach $120 million by 2026.

Current Challenges in Aerospace Ceramic Coating Technology

Despite significant advancements in ceramic coating technologies for aerospace applications, the industry continues to face substantial technical challenges. The extreme operating conditions of aerospace environments—characterized by temperatures exceeding 1200°C, rapid thermal cycling, and exposure to corrosive gases—push current ceramic coating systems to their physical limits. Traditional thermal barrier coatings (TBCs) based on yttria-stabilized zirconia (YSZ) struggle to maintain structural integrity under these demanding conditions.

A primary challenge lies in the thermal expansion mismatch between ceramic coatings and metallic substrates. This mismatch generates significant stress during thermal cycling, leading to coating delamination and spallation after repeated use. The aerospace industry reports that approximately 70% of coating failures stem from this fundamental incompatibility, particularly in high-thrust turbine applications.

Erosion resistance presents another critical challenge. Particulate matter in high-velocity airstreams causes progressive degradation of coating surfaces, reducing thermal protection capabilities and aerodynamic efficiency. Current ceramic systems demonstrate insufficient hardness-to-toughness ratios to withstand these erosive environments without compromising other essential properties.

The chemical stability of ceramic coatings in the presence of calcium-magnesium-alumino-silicate (CMAS) deposits represents an emerging concern. These naturally occurring contaminants melt at operating temperatures and infiltrate coating structures, causing catastrophic degradation through chemical interaction and mechanical disruption. Research indicates CMAS-related failures have increased by 35% in the past decade as engines operate at higher temperatures.

Manufacturing consistency at scale remains problematic. Advanced deposition techniques like electron beam physical vapor deposition (EB-PVD) and solution precursor plasma spray (SPPS) produce superior microstructures but suffer from batch-to-batch variability. Industry data suggests coating thickness variations of 15-20% across components, compromising performance predictability.

The integration of sensor capabilities within ceramic coatings for real-time health monitoring represents a technological frontier with significant challenges. Current sensing technologies cannot withstand the extreme temperatures where ceramic coatings operate, limiting the industry's ability to implement predictive maintenance strategies.

Environmental regulations present additional constraints, as traditional coating processes often involve hazardous materials. The industry faces increasing pressure to develop environmentally sustainable alternatives while maintaining or improving performance characteristics, creating a complex balance between regulatory compliance and technical requirements.

A primary challenge lies in the thermal expansion mismatch between ceramic coatings and metallic substrates. This mismatch generates significant stress during thermal cycling, leading to coating delamination and spallation after repeated use. The aerospace industry reports that approximately 70% of coating failures stem from this fundamental incompatibility, particularly in high-thrust turbine applications.

Erosion resistance presents another critical challenge. Particulate matter in high-velocity airstreams causes progressive degradation of coating surfaces, reducing thermal protection capabilities and aerodynamic efficiency. Current ceramic systems demonstrate insufficient hardness-to-toughness ratios to withstand these erosive environments without compromising other essential properties.

The chemical stability of ceramic coatings in the presence of calcium-magnesium-alumino-silicate (CMAS) deposits represents an emerging concern. These naturally occurring contaminants melt at operating temperatures and infiltrate coating structures, causing catastrophic degradation through chemical interaction and mechanical disruption. Research indicates CMAS-related failures have increased by 35% in the past decade as engines operate at higher temperatures.

Manufacturing consistency at scale remains problematic. Advanced deposition techniques like electron beam physical vapor deposition (EB-PVD) and solution precursor plasma spray (SPPS) produce superior microstructures but suffer from batch-to-batch variability. Industry data suggests coating thickness variations of 15-20% across components, compromising performance predictability.

The integration of sensor capabilities within ceramic coatings for real-time health monitoring represents a technological frontier with significant challenges. Current sensing technologies cannot withstand the extreme temperatures where ceramic coatings operate, limiting the industry's ability to implement predictive maintenance strategies.

Environmental regulations present additional constraints, as traditional coating processes often involve hazardous materials. The industry faces increasing pressure to develop environmentally sustainable alternatives while maintaining or improving performance characteristics, creating a complex balance between regulatory compliance and technical requirements.

State-of-the-Art Ceramic Coating Solutions for Extreme Environments

01 Thermal barrier ceramic coatings

Ceramic coatings are applied to provide thermal insulation and protection against high temperatures. These coatings typically consist of materials with low thermal conductivity that can withstand extreme heat conditions. They are commonly used in aerospace, power generation, and automotive applications to protect metal components from thermal degradation and extend their operational life in high-temperature environments.- Thermal barrier ceramic coatings: Ceramic coatings are applied to provide thermal insulation and protection against high temperatures. These coatings typically consist of materials with low thermal conductivity that can withstand extreme heat conditions. They are commonly used in aerospace, power generation, and automotive applications to protect metal components from thermal degradation and extend their operational life. The coatings often have a multi-layered structure to optimize thermal resistance and adhesion to the substrate.

- Wear-resistant ceramic coatings: Ceramic coatings are formulated to enhance surface hardness and wear resistance of various components. These coatings provide protection against abrasion, erosion, and friction, significantly extending the service life of the coated parts. The compositions typically include hard ceramic materials such as alumina, zirconia, or silicon carbide. Various deposition techniques are employed to create dense, adherent coatings with optimized microstructure for maximum wear resistance in demanding industrial applications.

- Corrosion-resistant ceramic coatings: Ceramic coatings provide effective barriers against chemical attack and corrosion in aggressive environments. These coatings are designed to protect underlying substrates from oxidation, acid attack, and other forms of chemical degradation. The formulations often include chemically stable oxides and non-oxide ceramics that remain inert in harsh conditions. The coatings can be engineered with controlled porosity or as fully dense layers depending on the specific corrosion protection requirements and operating environment.

- Ceramic coating deposition methods: Various techniques are employed for depositing ceramic coatings onto substrates, including thermal spraying, physical vapor deposition, chemical vapor deposition, and sol-gel processes. Each method offers distinct advantages in terms of coating thickness, adhesion, microstructure, and processing temperature. The selection of an appropriate deposition technique depends on the substrate material, desired coating properties, component geometry, and intended application. Advanced deposition methods allow for precise control of coating composition, structure, and properties to meet specific performance requirements.

- Functional ceramic coatings with special properties: Ceramic coatings can be engineered to provide specialized functional properties beyond basic protection. These include electrical insulation, electromagnetic shielding, optical properties, catalytic activity, and biocompatibility. The coatings can be tailored through composition and microstructure to achieve specific functional requirements. Advanced ceramic coating systems may incorporate dopants, nanostructures, or compositional gradients to enhance particular properties. These functional coatings enable components to perform in specialized applications where multiple property requirements must be satisfied simultaneously.

02 Ceramic coating deposition methods

Various techniques are employed for depositing ceramic coatings on substrates, including plasma spraying, chemical vapor deposition, physical vapor deposition, and sol-gel processes. Each method offers different advantages in terms of coating thickness, adhesion, uniformity, and microstructure. The selection of deposition method depends on the specific application requirements, substrate material, and desired coating properties.Expand Specific Solutions03 Wear-resistant ceramic coatings

Ceramic coatings are formulated to enhance surface hardness and wear resistance of components subjected to friction, abrasion, and erosion. These coatings typically incorporate hard ceramic materials such as alumina, zirconia, or silicon carbide to provide protection against mechanical wear. They are widely used in cutting tools, bearings, engine components, and industrial machinery to extend service life and maintain performance under harsh operating conditions.Expand Specific Solutions04 Corrosion-resistant ceramic coatings

Specialized ceramic coatings are designed to protect substrates from chemical attack and corrosion in aggressive environments. These coatings form a protective barrier that prevents direct contact between corrosive media and the underlying material. They are particularly valuable in chemical processing equipment, marine applications, and components exposed to acids, alkalis, or oxidizing environments where conventional materials would rapidly deteriorate.Expand Specific Solutions05 Multi-layer ceramic coating systems

Advanced ceramic coating systems often employ multiple layers with different compositions and functions to achieve enhanced performance. These systems typically include a bond coat for adhesion, a ceramic top coat for thermal or wear protection, and sometimes intermediate layers for stress management or additional functionality. The multi-layer approach allows for optimization of various properties such as thermal insulation, wear resistance, and durability while minimizing issues related to thermal expansion mismatch and mechanical stress.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Aerospace Ceramics

The ceramic coatings market for aerospace and turbine applications is in a growth phase, driven by increasing demand for high-performance materials in extreme environments. The market is expanding steadily with a projected size of several billion dollars by 2025. Technologically, the field is maturing with established players like RTX Corp., Safran SA, and General Electric leading commercial applications, while research institutions such as Beihang University and National Research Council of Canada advance fundamental innovations. Companies like Siemens Energy, Mitsubishi Heavy Industries, and United Technologies are developing specialized coatings for power generation applications. Emerging players including nGimat Co. and Teledyne Scientific are introducing novel nanomaterial-based solutions, while Chinese enterprises like XiAn Xinyao Ceramic Composite Materials are rapidly advancing their capabilities, creating a competitive landscape balanced between established aerospace giants and specialized materials technology firms.

United Technologies Corp.

Technical Solution: United Technologies (now part of RTX Corp) has developed innovative thermal barrier coating (TBC) systems for aerospace and gas turbine applications. Their advanced ceramic coating technology utilizes yttria-stabilized zirconia (YSZ) with controlled porosity and columnar microstructure, applied via electron beam physical vapor deposition (EB-PVD). This creates strain-tolerant coatings capable of withstanding thermal cycling between ambient and operating temperatures exceeding 1200°C. UTC's research has focused on developing gadolinium zirconate and other rare-earth zirconate compositions that offer superior resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration, a common cause of coating degradation in dusty environments. Their proprietary bond coat formulations enhance adhesion and oxidation resistance, while advanced manufacturing processes ensure coating uniformity and reproducibility across complex turbine components.

Strengths: Extensive experience in coating development for both aerospace and power generation applications, strong integration with engine design teams, and advanced testing capabilities. Weaknesses: Traditional YSZ coatings have temperature limitations, and newer compositions face challenges with thermal conductivity and long-term durability under extreme conditions.

General Electric Company

Technical Solution: GE has developed advanced environmental barrier coatings (EBCs) for ceramic matrix composites (CMCs) used in aerospace and gas turbine applications. Their proprietary multi-layer coating system consists of a bond coat, transition layer, and rare earth silicate top coat that provides protection against high-temperature oxidation and water vapor corrosion. GE's LEAP engine incorporates CMC components with specialized ceramic coatings that can withstand temperatures exceeding 2400°F while reducing weight by approximately 30% compared to traditional nickel superalloys. The company has pioneered the use of ytterbium disilicate-based coatings with enhanced phase stability and thermal cycling resistance for next-generation turbine applications. GE utilizes advanced deposition techniques including air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) to create tailored microstructures that optimize coating performance under extreme operating conditions.

Strengths: Industry-leading integration of ceramic coatings with CMC technology, extensive field validation in commercial engines, and proprietary multi-layer coating architectures. Weaknesses: Higher manufacturing costs compared to traditional materials, complex processing requirements, and potential challenges with coating uniformity across complex geometries.

Critical Patents and Innovations in Thermal Barrier Coating Systems

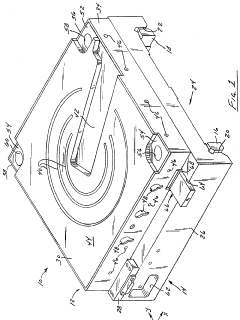

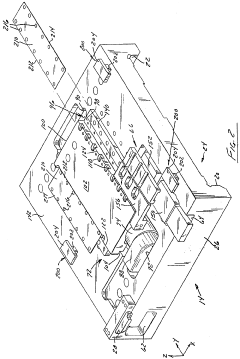

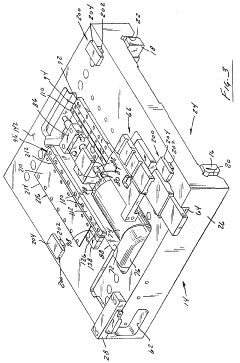

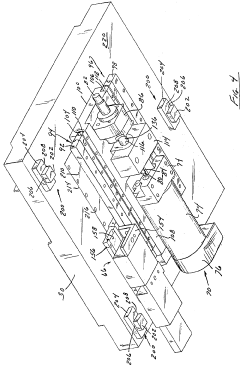

Sample stage including a slider assembly

PatentWO2000004304A9

Innovation

- A precision sample positioning system utilizing slider assemblies made from materials without a yield point, such as partially stabilized yttrium-aluminum-garnet (YSZ) or silicon nitride, which allow for smooth, lubricant-free sliding with minimal noise and surface degradation, ensuring flat and precise translation.

Environmental Impact and Sustainability of Ceramic Coating Processes

The production of ceramic coatings for aerospace and turbine applications involves various processes that have significant environmental implications. Traditional manufacturing methods often utilize energy-intensive processes, including high-temperature firing that consumes substantial amounts of fossil fuels and releases considerable carbon dioxide emissions. These processes contribute to the industry's carbon footprint, which has become increasingly scrutinized in the context of global climate change initiatives.

Water consumption represents another critical environmental concern in ceramic coating production. Wet processing techniques require large volumes of water, while the discharge of wastewater containing chemical additives, heavy metals, and suspended solids can lead to water pollution if not properly treated. Advanced filtration systems and closed-loop water recycling technologies are being implemented by leading manufacturers to mitigate these impacts.

Raw material extraction for ceramic coatings, particularly rare earth elements and specialized minerals, often involves mining operations that can result in habitat destruction, soil erosion, and biodiversity loss. The industry is gradually shifting toward more sustainable sourcing practices, including increased use of recycled materials and development of alternative compositions that reduce dependence on environmentally sensitive resources.

Hazardous waste management presents ongoing challenges, as certain coating processes generate toxic byproducts requiring specialized disposal methods. Recent innovations in green chemistry approaches have focused on developing non-toxic alternatives and waste minimization strategies. Companies like Praxair Surface Technologies and Oerlikon Metco have pioneered waste reduction initiatives that have decreased hazardous waste generation by up to 30% in some facilities.

Life cycle assessment (LCA) studies indicate that despite the environmental costs of production, ceramic coatings contribute significantly to sustainability through their application benefits. By extending component lifespans and improving operational efficiency in aerospace engines and gas turbines, these coatings reduce overall resource consumption and emissions throughout the product lifecycle. Research suggests that advanced thermal barrier coatings can improve turbine efficiency by 1-2%, translating to substantial fuel savings and emissions reductions over operational lifetimes.

Emerging sustainable manufacturing approaches include cold spray technologies that significantly reduce energy requirements compared to traditional thermal spray methods. Additionally, additive manufacturing techniques for ceramic coatings are showing promise for material efficiency, with waste reduction potential of up to 90% compared to conventional subtractive processes. These innovations represent the industry's response to increasing regulatory pressures and corporate sustainability commitments.

Water consumption represents another critical environmental concern in ceramic coating production. Wet processing techniques require large volumes of water, while the discharge of wastewater containing chemical additives, heavy metals, and suspended solids can lead to water pollution if not properly treated. Advanced filtration systems and closed-loop water recycling technologies are being implemented by leading manufacturers to mitigate these impacts.

Raw material extraction for ceramic coatings, particularly rare earth elements and specialized minerals, often involves mining operations that can result in habitat destruction, soil erosion, and biodiversity loss. The industry is gradually shifting toward more sustainable sourcing practices, including increased use of recycled materials and development of alternative compositions that reduce dependence on environmentally sensitive resources.

Hazardous waste management presents ongoing challenges, as certain coating processes generate toxic byproducts requiring specialized disposal methods. Recent innovations in green chemistry approaches have focused on developing non-toxic alternatives and waste minimization strategies. Companies like Praxair Surface Technologies and Oerlikon Metco have pioneered waste reduction initiatives that have decreased hazardous waste generation by up to 30% in some facilities.

Life cycle assessment (LCA) studies indicate that despite the environmental costs of production, ceramic coatings contribute significantly to sustainability through their application benefits. By extending component lifespans and improving operational efficiency in aerospace engines and gas turbines, these coatings reduce overall resource consumption and emissions throughout the product lifecycle. Research suggests that advanced thermal barrier coatings can improve turbine efficiency by 1-2%, translating to substantial fuel savings and emissions reductions over operational lifetimes.

Emerging sustainable manufacturing approaches include cold spray technologies that significantly reduce energy requirements compared to traditional thermal spray methods. Additionally, additive manufacturing techniques for ceramic coatings are showing promise for material efficiency, with waste reduction potential of up to 90% compared to conventional subtractive processes. These innovations represent the industry's response to increasing regulatory pressures and corporate sustainability commitments.

Certification Standards and Testing Protocols for Aerospace Ceramics

The certification landscape for aerospace ceramic coatings is governed by stringent international standards that ensure safety, reliability, and performance under extreme conditions. Key certification bodies include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO), which collectively establish the regulatory framework for ceramic materials in aerospace applications.

Testing protocols for aerospace ceramics typically follow a multi-phase approach. Initial material characterization tests assess fundamental properties such as chemical composition, microstructure, and phase stability. These tests employ advanced analytical techniques including X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) to verify material conformity to specifications.

Mechanical property testing represents a critical certification component, encompassing evaluations of tensile strength, compressive strength, flexural strength, and fracture toughness across temperature ranges from cryogenic to over 1600°C. These tests must be conducted according to ASTM C1161, C1211, and C1421 standards, which provide standardized methodologies for ceramic material evaluation under aerospace-relevant conditions.

Thermal performance testing protocols examine thermal shock resistance, thermal cycling behavior, and thermal conductivity. Standards such as ASTM C1171 and C1525 guide these evaluations, requiring materials to withstand rapid temperature fluctuations without degradation. For turbine applications, specialized hot gas path simulation tests assess coating performance under conditions mimicking actual engine operation.

Environmental durability testing represents another crucial certification requirement. Protocols include ASTM G211 for particulate erosion resistance, ASTM C1368 for slow crack growth testing, and custom protocols for CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration resistance. These tests simulate the harsh operating environments encountered during service, including exposure to volcanic ash, sand, and other environmental contaminants.

Non-destructive evaluation (NDE) techniques form an integral part of certification processes. Standards like ASTM E1419 for ultrasonic testing and ASTM E2580 for digital radiography guide the detection of subsurface defects without compromising coating integrity. These techniques must demonstrate reliability in detecting critical flaws that could lead to catastrophic failure during operation.

The certification process culminates in component-level testing and system integration validation. These final stages verify that ceramic-coated components meet performance requirements when integrated into complete systems, following standards such as SAE AMS2433 for thermal spray ceramic coatings and AMS7000 series for ceramic matrix composites in aerospace applications.

Testing protocols for aerospace ceramics typically follow a multi-phase approach. Initial material characterization tests assess fundamental properties such as chemical composition, microstructure, and phase stability. These tests employ advanced analytical techniques including X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) to verify material conformity to specifications.

Mechanical property testing represents a critical certification component, encompassing evaluations of tensile strength, compressive strength, flexural strength, and fracture toughness across temperature ranges from cryogenic to over 1600°C. These tests must be conducted according to ASTM C1161, C1211, and C1421 standards, which provide standardized methodologies for ceramic material evaluation under aerospace-relevant conditions.

Thermal performance testing protocols examine thermal shock resistance, thermal cycling behavior, and thermal conductivity. Standards such as ASTM C1171 and C1525 guide these evaluations, requiring materials to withstand rapid temperature fluctuations without degradation. For turbine applications, specialized hot gas path simulation tests assess coating performance under conditions mimicking actual engine operation.

Environmental durability testing represents another crucial certification requirement. Protocols include ASTM G211 for particulate erosion resistance, ASTM C1368 for slow crack growth testing, and custom protocols for CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration resistance. These tests simulate the harsh operating environments encountered during service, including exposure to volcanic ash, sand, and other environmental contaminants.

Non-destructive evaluation (NDE) techniques form an integral part of certification processes. Standards like ASTM E1419 for ultrasonic testing and ASTM E2580 for digital radiography guide the detection of subsurface defects without compromising coating integrity. These techniques must demonstrate reliability in detecting critical flaws that could lead to catastrophic failure during operation.

The certification process culminates in component-level testing and system integration validation. These final stages verify that ceramic-coated components meet performance requirements when integrated into complete systems, following standards such as SAE AMS2433 for thermal spray ceramic coatings and AMS7000 series for ceramic matrix composites in aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!