Multilayer Ceramic Coatings for Enhanced Durability

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Coating Evolution and Research Objectives

Ceramic coatings have evolved significantly over the past century, transforming from simple single-layer protective barriers to sophisticated multilayer systems with enhanced performance characteristics. The earliest ceramic coatings emerged in the 1940s, primarily used for thermal protection in aerospace applications. By the 1970s, advancements in material science enabled the development of more durable ceramic coatings with improved adhesion properties, expanding their application to industrial machinery and automotive components.

The 1990s marked a pivotal shift with the introduction of plasma-sprayed ceramic coatings, which offered superior thermal resistance and wear protection. This period also witnessed the emergence of early multilayer ceramic coating concepts, where different ceramic materials were combined to achieve complementary properties. The early 2000s saw significant progress in nanostructured ceramic coatings, providing unprecedented levels of hardness and wear resistance while maintaining relatively thin coating profiles.

Recent developments have focused on creating intelligent multilayer ceramic coating systems that can adapt to changing environmental conditions. These advanced coatings incorporate functional gradients, where composition and microstructure vary systematically across the coating thickness to optimize performance under specific operating conditions. The integration of self-healing mechanisms and damage-tolerant designs represents the cutting edge of current ceramic coating technology.

The global push toward sustainability and energy efficiency has further accelerated research in ceramic coatings, particularly for applications in extreme environments where traditional materials fail. Industries ranging from aerospace and automotive to medical devices and renewable energy now rely on advanced ceramic coatings to extend component lifespans and improve system efficiency.

The primary objective of this research is to develop next-generation multilayer ceramic coating systems with enhanced durability under extreme thermal, mechanical, and chemical stresses. Specifically, we aim to achieve a 50% improvement in coating lifespan compared to current state-of-the-art solutions while maintaining or reducing overall coating thickness. This research seeks to identify optimal material combinations, layer architectures, and deposition techniques that maximize adhesion strength, wear resistance, and thermal stability.

Additional objectives include developing predictive models for coating performance under various operating conditions, establishing standardized testing protocols for multilayer ceramic coatings, and exploring environmentally friendly coating materials and processes. The research will also investigate the scalability of advanced coating technologies for industrial applications, with particular emphasis on cost-effective manufacturing methods suitable for mass production.

The 1990s marked a pivotal shift with the introduction of plasma-sprayed ceramic coatings, which offered superior thermal resistance and wear protection. This period also witnessed the emergence of early multilayer ceramic coating concepts, where different ceramic materials were combined to achieve complementary properties. The early 2000s saw significant progress in nanostructured ceramic coatings, providing unprecedented levels of hardness and wear resistance while maintaining relatively thin coating profiles.

Recent developments have focused on creating intelligent multilayer ceramic coating systems that can adapt to changing environmental conditions. These advanced coatings incorporate functional gradients, where composition and microstructure vary systematically across the coating thickness to optimize performance under specific operating conditions. The integration of self-healing mechanisms and damage-tolerant designs represents the cutting edge of current ceramic coating technology.

The global push toward sustainability and energy efficiency has further accelerated research in ceramic coatings, particularly for applications in extreme environments where traditional materials fail. Industries ranging from aerospace and automotive to medical devices and renewable energy now rely on advanced ceramic coatings to extend component lifespans and improve system efficiency.

The primary objective of this research is to develop next-generation multilayer ceramic coating systems with enhanced durability under extreme thermal, mechanical, and chemical stresses. Specifically, we aim to achieve a 50% improvement in coating lifespan compared to current state-of-the-art solutions while maintaining or reducing overall coating thickness. This research seeks to identify optimal material combinations, layer architectures, and deposition techniques that maximize adhesion strength, wear resistance, and thermal stability.

Additional objectives include developing predictive models for coating performance under various operating conditions, establishing standardized testing protocols for multilayer ceramic coatings, and exploring environmentally friendly coating materials and processes. The research will also investigate the scalability of advanced coating technologies for industrial applications, with particular emphasis on cost-effective manufacturing methods suitable for mass production.

Market Analysis for High-Durability Ceramic Coatings

The global market for high-durability ceramic coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries including aerospace, automotive, energy, and medical devices. Current market valuation stands at approximately 9.2 billion USD with a compound annual growth rate (CAGR) of 7.3% projected through 2028, indicating robust expansion potential.

Aerospace and defense sectors represent the largest market segment, accounting for nearly 32% of total market share. These industries require coatings capable of withstanding extreme temperatures, corrosion, and mechanical stress. The automotive industry follows closely at 27%, where ceramic coatings are increasingly utilized for engine components, exhaust systems, and exterior protection applications.

Regional analysis reveals North America and Europe as dominant markets, collectively representing 58% of global consumption. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with an estimated CAGR of 9.1%, fueled by rapid industrialization and increasing manufacturing capabilities.

Customer demand patterns show a clear shift toward multilayer ceramic coating systems that offer enhanced performance characteristics. End-users increasingly prioritize coatings that provide multiple protective properties simultaneously, including thermal insulation, wear resistance, corrosion protection, and extended service life. This trend is particularly evident in high-value applications where component failure carries significant consequences.

Price sensitivity varies considerably across market segments. While industrial applications remain highly cost-conscious, high-performance sectors like aerospace and medical demonstrate willingness to pay premium prices for coatings that deliver demonstrable improvements in durability and reliability. The average price premium for advanced multilayer systems versus conventional coatings ranges between 30-45%.

Market challenges include stringent environmental regulations limiting certain coating materials and processes, particularly those containing hexavalent chromium and other hazardous substances. This regulatory landscape has accelerated research into environmentally compliant alternatives, creating both constraints and opportunities for innovation.

Supply chain analysis reveals moderate concentration among raw material suppliers, with approximately 65% of specialized ceramic powders and precursors controlled by ten major companies. This concentration creates potential vulnerabilities in material availability and pricing stability, particularly for advanced ceramic formulations requiring rare earth elements or specialized dopants.

Aerospace and defense sectors represent the largest market segment, accounting for nearly 32% of total market share. These industries require coatings capable of withstanding extreme temperatures, corrosion, and mechanical stress. The automotive industry follows closely at 27%, where ceramic coatings are increasingly utilized for engine components, exhaust systems, and exterior protection applications.

Regional analysis reveals North America and Europe as dominant markets, collectively representing 58% of global consumption. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with an estimated CAGR of 9.1%, fueled by rapid industrialization and increasing manufacturing capabilities.

Customer demand patterns show a clear shift toward multilayer ceramic coating systems that offer enhanced performance characteristics. End-users increasingly prioritize coatings that provide multiple protective properties simultaneously, including thermal insulation, wear resistance, corrosion protection, and extended service life. This trend is particularly evident in high-value applications where component failure carries significant consequences.

Price sensitivity varies considerably across market segments. While industrial applications remain highly cost-conscious, high-performance sectors like aerospace and medical demonstrate willingness to pay premium prices for coatings that deliver demonstrable improvements in durability and reliability. The average price premium for advanced multilayer systems versus conventional coatings ranges between 30-45%.

Market challenges include stringent environmental regulations limiting certain coating materials and processes, particularly those containing hexavalent chromium and other hazardous substances. This regulatory landscape has accelerated research into environmentally compliant alternatives, creating both constraints and opportunities for innovation.

Supply chain analysis reveals moderate concentration among raw material suppliers, with approximately 65% of specialized ceramic powders and precursors controlled by ten major companies. This concentration creates potential vulnerabilities in material availability and pricing stability, particularly for advanced ceramic formulations requiring rare earth elements or specialized dopants.

Global Ceramic Coating Technology Assessment and Barriers

The global ceramic coating technology landscape presents a complex array of advancements and persistent challenges. Currently, thermal spray technologies dominate the industrial ceramic coating sector, with plasma spray and high-velocity oxygen fuel (HVOF) methods being the most widely implemented. These technologies have reached maturity in aerospace, automotive, and energy sectors, yet significant barriers remain in achieving optimal performance for extreme environments.

Material composition limitations represent a primary constraint, as conventional ceramic formulations struggle to simultaneously deliver thermal resistance, mechanical durability, and chemical stability. The industry faces a critical challenge in developing ceramic matrices that can withstand thermal cycling without microcrack formation, particularly in applications exceeding 1200°C operating temperatures.

Processing barriers further complicate advancement, with precise control of coating microstructure remaining elusive at industrial scales. Current deposition technologies often produce inconsistent porosity distribution and interface bonding quality, leading to premature coating failure under thermal and mechanical stress. The transition from laboratory-scale success to industrial implementation frequently encounters reproducibility issues.

Economic factors constitute another significant barrier, as high-performance ceramic coating systems typically require specialized equipment and extensive quality control measures. The cost-benefit analysis often proves challenging for industries outside aerospace and high-end energy applications, limiting broader market penetration despite technical advantages.

Regulatory and standardization gaps present additional obstacles, with inconsistent testing protocols across regions creating market fragmentation. The absence of universally accepted performance metrics for multilayer ceramic systems complicates technology assessment and adoption decisions, particularly for multinational corporations with global manufacturing footprints.

Environmental considerations are increasingly influencing technology development, with traditional ceramic coating processes facing scrutiny for energy consumption and waste generation. Sustainable alternatives using water-based suspensions and lower-temperature processing show promise but currently deliver inferior performance compared to conventional methods.

The knowledge gap between academic research and industrial implementation remains substantial, with many theoretical advances in multilayer ceramic architectures failing to translate into commercial solutions. This disconnect stems partly from insufficient collaboration mechanisms between research institutions and manufacturing entities, as well as proprietary concerns limiting information sharing.

Addressing these barriers requires coordinated efforts across the value chain, from materials scientists developing novel ceramic compositions to equipment manufacturers enhancing deposition precision and end-users providing application-specific performance requirements. Recent consortium-based approaches in Europe and Asia demonstrate promising models for overcoming these collective challenges through pre-competitive collaboration.

Material composition limitations represent a primary constraint, as conventional ceramic formulations struggle to simultaneously deliver thermal resistance, mechanical durability, and chemical stability. The industry faces a critical challenge in developing ceramic matrices that can withstand thermal cycling without microcrack formation, particularly in applications exceeding 1200°C operating temperatures.

Processing barriers further complicate advancement, with precise control of coating microstructure remaining elusive at industrial scales. Current deposition technologies often produce inconsistent porosity distribution and interface bonding quality, leading to premature coating failure under thermal and mechanical stress. The transition from laboratory-scale success to industrial implementation frequently encounters reproducibility issues.

Economic factors constitute another significant barrier, as high-performance ceramic coating systems typically require specialized equipment and extensive quality control measures. The cost-benefit analysis often proves challenging for industries outside aerospace and high-end energy applications, limiting broader market penetration despite technical advantages.

Regulatory and standardization gaps present additional obstacles, with inconsistent testing protocols across regions creating market fragmentation. The absence of universally accepted performance metrics for multilayer ceramic systems complicates technology assessment and adoption decisions, particularly for multinational corporations with global manufacturing footprints.

Environmental considerations are increasingly influencing technology development, with traditional ceramic coating processes facing scrutiny for energy consumption and waste generation. Sustainable alternatives using water-based suspensions and lower-temperature processing show promise but currently deliver inferior performance compared to conventional methods.

The knowledge gap between academic research and industrial implementation remains substantial, with many theoretical advances in multilayer ceramic architectures failing to translate into commercial solutions. This disconnect stems partly from insufficient collaboration mechanisms between research institutions and manufacturing entities, as well as proprietary concerns limiting information sharing.

Addressing these barriers requires coordinated efforts across the value chain, from materials scientists developing novel ceramic compositions to equipment manufacturers enhancing deposition precision and end-users providing application-specific performance requirements. Recent consortium-based approaches in Europe and Asia demonstrate promising models for overcoming these collective challenges through pre-competitive collaboration.

Current Multilayer Ceramic Coating Methodologies

01 Composition and structure of multilayer ceramic coatings

Multilayer ceramic coatings consist of different layers with specific compositions and structures that contribute to their durability. These coatings typically include a base layer, intermediate layers, and a top layer, each serving different functions such as adhesion, stress distribution, and wear resistance. The careful selection of materials and layer arrangement can significantly enhance the overall durability of the coating system by providing protection against thermal cycling, mechanical stress, and environmental factors.- Composition and structure of multilayer ceramic coatings: Multilayer ceramic coatings consist of different layers with specific compositions and structures that contribute to their durability. These layers typically include a base layer, intermediate layers, and a top layer, each serving different functions such as adhesion, stress distribution, and surface protection. The composition may include materials like alumina, zirconia, or silicon nitride, arranged in a way that enhances the overall durability of the coating system.

- Thermal resistance and shock protection mechanisms: Multilayer ceramic coatings are designed to withstand extreme thermal conditions and protect against thermal shock. The layered structure helps distribute thermal stresses and prevent crack propagation. Specific materials and layer configurations are used to create thermal barriers that enhance the durability of the coating when exposed to rapid temperature changes or high-temperature environments.

- Wear and erosion resistance properties: The durability of multilayer ceramic coatings is significantly enhanced by their wear and erosion resistance properties. These coatings are formulated with hard ceramic materials and structured in ways that minimize material loss due to abrasion, friction, and particle impact. The multiple layers work together to absorb impact energy and prevent surface degradation, extending the service life of the coated components.

- Manufacturing techniques for durable ceramic coatings: Various manufacturing techniques are employed to produce durable multilayer ceramic coatings, including physical vapor deposition, chemical vapor deposition, plasma spraying, and sol-gel methods. These processes control the microstructure, density, and interfacial bonding of the ceramic layers, which are critical factors affecting the coating's durability. Advanced deposition methods can create nanoscale features that further enhance durability properties.

- Testing and evaluation methods for coating durability: Specific testing and evaluation methods are used to assess the durability of multilayer ceramic coatings. These include thermal cycling tests, scratch tests, indentation tests, and accelerated aging procedures. Advanced characterization techniques such as scanning electron microscopy and X-ray diffraction are employed to analyze coating integrity, adhesion strength, and failure mechanisms, providing valuable data for improving coating durability.

02 Thermal shock resistance in ceramic coatings

Thermal shock resistance is a critical factor in the durability of multilayer ceramic coatings, especially in applications involving rapid temperature changes. Engineered ceramic layers with controlled thermal expansion coefficients and porosity can minimize thermal stresses and prevent crack propagation. Specialized formulations and manufacturing techniques are employed to create coatings that can withstand repeated thermal cycling without delamination or failure, thereby extending the service life of the coated components.Expand Specific Solutions03 Wear and erosion resistance mechanisms

Multilayer ceramic coatings achieve enhanced wear and erosion resistance through carefully designed microstructures and phase compositions. Hard ceramic phases combined with toughening mechanisms prevent crack propagation and material loss during service. The incorporation of self-healing components and gradient structures in the coating system can further improve resistance to abrasive wear, particle erosion, and surface degradation under harsh operating conditions, significantly extending the coating's functional lifetime.Expand Specific Solutions04 Chemical and corrosion resistance properties

The durability of multilayer ceramic coatings in aggressive chemical environments depends on their resistance to corrosion and chemical attack. Specialized ceramic compositions with stable oxide phases provide protection against oxidation, sulfidation, and other corrosive processes. Barrier layers and controlled porosity in the coating structure prevent penetration of corrosive media to the substrate, while the use of chemically inert materials in the outer layers ensures long-term stability in harsh industrial environments.Expand Specific Solutions05 Advanced manufacturing techniques for durable ceramic coatings

Manufacturing processes significantly impact the durability of multilayer ceramic coatings. Advanced deposition techniques such as plasma spraying, physical vapor deposition, and atomic layer deposition enable precise control over coating microstructure and properties. Post-deposition treatments including controlled sintering, laser processing, and surface modification can further enhance coating adhesion, density, and mechanical properties. These manufacturing innovations result in more durable ceramic coating systems with improved resistance to mechanical, thermal, and environmental stresses.Expand Specific Solutions

Industry Leaders in Advanced Ceramic Coating Solutions

The multilayer ceramic coatings market for enhanced durability is currently in a growth phase, with increasing applications across automotive, electronics, and industrial sectors. The global market size is estimated to reach significant value due to rising demand for wear-resistant and high-performance materials. Leading players include established ceramic manufacturers like Murata Manufacturing and Samsung Electro-Mechanics, who leverage their expertise in multilayer ceramic technologies, alongside specialized coating companies such as Shanghai Excilon New Materials. The technology shows varying maturity levels, with companies like Taiyo Yuden and TDK advancing commercial applications, while research institutions like Guangdong University of Technology and Sichuan University focus on next-generation formulations. Industrial players including Safran Aircraft Engines and Praxair S.T. Technology are developing application-specific solutions, indicating the technology's transition from research to commercial implementation.

Siemens Energy Global GmbH & Co. KG

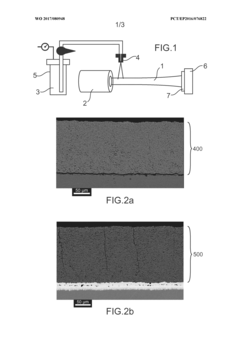

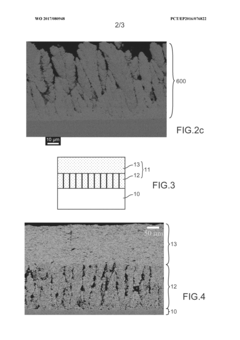

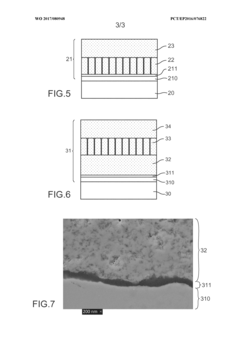

Technical Solution: Siemens Energy has developed advanced multilayer ceramic coating systems specifically for power generation components exposed to extreme conditions. Their technology combines atmospheric plasma spraying (APS) and suspension plasma spraying (SPS) to create tailored microstructures across different coating layers. Siemens' approach utilizes a bond coat of MCrAlY alloy, followed by a thermally grown oxide layer, and multiple ceramic layers with engineered porosity gradients. Their innovation includes the incorporation of rare earth zirconates in outer layers for superior CMAS (calcium-magnesium-alumino-silicate) resistance, critical for turbines operating in dusty environments. The company's coatings feature segmentation cracks introduced through controlled processing to enhance strain tolerance while maintaining thermal protection. Siemens has demonstrated coating lifespans exceeding 25,000 operating hours in commercial gas turbines, with their multilayer systems allowing for higher operating temperatures and improved efficiency compared to conventional coatings.

Strengths: Exceptional resistance to CMAS infiltration; proven field performance in commercial power generation; optimized for extremely long service life in steady-state operation. Weaknesses: Less suitable for applications with frequent thermal cycling; requires specialized application equipment; higher initial cost compared to simpler coating systems.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair has developed advanced thermal spray coating systems specifically for multilayer ceramic coatings that enhance durability in extreme environments. Their technology utilizes a proprietary plasma spray process that creates dense, highly adherent ceramic layers with controlled microstructure. The company's multilayer approach combines different ceramic materials (typically yttria-stabilized zirconia, alumina, and rare earth oxides) in precisely engineered layers to provide thermal insulation, wear resistance, and corrosion protection simultaneously. Their coatings feature nanoscale interlayers that improve adhesion between dissimilar materials and reduce thermal expansion mismatch stress. Praxair's process allows for precise thickness control (ranging from 100μm to several millimeters) and can be applied to complex geometries, making it suitable for aerospace components, industrial gas turbines, and high-temperature processing equipment.

Strengths: Superior thermal shock resistance due to engineered interfaces between layers; excellent adhesion to metallic substrates; proven longevity in high-temperature applications exceeding 1200°C. Weaknesses: Higher production costs compared to single-layer solutions; requires specialized application equipment; limited repair options once coating is damaged.

Key Patents and Innovations in Multilayer Ceramic Systems

Multilayer ceramic coating for high-temperature thermal protection, in particular for aeronautical application, and method for producing same

PatentWO2017080948A1

Innovation

- A multilayer ceramic coating with nanostructured or finely structured ceramic layers, produced using the SPS arc plasma spraying process, featuring columnar, segmented, or homogeneous architectures, is developed to enhance thermal cycling resistance and thermal conductivity, while also providing protection against CMAS infiltration.

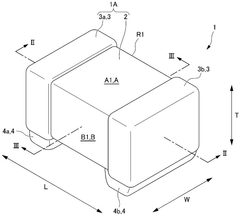

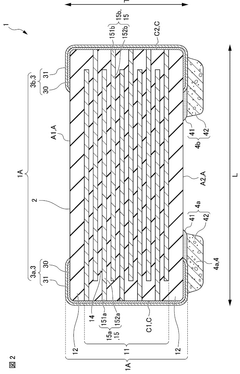

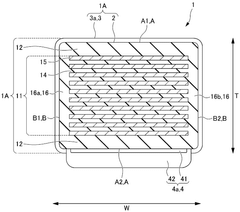

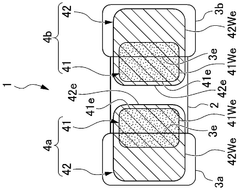

Multilayer ceramic electronic component

PatentWO2024252946A1

Innovation

- The use of a spacer with a first region covering a part of the laminate and a second region covering a part of the external electrode, both made of different materials, enhances the adhesion force between the capacitor body and the spacer, improving durability by using materials like metal films, insulating resins, and metal powders to ensure strong bonding.

Material Science Advancements Supporting Ceramic Coatings

Recent advancements in materials science have significantly contributed to the evolution of ceramic coating technologies, particularly in developing multilayer systems for enhanced durability. The fundamental understanding of ceramic microstructures at the atomic and molecular levels has enabled scientists to engineer coatings with precisely controlled properties. Innovations in nanotechnology have facilitated the incorporation of nanoparticles and nanostructures into ceramic matrices, resulting in superior mechanical properties and thermal resistance.

The development of advanced characterization techniques, such as high-resolution transmission electron microscopy (HRTEM) and atomic force microscopy (AFM), has provided unprecedented insights into the behavior of ceramic materials under various conditions. These tools allow researchers to observe interfacial phenomena between different ceramic layers, critical for optimizing adhesion and preventing delamination in multilayer systems.

Computational materials science has emerged as a powerful approach in ceramic coating research. Molecular dynamics simulations and density functional theory calculations enable the prediction of material properties and behavior before physical synthesis, significantly accelerating the development cycle. These computational methods have been instrumental in designing ceramic compositions with enhanced resistance to thermal cycling and mechanical stress.

Novel synthesis methods, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), have revolutionized the precision with which multilayer ceramic coatings can be fabricated. These techniques allow for the deposition of ultra-thin layers with controlled thickness and composition, enabling the creation of complex architectures with tailored functionality.

The integration of self-healing mechanisms represents another breakthrough in ceramic coating technology. By incorporating microencapsulated healing agents or designing intrinsic self-healing capabilities through phase transformations, researchers have developed ceramic coatings capable of autonomously repairing damage, significantly extending service life in harsh environments.

Hybrid ceramic materials, combining traditional ceramics with polymers or metals, have opened new possibilities for coating applications. These composites often exhibit synergistic properties, such as improved toughness and flexibility while maintaining the high-temperature resistance characteristic of ceramics. The development of ceramic-matrix composites reinforced with fibers or whiskers has particularly enhanced the fracture toughness of coating systems.

Environmental considerations have also driven materials science innovations, with research focusing on developing lead-free and other environmentally friendly ceramic formulations. These sustainable approaches maintain performance standards while reducing the environmental impact of coating technologies, aligning with global sustainability goals and regulatory requirements.

The development of advanced characterization techniques, such as high-resolution transmission electron microscopy (HRTEM) and atomic force microscopy (AFM), has provided unprecedented insights into the behavior of ceramic materials under various conditions. These tools allow researchers to observe interfacial phenomena between different ceramic layers, critical for optimizing adhesion and preventing delamination in multilayer systems.

Computational materials science has emerged as a powerful approach in ceramic coating research. Molecular dynamics simulations and density functional theory calculations enable the prediction of material properties and behavior before physical synthesis, significantly accelerating the development cycle. These computational methods have been instrumental in designing ceramic compositions with enhanced resistance to thermal cycling and mechanical stress.

Novel synthesis methods, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), have revolutionized the precision with which multilayer ceramic coatings can be fabricated. These techniques allow for the deposition of ultra-thin layers with controlled thickness and composition, enabling the creation of complex architectures with tailored functionality.

The integration of self-healing mechanisms represents another breakthrough in ceramic coating technology. By incorporating microencapsulated healing agents or designing intrinsic self-healing capabilities through phase transformations, researchers have developed ceramic coatings capable of autonomously repairing damage, significantly extending service life in harsh environments.

Hybrid ceramic materials, combining traditional ceramics with polymers or metals, have opened new possibilities for coating applications. These composites often exhibit synergistic properties, such as improved toughness and flexibility while maintaining the high-temperature resistance characteristic of ceramics. The development of ceramic-matrix composites reinforced with fibers or whiskers has particularly enhanced the fracture toughness of coating systems.

Environmental considerations have also driven materials science innovations, with research focusing on developing lead-free and other environmentally friendly ceramic formulations. These sustainable approaches maintain performance standards while reducing the environmental impact of coating technologies, aligning with global sustainability goals and regulatory requirements.

Environmental Impact and Sustainability Considerations

The environmental impact of multilayer ceramic coatings extends beyond their primary function of enhancing durability. These coatings significantly reduce the frequency of component replacement, thereby decreasing waste generation and resource consumption throughout product lifecycles. This reduction in material turnover represents a substantial contribution to sustainability efforts across various industries, particularly in aerospace, automotive, and industrial manufacturing sectors.

When evaluating the environmental footprint of ceramic coating technologies, production processes demand careful consideration. Traditional ceramic coating methods often involve energy-intensive firing processes that generate considerable carbon emissions. However, recent advancements in low-temperature deposition techniques, including sol-gel methods and room-temperature plasma spraying, have substantially reduced energy requirements. These innovations represent promising pathways toward more environmentally responsible manufacturing practices.

Raw material selection for multilayer ceramic coatings presents both challenges and opportunities from a sustainability perspective. While some formulations rely on rare earth elements with problematic extraction profiles, research into alternative compositions utilizing abundant, less environmentally impactful materials has shown promising results. Particularly noteworthy are bio-inspired ceramic compositions that mimic natural protective structures while minimizing dependence on scarce resources.

End-of-life considerations for ceramic-coated components have received increasing attention in recent sustainability assessments. The chemical stability of many ceramic materials presents recycling challenges, as they often resist conventional separation methods. Emerging technologies for selective dissolution and mechanical separation show potential for improving the recyclability of ceramic-coated components, though implementation at industrial scale remains limited.

Lifecycle assessment (LCA) studies comparing multilayer ceramic coatings against traditional protective solutions demonstrate significant environmental advantages. When accounting for extended service life, reduced maintenance requirements, and decreased energy consumption during operation, ceramic-coated components typically show favorable environmental performance metrics despite potentially higher initial production impacts. Quantitative analyses indicate that durability improvements of 2-3 times baseline can offset manufacturing emissions within the first third of the component's extended service life.

Regulatory frameworks increasingly recognize the sustainability benefits of enhanced durability solutions. Several jurisdictions have implemented incentive programs for technologies that demonstrably extend product lifecycles, creating additional market drivers for advanced ceramic coating adoption. These policy mechanisms complement technical development efforts and accelerate industry transition toward more sustainable material protection strategies.

When evaluating the environmental footprint of ceramic coating technologies, production processes demand careful consideration. Traditional ceramic coating methods often involve energy-intensive firing processes that generate considerable carbon emissions. However, recent advancements in low-temperature deposition techniques, including sol-gel methods and room-temperature plasma spraying, have substantially reduced energy requirements. These innovations represent promising pathways toward more environmentally responsible manufacturing practices.

Raw material selection for multilayer ceramic coatings presents both challenges and opportunities from a sustainability perspective. While some formulations rely on rare earth elements with problematic extraction profiles, research into alternative compositions utilizing abundant, less environmentally impactful materials has shown promising results. Particularly noteworthy are bio-inspired ceramic compositions that mimic natural protective structures while minimizing dependence on scarce resources.

End-of-life considerations for ceramic-coated components have received increasing attention in recent sustainability assessments. The chemical stability of many ceramic materials presents recycling challenges, as they often resist conventional separation methods. Emerging technologies for selective dissolution and mechanical separation show potential for improving the recyclability of ceramic-coated components, though implementation at industrial scale remains limited.

Lifecycle assessment (LCA) studies comparing multilayer ceramic coatings against traditional protective solutions demonstrate significant environmental advantages. When accounting for extended service life, reduced maintenance requirements, and decreased energy consumption during operation, ceramic-coated components typically show favorable environmental performance metrics despite potentially higher initial production impacts. Quantitative analyses indicate that durability improvements of 2-3 times baseline can offset manufacturing emissions within the first third of the component's extended service life.

Regulatory frameworks increasingly recognize the sustainability benefits of enhanced durability solutions. Several jurisdictions have implemented incentive programs for technologies that demonstrably extend product lifecycles, creating additional market drivers for advanced ceramic coating adoption. These policy mechanisms complement technical development efforts and accelerate industry transition toward more sustainable material protection strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!