Advanced Casting Processes for Nitinol Components

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Casting Evolution

The evolution of Nitinol casting processes has been a journey of continuous innovation and refinement since the discovery of this unique shape memory alloy in the 1960s. Initially, Nitinol components were primarily produced through conventional methods such as melting and casting, followed by extensive hot and cold working. These early techniques often resulted in inconsistent material properties and limited shape complexity.

As the demand for Nitinol components grew, particularly in the medical device industry, researchers and manufacturers began exploring more advanced casting processes. The 1980s saw the introduction of vacuum induction melting (VIM), which significantly improved the purity and homogeneity of Nitinol castings. This technique allowed for better control over the alloy composition and reduced the presence of impurities that could affect the material's performance.

In the 1990s, the development of vacuum arc remelting (VAR) further enhanced the quality of Nitinol castings. VAR, often used in combination with VIM, helped to refine the microstructure and reduce the occurrence of inclusions and segregation. This dual melting process became a standard in the industry for producing high-quality Nitinol ingots.

The turn of the millennium brought about significant advancements in precision casting techniques for Nitinol. Investment casting, also known as lost-wax casting, was adapted for Nitinol production, enabling the creation of complex geometries with improved dimensional accuracy. This process proved particularly valuable for manufacturing intricate medical devices and aerospace components.

Concurrent with these developments, powder metallurgy techniques began to gain traction in Nitinol processing. Hot isostatic pressing (HIP) of Nitinol powders emerged as a promising method for producing near-net-shape components with excellent mechanical properties. This approach offered advantages in terms of material utilization and the ability to create porous structures, which are beneficial for certain biomedical applications.

Recent years have seen the integration of additive manufacturing technologies into Nitinol production. Selective laser melting (SLM) and electron beam melting (EBM) have opened up new possibilities for creating custom, complex Nitinol structures with unprecedented design freedom. These 3D printing techniques are particularly promising for patient-specific medical implants and high-performance aerospace components.

The latest frontier in Nitinol casting evolution involves the development of advanced simulation and modeling tools. Computational fluid dynamics (CFD) and finite element analysis (FEA) are now routinely employed to optimize casting parameters and predict material behavior. These digital tools have significantly reduced the time and cost associated with process development and have led to improvements in casting quality and consistency.

As the demand for Nitinol components grew, particularly in the medical device industry, researchers and manufacturers began exploring more advanced casting processes. The 1980s saw the introduction of vacuum induction melting (VIM), which significantly improved the purity and homogeneity of Nitinol castings. This technique allowed for better control over the alloy composition and reduced the presence of impurities that could affect the material's performance.

In the 1990s, the development of vacuum arc remelting (VAR) further enhanced the quality of Nitinol castings. VAR, often used in combination with VIM, helped to refine the microstructure and reduce the occurrence of inclusions and segregation. This dual melting process became a standard in the industry for producing high-quality Nitinol ingots.

The turn of the millennium brought about significant advancements in precision casting techniques for Nitinol. Investment casting, also known as lost-wax casting, was adapted for Nitinol production, enabling the creation of complex geometries with improved dimensional accuracy. This process proved particularly valuable for manufacturing intricate medical devices and aerospace components.

Concurrent with these developments, powder metallurgy techniques began to gain traction in Nitinol processing. Hot isostatic pressing (HIP) of Nitinol powders emerged as a promising method for producing near-net-shape components with excellent mechanical properties. This approach offered advantages in terms of material utilization and the ability to create porous structures, which are beneficial for certain biomedical applications.

Recent years have seen the integration of additive manufacturing technologies into Nitinol production. Selective laser melting (SLM) and electron beam melting (EBM) have opened up new possibilities for creating custom, complex Nitinol structures with unprecedented design freedom. These 3D printing techniques are particularly promising for patient-specific medical implants and high-performance aerospace components.

The latest frontier in Nitinol casting evolution involves the development of advanced simulation and modeling tools. Computational fluid dynamics (CFD) and finite element analysis (FEA) are now routinely employed to optimize casting parameters and predict material behavior. These digital tools have significantly reduced the time and cost associated with process development and have led to improvements in casting quality and consistency.

Market Demand Analysis

The market demand for advanced casting processes for Nitinol components has been experiencing significant growth in recent years, driven by the unique properties of Nitinol and its expanding applications across various industries. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic characteristics, has found increasing use in medical devices, aerospace, automotive, and consumer electronics sectors.

In the medical device industry, Nitinol components are widely used in minimally invasive surgical instruments, stents, orthodontic wires, and implants. The global medical Nitinol market is projected to grow at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of cardiovascular diseases and the increasing adoption of minimally invasive surgical procedures.

The aerospace sector has also shown a growing interest in Nitinol components due to their lightweight nature and ability to withstand extreme temperatures. Advanced casting processes for Nitinol are being explored for applications in aircraft actuators, vibration damping systems, and morphing structures. The aerospace Nitinol market is expected to witness steady growth, with a CAGR of approximately 6% over the next five years.

In the automotive industry, Nitinol components are gaining traction for use in adaptive headlights, self-repairing body panels, and engine components. The automotive Nitinol market is anticipated to grow at a CAGR of around 7% from 2021 to 2026, driven by the increasing demand for fuel-efficient and technologically advanced vehicles.

The consumer electronics sector is also contributing to the demand for advanced Nitinol casting processes. Nitinol is being used in smartphone antennas, laptop hinges, and wearable devices. The consumer electronics Nitinol market is expected to grow at a CAGR of over 9% in the coming years, fueled by the rapid advancements in smart devices and wearable technology.

Despite the positive market outlook, challenges remain in the widespread adoption of advanced casting processes for Nitinol components. The high cost of raw materials and complex manufacturing processes are significant barriers to market growth. Additionally, the need for specialized equipment and expertise in Nitinol casting limits the number of manufacturers capable of producing high-quality components.

To address these challenges and meet the growing market demand, there is a strong focus on research and development to improve casting techniques, reduce production costs, and enhance the overall quality of Nitinol components. Innovations in powder metallurgy, additive manufacturing, and precision casting are expected to drive the market forward and open up new applications for Nitinol across various industries.

In the medical device industry, Nitinol components are widely used in minimally invasive surgical instruments, stents, orthodontic wires, and implants. The global medical Nitinol market is projected to grow at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of cardiovascular diseases and the increasing adoption of minimally invasive surgical procedures.

The aerospace sector has also shown a growing interest in Nitinol components due to their lightweight nature and ability to withstand extreme temperatures. Advanced casting processes for Nitinol are being explored for applications in aircraft actuators, vibration damping systems, and morphing structures. The aerospace Nitinol market is expected to witness steady growth, with a CAGR of approximately 6% over the next five years.

In the automotive industry, Nitinol components are gaining traction for use in adaptive headlights, self-repairing body panels, and engine components. The automotive Nitinol market is anticipated to grow at a CAGR of around 7% from 2021 to 2026, driven by the increasing demand for fuel-efficient and technologically advanced vehicles.

The consumer electronics sector is also contributing to the demand for advanced Nitinol casting processes. Nitinol is being used in smartphone antennas, laptop hinges, and wearable devices. The consumer electronics Nitinol market is expected to grow at a CAGR of over 9% in the coming years, fueled by the rapid advancements in smart devices and wearable technology.

Despite the positive market outlook, challenges remain in the widespread adoption of advanced casting processes for Nitinol components. The high cost of raw materials and complex manufacturing processes are significant barriers to market growth. Additionally, the need for specialized equipment and expertise in Nitinol casting limits the number of manufacturers capable of producing high-quality components.

To address these challenges and meet the growing market demand, there is a strong focus on research and development to improve casting techniques, reduce production costs, and enhance the overall quality of Nitinol components. Innovations in powder metallurgy, additive manufacturing, and precision casting are expected to drive the market forward and open up new applications for Nitinol across various industries.

Technical Challenges

The development of advanced casting processes for Nitinol components faces several significant technical challenges. These challenges stem from the unique properties of Nitinol and the complex requirements for producing high-quality, precision components.

One of the primary challenges is controlling the composition and microstructure of Nitinol during the casting process. Nitinol's properties are highly sensitive to slight variations in composition, particularly the ratio of nickel to titanium. Achieving and maintaining the precise stoichiometric composition throughout the casting process is crucial for ensuring consistent shape memory and superelastic properties in the final component.

The high reactivity of molten Nitinol presents another significant hurdle. When exposed to oxygen or other atmospheric gases, Nitinol readily forms oxides and other unwanted compounds. This necessitates the use of specialized vacuum or inert atmosphere casting techniques, which add complexity and cost to the manufacturing process.

Controlling the cooling rate during solidification is also critical. The transformation temperatures and mechanical properties of Nitinol are strongly influenced by its thermal history. Achieving uniform cooling rates throughout the cast component, especially for complex geometries, is technically challenging but essential for consistent performance.

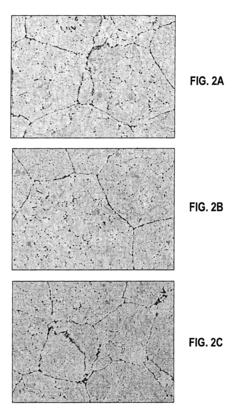

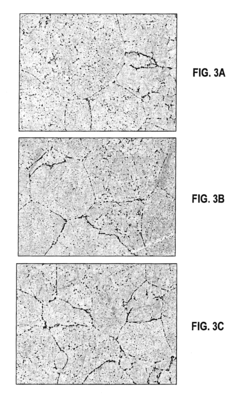

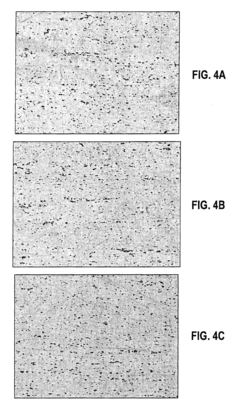

Porosity and inclusions are common defects in cast Nitinol components. These can significantly impact the mechanical properties and fatigue life of the final product. Developing casting techniques that minimize these defects while maintaining the desired microstructure is an ongoing challenge in the field.

The high melting point of Nitinol (around 1300°C) poses additional difficulties. It requires specialized high-temperature casting equipment and mold materials that can withstand these extreme conditions without contaminating the alloy or compromising the mold integrity.

Post-casting processing presents its own set of challenges. Heat treatment is often necessary to optimize the shape memory and superelastic properties of Nitinol components. However, the precise control of temperature and time required for these treatments can be difficult to achieve consistently, especially for complex or large components.

Machining and finishing of cast Nitinol components are also problematic due to the material's high work hardening rate and tendency to form a hard oxide layer. This necessitates the development of specialized cutting tools and techniques, adding to the overall complexity and cost of component production.

Lastly, the development of non-destructive testing methods for cast Nitinol components remains a challenge. Conventional techniques may not be suitable for detecting all relevant defects or variations in composition and microstructure that can affect the performance of Nitinol components.

One of the primary challenges is controlling the composition and microstructure of Nitinol during the casting process. Nitinol's properties are highly sensitive to slight variations in composition, particularly the ratio of nickel to titanium. Achieving and maintaining the precise stoichiometric composition throughout the casting process is crucial for ensuring consistent shape memory and superelastic properties in the final component.

The high reactivity of molten Nitinol presents another significant hurdle. When exposed to oxygen or other atmospheric gases, Nitinol readily forms oxides and other unwanted compounds. This necessitates the use of specialized vacuum or inert atmosphere casting techniques, which add complexity and cost to the manufacturing process.

Controlling the cooling rate during solidification is also critical. The transformation temperatures and mechanical properties of Nitinol are strongly influenced by its thermal history. Achieving uniform cooling rates throughout the cast component, especially for complex geometries, is technically challenging but essential for consistent performance.

Porosity and inclusions are common defects in cast Nitinol components. These can significantly impact the mechanical properties and fatigue life of the final product. Developing casting techniques that minimize these defects while maintaining the desired microstructure is an ongoing challenge in the field.

The high melting point of Nitinol (around 1300°C) poses additional difficulties. It requires specialized high-temperature casting equipment and mold materials that can withstand these extreme conditions without contaminating the alloy or compromising the mold integrity.

Post-casting processing presents its own set of challenges. Heat treatment is often necessary to optimize the shape memory and superelastic properties of Nitinol components. However, the precise control of temperature and time required for these treatments can be difficult to achieve consistently, especially for complex or large components.

Machining and finishing of cast Nitinol components are also problematic due to the material's high work hardening rate and tendency to form a hard oxide layer. This necessitates the development of specialized cutting tools and techniques, adding to the overall complexity and cost of component production.

Lastly, the development of non-destructive testing methods for cast Nitinol components remains a challenge. Conventional techniques may not be suitable for detecting all relevant defects or variations in composition and microstructure that can affect the performance of Nitinol components.

Current Casting Methods

01 Shape memory properties of Nitinol

Nitinol, a nickel-titanium alloy, exhibits unique shape memory and superelastic properties. These characteristics allow Nitinol components to return to their original shape after deformation when heated or to undergo large deformations without permanent damage. This makes Nitinol ideal for various applications in medical devices, aerospace, and automotive industries.- Shape memory properties of Nitinol: Nitinol, a nickel-titanium alloy, exhibits unique shape memory and superelastic properties. These characteristics allow Nitinol components to return to their original shape after deformation when heated or to undergo large deformations without permanent damage. This makes Nitinol ideal for various applications in medical devices, aerospace, and automotive industries.

- Medical applications of Nitinol components: Nitinol is widely used in medical devices due to its biocompatibility and unique properties. Applications include stents, guidewires, orthodontic archwires, and surgical instruments. The shape memory effect allows for minimally invasive procedures, as devices can be inserted in a compact form and then expand to their functional shape when deployed in the body.

- Manufacturing processes for Nitinol components: Various manufacturing processes are employed to produce Nitinol components, including melting, casting, hot working, cold working, and heat treatment. These processes are crucial in achieving the desired shape memory and superelastic properties. Advanced techniques such as laser cutting and additive manufacturing are also used to create complex Nitinol structures.

- Actuators and sensors using Nitinol: Nitinol's shape memory effect makes it suitable for use in actuators and sensors. These components can be designed to respond to temperature changes or electrical stimuli, enabling applications in robotics, automotive systems, and smart materials. Nitinol-based actuators offer advantages such as high power-to-weight ratio and silent operation.

- Surface treatment and coating of Nitinol components: Surface treatment and coating techniques are applied to Nitinol components to enhance their properties and performance. These processes can improve corrosion resistance, biocompatibility, and wear resistance. Methods include electropolishing, passivation, and the application of various coatings such as titanium nitride or diamond-like carbon.

02 Medical applications of Nitinol components

Nitinol is widely used in medical devices due to its biocompatibility and unique properties. Applications include stents, guidewires, orthodontic archwires, and surgical instruments. The shape memory effect allows for minimally invasive procedures, as devices can be inserted in a compact form and then expand to their functional shape when reaching body temperature.Expand Specific Solutions03 Manufacturing and processing of Nitinol components

The production of Nitinol components involves specialized manufacturing processes due to the material's unique properties. These processes may include precision machining, heat treatment, and surface finishing techniques. Advanced manufacturing methods are employed to ensure the desired shape memory and superelastic characteristics are achieved in the final components.Expand Specific Solutions04 Nitinol in mechanical systems and actuators

Nitinol components are utilized in various mechanical systems and actuators due to their ability to generate significant force and displacement when transitioning between martensite and austenite phases. This property makes Nitinol suitable for applications such as thermal actuators, vibration damping systems, and adaptive structures in aerospace and automotive industries.Expand Specific Solutions05 Surface treatment and coating of Nitinol components

Surface treatment and coating techniques are applied to Nitinol components to enhance their performance, biocompatibility, and corrosion resistance. These processes may include electropolishing, passivation, and the application of specialized coatings. Such treatments are crucial for improving the longevity and functionality of Nitinol components, particularly in medical and industrial applications.Expand Specific Solutions

Key Industry Players

The advanced casting processes for Nitinol components market is in a growth phase, driven by increasing demand in medical devices and aerospace applications. The global market size is estimated to reach several hundred million dollars by 2025, with a compound annual growth rate of around 8-10%. The technology maturity varies across different casting techniques, with some established methods and others still in development. Key players like Northwest Nonferrous Metal Research Institute, Naval Research Laboratory, and MTU Aero Engines AG are investing in R&D to improve process efficiency and material properties. Universities such as the University of Science & Technology Beijing and Nankai University are contributing to fundamental research, while companies like Xian Saite Simai Titanium Industry Co., Ltd. and IHI Corp. are focusing on commercial applications and scaling up production capabilities.

Northwest Nonferrous Metal Research Institute

Technical Solution: The Northwest Nonferrous Metal Research Institute has developed a novel casting process for Nitinol components that combines elements of powder metallurgy with traditional casting techniques. Their method involves creating a semi-solid slurry of Nitinol powder mixed with a binder, which is then injected into precision molds under high pressure[7]. This approach allows for the production of near-net-shape components with complex geometries. The institute has also developed a specialized sintering process that removes the binder and consolidates the Nitinol particles, resulting in a dense, homogeneous structure. Their technique includes careful control of the cooling rate to achieve the desired martensitic and austenitic phases in the final product. Additionally, they have implemented post-casting surface treatment methods to enhance the biocompatibility and corrosion resistance of the Nitinol components, particularly for medical applications[8].

Strengths: Ability to produce complex shapes, good control over material composition, enhanced surface properties. Weaknesses: Potential for residual porosity, may require additional post-processing for certain applications.

University of Science & Technology Beijing

Technical Solution: The University of Science & Technology Beijing has developed an innovative casting process for Nitinol components that utilizes electromagnetic levitation melting combined with rapid solidification techniques. This method allows for the production of high-purity Nitinol alloys with fine-grained microstructures[9]. Their process incorporates in-situ alloying, where elemental nickel and titanium are mixed and melted in precise ratios under an inert atmosphere, ensuring homogeneous composition. The university has also developed a unique mold system that allows for directional solidification, enabling the creation of Nitinol components with tailored anisotropic properties. Their technique includes a rapid quenching step that can be adjusted to control the formation of precipitates and optimize the shape memory effect. Additionally, they have implemented advanced characterization methods, including in-situ synchrotron X-ray diffraction, to study the phase transformation behavior during the casting process[10].

Strengths: High-purity alloy production, fine-grained microstructures, ability to create components with anisotropic properties. Weaknesses: Potentially limited to smaller component sizes, may require specialized equipment not readily available for large-scale production.

Innovative Casting Tech

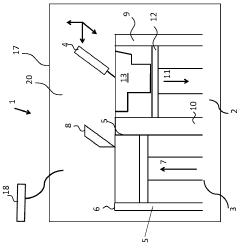

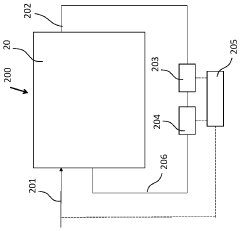

Method of producing components from nickel titanium alloy

PatentWO2023117134A1

Innovation

- A method involving continuous control of oxygen levels in the manufacturing space using dual oxygen sensors and a controller to maintain oxygen concentrations below 20 ppm, ensuring a controlled atmosphere during the additive manufacturing process, particularly in Laser Powder Bed Fusion (L-PBF), to prevent oxide layer formation and maintain the alloy's properties.

Processing of nickel-titanium alloys

PatentActiveUS9440286B2

Innovation

- A process involving melting and atomizing pre-alloyed near-equiatomic nickel-titanium alloys to form powders, which are then consolidated and hot worked, resulting in articles with second phases of less than 10 micrometers in size, thereby improving microstructure and reducing the area fraction of these phases.

Material Properties

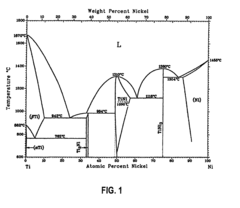

Nitinol, an equiatomic alloy of nickel and titanium, exhibits remarkable properties that make it highly desirable for various applications, particularly in the medical device industry. The unique characteristics of Nitinol stem from its shape memory effect and superelasticity, which are intrinsically linked to its crystalline structure and phase transformations.

At room temperature, Nitinol typically exists in its austenite phase, characterized by a cubic crystal structure. When cooled below a critical temperature, it transforms into the martensite phase, which has a monoclinic crystal structure. This phase transformation is the key to Nitinol's shape memory effect. The material can be deformed in its martensite phase and, upon heating, will return to its original shape as it transforms back to austenite.

The superelastic behavior of Nitinol is observed when the material is stressed at a temperature above its austenite finish temperature. Under stress, the austenite phase transforms into stress-induced martensite, allowing for large reversible strains of up to 8%. This property enables Nitinol components to undergo significant deformation and return to their original shape upon removal of the stress.

The mechanical properties of Nitinol are highly dependent on its composition and processing history. The nickel content can be varied slightly from the equiatomic ratio to adjust the transformation temperatures. Typical values for the austenite start (As) and finish (Af) temperatures range from -20°C to 100°C, depending on the specific alloy composition and processing.

Nitinol exhibits excellent biocompatibility, making it suitable for implantable medical devices. Its corrosion resistance is comparable to that of stainless steel and titanium alloys, primarily due to the formation of a stable titanium oxide layer on its surface. This protective layer also contributes to its biocompatibility by preventing the release of nickel ions into the body.

The thermal and electrical properties of Nitinol are also noteworthy. It has a relatively low thermal conductivity compared to other metallic materials, which can be advantageous in certain applications. The electrical resistivity of Nitinol is higher than that of many other metals and alloys, and it exhibits a significant change in resistivity during phase transformation, which can be utilized in sensing applications.

In terms of fatigue resistance, Nitinol demonstrates excellent performance, particularly in the superelastic regime. This property is crucial for applications involving cyclic loading, such as cardiovascular stents. However, the fatigue behavior of Nitinol is complex and depends on factors such as the applied strain amplitude, mean stress, and environmental conditions.

At room temperature, Nitinol typically exists in its austenite phase, characterized by a cubic crystal structure. When cooled below a critical temperature, it transforms into the martensite phase, which has a monoclinic crystal structure. This phase transformation is the key to Nitinol's shape memory effect. The material can be deformed in its martensite phase and, upon heating, will return to its original shape as it transforms back to austenite.

The superelastic behavior of Nitinol is observed when the material is stressed at a temperature above its austenite finish temperature. Under stress, the austenite phase transforms into stress-induced martensite, allowing for large reversible strains of up to 8%. This property enables Nitinol components to undergo significant deformation and return to their original shape upon removal of the stress.

The mechanical properties of Nitinol are highly dependent on its composition and processing history. The nickel content can be varied slightly from the equiatomic ratio to adjust the transformation temperatures. Typical values for the austenite start (As) and finish (Af) temperatures range from -20°C to 100°C, depending on the specific alloy composition and processing.

Nitinol exhibits excellent biocompatibility, making it suitable for implantable medical devices. Its corrosion resistance is comparable to that of stainless steel and titanium alloys, primarily due to the formation of a stable titanium oxide layer on its surface. This protective layer also contributes to its biocompatibility by preventing the release of nickel ions into the body.

The thermal and electrical properties of Nitinol are also noteworthy. It has a relatively low thermal conductivity compared to other metallic materials, which can be advantageous in certain applications. The electrical resistivity of Nitinol is higher than that of many other metals and alloys, and it exhibits a significant change in resistivity during phase transformation, which can be utilized in sensing applications.

In terms of fatigue resistance, Nitinol demonstrates excellent performance, particularly in the superelastic regime. This property is crucial for applications involving cyclic loading, such as cardiovascular stents. However, the fatigue behavior of Nitinol is complex and depends on factors such as the applied strain amplitude, mean stress, and environmental conditions.

Quality Control Measures

Quality control is paramount in the advanced casting processes for Nitinol components, given the material's unique properties and critical applications in medical devices and aerospace industries. The implementation of robust quality control measures ensures the consistency, reliability, and safety of Nitinol components produced through casting processes.

One of the primary quality control measures involves precise temperature monitoring throughout the casting process. Nitinol's shape memory and superelastic properties are highly dependent on its thermal history, making temperature control crucial. Advanced thermal imaging systems and high-precision thermocouples are employed to maintain and record temperature profiles during melting, pouring, and solidification stages.

Composition control is another critical aspect of quality assurance in Nitinol casting. X-ray fluorescence (XRF) spectroscopy and inductively coupled plasma mass spectrometry (ICP-MS) are utilized to verify the exact nickel-titanium ratio and detect any impurities that could affect the alloy's performance. Strict tolerances are maintained to ensure the desired transformation temperatures and mechanical properties are achieved.

Non-destructive testing (NDT) techniques play a vital role in quality control for Nitinol castings. Ultrasonic testing is employed to detect internal defects, such as voids or inclusions, while X-ray computed tomography (CT) scanning provides detailed 3D imaging of the component's internal structure. These methods allow for comprehensive inspection without compromising the integrity of the cast parts.

Mechanical testing is essential to verify the Nitinol components' performance characteristics. Tensile testing, fatigue testing, and differential scanning calorimetry (DSC) are conducted to assess strength, durability, and phase transformation temperatures. These tests ensure that the cast components meet the required specifications for their intended applications.

Surface quality is a critical factor in Nitinol components, particularly for medical implants. Advanced surface analysis techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are used to evaluate surface topography and detect any irregularities that could affect biocompatibility or performance.

Statistical process control (SPC) methods are implemented to monitor and control variability in the casting process. Key process parameters are continuously tracked, and control charts are utilized to identify trends or deviations that may impact product quality. This proactive approach allows for timely adjustments to maintain consistent output.

Lastly, traceability is ensured through comprehensive documentation and record-keeping. Each batch of Nitinol castings is assigned a unique identifier, allowing for the tracking of raw materials, process parameters, and quality control data throughout the production lifecycle. This traceability is crucial for regulatory compliance and facilitates rapid response in case of any quality issues.

One of the primary quality control measures involves precise temperature monitoring throughout the casting process. Nitinol's shape memory and superelastic properties are highly dependent on its thermal history, making temperature control crucial. Advanced thermal imaging systems and high-precision thermocouples are employed to maintain and record temperature profiles during melting, pouring, and solidification stages.

Composition control is another critical aspect of quality assurance in Nitinol casting. X-ray fluorescence (XRF) spectroscopy and inductively coupled plasma mass spectrometry (ICP-MS) are utilized to verify the exact nickel-titanium ratio and detect any impurities that could affect the alloy's performance. Strict tolerances are maintained to ensure the desired transformation temperatures and mechanical properties are achieved.

Non-destructive testing (NDT) techniques play a vital role in quality control for Nitinol castings. Ultrasonic testing is employed to detect internal defects, such as voids or inclusions, while X-ray computed tomography (CT) scanning provides detailed 3D imaging of the component's internal structure. These methods allow for comprehensive inspection without compromising the integrity of the cast parts.

Mechanical testing is essential to verify the Nitinol components' performance characteristics. Tensile testing, fatigue testing, and differential scanning calorimetry (DSC) are conducted to assess strength, durability, and phase transformation temperatures. These tests ensure that the cast components meet the required specifications for their intended applications.

Surface quality is a critical factor in Nitinol components, particularly for medical implants. Advanced surface analysis techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are used to evaluate surface topography and detect any irregularities that could affect biocompatibility or performance.

Statistical process control (SPC) methods are implemented to monitor and control variability in the casting process. Key process parameters are continuously tracked, and control charts are utilized to identify trends or deviations that may impact product quality. This proactive approach allows for timely adjustments to maintain consistent output.

Lastly, traceability is ensured through comprehensive documentation and record-keeping. Each batch of Nitinol castings is assigned a unique identifier, allowing for the tracking of raw materials, process parameters, and quality control data throughout the production lifecycle. This traceability is crucial for regulatory compliance and facilitates rapid response in case of any quality issues.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!