Ceramic Thermal Spray Coatings Materials Methods and Performance

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Thermal Spray Coating Evolution and Objectives

Ceramic thermal spray coating technology has evolved significantly over the past century, with its origins dating back to the early 1900s when Dr. Max Ulrich Schoop developed the first metal spray process. The fundamental concept of propelling heated or molten particles onto a substrate surface has remained consistent, though methodologies have dramatically advanced. By the mid-20th century, plasma spray techniques emerged, enabling the application of ceramic materials with substantially higher melting points, which marked a pivotal advancement in the field.

The evolution of ceramic thermal spray coatings has been driven primarily by increasing demands for enhanced material performance in extreme environments. Industries such as aerospace, power generation, and automotive manufacturing have continuously pushed for coatings with superior thermal resistance, wear protection, and corrosion resistance. This industrial pressure has catalyzed significant technological innovations, including the development of solution precursor plasma spray, suspension plasma spray, and cold spray techniques in recent decades.

Current technological trajectories indicate a shift toward more precise control of coating microstructures and properties. Nano-structured coatings have emerged as a promising direction, offering unprecedented combinations of hardness, toughness, and thermal stability. Additionally, computational modeling and simulation tools are increasingly being integrated into the development process, allowing for more efficient optimization of spray parameters and prediction of coating performance.

The primary objectives of contemporary ceramic thermal spray coating research encompass several dimensions. First, there is a concentrated effort to develop coatings with enhanced durability under extreme thermal cycling conditions, particularly for turbine components in aerospace and power generation applications. Second, researchers aim to improve coating deposition efficiency and reduce material waste, addressing both economic and environmental concerns. Third, there is growing interest in developing multi-functional coatings that can simultaneously provide thermal insulation, wear resistance, and self-healing capabilities.

Another significant objective involves the expansion of suitable substrate materials, including lightweight alloys and composites that traditionally present challenges for coating adhesion. Furthermore, the industry is actively pursuing more environmentally sustainable coating solutions, reducing reliance on toxic materials and energy-intensive processes. The integration of in-situ monitoring and quality control systems represents another critical goal, enabling real-time adjustments during the coating process to ensure consistent performance.

As we look toward future developments, the convergence of ceramic thermal spray technology with additive manufacturing principles presents intriguing possibilities for creating gradient structures and complex geometries with tailored properties at different depths and regions.

The evolution of ceramic thermal spray coatings has been driven primarily by increasing demands for enhanced material performance in extreme environments. Industries such as aerospace, power generation, and automotive manufacturing have continuously pushed for coatings with superior thermal resistance, wear protection, and corrosion resistance. This industrial pressure has catalyzed significant technological innovations, including the development of solution precursor plasma spray, suspension plasma spray, and cold spray techniques in recent decades.

Current technological trajectories indicate a shift toward more precise control of coating microstructures and properties. Nano-structured coatings have emerged as a promising direction, offering unprecedented combinations of hardness, toughness, and thermal stability. Additionally, computational modeling and simulation tools are increasingly being integrated into the development process, allowing for more efficient optimization of spray parameters and prediction of coating performance.

The primary objectives of contemporary ceramic thermal spray coating research encompass several dimensions. First, there is a concentrated effort to develop coatings with enhanced durability under extreme thermal cycling conditions, particularly for turbine components in aerospace and power generation applications. Second, researchers aim to improve coating deposition efficiency and reduce material waste, addressing both economic and environmental concerns. Third, there is growing interest in developing multi-functional coatings that can simultaneously provide thermal insulation, wear resistance, and self-healing capabilities.

Another significant objective involves the expansion of suitable substrate materials, including lightweight alloys and composites that traditionally present challenges for coating adhesion. Furthermore, the industry is actively pursuing more environmentally sustainable coating solutions, reducing reliance on toxic materials and energy-intensive processes. The integration of in-situ monitoring and quality control systems represents another critical goal, enabling real-time adjustments during the coating process to ensure consistent performance.

As we look toward future developments, the convergence of ceramic thermal spray technology with additive manufacturing principles presents intriguing possibilities for creating gradient structures and complex geometries with tailored properties at different depths and regions.

Market Analysis of Thermal Spray Coating Applications

The global thermal spray coating market has witnessed substantial growth, valued at approximately $10.1 billion in 2022 and projected to reach $15.7 billion by 2028, with a compound annual growth rate of 7.6%. This growth is primarily driven by increasing demand across various industrial sectors including aerospace, automotive, energy, and healthcare.

Aerospace remains the dominant application sector, accounting for nearly 30% of the market share. The industry's stringent requirements for high-performance components that can withstand extreme temperatures and corrosive environments make ceramic thermal spray coatings indispensable. These coatings significantly extend the service life of turbine blades, combustion chambers, and other critical components, resulting in substantial cost savings through reduced maintenance and replacement cycles.

The automotive industry represents the second-largest application segment, with ceramic thermal spray coatings increasingly utilized in engine components, exhaust systems, and brake parts. The transition toward electric vehicles has created new opportunities, particularly in battery thermal management systems where ceramic coatings provide essential thermal regulation properties.

Energy sector applications have shown remarkable growth, particularly in power generation equipment. Gas turbines, boilers, and heat exchangers benefit from ceramic coatings that enhance efficiency and durability under extreme operating conditions. The renewable energy sector, especially concentrated solar power systems, has emerged as a promising growth area for specialized high-temperature ceramic coatings.

Regional analysis reveals Asia-Pacific as the fastest-growing market, driven by rapid industrialization in China and India. North America and Europe maintain significant market shares due to their established aerospace and automotive manufacturing bases and increasing focus on energy efficiency improvements.

The healthcare sector represents an emerging application area with substantial growth potential. Biocompatible ceramic coatings for medical implants and surgical instruments have demonstrated excellent performance characteristics, driving adoption in orthopedic and dental applications.

Market trends indicate increasing demand for environmentally friendly coating solutions with reduced hazardous materials and lower energy consumption during application. This has accelerated research into water-based ceramic slurry formulations and advanced cold spray techniques that minimize environmental impact while maintaining performance standards.

Customer requirements are evolving toward customized coating solutions with specific property combinations rather than generic offerings. This trend has prompted coating service providers to develop specialized expertise and tailored solutions for specific industry applications, creating new market niches and competitive advantages.

Aerospace remains the dominant application sector, accounting for nearly 30% of the market share. The industry's stringent requirements for high-performance components that can withstand extreme temperatures and corrosive environments make ceramic thermal spray coatings indispensable. These coatings significantly extend the service life of turbine blades, combustion chambers, and other critical components, resulting in substantial cost savings through reduced maintenance and replacement cycles.

The automotive industry represents the second-largest application segment, with ceramic thermal spray coatings increasingly utilized in engine components, exhaust systems, and brake parts. The transition toward electric vehicles has created new opportunities, particularly in battery thermal management systems where ceramic coatings provide essential thermal regulation properties.

Energy sector applications have shown remarkable growth, particularly in power generation equipment. Gas turbines, boilers, and heat exchangers benefit from ceramic coatings that enhance efficiency and durability under extreme operating conditions. The renewable energy sector, especially concentrated solar power systems, has emerged as a promising growth area for specialized high-temperature ceramic coatings.

Regional analysis reveals Asia-Pacific as the fastest-growing market, driven by rapid industrialization in China and India. North America and Europe maintain significant market shares due to their established aerospace and automotive manufacturing bases and increasing focus on energy efficiency improvements.

The healthcare sector represents an emerging application area with substantial growth potential. Biocompatible ceramic coatings for medical implants and surgical instruments have demonstrated excellent performance characteristics, driving adoption in orthopedic and dental applications.

Market trends indicate increasing demand for environmentally friendly coating solutions with reduced hazardous materials and lower energy consumption during application. This has accelerated research into water-based ceramic slurry formulations and advanced cold spray techniques that minimize environmental impact while maintaining performance standards.

Customer requirements are evolving toward customized coating solutions with specific property combinations rather than generic offerings. This trend has prompted coating service providers to develop specialized expertise and tailored solutions for specific industry applications, creating new market niches and competitive advantages.

Global Status and Technical Barriers in Ceramic Coatings

Ceramic thermal spray coatings have emerged as critical surface engineering solutions across various industrial sectors globally. Currently, the United States, Japan, Germany, and China lead in research and development of advanced ceramic coating technologies. The global market for thermal spray coatings reached approximately $10.1 billion in 2022 and is projected to grow at a CAGR of 4.9% through 2028, with ceramic coatings representing a significant segment of this expansion.

Despite widespread adoption, several technical barriers impede the further advancement of ceramic thermal spray coatings. Material-related challenges include limited thermal shock resistance, with many ceramic coatings exhibiting susceptibility to cracking under rapid temperature fluctuations. This limitation is particularly problematic in applications involving thermal cycling, such as gas turbine components and aerospace structures.

Adhesion strength between ceramic coatings and metallic substrates remains suboptimal, often requiring complex intermediate layers or surface preparation techniques. The fundamental mismatch in thermal expansion coefficients between ceramics and metals creates residual stresses that can lead to delamination during service conditions, particularly at elevated temperatures.

Process-related barriers include inconsistent coating microstructure and properties when scaling from laboratory to industrial production. The thermal spray process parameters significantly influence coating quality, yet achieving reproducible results across different equipment setups and production batches presents considerable challenges. Porosity control remains problematic, with excessive porosity compromising mechanical properties while insufficient porosity reducing thermal insulation capabilities.

Environmental considerations pose additional challenges, as traditional ceramic coating processes often involve hazardous materials and generate significant waste. Regulatory pressures are driving the need for more environmentally friendly coating solutions with reduced environmental footprints.

Characterization and testing standardization represents another significant barrier. The lack of universally accepted testing protocols for ceramic coatings makes cross-comparison between different research findings difficult, hampering technological advancement. Non-destructive evaluation techniques for in-service coating assessment remain limited, complicating maintenance and lifetime prediction efforts.

Economically, the high cost of advanced ceramic materials and sophisticated application equipment restricts widespread adoption, particularly in cost-sensitive industries. The energy-intensive nature of many ceramic coating processes further contributes to elevated production costs, limiting market penetration in emerging economies.

Geographically, significant disparities exist in ceramic coating technology development. While advanced economies have established robust research infrastructures and industrial applications, developing nations face substantial barriers to entry, including limited access to specialized equipment and technical expertise. This technological divide creates challenges for global standardization and technology transfer.

Despite widespread adoption, several technical barriers impede the further advancement of ceramic thermal spray coatings. Material-related challenges include limited thermal shock resistance, with many ceramic coatings exhibiting susceptibility to cracking under rapid temperature fluctuations. This limitation is particularly problematic in applications involving thermal cycling, such as gas turbine components and aerospace structures.

Adhesion strength between ceramic coatings and metallic substrates remains suboptimal, often requiring complex intermediate layers or surface preparation techniques. The fundamental mismatch in thermal expansion coefficients between ceramics and metals creates residual stresses that can lead to delamination during service conditions, particularly at elevated temperatures.

Process-related barriers include inconsistent coating microstructure and properties when scaling from laboratory to industrial production. The thermal spray process parameters significantly influence coating quality, yet achieving reproducible results across different equipment setups and production batches presents considerable challenges. Porosity control remains problematic, with excessive porosity compromising mechanical properties while insufficient porosity reducing thermal insulation capabilities.

Environmental considerations pose additional challenges, as traditional ceramic coating processes often involve hazardous materials and generate significant waste. Regulatory pressures are driving the need for more environmentally friendly coating solutions with reduced environmental footprints.

Characterization and testing standardization represents another significant barrier. The lack of universally accepted testing protocols for ceramic coatings makes cross-comparison between different research findings difficult, hampering technological advancement. Non-destructive evaluation techniques for in-service coating assessment remain limited, complicating maintenance and lifetime prediction efforts.

Economically, the high cost of advanced ceramic materials and sophisticated application equipment restricts widespread adoption, particularly in cost-sensitive industries. The energy-intensive nature of many ceramic coating processes further contributes to elevated production costs, limiting market penetration in emerging economies.

Geographically, significant disparities exist in ceramic coating technology development. While advanced economies have established robust research infrastructures and industrial applications, developing nations face substantial barriers to entry, including limited access to specialized equipment and technical expertise. This technological divide creates challenges for global standardization and technology transfer.

Current Ceramic Coating Deposition Methodologies

01 Thermal barrier properties of ceramic coatings

Ceramic thermal spray coatings provide excellent thermal barrier properties, protecting underlying substrates from high temperatures and thermal cycling. These coatings typically consist of materials like zirconia or alumina that have low thermal conductivity. The microstructure of the coating, including porosity and crack networks, contributes to its insulating capabilities. These thermal barrier coatings (TBCs) are particularly valuable in high-temperature applications such as gas turbines and aerospace components.- Thermal barrier properties of ceramic coatings: Ceramic thermal spray coatings provide excellent thermal barrier properties, protecting underlying substrates from high temperatures and thermal cycling. These coatings typically consist of materials like zirconia or alumina that have low thermal conductivity. The microstructure of these coatings, including porosity and crack networks, contributes to their insulating capabilities, making them ideal for applications in turbine engines, combustion chambers, and other high-temperature environments.

- Wear and corrosion resistance characteristics: Ceramic thermal spray coatings offer superior wear and corrosion resistance in harsh operating conditions. These coatings can withstand abrasive environments, chemical exposure, and oxidation at elevated temperatures. The dense microstructure and chemical stability of ceramics like chromium oxide and titanium dioxide contribute to their protective properties. These coatings significantly extend the service life of components in industrial applications such as pumps, valves, and processing equipment.

- Composition and microstructure optimization: The performance of ceramic thermal spray coatings can be optimized through careful control of composition and microstructure. Adding dopants, creating composite structures, or developing nanostructured coatings can enhance properties like toughness, adhesion, and thermal shock resistance. The spray parameters, including particle size, spray distance, and cooling rates, significantly influence the resulting microstructure. Advanced characterization techniques help in understanding the relationship between processing, structure, and performance of these coatings.

- Application techniques and process parameters: Various thermal spray techniques, including plasma spray, high-velocity oxy-fuel (HVOF), and suspension spray, are used to deposit ceramic coatings. Each technique offers different advantages in terms of coating density, adhesion strength, and deposition efficiency. Process parameters such as spray distance, gun power, powder feed rate, and substrate preparation significantly affect coating quality and performance. Optimization of these parameters is essential to achieve desired coating properties for specific applications.

- Environmental and high-temperature performance: Ceramic thermal spray coatings demonstrate exceptional performance in extreme environments, including high temperatures, thermal cycling, and corrosive atmospheres. These coatings maintain their structural integrity and protective functions under severe operating conditions. Advanced ceramic formulations incorporate phase stabilizers and rare earth elements to enhance high-temperature stability. The coatings' resistance to thermal shock, spallation, and chemical degradation makes them crucial for applications in aerospace, power generation, and chemical processing industries.

02 Wear and corrosion resistance characteristics

Ceramic thermal spray coatings exhibit superior wear and corrosion resistance properties. These coatings form a protective barrier that shields components from abrasive wear, erosion, and chemical attack. The hardness and chemical stability of ceramic materials like chromium oxide and titanium dioxide contribute to their excellent tribological properties. The coatings can be engineered with specific compositions to enhance resistance to particular corrosive environments, extending the service life of components in aggressive operating conditions.Expand Specific Solutions03 Composition and microstructure optimization

The performance of ceramic thermal spray coatings can be optimized through careful control of composition and microstructure. Adding specific dopants or creating composite structures with multiple ceramic phases can enhance properties like toughness and thermal shock resistance. The porosity level, grain size, and phase distribution significantly impact coating performance. Advanced processing techniques allow for tailored microstructures that balance competing properties such as thermal insulation and mechanical strength, resulting in coatings with optimized performance for specific applications.Expand Specific Solutions04 Adhesion and bonding mechanisms

The performance of ceramic thermal spray coatings heavily depends on their adhesion to the substrate. Various bonding mechanisms, including mechanical interlocking, chemical bonding, and metallurgical interactions, contribute to coating adhesion. Surface preparation techniques such as grit blasting and the application of bond coats significantly improve adhesion strength. The thermal expansion mismatch between coating and substrate must be managed to prevent delamination during thermal cycling. Advanced coating designs often incorporate gradient structures or specialized bond layers to enhance adhesion and overall coating durability.Expand Specific Solutions05 Novel application techniques and performance enhancement

Innovative thermal spray techniques have been developed to enhance ceramic coating performance. Methods such as solution precursor plasma spray, suspension plasma spray, and cold spray offer improved control over coating microstructure and properties. Post-deposition treatments including laser glazing, hot isostatic pressing, and sealing treatments can further enhance coating performance by reducing porosity and increasing density. The integration of nanostructured materials and functionally graded designs has led to significant improvements in coating durability, thermal cycling resistance, and overall performance in extreme environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

Ceramic thermal spray coatings technology is currently in a mature growth phase, with an expanding market driven by increasing applications in aerospace, automotive, and energy sectors. The global market size is estimated to exceed $12 billion, growing at 6-7% annually. Leading players demonstrate varying levels of technical maturity: Oerlikon Metco and Praxair Technology represent the most advanced commercial applications with comprehensive solutions, while Toyota, Nissan, and Mitsubishi Heavy Industries have developed specialized proprietary technologies. Academic institutions like Xi'an Jiaotong University and Harbin Institute of Technology are advancing fundamental research. TOCALO and Fujimi have established strong positions in specialized ceramic coating materials, while newer entrants like Niterra are focusing on niche applications for technical ceramics in automotive and semiconductor industries.

TOCALO Co., Ltd.

Technical Solution: TOCALO has developed proprietary ceramic thermal spray coating technologies focusing on atmospheric plasma spray (APS) and high-velocity oxygen fuel (HVOF) processes optimized for industrial applications. Their ceramic material portfolio includes specially formulated chromium oxide, titanium oxide, and zirconia-based compositions with controlled particle morphology and size distribution (typically 15-53 μm) to enhance deposition efficiency and coating quality. TOCALO's advanced plasma spray parameters achieve coating deposition rates of 2-4 kg/h while maintaining porosity levels below 3% for wear-resistant applications. Their ceramic coatings demonstrate exceptional hardness values (>1200 HV) and wear resistance (volume loss <10 mm³ in ASTM G65 testing). For thermal applications, TOCALO has developed multi-layer ceramic systems incorporating a gradient structure that transitions from dense to porous layers, providing both thermal insulation and mechanical durability. Recent innovations include nano-structured ceramic feedstock materials that create coatings with enhanced toughness and thermal shock resistance, demonstrating performance improvements of approximately 30% compared to conventional materials in thermal cycling tests.

Strengths: Exceptional coating density and hardness for wear applications; specialized formulations for specific industrial environments; advanced multi-layer systems with gradient structures. Weaknesses: Limited global presence compared to larger competitors; some specialized solutions may have higher implementation costs; technology transfer may require significant technical support.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed advanced ceramic thermal spray coating solutions utilizing both atmospheric plasma spray (APS) and high velocity oxy-fuel (HVOF) processes. Their proprietary ceramic materials include yttria-stabilized zirconia (YSZ), aluminum oxide, and titanium oxide formulations engineered for specific industrial applications. The company's HVOF process for ceramic coatings achieves exceptional density (>98%) and bond strength (>70 MPa), significantly reducing porosity compared to conventional methods. Their dual-layer thermal barrier coating (TBC) system combines a metallic bond coat with ceramic top layer, providing thermal protection up to 1200°C while maintaining structural integrity through thermal cycling. Oerlikon's recent innovations include suspension plasma spray technology that enables the deposition of nanostructured ceramic coatings with enhanced strain tolerance and thermal insulation properties, achieving thermal conductivity values as low as 0.8-1.0 W/m·K.

Strengths: Industry-leading coating density and adhesion strength; proprietary material formulations optimized for specific applications; advanced multi-layer systems with excellent thermal cycling resistance. Weaknesses: Higher implementation costs compared to conventional methods; requires specialized equipment and expertise; some solutions may have limited flexibility for customization.

Critical Patents and Innovations in Thermal Spray Materials

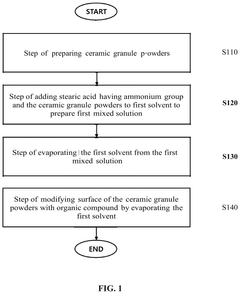

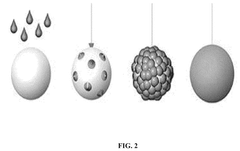

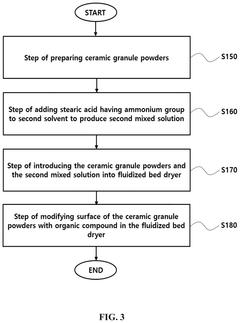

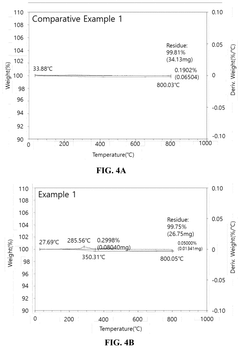

Ceramic thermal spray coating material and method for manufacturing of the same

PatentPendingUS20250289768A1

Innovation

- A ceramic thermal spray coating material is developed with a surface-modified ceramic granule powder using stearic acid with an ammonium group, applied through methods like spray drying or fluidized bed drying, to enhance fluidity and minimize residue.

Thermal spray material, and method of forming thermal spray coating with the same

PatentActiveJP2022039789A

Innovation

- A thermal spray material comprising a mixture of rare earth halide and oxide powders, thermally sprayed onto a substrate to form a rare earth oxyhalide coating, eliminating the need for prior sintering and pulverization steps.

Environmental Impact and Sustainability Considerations

Ceramic thermal spray coatings have significant environmental implications throughout their lifecycle, from raw material extraction to end-of-life disposal. The production of ceramic materials often involves energy-intensive processes, with substantial carbon footprints associated with high-temperature sintering and processing. However, when compared to alternative coating technologies such as electroplating, thermal spray processes generally produce fewer toxic byproducts and hazardous wastes, positioning them as relatively more environmentally friendly options within the industrial coatings sector.

During application, different thermal spray methods exhibit varying degrees of environmental impact. Atmospheric plasma spraying typically consumes substantial electrical energy, while high-velocity oxy-fuel spraying utilizes fossil fuels that contribute to greenhouse gas emissions. The overspray and particulate matter generated during application processes present occupational health concerns and require appropriate filtration and ventilation systems to mitigate workplace exposure and environmental release.

Recent advancements in thermal spray technologies have focused on reducing environmental footprints through process optimization. Water-stabilized plasma systems have demonstrated up to 30% energy efficiency improvements over conventional methods. Similarly, innovations in feedstock preparation and delivery systems have reduced material waste by 15-25% in modern facilities, representing significant progress toward more sustainable manufacturing practices.

The durability and performance characteristics of ceramic thermal spray coatings contribute substantially to their sustainability profile. By extending component lifespans in harsh operating environments, these coatings reduce the frequency of replacement and associated resource consumption. For instance, thermal barrier coatings in gas turbines improve fuel efficiency by 1-2%, translating to substantial emissions reductions over operational lifetimes. Similarly, wear-resistant coatings in industrial machinery can extend service intervals by 2-3 times, significantly reducing maintenance-related environmental impacts.

End-of-life considerations remain challenging for ceramic-coated components. The composite nature of these materials often complicates recycling efforts, as separation of the coating from the substrate requires energy-intensive processes. Research into design-for-disassembly approaches and specialized recycling technologies shows promise for improving circularity. Some manufacturers have implemented take-back programs for coated components, achieving recycling rates of 60-70% for certain applications, though widespread adoption remains limited.

Regulatory frameworks increasingly influence the development and application of ceramic thermal spray coatings. Restrictions on hexavalent chromium and other hazardous substances have accelerated research into environmentally benign alternatives. Similarly, life cycle assessment methodologies are being integrated into material selection and process development, enabling more holistic evaluation of environmental impacts across the entire value chain.

During application, different thermal spray methods exhibit varying degrees of environmental impact. Atmospheric plasma spraying typically consumes substantial electrical energy, while high-velocity oxy-fuel spraying utilizes fossil fuels that contribute to greenhouse gas emissions. The overspray and particulate matter generated during application processes present occupational health concerns and require appropriate filtration and ventilation systems to mitigate workplace exposure and environmental release.

Recent advancements in thermal spray technologies have focused on reducing environmental footprints through process optimization. Water-stabilized plasma systems have demonstrated up to 30% energy efficiency improvements over conventional methods. Similarly, innovations in feedstock preparation and delivery systems have reduced material waste by 15-25% in modern facilities, representing significant progress toward more sustainable manufacturing practices.

The durability and performance characteristics of ceramic thermal spray coatings contribute substantially to their sustainability profile. By extending component lifespans in harsh operating environments, these coatings reduce the frequency of replacement and associated resource consumption. For instance, thermal barrier coatings in gas turbines improve fuel efficiency by 1-2%, translating to substantial emissions reductions over operational lifetimes. Similarly, wear-resistant coatings in industrial machinery can extend service intervals by 2-3 times, significantly reducing maintenance-related environmental impacts.

End-of-life considerations remain challenging for ceramic-coated components. The composite nature of these materials often complicates recycling efforts, as separation of the coating from the substrate requires energy-intensive processes. Research into design-for-disassembly approaches and specialized recycling technologies shows promise for improving circularity. Some manufacturers have implemented take-back programs for coated components, achieving recycling rates of 60-70% for certain applications, though widespread adoption remains limited.

Regulatory frameworks increasingly influence the development and application of ceramic thermal spray coatings. Restrictions on hexavalent chromium and other hazardous substances have accelerated research into environmentally benign alternatives. Similarly, life cycle assessment methodologies are being integrated into material selection and process development, enabling more holistic evaluation of environmental impacts across the entire value chain.

Quality Control and Testing Standards for Thermal Spray Coatings

Quality control and testing standards are critical components in ensuring the reliability and performance of ceramic thermal spray coatings. The industry has established comprehensive frameworks for evaluating coating quality through various testing methodologies that assess both physical and mechanical properties.

ASTM International and ISO have developed specific standards for thermal spray coatings, including ASTM C633 for adhesion strength testing and ISO 14923 for characterization of thermal spray coatings. These standards provide consistent methodologies for evaluating coating performance across different applications and industries.

Non-destructive testing (NDT) techniques play a vital role in quality assurance without compromising coating integrity. Ultrasonic testing can detect delamination and internal defects, while eddy current testing identifies surface and near-surface discontinuities. Thermography has emerged as an effective method for detecting subsurface defects by measuring thermal conductivity variations.

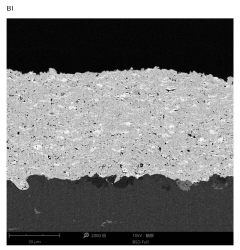

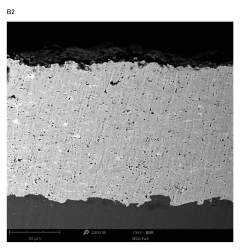

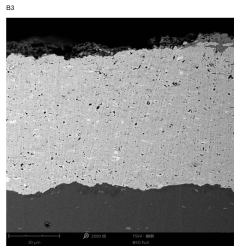

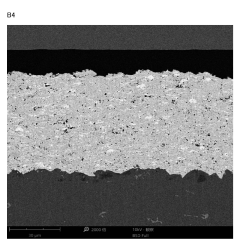

Microstructural analysis through scanning electron microscopy (SEM) and X-ray diffraction (XRD) provides critical insights into coating morphology, porosity levels, and phase composition. Porosity measurement is particularly important as it directly influences thermal and mechanical properties, with standards typically specifying acceptable porosity ranges between 1-10% depending on the application.

Mechanical property testing includes hardness measurements (Vickers, Knoop, or Rockwell scales), wear resistance evaluation through pin-on-disk tests, and erosion resistance assessment. Thermal cycling tests are essential for applications involving temperature fluctuations, as they evaluate coating resistance to spallation under thermal stress.

Corrosion resistance testing follows standards like ASTM B117 (salt spray test) and electrochemical impedance spectroscopy (EIS) to evaluate coating performance in aggressive environments. These tests are particularly important for coatings used in marine, chemical processing, and aerospace applications.

Statistical process control (SPC) methodologies are increasingly being implemented to monitor coating quality during production. Key parameters such as particle velocity, temperature, and standoff distance are continuously monitored to ensure consistency and reduce variability in coating properties.

Advanced digital inspection technologies, including machine vision systems and artificial intelligence algorithms, are emerging as next-generation quality control tools. These systems can detect subtle defects and variations that might be missed by conventional inspection methods, improving overall coating reliability and performance.

ASTM International and ISO have developed specific standards for thermal spray coatings, including ASTM C633 for adhesion strength testing and ISO 14923 for characterization of thermal spray coatings. These standards provide consistent methodologies for evaluating coating performance across different applications and industries.

Non-destructive testing (NDT) techniques play a vital role in quality assurance without compromising coating integrity. Ultrasonic testing can detect delamination and internal defects, while eddy current testing identifies surface and near-surface discontinuities. Thermography has emerged as an effective method for detecting subsurface defects by measuring thermal conductivity variations.

Microstructural analysis through scanning electron microscopy (SEM) and X-ray diffraction (XRD) provides critical insights into coating morphology, porosity levels, and phase composition. Porosity measurement is particularly important as it directly influences thermal and mechanical properties, with standards typically specifying acceptable porosity ranges between 1-10% depending on the application.

Mechanical property testing includes hardness measurements (Vickers, Knoop, or Rockwell scales), wear resistance evaluation through pin-on-disk tests, and erosion resistance assessment. Thermal cycling tests are essential for applications involving temperature fluctuations, as they evaluate coating resistance to spallation under thermal stress.

Corrosion resistance testing follows standards like ASTM B117 (salt spray test) and electrochemical impedance spectroscopy (EIS) to evaluate coating performance in aggressive environments. These tests are particularly important for coatings used in marine, chemical processing, and aerospace applications.

Statistical process control (SPC) methodologies are increasingly being implemented to monitor coating quality during production. Key parameters such as particle velocity, temperature, and standoff distance are continuously monitored to ensure consistency and reduce variability in coating properties.

Advanced digital inspection technologies, including machine vision systems and artificial intelligence algorithms, are emerging as next-generation quality control tools. These systems can detect subtle defects and variations that might be missed by conventional inspection methods, improving overall coating reliability and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!