Functionally Graded Ceramic Coatings for Thermal Management

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FGC Coating Evolution and Objectives

Functionally Graded Ceramic Coatings (FGCs) have evolved significantly over the past three decades, transitioning from theoretical concepts to practical applications in thermal management systems. The evolution began in the early 1990s when researchers first proposed the concept of gradual compositional changes within ceramic materials to mitigate thermal stress and improve performance under extreme temperature conditions. This marked a paradigm shift from traditional homogeneous coatings that often failed due to thermal expansion mismatches between substrate and coating materials.

By the early 2000s, experimental techniques for producing FGCs had advanced significantly, with plasma spraying and chemical vapor deposition emerging as viable manufacturing methods. These developments enabled the creation of coatings with controlled porosity gradients and compositional variations, allowing for customized thermal conductivity profiles across the coating thickness. The period between 2005-2015 saw substantial improvements in coating durability and thermal cycling resistance, addressing key limitations that had previously restricted industrial adoption.

Recent advancements have focused on nano-engineered FGCs, incorporating nanoscale features to further enhance thermal management capabilities. The integration of computational modeling with experimental approaches has accelerated development, enabling precise prediction of thermal behavior and optimization of gradient structures before physical prototyping. This has led to more efficient development cycles and better-performing coatings.

The primary objective of modern FGC technology is to create thermally efficient barriers that can withstand extreme temperature gradients while maintaining structural integrity. Specific goals include developing coatings capable of operating in environments exceeding 1500°C, extending component lifespans by at least 30% compared to conventional coatings, and reducing thermal conductivity by 40-60% without compromising mechanical properties.

Additional objectives include enhancing manufacturing scalability to enable cost-effective production for commercial applications, particularly in aerospace, power generation, and high-temperature industrial processes. There is also growing emphasis on developing environmentally sustainable FGC solutions with reduced rare earth element content, addressing both supply chain vulnerabilities and environmental concerns.

The technology trajectory suggests continued evolution toward multi-functional FGCs that simultaneously address thermal management, wear resistance, and corrosion protection. Future development will likely focus on smart FGCs with self-healing capabilities and in-situ monitoring features, representing the next frontier in adaptive thermal management systems for extreme environments.

By the early 2000s, experimental techniques for producing FGCs had advanced significantly, with plasma spraying and chemical vapor deposition emerging as viable manufacturing methods. These developments enabled the creation of coatings with controlled porosity gradients and compositional variations, allowing for customized thermal conductivity profiles across the coating thickness. The period between 2005-2015 saw substantial improvements in coating durability and thermal cycling resistance, addressing key limitations that had previously restricted industrial adoption.

Recent advancements have focused on nano-engineered FGCs, incorporating nanoscale features to further enhance thermal management capabilities. The integration of computational modeling with experimental approaches has accelerated development, enabling precise prediction of thermal behavior and optimization of gradient structures before physical prototyping. This has led to more efficient development cycles and better-performing coatings.

The primary objective of modern FGC technology is to create thermally efficient barriers that can withstand extreme temperature gradients while maintaining structural integrity. Specific goals include developing coatings capable of operating in environments exceeding 1500°C, extending component lifespans by at least 30% compared to conventional coatings, and reducing thermal conductivity by 40-60% without compromising mechanical properties.

Additional objectives include enhancing manufacturing scalability to enable cost-effective production for commercial applications, particularly in aerospace, power generation, and high-temperature industrial processes. There is also growing emphasis on developing environmentally sustainable FGC solutions with reduced rare earth element content, addressing both supply chain vulnerabilities and environmental concerns.

The technology trajectory suggests continued evolution toward multi-functional FGCs that simultaneously address thermal management, wear resistance, and corrosion protection. Future development will likely focus on smart FGCs with self-healing capabilities and in-situ monitoring features, representing the next frontier in adaptive thermal management systems for extreme environments.

Thermal Management Market Demand Analysis

The thermal management market is experiencing robust growth driven by increasing demands across multiple sectors. The global thermal management market was valued at approximately $8.6 billion in 2020 and is projected to reach $12.8 billion by 2025, growing at a CAGR of 8.2%. This growth is primarily fueled by the rapid advancement of electronics miniaturization, increasing power densities, and the need for enhanced reliability in extreme operating environments.

In the electronics sector, the continuous miniaturization of components coupled with higher processing power has created significant thermal challenges. Modern processors, power electronics, and high-performance computing systems generate substantial heat that must be efficiently dissipated to maintain optimal performance and prevent premature failure. The demand for advanced thermal management solutions in this sector is particularly acute in data centers, where cooling costs can represent up to 40% of the total operating expenses.

The aerospace and defense industries present another significant market for thermal management solutions, particularly functionally graded ceramic coatings. Aircraft engines, hypersonic vehicles, and space systems operate under extreme temperature conditions, requiring materials that can withstand thermal gradients exceeding 1000°C. The market demand in this sector is driven by the need for lightweight, durable solutions that can enhance fuel efficiency while maintaining structural integrity under thermal cycling.

The automotive industry, especially with the rapid growth of electric vehicles (EVs), represents an emerging market for advanced thermal management. Battery thermal management systems are critical for EV performance, safety, and longevity. The global EV thermal management market is expected to grow at a CAGR of 24% through 2026, creating substantial opportunities for innovative ceramic coating technologies.

Industrial applications, including power generation, metal processing, and chemical manufacturing, also contribute significantly to market demand. These sectors require thermal barrier coatings that can protect equipment operating in corrosive environments at elevated temperatures, extending operational lifespans and reducing maintenance costs.

Regionally, North America and Europe currently dominate the thermal management market due to their advanced manufacturing capabilities and substantial R&D investments. However, the Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, expanding electronics manufacturing, and increasing adoption of electric vehicles in countries like China, Japan, and South Korea.

Customer requirements are evolving toward solutions that offer multifunctional benefits beyond thermal management, including wear resistance, corrosion protection, and self-diagnostic capabilities. This trend is creating new market opportunities for functionally graded ceramic coatings that can be tailored to specific application requirements through compositional and microstructural gradients.

In the electronics sector, the continuous miniaturization of components coupled with higher processing power has created significant thermal challenges. Modern processors, power electronics, and high-performance computing systems generate substantial heat that must be efficiently dissipated to maintain optimal performance and prevent premature failure. The demand for advanced thermal management solutions in this sector is particularly acute in data centers, where cooling costs can represent up to 40% of the total operating expenses.

The aerospace and defense industries present another significant market for thermal management solutions, particularly functionally graded ceramic coatings. Aircraft engines, hypersonic vehicles, and space systems operate under extreme temperature conditions, requiring materials that can withstand thermal gradients exceeding 1000°C. The market demand in this sector is driven by the need for lightweight, durable solutions that can enhance fuel efficiency while maintaining structural integrity under thermal cycling.

The automotive industry, especially with the rapid growth of electric vehicles (EVs), represents an emerging market for advanced thermal management. Battery thermal management systems are critical for EV performance, safety, and longevity. The global EV thermal management market is expected to grow at a CAGR of 24% through 2026, creating substantial opportunities for innovative ceramic coating technologies.

Industrial applications, including power generation, metal processing, and chemical manufacturing, also contribute significantly to market demand. These sectors require thermal barrier coatings that can protect equipment operating in corrosive environments at elevated temperatures, extending operational lifespans and reducing maintenance costs.

Regionally, North America and Europe currently dominate the thermal management market due to their advanced manufacturing capabilities and substantial R&D investments. However, the Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, expanding electronics manufacturing, and increasing adoption of electric vehicles in countries like China, Japan, and South Korea.

Customer requirements are evolving toward solutions that offer multifunctional benefits beyond thermal management, including wear resistance, corrosion protection, and self-diagnostic capabilities. This trend is creating new market opportunities for functionally graded ceramic coatings that can be tailored to specific application requirements through compositional and microstructural gradients.

Global FGC Technology Status and Barriers

Functionally Graded Ceramic Coatings (FGCs) have emerged as a critical technology for thermal management applications globally, with significant advancements in recent years. Currently, the United States, Japan, China, and several European countries lead FGC research and development. The U.S. maintains technological superiority through substantial investments from both government agencies like NASA and DARPA, and private corporations in aerospace and defense sectors. Japan has established itself as a pioneer in FGC technology since the 1980s, with strong industry-academia collaboration networks. China has rapidly accelerated its research efforts in the past decade, particularly focusing on industrial applications.

Despite global progress, FGC technology faces several significant barriers. Material compatibility remains a primary challenge, as the creation of gradual transitions between dissimilar materials with vastly different thermal expansion coefficients continues to present difficulties in preventing delamination and cracking under thermal cycling. Processing limitations also constrain widespread adoption, with conventional ceramic coating techniques struggling to achieve precise compositional gradients at industrial scales.

The high manufacturing costs associated with FGC production represent another major barrier. Current production methods require sophisticated equipment and precise control systems, resulting in prohibitively expensive components for many potential applications. This cost factor has limited FGC implementation primarily to high-value sectors like aerospace and specialized industrial equipment.

Quality control and standardization issues further complicate global FGC advancement. The lack of universally accepted testing protocols and performance standards makes it difficult to compare different FGC solutions across international markets. This standardization gap has slowed technology transfer and commercial adoption outside specialized applications.

Durability under extreme conditions remains problematic for many FGC systems. While theoretical models predict excellent performance, real-world applications often reveal limitations in coating longevity when subjected to thermal cycling, mechanical stresses, and corrosive environments simultaneously. Research groups worldwide are actively addressing this challenge through novel material combinations and processing techniques.

Knowledge gaps in fundamental understanding of interfacial phenomena between gradient layers continue to impede optimization efforts. The complex interactions at material interfaces during thermal cycling are not fully characterized, making predictive modeling difficult. International research collaborations are increasingly focusing on these fundamental aspects to overcome current technological barriers.

Recent technological breakthroughs in additive manufacturing and atomic-level deposition techniques show promise for addressing many current limitations, potentially enabling more widespread adoption of FGC technology across diverse industrial sectors in the coming decade.

Despite global progress, FGC technology faces several significant barriers. Material compatibility remains a primary challenge, as the creation of gradual transitions between dissimilar materials with vastly different thermal expansion coefficients continues to present difficulties in preventing delamination and cracking under thermal cycling. Processing limitations also constrain widespread adoption, with conventional ceramic coating techniques struggling to achieve precise compositional gradients at industrial scales.

The high manufacturing costs associated with FGC production represent another major barrier. Current production methods require sophisticated equipment and precise control systems, resulting in prohibitively expensive components for many potential applications. This cost factor has limited FGC implementation primarily to high-value sectors like aerospace and specialized industrial equipment.

Quality control and standardization issues further complicate global FGC advancement. The lack of universally accepted testing protocols and performance standards makes it difficult to compare different FGC solutions across international markets. This standardization gap has slowed technology transfer and commercial adoption outside specialized applications.

Durability under extreme conditions remains problematic for many FGC systems. While theoretical models predict excellent performance, real-world applications often reveal limitations in coating longevity when subjected to thermal cycling, mechanical stresses, and corrosive environments simultaneously. Research groups worldwide are actively addressing this challenge through novel material combinations and processing techniques.

Knowledge gaps in fundamental understanding of interfacial phenomena between gradient layers continue to impede optimization efforts. The complex interactions at material interfaces during thermal cycling are not fully characterized, making predictive modeling difficult. International research collaborations are increasingly focusing on these fundamental aspects to overcome current technological barriers.

Recent technological breakthroughs in additive manufacturing and atomic-level deposition techniques show promise for addressing many current limitations, potentially enabling more widespread adoption of FGC technology across diverse industrial sectors in the coming decade.

Current FGC Fabrication Methodologies

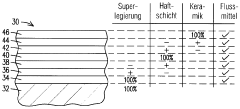

01 Composition and structure of functionally graded ceramic coatings

Functionally graded ceramic coatings are designed with varying compositions and structures throughout their thickness to optimize thermal management properties. These coatings typically consist of multiple layers with gradual transitions in material properties, such as thermal conductivity, coefficient of thermal expansion, and porosity. The gradation helps to minimize thermal stresses and improve durability under thermal cycling conditions. Materials commonly used include zirconia, alumina, and various metal oxides, which can be combined in different proportions to achieve desired thermal properties.- Composition and structure of functionally graded ceramic coatings: Functionally graded ceramic coatings are designed with varying compositions and structures throughout their thickness to optimize thermal management properties. These coatings typically consist of multiple layers with gradual transitions in material properties, such as thermal conductivity, coefficient of thermal expansion, and porosity. The gradual change in composition helps to minimize thermal stresses and improve the coating's resistance to thermal shock, making them ideal for high-temperature applications.

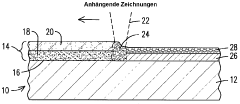

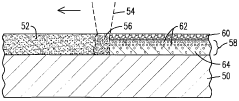

- Deposition techniques for functionally graded ceramic coatings: Various deposition techniques are employed to create functionally graded ceramic coatings for thermal management applications. These include plasma spraying, physical vapor deposition, chemical vapor deposition, and sol-gel processes. Each technique offers different advantages in terms of coating thickness, microstructure control, and adhesion to the substrate. Advanced deposition methods allow for precise control over the compositional gradient, which is crucial for optimizing the thermal management properties of the coating.

- Thermal barrier applications in high-temperature environments: Functionally graded ceramic coatings serve as effective thermal barriers in high-temperature environments, such as gas turbine engines, combustion chambers, and aerospace components. These coatings provide insulation to protect underlying metal substrates from extreme temperatures, extending component life and improving system efficiency. The graded structure helps to accommodate the mismatch in thermal expansion between the ceramic coating and metal substrate, reducing the risk of delamination during thermal cycling.

- Integration of cooling systems with ceramic coatings: Advanced thermal management solutions combine functionally graded ceramic coatings with active cooling systems to enhance heat dissipation in extreme environments. These integrated approaches may include transpiration cooling, impingement cooling, or microchannels within or beneath the coating. The ceramic coating provides thermal insulation while the cooling system actively removes heat, creating a more effective thermal management solution for components exposed to extreme heat loads.

- Novel materials and additives for enhanced thermal performance: Research in functionally graded ceramic coatings focuses on incorporating novel materials and additives to enhance thermal performance. These include rare earth oxides, nanostructured ceramics, and composite materials with tailored thermal properties. By carefully selecting and combining materials with complementary thermal characteristics, researchers can develop coatings with superior thermal resistance, lower thermal conductivity, or enhanced thermal stability. These innovations are driving improvements in the efficiency and durability of components operating in thermally demanding environments.

02 Deposition techniques for thermal barrier coatings

Various deposition techniques are employed to create functionally graded ceramic coatings for thermal management applications. These include plasma spraying, physical vapor deposition, chemical vapor deposition, and sol-gel processes. Each technique offers different advantages in terms of coating thickness, microstructure control, and adhesion properties. Advanced methods like electron beam physical vapor deposition (EB-PVD) allow for precise control of the coating architecture, creating columnar structures that enhance strain tolerance and thermal cycling resistance while maintaining effective thermal insulation properties.Expand Specific Solutions03 Thermal management in high-temperature applications

Functionally graded ceramic coatings are crucial for thermal management in high-temperature applications such as gas turbines, aerospace components, and industrial furnaces. These coatings provide thermal insulation, reducing heat transfer to underlying metal substrates and extending component life. The graded structure helps distribute thermal stresses, preventing delamination and spallation during thermal cycling. Advanced ceramic compositions incorporate rare earth elements and complex oxides to enhance high-temperature stability and reduce thermal conductivity, enabling operation at higher temperatures and improving overall system efficiency.Expand Specific Solutions04 Porosity control and microstructural engineering

Controlling porosity and microstructure in functionally graded ceramic coatings is essential for optimizing thermal management properties. Engineered porosity can significantly reduce thermal conductivity while maintaining mechanical integrity. Techniques such as incorporating fugitive materials, controlling spray parameters, and post-deposition treatments allow for precise manipulation of pore size, distribution, and connectivity. Microstructural features like microcracks, segmentation cracks, and columnar structures can be deliberately introduced to enhance strain tolerance while maintaining thermal insulation properties. The relationship between microstructure and thermal-mechanical properties is carefully balanced to achieve optimal performance in specific applications.Expand Specific Solutions05 Novel ceramic compositions and additives

Research in functionally graded ceramic coatings focuses on developing novel compositions and additives to enhance thermal management capabilities. Advanced materials include rare-earth zirconates, pyrochlores, perovskites, and ceramic-metal composites (cermets). These materials offer improved phase stability, lower thermal conductivity, and better resistance to sintering at elevated temperatures. Nanoscale additives and dopants are incorporated to modify grain boundary characteristics, create phonon scattering sites, and improve toughness. Multilayered systems with complementary compositions can provide both thermal insulation and environmental protection, extending component life in harsh operating environments.Expand Specific Solutions

Leading Companies in FGC Thermal Solutions

The functionally graded ceramic coating market for thermal management is in a growth phase, with increasing demand driven by aerospace, energy, and automotive applications. The market is projected to expand significantly as industries seek advanced thermal solutions. Technologically, companies like Siemens AG and Siemens Energy are leading commercial development with established manufacturing capabilities, while specialized firms such as nGimat Co. and Modumetal are advancing innovative nanostructured coating technologies. Academic institutions including Shanghai Jiao Tong University and RWTH Aachen University contribute fundamental research, creating a competitive ecosystem where industry-academia partnerships accelerate commercialization. The technology is approaching maturity in certain applications but continues to evolve with new compositional and manufacturing approaches.

Modumetal, Inc.

Technical Solution: Modumetal has pioneered an innovative approach to functionally graded ceramic coatings through their proprietary nanolaminated materials technology. Their process utilizes electrochemical deposition methods to create precisely controlled gradients in composition, microstructure, and properties throughout the coating thickness. For thermal management applications, Modumetal has developed ceramic-metal hybrid coatings with nanoscale layering that provides unique combinations of thermal barrier properties and mechanical durability. Their technology allows for the incorporation of ceramic phases within a metallic matrix in gradually changing proportions, creating seamless transitions between dissimilar materials. This approach effectively addresses thermal expansion mismatch issues that typically plague conventional ceramic coatings. Modumetal's coatings demonstrate exceptional resistance to thermal cycling fatigue, with laboratory tests showing up to 3x improvement in thermal shock resistance compared to traditional ceramic coatings. The company has successfully applied this technology in aerospace, energy, and industrial processing applications where components are exposed to extreme thermal gradients.

Strengths: Excellent adhesion to metallic substrates due to gradual transition from metal to ceramic; superior thermal cycling durability; good erosion resistance. Weaknesses: Limited maximum service temperature compared to pure ceramic systems; relatively new technology with limited long-term performance data; higher production costs for complex compositions.

Siemens AG

Technical Solution: Siemens has developed advanced functionally graded ceramic coating systems primarily for gas turbine applications, where thermal management is critical for efficiency and component longevity. Their technology employs a sophisticated multi-layer approach with compositional gradients that transition from metallic bond coats to ceramic top coats. The company utilizes electron beam physical vapor deposition (EB-PVD) and advanced plasma spray techniques to create columnar microstructures that enhance strain tolerance while maintaining thermal barrier properties. Siemens' coatings incorporate yttria-stabilized zirconia (YSZ) with carefully controlled porosity gradients and dopant distributions to optimize thermal conductivity profiles. Their latest innovations include the integration of rare earth zirconates and hafnates in the outer layers to improve phase stability at temperatures exceeding 1300°C, while maintaining thermal expansion compatibility with underlying layers. This technology has demonstrated up to 30% improvement in coating lifetime under thermal cycling conditions compared to conventional thermal barrier coatings.

Strengths: Superior thermal cycling resistance due to strain-tolerant microstructure; excellent high-temperature stability; proven performance in demanding industrial applications. Weaknesses: High manufacturing costs; complex quality control requirements; limited repairability in field conditions.

Key Patents in Gradient Ceramic Structures

functionally graded thermal insulation coating system

PatentInactiveDE112014003451T5

Innovation

- A functionally graded thermal barrier coating system is developed using a powder deposition process with laser melting, incorporating a flux to control the composition gradient, ensuring crack-free deposits and improved adhesion, allowing for layers with varying material ratios to adapt to temperature gradients.

A coating process for medical waste incinerator

PatentInactiveIN201911000733A

Innovation

- The implementation of a post-treatment burnishing process on NiCrAlY cold spray coatings to reduce porosity, increase surface hardness, and enhance surface finish, using roller burnishing to improve erosion-corrosion resistance and mechanical properties, specifically for super alloys in medical waste incineration environments.

Materials Sustainability and Lifecycle Assessment

The sustainability aspects of functionally graded ceramic coatings (FGCCs) represent a critical dimension in their development and application for thermal management systems. These advanced materials must be evaluated not only for their performance but also for their environmental impact throughout their entire lifecycle.

The raw material extraction phase for FGCCs presents significant sustainability challenges. Many ceramic components require rare earth elements or other materials with limited global reserves. Mining operations for these materials often generate substantial environmental disruption, including habitat destruction, water pollution, and high energy consumption. The carbon footprint associated with extracting these specialized materials frequently exceeds that of conventional coating materials.

Manufacturing processes for FGCCs typically involve high-temperature sintering, plasma spraying, or chemical vapor deposition, all of which demand considerable energy inputs. Current production methods generate approximately 30-40% more greenhouse gas emissions compared to traditional ceramic coating processes due to the precision required for creating functional gradients. However, emerging technologies such as additive manufacturing show promise for reducing energy consumption by up to 25% while minimizing material waste.

During the use phase, FGCCs demonstrate superior sustainability credentials. Their enhanced thermal management capabilities can extend the operational lifespan of protected components by 40-60% compared to homogeneous coatings. This longevity translates directly into reduced resource consumption and waste generation over time. Additionally, the improved thermal efficiency provided by FGCCs can decrease overall system energy requirements by 15-20% in applications such as gas turbines and electronic cooling systems.

End-of-life considerations present particular challenges for FGCCs. The multi-material, graded nature of these coatings complicates recycling efforts, as separation of the constituent materials often proves technically difficult and economically unfeasible. Current recycling rates for FGCCs remain below 10%, significantly lower than for single-material ceramic coatings.

Life cycle assessment (LCA) studies indicate that the environmental benefits of FGCCs during their operational phase generally outweigh the increased environmental burden of their production, provided their service life exceeds certain thresholds. For thermal barrier coatings in aerospace applications, this breakeven point typically occurs after 3-5 years of service, after which net environmental benefits accumulate.

Future research directions should focus on developing more sustainable manufacturing processes, increasing material efficiency, and improving end-of-life recyclability. Bio-inspired ceramic formulations and water-based processing techniques represent promising approaches for reducing the environmental footprint of FGCC production while maintaining or enhancing their thermal management capabilities.

The raw material extraction phase for FGCCs presents significant sustainability challenges. Many ceramic components require rare earth elements or other materials with limited global reserves. Mining operations for these materials often generate substantial environmental disruption, including habitat destruction, water pollution, and high energy consumption. The carbon footprint associated with extracting these specialized materials frequently exceeds that of conventional coating materials.

Manufacturing processes for FGCCs typically involve high-temperature sintering, plasma spraying, or chemical vapor deposition, all of which demand considerable energy inputs. Current production methods generate approximately 30-40% more greenhouse gas emissions compared to traditional ceramic coating processes due to the precision required for creating functional gradients. However, emerging technologies such as additive manufacturing show promise for reducing energy consumption by up to 25% while minimizing material waste.

During the use phase, FGCCs demonstrate superior sustainability credentials. Their enhanced thermal management capabilities can extend the operational lifespan of protected components by 40-60% compared to homogeneous coatings. This longevity translates directly into reduced resource consumption and waste generation over time. Additionally, the improved thermal efficiency provided by FGCCs can decrease overall system energy requirements by 15-20% in applications such as gas turbines and electronic cooling systems.

End-of-life considerations present particular challenges for FGCCs. The multi-material, graded nature of these coatings complicates recycling efforts, as separation of the constituent materials often proves technically difficult and economically unfeasible. Current recycling rates for FGCCs remain below 10%, significantly lower than for single-material ceramic coatings.

Life cycle assessment (LCA) studies indicate that the environmental benefits of FGCCs during their operational phase generally outweigh the increased environmental burden of their production, provided their service life exceeds certain thresholds. For thermal barrier coatings in aerospace applications, this breakeven point typically occurs after 3-5 years of service, after which net environmental benefits accumulate.

Future research directions should focus on developing more sustainable manufacturing processes, increasing material efficiency, and improving end-of-life recyclability. Bio-inspired ceramic formulations and water-based processing techniques represent promising approaches for reducing the environmental footprint of FGCC production while maintaining or enhancing their thermal management capabilities.

Performance Testing Standards for FGC Systems

The standardization of performance testing for Functionally Graded Ceramic (FGC) coating systems represents a critical aspect of their industrial adoption and quality assurance. Currently, several international organizations including ASTM International, ISO, and NACE have developed specific testing protocols that address the unique properties of graded ceramic structures. These standards typically encompass thermal cycling resistance, thermal shock behavior, adhesion strength, and thermal conductivity measurements under various environmental conditions.

ASTM C633 has been adapted specifically for FGC systems to evaluate coating adhesion strength, while ASTM E1461 provides guidelines for measuring thermal diffusivity using the laser flash method—particularly valuable for characterizing the gradient thermal properties across coating layers. For thermal cycling performance, modified versions of ISO 13123 are commonly employed, subjecting specimens to rapid temperature fluctuations between -40°C and 1200°C to simulate extreme operational conditions.

Erosion resistance testing follows ASTM G76 protocols, though with adjustments for the heterogeneous nature of graded ceramics. These tests typically employ aluminum oxide particles at controlled velocities to assess material removal rates across the gradient structure. Importantly, specialized procedures have emerged for evaluating interfacial thermal resistance, a critical parameter in thermal management applications that conventional standards inadequately address.

The aerospace and energy sectors have developed supplementary testing requirements that exceed standard protocols. These include combined thermal-mechanical fatigue testing under simulated combustion environments and hot corrosion resistance evaluations using molten salt exposure at elevated temperatures. Such industry-specific standards often incorporate acoustic emission monitoring during thermal cycling to detect microcrack formation before catastrophic failure occurs.

Recent developments in testing methodologies include non-destructive evaluation techniques such as infrared thermography and impedance spectroscopy, which allow for in-situ monitoring of coating degradation. These approaches are increasingly being incorporated into standardized testing procedures, enabling more comprehensive performance assessment throughout a component's service life.

A significant challenge in FGC testing standardization remains the correlation between accelerated laboratory tests and actual field performance. Current research focuses on developing digital twin models that can predict long-term performance based on short-term test results, potentially revolutionizing qualification procedures for these advanced coating systems in thermal management applications.

ASTM C633 has been adapted specifically for FGC systems to evaluate coating adhesion strength, while ASTM E1461 provides guidelines for measuring thermal diffusivity using the laser flash method—particularly valuable for characterizing the gradient thermal properties across coating layers. For thermal cycling performance, modified versions of ISO 13123 are commonly employed, subjecting specimens to rapid temperature fluctuations between -40°C and 1200°C to simulate extreme operational conditions.

Erosion resistance testing follows ASTM G76 protocols, though with adjustments for the heterogeneous nature of graded ceramics. These tests typically employ aluminum oxide particles at controlled velocities to assess material removal rates across the gradient structure. Importantly, specialized procedures have emerged for evaluating interfacial thermal resistance, a critical parameter in thermal management applications that conventional standards inadequately address.

The aerospace and energy sectors have developed supplementary testing requirements that exceed standard protocols. These include combined thermal-mechanical fatigue testing under simulated combustion environments and hot corrosion resistance evaluations using molten salt exposure at elevated temperatures. Such industry-specific standards often incorporate acoustic emission monitoring during thermal cycling to detect microcrack formation before catastrophic failure occurs.

Recent developments in testing methodologies include non-destructive evaluation techniques such as infrared thermography and impedance spectroscopy, which allow for in-situ monitoring of coating degradation. These approaches are increasingly being incorporated into standardized testing procedures, enabling more comprehensive performance assessment throughout a component's service life.

A significant challenge in FGC testing standardization remains the correlation between accelerated laboratory tests and actual field performance. Current research focuses on developing digital twin models that can predict long-term performance based on short-term test results, potentially revolutionizing qualification procedures for these advanced coating systems in thermal management applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!