Thermal Barrier Coatings via Ceramic Thermal Spray Processes

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Evolution and Objectives

Thermal Barrier Coatings (TBCs) have evolved significantly since their inception in the 1960s, initially developed for aerospace applications to protect metal components from extreme temperatures in gas turbine engines. The evolution of TBCs represents a remarkable journey of materials science and engineering innovation, driven by the continuous demand for higher operating temperatures and improved durability in extreme environments.

The first generation of TBCs consisted primarily of zirconia stabilized with magnesia (MgO-ZrO2), which provided basic thermal protection but suffered from phase destabilization during thermal cycling. By the 1970s, the industry shifted toward yttria-stabilized zirconia (YSZ) systems, which offered superior phase stability and became the industry standard that continues to dominate applications today.

The 1980s and 1990s witnessed significant advancements in deposition techniques, particularly the refinement of plasma spray processes and the introduction of electron beam physical vapor deposition (EB-PVD). These technological improvements enabled more precise control over coating microstructure, enhancing both thermal insulation properties and strain tolerance during thermal cycling.

Recent decades have seen the development of multi-layered TBC systems with functionally graded materials (FGMs) that provide smoother property transitions between the substrate and the ceramic top coat. Additionally, researchers have explored alternative ceramic materials such as gadolinium zirconate (Gd2Zr2O7) and lanthanum zirconate (La2Zr2O7) that offer lower thermal conductivity and improved phase stability at ultra-high temperatures compared to conventional YSZ.

The primary objective of modern TBC research is to develop coating systems capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity through thousands of thermal cycles. This includes improving resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration, which has emerged as a significant degradation mechanism in dusty operating environments.

Additional objectives include reducing production costs through more efficient deposition processes, extending service life through enhanced erosion and corrosion resistance, and developing non-destructive evaluation techniques for in-service monitoring of coating degradation. The integration of self-healing capabilities represents another frontier, with research focused on incorporating materials that can autonomously repair microstructural damage during operation.

As industrial gas turbines and aerospace engines continue to push efficiency boundaries, the development of next-generation TBCs remains critical for enabling higher operating temperatures while ensuring component reliability and longevity. The ultimate goal is to create multifunctional coating systems that simultaneously provide thermal insulation, oxidation protection, and mechanical stability in increasingly demanding service environments.

The first generation of TBCs consisted primarily of zirconia stabilized with magnesia (MgO-ZrO2), which provided basic thermal protection but suffered from phase destabilization during thermal cycling. By the 1970s, the industry shifted toward yttria-stabilized zirconia (YSZ) systems, which offered superior phase stability and became the industry standard that continues to dominate applications today.

The 1980s and 1990s witnessed significant advancements in deposition techniques, particularly the refinement of plasma spray processes and the introduction of electron beam physical vapor deposition (EB-PVD). These technological improvements enabled more precise control over coating microstructure, enhancing both thermal insulation properties and strain tolerance during thermal cycling.

Recent decades have seen the development of multi-layered TBC systems with functionally graded materials (FGMs) that provide smoother property transitions between the substrate and the ceramic top coat. Additionally, researchers have explored alternative ceramic materials such as gadolinium zirconate (Gd2Zr2O7) and lanthanum zirconate (La2Zr2O7) that offer lower thermal conductivity and improved phase stability at ultra-high temperatures compared to conventional YSZ.

The primary objective of modern TBC research is to develop coating systems capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity through thousands of thermal cycles. This includes improving resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration, which has emerged as a significant degradation mechanism in dusty operating environments.

Additional objectives include reducing production costs through more efficient deposition processes, extending service life through enhanced erosion and corrosion resistance, and developing non-destructive evaluation techniques for in-service monitoring of coating degradation. The integration of self-healing capabilities represents another frontier, with research focused on incorporating materials that can autonomously repair microstructural damage during operation.

As industrial gas turbines and aerospace engines continue to push efficiency boundaries, the development of next-generation TBCs remains critical for enabling higher operating temperatures while ensuring component reliability and longevity. The ultimate goal is to create multifunctional coating systems that simultaneously provide thermal insulation, oxidation protection, and mechanical stability in increasingly demanding service environments.

Market Analysis for High-Temperature Applications

The global market for Thermal Barrier Coatings (TBCs) applied via ceramic thermal spray processes is experiencing robust growth, primarily driven by increasing demands in high-temperature applications across multiple industries. The aerospace sector remains the dominant consumer, accounting for approximately 45% of the total market share, with gas turbine engines representing the most significant application segment.

Market valuation for TBCs reached $1.2 billion in 2022, with projections indicating growth to $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 8.4%. This growth trajectory is supported by the expanding power generation sector, particularly in emerging economies where energy infrastructure development is accelerating.

The automotive industry presents an emerging market for TBCs, especially with the growing interest in improving engine efficiency and reducing emissions. High-performance vehicles and racing applications currently lead this segment, but mainstream adoption is anticipated as environmental regulations become more stringent globally.

Regional analysis reveals North America and Europe as mature markets with stable growth rates of 6-7% annually, while the Asia-Pacific region demonstrates more aggressive expansion at 10-12% yearly, led by China and India's industrial development and increasing aerospace manufacturing capabilities.

Material preferences within the market show yttria-stabilized zirconia (YSZ) dominating with approximately 70% market share due to its established performance profile and cost-effectiveness. However, newer compositions including gadolinium zirconate and lanthanum zirconate are gaining traction in ultra-high-temperature applications, growing at 15% annually from a smaller base.

Customer demand is increasingly focused on coatings that can withstand temperatures exceeding 1300°C while maintaining longer service intervals. This requirement is driving premium pricing for advanced formulations, with customers willing to pay 30-40% more for coatings that can extend component life by at least 25%.

The competitive landscape features both specialized coating service providers and integrated manufacturers who offer coating as part of their component manufacturing process. This dual market structure creates varied pricing models and service offerings, with specialized providers focusing on customization and integrated manufacturers emphasizing turnkey solutions.

Future market expansion will likely be influenced by developments in additive manufacturing, which may enable more complex coating architectures and gradient compositions that were previously unachievable with conventional thermal spray processes.

Market valuation for TBCs reached $1.2 billion in 2022, with projections indicating growth to $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 8.4%. This growth trajectory is supported by the expanding power generation sector, particularly in emerging economies where energy infrastructure development is accelerating.

The automotive industry presents an emerging market for TBCs, especially with the growing interest in improving engine efficiency and reducing emissions. High-performance vehicles and racing applications currently lead this segment, but mainstream adoption is anticipated as environmental regulations become more stringent globally.

Regional analysis reveals North America and Europe as mature markets with stable growth rates of 6-7% annually, while the Asia-Pacific region demonstrates more aggressive expansion at 10-12% yearly, led by China and India's industrial development and increasing aerospace manufacturing capabilities.

Material preferences within the market show yttria-stabilized zirconia (YSZ) dominating with approximately 70% market share due to its established performance profile and cost-effectiveness. However, newer compositions including gadolinium zirconate and lanthanum zirconate are gaining traction in ultra-high-temperature applications, growing at 15% annually from a smaller base.

Customer demand is increasingly focused on coatings that can withstand temperatures exceeding 1300°C while maintaining longer service intervals. This requirement is driving premium pricing for advanced formulations, with customers willing to pay 30-40% more for coatings that can extend component life by at least 25%.

The competitive landscape features both specialized coating service providers and integrated manufacturers who offer coating as part of their component manufacturing process. This dual market structure creates varied pricing models and service offerings, with specialized providers focusing on customization and integrated manufacturers emphasizing turnkey solutions.

Future market expansion will likely be influenced by developments in additive manufacturing, which may enable more complex coating architectures and gradient compositions that were previously unachievable with conventional thermal spray processes.

Current TBC Technologies and Challenges

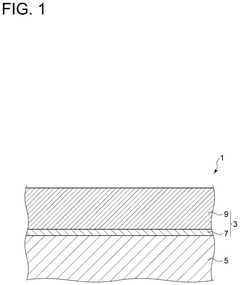

Thermal Barrier Coatings (TBCs) represent a critical technology in high-temperature applications, particularly in gas turbine engines for aerospace and power generation. Current TBC systems typically consist of a ceramic top coat, predominantly yttria-stabilized zirconia (YSZ), and a metallic bond coat, usually MCrAlY (where M represents Ni, Co, or a combination). These coatings are applied through two primary methods: Atmospheric Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD).

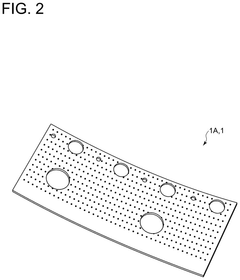

APS technology produces coatings with characteristic splat microstructures and inter-splat boundaries, resulting in lower thermal conductivity but reduced strain tolerance. The process involves injecting ceramic powder into a high-temperature plasma jet, where particles melt and accelerate toward the substrate, forming a layered structure upon impact. This method is cost-effective and suitable for large components but faces challenges in coating complex geometries.

EB-PVD, conversely, creates columnar microstructures with superior strain tolerance and erosion resistance, albeit with higher thermal conductivity. The process vaporizes ceramic material using an electron beam, with vapor condensing on the substrate to form the columnar structure. While offering excellent coating quality, EB-PVD requires sophisticated vacuum equipment and has lower deposition rates, resulting in higher production costs.

A significant challenge in current TBC technologies is balancing thermal insulation with mechanical durability. YSZ, the industry standard ceramic material, has temperature limitations around 1200°C due to phase destabilization and sintering effects at higher temperatures. This constraint has prompted research into alternative ceramics such as gadolinium zirconate and lanthanum zirconate, which offer improved phase stability but often compromise other properties.

Bond coat oxidation represents another critical challenge, as the formation of thermally grown oxide (TGO) at the interface between the ceramic top coat and metallic bond coat can lead to spallation failure. Controlling TGO growth rate and adhesion remains a significant research focus in the industry.

Manufacturing consistency presents persistent difficulties, with variations in spray parameters, powder characteristics, and environmental conditions affecting coating quality. These variations can lead to unpredictable service life and performance inconsistencies across components.

Emerging challenges include developing TBCs capable of withstanding higher operating temperatures (>1300°C) to improve engine efficiency, addressing CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration issues in dusty environments, and developing non-destructive evaluation techniques for in-service coating condition monitoring. Additionally, environmental regulations are driving research toward more sustainable manufacturing processes with reduced waste and energy consumption.

APS technology produces coatings with characteristic splat microstructures and inter-splat boundaries, resulting in lower thermal conductivity but reduced strain tolerance. The process involves injecting ceramic powder into a high-temperature plasma jet, where particles melt and accelerate toward the substrate, forming a layered structure upon impact. This method is cost-effective and suitable for large components but faces challenges in coating complex geometries.

EB-PVD, conversely, creates columnar microstructures with superior strain tolerance and erosion resistance, albeit with higher thermal conductivity. The process vaporizes ceramic material using an electron beam, with vapor condensing on the substrate to form the columnar structure. While offering excellent coating quality, EB-PVD requires sophisticated vacuum equipment and has lower deposition rates, resulting in higher production costs.

A significant challenge in current TBC technologies is balancing thermal insulation with mechanical durability. YSZ, the industry standard ceramic material, has temperature limitations around 1200°C due to phase destabilization and sintering effects at higher temperatures. This constraint has prompted research into alternative ceramics such as gadolinium zirconate and lanthanum zirconate, which offer improved phase stability but often compromise other properties.

Bond coat oxidation represents another critical challenge, as the formation of thermally grown oxide (TGO) at the interface between the ceramic top coat and metallic bond coat can lead to spallation failure. Controlling TGO growth rate and adhesion remains a significant research focus in the industry.

Manufacturing consistency presents persistent difficulties, with variations in spray parameters, powder characteristics, and environmental conditions affecting coating quality. These variations can lead to unpredictable service life and performance inconsistencies across components.

Emerging challenges include developing TBCs capable of withstanding higher operating temperatures (>1300°C) to improve engine efficiency, addressing CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration issues in dusty environments, and developing non-destructive evaluation techniques for in-service coating condition monitoring. Additionally, environmental regulations are driving research toward more sustainable manufacturing processes with reduced waste and energy consumption.

State-of-the-Art Ceramic Thermal Spray Techniques

01 Ceramic-based thermal barrier coatings

Ceramic materials are widely used in thermal barrier coatings due to their excellent heat resistance and insulating properties. These coatings typically consist of yttria-stabilized zirconia (YSZ) or other ceramic compositions that provide effective thermal protection for underlying substrates. The ceramic layers are designed with specific microstructures to minimize thermal conductivity while maintaining structural integrity at high temperatures, making them ideal for applications in gas turbines, aerospace components, and other high-temperature environments.- Ceramic-based thermal barrier coatings: Ceramic materials are widely used in thermal barrier coatings due to their excellent heat resistance and insulating properties. These coatings typically consist of yttria-stabilized zirconia (YSZ) or other ceramic compositions that provide effective thermal protection for underlying substrates. The ceramic layers can be applied through various deposition techniques to achieve optimal thickness and microstructure for maximum thermal protection while maintaining durability under extreme temperature conditions.

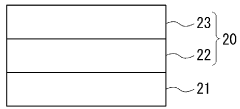

- Multi-layer coating systems for enhanced thermal protection: Multi-layer thermal barrier coating systems incorporate different functional layers to provide comprehensive thermal protection. These systems typically include a bond coat for adhesion, a thermally grown oxide layer for oxidation resistance, and a ceramic top coat for thermal insulation. The combination of these layers creates a synergistic effect that enhances overall thermal protection while addressing issues such as thermal expansion mismatch and mechanical stress. Advanced multi-layer systems may also include gradient or composite layers to further optimize performance.

- Novel materials and compositions for improved thermal barrier performance: Research into novel materials and compositions has led to significant advancements in thermal barrier coating technology. These innovations include rare earth zirconates, pyrochlore structures, and composite materials that offer superior thermal resistance compared to conventional coatings. Some novel compositions incorporate phase-change materials or nanostructured elements that provide enhanced thermal protection through additional energy absorption mechanisms. These advanced materials can withstand higher temperatures and provide better insulation properties for critical components in extreme environments.

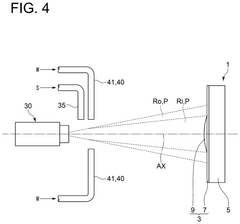

- Deposition techniques for thermal barrier coatings: Various deposition techniques are employed to apply thermal barrier coatings, each offering specific advantages for thermal protection applications. These methods include electron beam physical vapor deposition (EB-PVD), plasma spraying, chemical vapor deposition (CVD), and solution precursor techniques. The choice of deposition method significantly influences the microstructure, porosity, and adhesion of the coating, which in turn affects its thermal insulation properties and durability. Advanced deposition techniques can create columnar structures or controlled porosity that enhance thermal protection while maintaining mechanical integrity.

- Testing and performance evaluation of thermal barrier coatings: Rigorous testing and performance evaluation methods are essential for developing effective thermal barrier coatings. These include thermal cycling tests, erosion resistance measurements, thermal conductivity assessments, and high-temperature oxidation studies. Advanced techniques such as thermal imaging, non-destructive evaluation, and accelerated aging tests help predict the long-term performance and failure mechanisms of thermal barrier coatings. These evaluation methods ensure that coatings provide reliable thermal protection under the extreme conditions encountered in applications such as gas turbines, aerospace components, and industrial equipment.

02 Multi-layer thermal barrier coating systems

Multi-layer thermal barrier coating systems incorporate different functional layers to enhance thermal protection performance. These systems typically include a bond coat that improves adhesion to the substrate, a thermally grown oxide layer that provides oxidation resistance, and a top ceramic layer that provides thermal insulation. This layered approach allows for optimization of different properties such as thermal resistance, mechanical strength, and durability, resulting in superior thermal protection for components exposed to extreme temperature conditions.Expand Specific Solutions03 Advanced deposition techniques for thermal barrier coatings

Various deposition techniques are employed to create high-performance thermal barrier coatings with controlled microstructures and compositions. These methods include electron beam physical vapor deposition (EB-PVD), plasma spraying, chemical vapor deposition (CVD), and solution precursor plasma spray. Each technique offers specific advantages in terms of coating density, columnar structure, porosity control, and adhesion strength, allowing for customization of thermal barrier properties based on specific application requirements and operating conditions.Expand Specific Solutions04 Novel material compositions for enhanced thermal protection

Research has led to the development of novel material compositions that offer improved thermal protection compared to conventional thermal barrier coatings. These include rare earth zirconates, hafnates, pyrochlore structures, and composite materials with engineered thermal properties. The incorporation of dopants, nanoparticles, and phase-stabilizing elements enhances the high-temperature stability, reduces thermal conductivity, and improves resistance to sintering and phase transformations, resulting in coatings with superior thermal protection capabilities for extreme environment applications.Expand Specific Solutions05 Testing and performance evaluation methods for thermal barrier coatings

Specialized testing methods are essential for evaluating the performance and durability of thermal barrier coatings under simulated service conditions. These include thermal cycling tests, thermal shock resistance measurements, erosion testing, and high-temperature oxidation studies. Advanced characterization techniques such as thermal imaging, non-destructive evaluation, and microstructural analysis are employed to assess coating integrity, failure mechanisms, and thermal protection efficiency. These testing protocols help in optimizing coating designs and predicting service life in real-world applications.Expand Specific Solutions

Leading Companies in Thermal Barrier Coating Industry

The thermal barrier coatings (TBC) market via ceramic thermal spray processes is in a growth phase, driven by increasing demand in aerospace, power generation, and automotive sectors. The market is projected to expand significantly due to rising needs for high-temperature protection in gas turbines and engines. Leading players include established aerospace and industrial giants like General Electric, Siemens AG, RTX Corp., and Mitsubishi Heavy Industries, alongside specialized coating technology providers such as Oerlikon Metco and Praxair S.T. Technology. Academic institutions like Beihang University and research centers like Japan Fine Ceramics Center contribute to technological advancement. The technology shows moderate maturity with ongoing innovation focused on improving coating durability, thermal resistance, and application efficiency for next-generation turbine systems.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair S.T. Technology has developed sophisticated thermal barrier coating systems utilizing their proprietary HVOF (High Velocity Oxygen Fuel) and APS (Air Plasma Spray) technologies. Their approach centers on engineered ceramic powders with specific particle morphologies and size distributions (typically 10-45 μm) to optimize deposition efficiency and coating microstructure. Praxair's TBC systems feature yttria-stabilized zirconia (YSZ) with 7-8 wt% Y2O3 as the primary ceramic material, applied via their patented SG-100 plasma spray guns operating at optimized parameters (40-60 kW power, 40-50 slpm primary gas flow). Their process creates coatings with controlled porosity (15-25%) and segmentation crack networks that enhance strain tolerance while maintaining low thermal conductivity (0.8-1.2 W/m·K). Praxair has pioneered the development of vertically cracked TBCs through their DVC (Dense Vertically Cracked) process, which introduces controlled segmentation cracks to improve thermal cycling durability. Their bond coat technology utilizes MCrAlY compositions (where M represents Ni, Co, or a combination) with precisely controlled aluminum content (8-12 wt%) to optimize oxidation resistance and coating adhesion[4][6].

Strengths: Superior powder manufacturing capabilities ensuring consistent coating quality; advanced process control systems for reproducible coating properties; extensive material portfolio with customizable solutions. Weaknesses: Higher production costs compared to conventional ceramic coating methods; potential for increased thermal conductivity after prolonged high-temperature exposure; limited thickness capabilities compared to some competing technologies.

General Electric Company

Technical Solution: General Electric has developed advanced Thermal Barrier Coating (TBC) systems using Electron Beam Physical Vapor Deposition (EB-PVD) and Air Plasma Spray (APS) processes. Their proprietary DVC (Dense Vertically Cracked) TBC system utilizes yttria-stabilized zirconia (YSZ) with 7-8 wt% Y2O3 as the primary ceramic material. GE's approach incorporates a MCrAlY bond coat (where M represents Ni, Co, or a combination) applied via High Velocity Oxygen Fuel (HVOF) spraying to enhance adhesion and oxidation resistance. Their TBC systems feature controlled microstructure with columnar grains in EB-PVD coatings and engineered porosity in APS coatings to optimize strain tolerance and thermal conductivity. GE has also pioneered multi-layer TBC systems with gradient compositions to manage thermal expansion mismatch and enhance durability in extreme temperature environments exceeding 1200°C. Recent innovations include rare-earth doped zirconia compositions that demonstrate improved phase stability and sintering resistance during thermal cycling[1][3].

Strengths: Superior thermal cycling durability due to engineered microstructures; excellent strain tolerance from columnar structures in EB-PVD coatings; industry-leading bond coat technology for enhanced adhesion. Weaknesses: Higher production costs associated with EB-PVD process; thickness limitations compared to some competing technologies; potential for increased thermal conductivity after extended high-temperature exposure.

Critical Patents in TBC Spray Technology

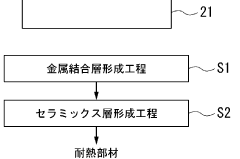

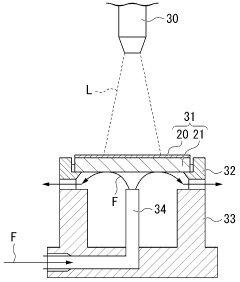

Method for applying thermal barrier coating and heat-resistant member

PatentPendingUS20250092502A1

Innovation

- A method involving thermal spraying of a ceramic powder suspension with atmospheric pressure plasma spraying, where water is used to cool the plasma flame at a rate of 25-100 ml/min, forming a top coat layer on a bond coat layer over a heat-resistant alloy base material.

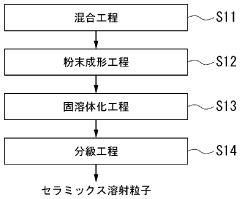

Ceramic thermal spray particles and method for forming thermal barrier coating layer

PatentWO2023248784A1

Innovation

- The method involves forming ceramic spray particles composed of ZrO2 and Yb2O3 with a standard deviation of 2% to 7% by mass, which are then used to create a thermal barrier coating layer with a metal bonding layer, achieving low thermal conductivity and enhanced thermal cycle durability through specific manufacturing processes like plasma spraying.

Material Science Advancements for TBCs

Recent advancements in material science have significantly enhanced the performance and durability of Thermal Barrier Coatings (TBCs). The evolution of ceramic materials for TBCs has moved beyond traditional yttria-stabilized zirconia (YSZ) to incorporate more complex compositions with superior thermal and mechanical properties. These next-generation materials include gadolinium zirconate, lanthanum zirconate, and other rare-earth element-doped ceramics that demonstrate lower thermal conductivity and better phase stability at elevated temperatures.

Nanostructured ceramics represent another breakthrough, offering unprecedented control over coating microstructure. By manipulating grain size and distribution at the nanoscale, researchers have developed TBCs with enhanced strain tolerance and reduced thermal conductivity. These nanostructured coatings often exhibit columnar microstructures that accommodate thermal expansion mismatch between the coating and substrate, thereby extending service life in extreme thermal cycling environments.

Multilayer and functionally graded TBCs have emerged as sophisticated solutions to address the limitations of single-layer coatings. These systems feature compositional and microstructural gradients that optimize performance across the coating thickness. The gradual transition in properties minimizes stress concentrations at interfaces, reducing the risk of delamination and spallation during thermal cycling.

Advanced characterization techniques have been instrumental in understanding the fundamental mechanisms governing TBC performance. High-resolution electron microscopy, synchrotron X-ray diffraction, and neutron scattering methods now allow researchers to observe microstructural evolution and phase transformations in real-time under operating conditions. This insight has led to the development of predictive models for coating degradation and failure.

Computational materials science has accelerated the discovery and optimization of new TBC materials. Machine learning algorithms combined with high-throughput experimental methods enable rapid screening of thousands of potential ceramic compositions. These approaches have identified promising candidates with previously unexplored combinations of elements that exhibit exceptional thermal stability and resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration.

Self-healing TBCs represent the frontier of material science innovation in this field. These smart coatings incorporate phases that can flow and seal cracks at high temperatures, extending coating lifetime. Preliminary studies have demonstrated the feasibility of incorporating metastable phases that undergo controlled phase transformations upon damage, releasing material that fills voids and restores coating integrity without external intervention.

Nanostructured ceramics represent another breakthrough, offering unprecedented control over coating microstructure. By manipulating grain size and distribution at the nanoscale, researchers have developed TBCs with enhanced strain tolerance and reduced thermal conductivity. These nanostructured coatings often exhibit columnar microstructures that accommodate thermal expansion mismatch between the coating and substrate, thereby extending service life in extreme thermal cycling environments.

Multilayer and functionally graded TBCs have emerged as sophisticated solutions to address the limitations of single-layer coatings. These systems feature compositional and microstructural gradients that optimize performance across the coating thickness. The gradual transition in properties minimizes stress concentrations at interfaces, reducing the risk of delamination and spallation during thermal cycling.

Advanced characterization techniques have been instrumental in understanding the fundamental mechanisms governing TBC performance. High-resolution electron microscopy, synchrotron X-ray diffraction, and neutron scattering methods now allow researchers to observe microstructural evolution and phase transformations in real-time under operating conditions. This insight has led to the development of predictive models for coating degradation and failure.

Computational materials science has accelerated the discovery and optimization of new TBC materials. Machine learning algorithms combined with high-throughput experimental methods enable rapid screening of thousands of potential ceramic compositions. These approaches have identified promising candidates with previously unexplored combinations of elements that exhibit exceptional thermal stability and resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration.

Self-healing TBCs represent the frontier of material science innovation in this field. These smart coatings incorporate phases that can flow and seal cracks at high temperatures, extending coating lifetime. Preliminary studies have demonstrated the feasibility of incorporating metastable phases that undergo controlled phase transformations upon damage, releasing material that fills voids and restores coating integrity without external intervention.

Environmental Impact and Sustainability Considerations

The environmental impact of Thermal Barrier Coatings (TBCs) applied via ceramic thermal spray processes extends throughout their lifecycle, from raw material extraction to end-of-life disposal. Traditional ceramic thermal spray operations consume significant energy, with plasma spray processes requiring temperatures exceeding 10,000°C, contributing substantially to carbon emissions. Additionally, the production of ceramic materials like yttria-stabilized zirconia (YSZ) involves energy-intensive mining and processing operations that generate considerable environmental footprints.

Particulate emissions represent another critical environmental concern. During thermal spray application, fine ceramic particles and metal oxides are released into the atmosphere, potentially causing air quality degradation and respiratory health risks for workers and surrounding communities. These emissions necessitate sophisticated filtration systems and proper ventilation infrastructure, adding to operational complexity and costs.

Water usage and contamination issues arise from cooling systems and post-processing operations. The quenching and cleaning processes employed after coating application can introduce ceramic particles and chemical contaminants into wastewater streams, requiring treatment before discharge to prevent ecological damage to aquatic ecosystems.

Recent sustainability advancements in TBC technology show promising developments. Manufacturers are increasingly adopting closed-loop water systems that recycle process water, significantly reducing consumption and contamination risks. Energy efficiency improvements through equipment optimization and process refinement have reduced the carbon footprint of thermal spray operations by up to 30% in advanced facilities.

Material innovation represents a frontier for sustainability enhancement in TBCs. Research into bio-derived ceramics and environmentally benign stabilizers aims to reduce dependence on rare earth elements and environmentally problematic mining operations. Additionally, coating formulations designed for longer service life directly contribute to sustainability by reducing replacement frequency and associated resource consumption.

End-of-life considerations for TBC components have historically been neglected, with coated parts typically landfilled after service. Emerging recycling technologies now enable the recovery of valuable substrate metals while separating ceramic coating materials for potential reuse or proper disposal, closing the material loop and aligning with circular economy principles.

Regulatory frameworks worldwide are increasingly imposing stricter environmental standards on thermal spray operations, driving industry innovation toward cleaner production methods. Companies adopting proactive environmental management strategies for their TBC operations not only ensure compliance but often realize cost savings through improved resource efficiency and waste reduction.

Particulate emissions represent another critical environmental concern. During thermal spray application, fine ceramic particles and metal oxides are released into the atmosphere, potentially causing air quality degradation and respiratory health risks for workers and surrounding communities. These emissions necessitate sophisticated filtration systems and proper ventilation infrastructure, adding to operational complexity and costs.

Water usage and contamination issues arise from cooling systems and post-processing operations. The quenching and cleaning processes employed after coating application can introduce ceramic particles and chemical contaminants into wastewater streams, requiring treatment before discharge to prevent ecological damage to aquatic ecosystems.

Recent sustainability advancements in TBC technology show promising developments. Manufacturers are increasingly adopting closed-loop water systems that recycle process water, significantly reducing consumption and contamination risks. Energy efficiency improvements through equipment optimization and process refinement have reduced the carbon footprint of thermal spray operations by up to 30% in advanced facilities.

Material innovation represents a frontier for sustainability enhancement in TBCs. Research into bio-derived ceramics and environmentally benign stabilizers aims to reduce dependence on rare earth elements and environmentally problematic mining operations. Additionally, coating formulations designed for longer service life directly contribute to sustainability by reducing replacement frequency and associated resource consumption.

End-of-life considerations for TBC components have historically been neglected, with coated parts typically landfilled after service. Emerging recycling technologies now enable the recovery of valuable substrate metals while separating ceramic coating materials for potential reuse or proper disposal, closing the material loop and aligning with circular economy principles.

Regulatory frameworks worldwide are increasingly imposing stricter environmental standards on thermal spray operations, driving industry innovation toward cleaner production methods. Companies adopting proactive environmental management strategies for their TBC operations not only ensure compliance but often realize cost savings through improved resource efficiency and waste reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!