Advanced diagnostics in L92 engine problem solving

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Diagnostics Background and Objectives

The L92 engine, a powerful V8 powerplant developed by General Motors, has been a cornerstone in high-performance vehicles since its introduction. As automotive technology continues to advance, the need for sophisticated diagnostic tools and techniques has become increasingly crucial in maintaining and optimizing these engines. The field of advanced diagnostics for L92 engine problem-solving has evolved significantly over the past decade, driven by the growing complexity of engine management systems and the demand for improved fuel efficiency and reduced emissions.

The primary objective of advanced diagnostics in L92 engine problem-solving is to enhance the accuracy, speed, and efficiency of fault detection and resolution. This involves developing and implementing cutting-edge diagnostic tools, software, and methodologies that can quickly identify and isolate issues within the engine's various subsystems. By leveraging advanced sensor technologies, data analytics, and machine learning algorithms, these diagnostic systems aim to provide real-time insights into engine performance and potential problems.

One of the key drivers behind the development of advanced diagnostics for the L92 engine is the increasing integration of electronic control units (ECUs) and sophisticated engine management systems. These systems generate vast amounts of data, which, when properly analyzed, can reveal subtle performance issues and potential failures before they become critical. The goal is to transition from reactive maintenance to predictive and preventive strategies, ultimately reducing downtime and extending engine life.

Another significant aspect of the L92 engine diagnostics evolution is the focus on emissions control and fuel efficiency optimization. As environmental regulations become more stringent, advanced diagnostic tools play a crucial role in ensuring that these engines operate within prescribed emission limits while maintaining optimal performance. This involves continuous monitoring of exhaust gases, fuel mixture ratios, and combustion efficiency, with the ability to make real-time adjustments to engine parameters.

The development of advanced diagnostics also aims to address the challenges posed by the L92 engine's complex variable valve timing (VVT) system and direct fuel injection technology. These features, while enhancing performance and efficiency, introduce additional variables that require sophisticated diagnostic approaches to troubleshoot effectively. The objective is to create diagnostic tools that can accurately interpret the interplay between these advanced systems and identify root causes of performance issues.

Looking ahead, the future of L92 engine diagnostics is likely to involve increased integration of artificial intelligence and machine learning technologies. These advancements will enable more accurate predictive maintenance schedules, automated fault diagnosis, and even self-healing capabilities in some subsystems. The ultimate goal is to create a diagnostic ecosystem that not only identifies problems but also provides actionable insights for optimization and performance enhancement.

The primary objective of advanced diagnostics in L92 engine problem-solving is to enhance the accuracy, speed, and efficiency of fault detection and resolution. This involves developing and implementing cutting-edge diagnostic tools, software, and methodologies that can quickly identify and isolate issues within the engine's various subsystems. By leveraging advanced sensor technologies, data analytics, and machine learning algorithms, these diagnostic systems aim to provide real-time insights into engine performance and potential problems.

One of the key drivers behind the development of advanced diagnostics for the L92 engine is the increasing integration of electronic control units (ECUs) and sophisticated engine management systems. These systems generate vast amounts of data, which, when properly analyzed, can reveal subtle performance issues and potential failures before they become critical. The goal is to transition from reactive maintenance to predictive and preventive strategies, ultimately reducing downtime and extending engine life.

Another significant aspect of the L92 engine diagnostics evolution is the focus on emissions control and fuel efficiency optimization. As environmental regulations become more stringent, advanced diagnostic tools play a crucial role in ensuring that these engines operate within prescribed emission limits while maintaining optimal performance. This involves continuous monitoring of exhaust gases, fuel mixture ratios, and combustion efficiency, with the ability to make real-time adjustments to engine parameters.

The development of advanced diagnostics also aims to address the challenges posed by the L92 engine's complex variable valve timing (VVT) system and direct fuel injection technology. These features, while enhancing performance and efficiency, introduce additional variables that require sophisticated diagnostic approaches to troubleshoot effectively. The objective is to create diagnostic tools that can accurately interpret the interplay between these advanced systems and identify root causes of performance issues.

Looking ahead, the future of L92 engine diagnostics is likely to involve increased integration of artificial intelligence and machine learning technologies. These advancements will enable more accurate predictive maintenance schedules, automated fault diagnosis, and even self-healing capabilities in some subsystems. The ultimate goal is to create a diagnostic ecosystem that not only identifies problems but also provides actionable insights for optimization and performance enhancement.

Market Demand for Advanced Engine Diagnostics

The market demand for advanced diagnostics in L92 engine problem solving has been steadily increasing in recent years, driven by several key factors. As automotive technologies continue to evolve, engines are becoming more complex, necessitating more sophisticated diagnostic tools and techniques. The L92 engine, known for its high performance and efficiency, is no exception to this trend.

One of the primary drivers of market demand is the growing emphasis on vehicle reliability and longevity. Vehicle owners and fleet operators are increasingly seeking ways to minimize downtime and extend the lifespan of their engines. Advanced diagnostics provide a proactive approach to maintenance, allowing for early detection of potential issues before they escalate into major problems. This preventive strategy not only reduces repair costs but also enhances overall vehicle performance and fuel efficiency.

Environmental regulations and emissions standards have also played a significant role in boosting the demand for advanced engine diagnostics. With stricter emissions requirements being implemented globally, there is a pressing need for precise monitoring and adjustment of engine parameters to ensure compliance. Advanced diagnostic systems enable real-time monitoring of emissions-related data, allowing for timely adjustments and optimizations to meet these stringent standards.

The automotive aftermarket has recognized the potential of advanced diagnostics, leading to increased investment in this sector. Independent repair shops and service centers are adopting more sophisticated diagnostic tools to remain competitive and provide high-quality services to their customers. This trend has created a robust market for diagnostic equipment manufacturers and software developers specializing in L92 engine solutions.

Furthermore, the rise of connected vehicle technologies and the Internet of Things (IoT) has opened up new possibilities for remote diagnostics and predictive maintenance. Fleet managers and vehicle owners are increasingly demanding real-time access to engine performance data and diagnostic information. This has led to the development of cloud-based diagnostic platforms and mobile applications, further expanding the market for advanced L92 engine diagnostics.

The automotive industry's shift towards electrification and hybrid technologies has also indirectly boosted the demand for advanced diagnostics in traditional combustion engines like the L92. As manufacturers allocate resources to electric vehicle development, there is a parallel need to optimize and extend the life of existing combustion engine technologies, driving investment in advanced diagnostic solutions.

In conclusion, the market demand for advanced diagnostics in L92 engine problem solving is robust and multifaceted. It is driven by the need for improved reliability, regulatory compliance, competitive advantage in the aftermarket, and the integration of connected technologies. As these trends continue to evolve, the market for advanced L92 engine diagnostics is expected to grow further, presenting significant opportunities for innovation and technological advancement in the automotive sector.

One of the primary drivers of market demand is the growing emphasis on vehicle reliability and longevity. Vehicle owners and fleet operators are increasingly seeking ways to minimize downtime and extend the lifespan of their engines. Advanced diagnostics provide a proactive approach to maintenance, allowing for early detection of potential issues before they escalate into major problems. This preventive strategy not only reduces repair costs but also enhances overall vehicle performance and fuel efficiency.

Environmental regulations and emissions standards have also played a significant role in boosting the demand for advanced engine diagnostics. With stricter emissions requirements being implemented globally, there is a pressing need for precise monitoring and adjustment of engine parameters to ensure compliance. Advanced diagnostic systems enable real-time monitoring of emissions-related data, allowing for timely adjustments and optimizations to meet these stringent standards.

The automotive aftermarket has recognized the potential of advanced diagnostics, leading to increased investment in this sector. Independent repair shops and service centers are adopting more sophisticated diagnostic tools to remain competitive and provide high-quality services to their customers. This trend has created a robust market for diagnostic equipment manufacturers and software developers specializing in L92 engine solutions.

Furthermore, the rise of connected vehicle technologies and the Internet of Things (IoT) has opened up new possibilities for remote diagnostics and predictive maintenance. Fleet managers and vehicle owners are increasingly demanding real-time access to engine performance data and diagnostic information. This has led to the development of cloud-based diagnostic platforms and mobile applications, further expanding the market for advanced L92 engine diagnostics.

The automotive industry's shift towards electrification and hybrid technologies has also indirectly boosted the demand for advanced diagnostics in traditional combustion engines like the L92. As manufacturers allocate resources to electric vehicle development, there is a parallel need to optimize and extend the life of existing combustion engine technologies, driving investment in advanced diagnostic solutions.

In conclusion, the market demand for advanced diagnostics in L92 engine problem solving is robust and multifaceted. It is driven by the need for improved reliability, regulatory compliance, competitive advantage in the aftermarket, and the integration of connected technologies. As these trends continue to evolve, the market for advanced L92 engine diagnostics is expected to grow further, presenting significant opportunities for innovation and technological advancement in the automotive sector.

Current Challenges in L92 Engine Problem Solving

The L92 engine, a prominent V8 powerplant, faces several challenges in problem-solving and diagnostics. One of the primary issues is the complexity of its advanced electronic control systems. These sophisticated systems, while offering improved performance and efficiency, also introduce a higher level of intricacy in fault detection and resolution.

Intermittent faults pose a significant challenge in L92 engine diagnostics. These sporadic issues often elude traditional diagnostic methods, making it difficult for technicians to replicate and identify the root cause. This unpredictability leads to increased downtime and customer dissatisfaction, highlighting the need for more advanced diagnostic tools and techniques.

The integration of multiple subsystems within the L92 engine creates interdependencies that complicate troubleshooting processes. A malfunction in one component can trigger cascading effects across various systems, obscuring the original source of the problem. This interconnectedness demands a holistic approach to diagnostics, requiring technicians to possess a comprehensive understanding of the engine's entire ecosystem.

Environmental factors present another hurdle in L92 engine problem-solving. Variations in temperature, humidity, and altitude can significantly impact engine performance and mask underlying issues. Diagnostic procedures must account for these external influences to ensure accurate fault identification and appropriate corrective actions.

The rapid pace of technological advancements in engine design and control systems creates a continuous challenge for diagnostic tools and methodologies to keep up. As new features and optimizations are introduced, existing diagnostic equipment and procedures may become obsolete or insufficient, necessitating frequent updates and retraining of technical personnel.

Data interpretation remains a critical challenge in L92 engine diagnostics. The vast amount of sensor data and diagnostic trouble codes generated by modern engines can overwhelm technicians, leading to misinterpretation or overlooked critical information. Developing effective data analysis techniques and visualization tools is crucial for improving diagnostic accuracy and efficiency.

Lastly, the increasing emphasis on emissions compliance and fuel efficiency adds another layer of complexity to L92 engine problem-solving. Technicians must navigate stringent regulatory requirements while diagnosing and resolving performance issues, often requiring a delicate balance between optimal engine operation and environmental considerations.

Intermittent faults pose a significant challenge in L92 engine diagnostics. These sporadic issues often elude traditional diagnostic methods, making it difficult for technicians to replicate and identify the root cause. This unpredictability leads to increased downtime and customer dissatisfaction, highlighting the need for more advanced diagnostic tools and techniques.

The integration of multiple subsystems within the L92 engine creates interdependencies that complicate troubleshooting processes. A malfunction in one component can trigger cascading effects across various systems, obscuring the original source of the problem. This interconnectedness demands a holistic approach to diagnostics, requiring technicians to possess a comprehensive understanding of the engine's entire ecosystem.

Environmental factors present another hurdle in L92 engine problem-solving. Variations in temperature, humidity, and altitude can significantly impact engine performance and mask underlying issues. Diagnostic procedures must account for these external influences to ensure accurate fault identification and appropriate corrective actions.

The rapid pace of technological advancements in engine design and control systems creates a continuous challenge for diagnostic tools and methodologies to keep up. As new features and optimizations are introduced, existing diagnostic equipment and procedures may become obsolete or insufficient, necessitating frequent updates and retraining of technical personnel.

Data interpretation remains a critical challenge in L92 engine diagnostics. The vast amount of sensor data and diagnostic trouble codes generated by modern engines can overwhelm technicians, leading to misinterpretation or overlooked critical information. Developing effective data analysis techniques and visualization tools is crucial for improving diagnostic accuracy and efficiency.

Lastly, the increasing emphasis on emissions compliance and fuel efficiency adds another layer of complexity to L92 engine problem-solving. Technicians must navigate stringent regulatory requirements while diagnosing and resolving performance issues, often requiring a delicate balance between optimal engine operation and environmental considerations.

Existing L92 Engine Diagnostic Solutions

01 Diagnostic systems for L92 engine

Advanced diagnostic systems are developed to identify and troubleshoot issues in L92 engines. These systems utilize sensors and data analysis to pinpoint problems, enabling faster and more accurate problem-solving. They can detect issues related to fuel injection, ignition timing, and other critical engine functions.- Diagnostic and monitoring systems for L92 engines: Advanced diagnostic and monitoring systems are developed to identify and solve problems in L92 engines. These systems utilize sensors and data analysis to detect anomalies, predict potential issues, and provide real-time feedback for efficient troubleshooting and maintenance.

- Engine control optimization techniques: Various optimization techniques are employed to enhance L92 engine performance and resolve issues. These include adaptive control algorithms, machine learning approaches, and intelligent software solutions that fine-tune engine parameters for optimal operation under different conditions.

- Innovative component designs for L92 engines: New designs and improvements in L92 engine components are developed to address common problems and enhance overall performance. These innovations focus on areas such as fuel injection systems, combustion chambers, and cooling systems to increase efficiency and reliability.

- Thermal management solutions: Advanced thermal management techniques are implemented to solve heat-related issues in L92 engines. These solutions include improved cooling systems, heat dissipation methods, and temperature control mechanisms to maintain optimal engine performance and longevity.

- Emissions reduction and environmental compliance: Technologies and methods are developed to address emissions-related problems in L92 engines, ensuring compliance with environmental regulations. These include advanced exhaust aftertreatment systems, combustion optimization techniques, and innovative fuel management strategies to reduce harmful emissions.

02 Engine control optimization

Optimization techniques are applied to L92 engine control systems to improve performance and efficiency. This includes fine-tuning engine parameters, adjusting fuel mixture ratios, and optimizing ignition timing. Advanced algorithms and machine learning techniques are employed to continuously adapt and improve engine operation.Expand Specific Solutions03 Thermal management solutions

Innovative thermal management solutions are developed to address overheating issues in L92 engines. These include advanced cooling systems, improved heat dissipation techniques, and intelligent temperature control mechanisms. Such solutions help maintain optimal engine temperature and prevent heat-related problems.Expand Specific Solutions04 Vibration reduction and noise control

Techniques are implemented to reduce vibration and control noise in L92 engines. This involves the use of advanced materials, improved engine mounts, and redesigned components to minimize vibration transmission. Acoustic engineering principles are applied to reduce engine noise and improve overall operation smoothness.Expand Specific Solutions05 Predictive maintenance systems

Predictive maintenance systems are developed for L92 engines to anticipate and prevent potential issues. These systems use data analytics, machine learning, and sensor technologies to monitor engine health, predict failures, and schedule maintenance activities proactively. This approach helps reduce downtime and extend engine life.Expand Specific Solutions

Key Players in Automotive Diagnostics Industry

The advanced diagnostics in L92 engine problem solving market is in a growth phase, driven by increasing demand for efficient engine performance and emission control. The market size is expanding as automotive manufacturers seek innovative diagnostic solutions. Technologically, the field is rapidly evolving, with companies like DENSO Corp., Robert Bosch GmbH, and GM Global Technology Operations LLC leading the way. These firms are investing heavily in R&D to develop sophisticated diagnostic tools and software. Emerging players such as Delphi Technology and Visteon Global Technologies are also making significant strides, contributing to the competitive landscape and driving technological advancements in the sector.

DENSO Corp.

Technical Solution: DENSO's advanced diagnostics for L92 engine problem solving is centered around their Intelligent Diagnostic System (IDS). This system incorporates high-precision sensors and advanced signal processing to monitor engine performance in real-time[1]. DENSO has developed a unique thermal imaging technology that can detect abnormal heat distributions within the engine, allowing for early identification of component stress or failure[3]. Their diagnostic approach also includes a sophisticated exhaust gas analysis system that can detect minute changes in emissions composition, providing insights into combustion efficiency and potential issues[5]. DENSO's system is integrated with a machine learning platform that continuously refines its diagnostic algorithms based on data collected from millions of vehicles worldwide[7]. Additionally, they have implemented a blockchain-based secure data sharing system that allows for anonymous aggregation of diagnostic data across multiple manufacturers, enhancing the overall accuracy of their predictive models[9].

Strengths: Innovative thermal imaging diagnostics, advanced emissions analysis, and secure cross-manufacturer data sharing. Weaknesses: May require significant infrastructure investment for full implementation, potential privacy concerns with data collection.

GM Global Technology Operations LLC

Technical Solution: GM's advanced diagnostics for L92 engine problem solving incorporates a multi-layered approach. They utilize sophisticated onboard diagnostic (OBD) systems that continuously monitor engine performance parameters[1]. The system employs machine learning algorithms to analyze real-time data from multiple sensors, enabling predictive maintenance and early fault detection[3]. GM has also developed a proprietary diagnostic tool that interfaces with the engine control module (ECM) to provide detailed error codes and suggested repair procedures[5]. This tool integrates with a cloud-based database that aggregates diagnostic data from millions of vehicles, allowing for pattern recognition and improved accuracy in problem identification[7].

Strengths: Comprehensive data analysis, predictive maintenance capabilities, and integration with a vast knowledge base. Weaknesses: Potential over-reliance on technology, possible high costs for implementation and maintenance.

Core Innovations in Engine Problem Solving

Engine abnormality diagnosis method, engine abnormality diagnosis program, and engine abnormality diagnosis system

PatentWO2022009904A1

Innovation

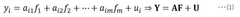

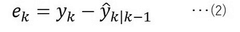

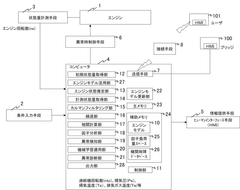

- An engine abnormality diagnosis method utilizing a mathematical engine model that incorporates a nonlinear Kalman filter for state estimation, factor analysis, and machine learning to detect anomalies and update the engine model, enabling early detection and diagnosis of engine issues based on measured state quantities and residual differences.

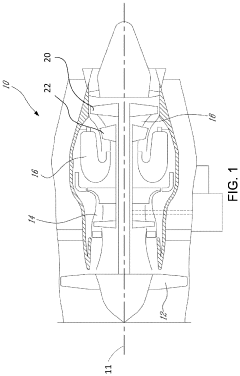

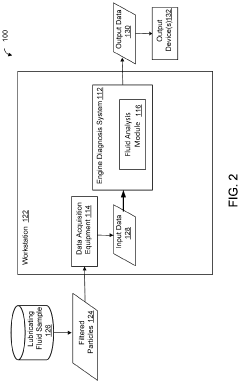

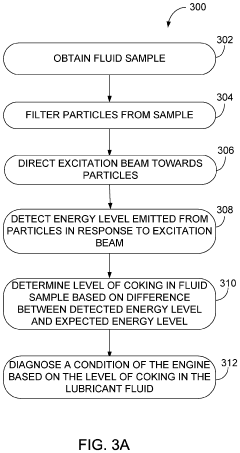

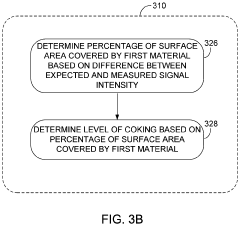

System and method for diagnosing a condition of an engine

PatentActiveUS20200393082A1

Innovation

- A method and system that involve obtaining a lubricating fluid sample, filtering particles, directing an excitation beam to detect energy levels, determining the level of coking by comparing detected and expected energy levels, and diagnosing engine conditions based on this analysis, using a combination of SEM and XRF or EDX spectroscopy to analyze particles and estimate carbon deposits.

Environmental Impact of Engine Diagnostics

The environmental impact of engine diagnostics in L92 engine problem solving is a critical consideration in the automotive industry's pursuit of sustainability. Advanced diagnostic techniques have significantly improved the efficiency and accuracy of identifying and resolving engine issues, leading to reduced emissions and improved fuel economy.

One of the primary environmental benefits of advanced diagnostics is the reduction of unnecessary parts replacement. Traditional diagnostic methods often relied on a trial-and-error approach, resulting in the replacement of multiple components before identifying the root cause of an issue. This practice not only increased waste but also contributed to higher resource consumption and manufacturing-related emissions. With advanced diagnostics, technicians can pinpoint specific problems more accurately, minimizing unnecessary parts replacement and reducing the overall environmental footprint of engine maintenance.

Furthermore, advanced diagnostics enable more precise engine tuning and optimization. By identifying minor inefficiencies and performance issues early on, technicians can make adjustments that improve fuel efficiency and reduce emissions. This proactive approach helps maintain engines at peak performance levels, ensuring they operate within designed environmental parameters for extended periods.

The implementation of on-board diagnostic systems in L92 engines has also contributed to reduced emissions. These systems continuously monitor engine performance and alert drivers to potential issues before they escalate into more significant problems. By addressing minor issues promptly, vehicles maintain optimal performance, leading to lower fuel consumption and reduced emissions over the vehicle's lifetime.

Advanced diagnostics have also played a crucial role in the development and refinement of emission control systems. By providing detailed data on engine performance and exhaust composition, these diagnostic tools enable engineers to design more effective catalytic converters and other emission control devices. This iterative process of data collection, analysis, and design improvement has led to significant reductions in harmful emissions from L92 engines.

Moreover, the shift towards remote diagnostics and over-the-air updates has further reduced the environmental impact of engine maintenance. By allowing technicians to diagnose and sometimes resolve issues without physical intervention, these technologies reduce the need for service-related travel, thereby decreasing the carbon footprint associated with vehicle maintenance.

In conclusion, advanced diagnostics in L92 engine problem solving have made substantial contributions to reducing the environmental impact of automotive operations. Through more accurate problem identification, improved engine optimization, and the facilitation of proactive maintenance, these diagnostic tools play a vital role in the industry's efforts to minimize emissions and improve overall environmental sustainability.

One of the primary environmental benefits of advanced diagnostics is the reduction of unnecessary parts replacement. Traditional diagnostic methods often relied on a trial-and-error approach, resulting in the replacement of multiple components before identifying the root cause of an issue. This practice not only increased waste but also contributed to higher resource consumption and manufacturing-related emissions. With advanced diagnostics, technicians can pinpoint specific problems more accurately, minimizing unnecessary parts replacement and reducing the overall environmental footprint of engine maintenance.

Furthermore, advanced diagnostics enable more precise engine tuning and optimization. By identifying minor inefficiencies and performance issues early on, technicians can make adjustments that improve fuel efficiency and reduce emissions. This proactive approach helps maintain engines at peak performance levels, ensuring they operate within designed environmental parameters for extended periods.

The implementation of on-board diagnostic systems in L92 engines has also contributed to reduced emissions. These systems continuously monitor engine performance and alert drivers to potential issues before they escalate into more significant problems. By addressing minor issues promptly, vehicles maintain optimal performance, leading to lower fuel consumption and reduced emissions over the vehicle's lifetime.

Advanced diagnostics have also played a crucial role in the development and refinement of emission control systems. By providing detailed data on engine performance and exhaust composition, these diagnostic tools enable engineers to design more effective catalytic converters and other emission control devices. This iterative process of data collection, analysis, and design improvement has led to significant reductions in harmful emissions from L92 engines.

Moreover, the shift towards remote diagnostics and over-the-air updates has further reduced the environmental impact of engine maintenance. By allowing technicians to diagnose and sometimes resolve issues without physical intervention, these technologies reduce the need for service-related travel, thereby decreasing the carbon footprint associated with vehicle maintenance.

In conclusion, advanced diagnostics in L92 engine problem solving have made substantial contributions to reducing the environmental impact of automotive operations. Through more accurate problem identification, improved engine optimization, and the facilitation of proactive maintenance, these diagnostic tools play a vital role in the industry's efforts to minimize emissions and improve overall environmental sustainability.

Data Privacy in Vehicle Diagnostics

Data privacy in vehicle diagnostics has become a critical concern as modern vehicles increasingly rely on advanced electronic systems and connectivity features. The collection, transmission, and storage of diagnostic data raise significant privacy implications for vehicle owners and users. This data often includes sensitive information such as vehicle location, driving patterns, and performance metrics, which could potentially be used to infer personal habits and behaviors.

One of the primary challenges in ensuring data privacy in vehicle diagnostics is balancing the need for comprehensive diagnostic information with the protection of personal data. Manufacturers and service providers require detailed data to effectively diagnose and resolve issues, while vehicle owners have a right to privacy and control over their personal information. This tension has led to the development of various technical and regulatory approaches to address privacy concerns.

Encryption and secure data transmission protocols play a crucial role in protecting diagnostic data during transmission between the vehicle and diagnostic systems. Advanced encryption algorithms and secure communication channels help prevent unauthorized access and interception of sensitive information. Additionally, anonymization techniques are employed to remove or obscure personally identifiable information from diagnostic data before it is analyzed or stored.

Data minimization principles are increasingly being adopted in vehicle diagnostic systems. This approach involves collecting and retaining only the data necessary for specific diagnostic purposes, reducing the risk of privacy breaches and unauthorized data use. Manufacturers are also implementing user consent mechanisms, allowing vehicle owners to have greater control over what data is collected and how it is used.

The regulatory landscape surrounding data privacy in vehicle diagnostics is evolving rapidly. Legislation such as the European Union's General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) have significant implications for how vehicle diagnostic data is handled. These regulations impose strict requirements on data collection, storage, and processing, necessitating robust privacy protection measures in diagnostic systems.

As vehicle connectivity and autonomous technologies advance, the volume and complexity of diagnostic data will continue to increase. This trend underscores the importance of developing privacy-preserving diagnostic techniques that can effectively analyze and interpret data without compromising individual privacy. Emerging technologies such as federated learning and homomorphic encryption show promise in enabling advanced diagnostics while maintaining data confidentiality.

One of the primary challenges in ensuring data privacy in vehicle diagnostics is balancing the need for comprehensive diagnostic information with the protection of personal data. Manufacturers and service providers require detailed data to effectively diagnose and resolve issues, while vehicle owners have a right to privacy and control over their personal information. This tension has led to the development of various technical and regulatory approaches to address privacy concerns.

Encryption and secure data transmission protocols play a crucial role in protecting diagnostic data during transmission between the vehicle and diagnostic systems. Advanced encryption algorithms and secure communication channels help prevent unauthorized access and interception of sensitive information. Additionally, anonymization techniques are employed to remove or obscure personally identifiable information from diagnostic data before it is analyzed or stored.

Data minimization principles are increasingly being adopted in vehicle diagnostic systems. This approach involves collecting and retaining only the data necessary for specific diagnostic purposes, reducing the risk of privacy breaches and unauthorized data use. Manufacturers are also implementing user consent mechanisms, allowing vehicle owners to have greater control over what data is collected and how it is used.

The regulatory landscape surrounding data privacy in vehicle diagnostics is evolving rapidly. Legislation such as the European Union's General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) have significant implications for how vehicle diagnostic data is handled. These regulations impose strict requirements on data collection, storage, and processing, necessitating robust privacy protection measures in diagnostic systems.

As vehicle connectivity and autonomous technologies advance, the volume and complexity of diagnostic data will continue to increase. This trend underscores the importance of developing privacy-preserving diagnostic techniques that can effectively analyze and interpret data without compromising individual privacy. Emerging technologies such as federated learning and homomorphic encryption show promise in enabling advanced diagnostics while maintaining data confidentiality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!